Tin and niobium composite alloying gray pig iron and production process thereof

A composite alloy and production process technology, applied in the field of casting alloys, can solve the problems of easy occurrence of hot cracks, poor thermal conductivity, and low carbon equivalent of gray cast iron, and achieve the effects of improving strength and increasing pearlite content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

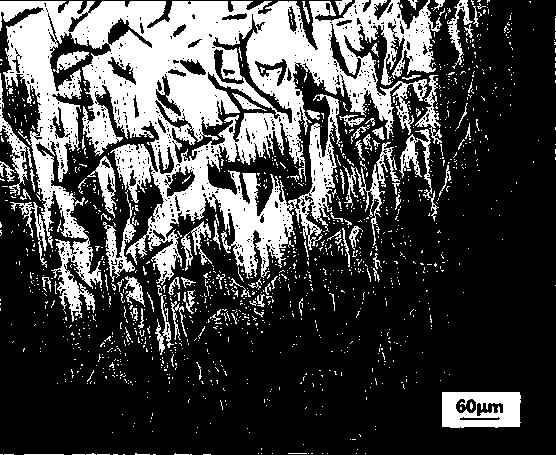

Image

Examples

Embodiment 1

[0017] A formula of tin-niobium composite alloyed gray cast iron of the present invention is: C: 3.82%, Si: 1.97%, Mn: 0.68%, P: 0.05%, S: 0.05%, Sn: 0.058%, Nb: 0.19%, Fe balance

[0018] The production process of this gray cast iron includes the following steps:

[0019] (1) Alloy smelting: cast pig iron, low and medium carbon carbon steel scrap, recycled similar cast iron, pure tin, ferromanganese, ferroniobium, etc. are used as raw materials

[0020] Alloy cast iron is smelted in a conventional intermediate frequency induction furnace. First, cast pig iron, low and medium carbon carbon scrap steel, and recycled similar cast iron are added to the furnace. Then raise the temperature to 1400°C~1430°C, adjust the composition according to the test results of the molten iron composition in the furnace, after adjusting the composition, raise the temperature of the molten iron to 1490°C-1540°C, after melting all the raw materials, keep them in the furnace for 10-20 minutes to mak...

Embodiment 2

[0024] A formula of tin-niobium composite alloyed gray cast iron of the present invention is: C: 3.78%, Si: 2.48%, Mn: 0.66%, P: 0.04%, S: 0.06%, Cu: 0.41%, Cr: 0.33%, Sn: 0.037%, Nb: 0.12%, Fe balance. (Cu and Cr are added to the furnace together with the cold material, and other production processes are the same as in Example 1)

Embodiment 3

[0026] A formula of tin-niobium composite alloyed gray cast iron of the present invention is: C: 3.86%, Si: 2.15%, Mn: 0.64%, P: 0.05%, S: 0.06%, Cu: 0.45%, Cr: 0.29%, V: 0.06%, Ti: 0.07%, Sn: 0.029%, Nb: 0.094%, Fe balance. (Cu and Cr are added into the furnace together with the cold material, V and Ti alloys are added into the furnace 10-15 minutes before being released from the furnace, and other production processes are the same as in Example 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com