Fusible chaplet for thin-walled iron casting, application method and combined core

An application method and iron casting technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of incomplete fusion between core support and casting, achieve good anti-oxidation effect, prevent sand core deformation, and improve fusion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

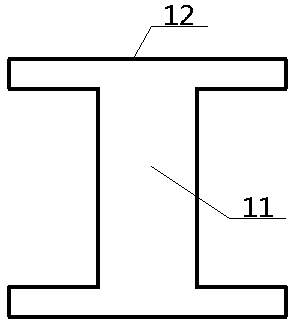

[0051] see Figure 1 to Figure 6 , a kind of fusible core support for thin-walled iron castings; the fusible core support includes an inner copper body 11 and an outer tin layer 12, and the outer tin layer 12 is a layer wrapped on the outside of the inner copper body 11; the The inner copper body 11 is made of copper, the outer tin layer 12 is made of tin, and the mass of the inner copper body 11 is greater than that of the outer tin layer 12 .

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

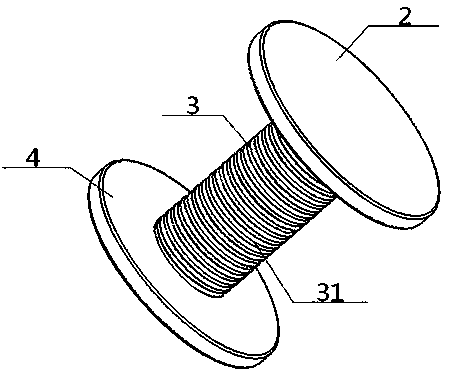

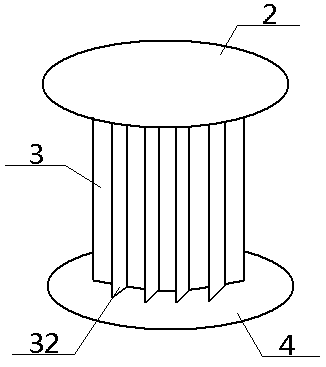

[0054] The inner copper body 11 includes an upper support 2, a connecting column 3 and a lower support 4, the bottom surface of the upper support 2 is vertically connected with the top surface of the lower support 4 through the connecting column 3; the upper support 2 , The cross section of the lower support 4 is circular, oval, triangular or polygonal. Preferably, the diameter of the connecting column 3 is greater than the thickness of the upper support 2 and the lower support 4 .

[0055] A combination core for the above-mentioned thin-walled iron castings where the fusible core brace is located, the composite core includes an upper water jacket core 5, a round rod core 6 and a core brace 1, the number of the upper water jacket core 5 is one, and the round rod core 6. The number of core supports 1 is multiple, and the round rod core 6 and the core supports 1 correspond one by one; the top surface of the ...

Embodiment 3

[0060] Basic content is the same as embodiment 1, the difference is:

[0061] In the fusible core support, the mass ratio of the inner copper body 11 is 99.90%-99.95%, and the mass ratio of the outer tin layer 12 is 0.05%-0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com