Die punch for manufacturing fasteners

A technology for die punches and fasteners, which is applied in the field of die punches for manufacturing fasteners, and can solve the problems of reduced precision, inability to cooperate smoothly with tools and workpieces, and uneven spatial distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

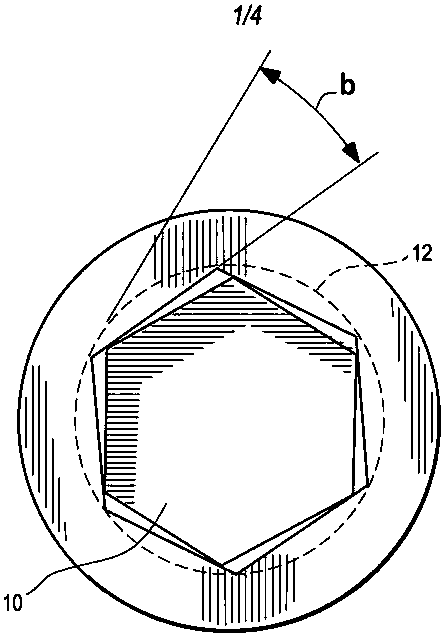

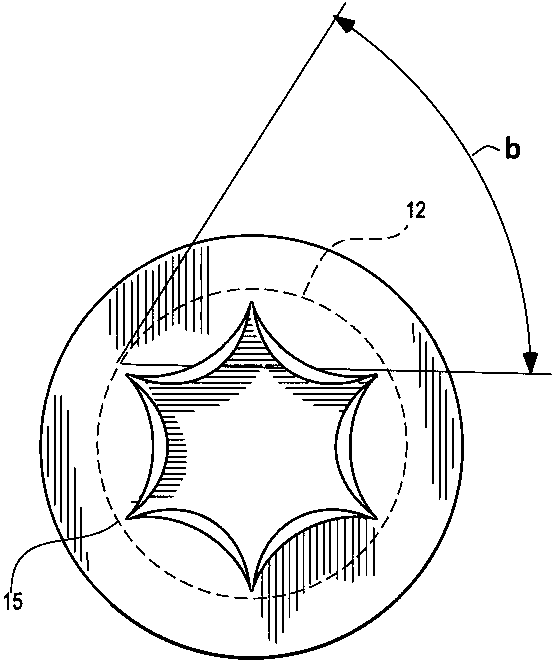

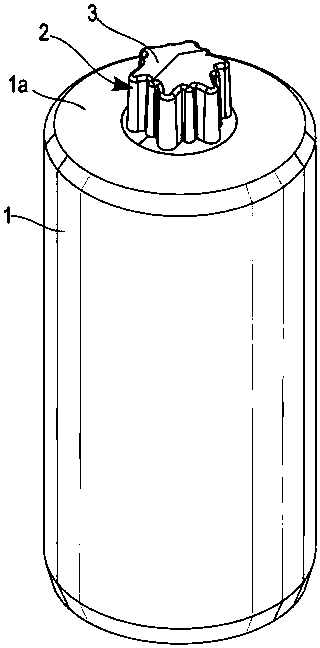

[0032] In order to more clearly understand the technical content used in the present invention, the creation purpose and the effect achieved, the detailed description is as follows in conjunction with the relevant drawings.

[0033] In order to clearly show the principle of the present invention, each component in the figure is not necessarily drawn according to actual scale. In each view, there are reference numbers corresponding to each component.

[0034] The content described below is the best embodiment of the present invention, and any other selection or modification that produces changes in function, purpose, and structure falls within the protection scope of the present invention.

[0035] Such as Figure 2 to Figure 3 As shown, in a preferred embodiment of the present invention, a screw punch die includes a main body 1, a punch 2, and a cone 3, the main body 1 is a cylinder, and a plane 1a is provided at its top , the punch 2 is integrally formed with the main body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com