Cold bridge-blocking composite insulation board and wallboard

A technology of composite thermal insulation and thermal insulation wall panels, which is applied in building components, buildings, building structures, etc., can solve the problems of non-groove splicing structure of wall panels, difficult to set, etc., to achieve good installation and decoration effect, convenient and fast construction, The effect of improving the overall thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

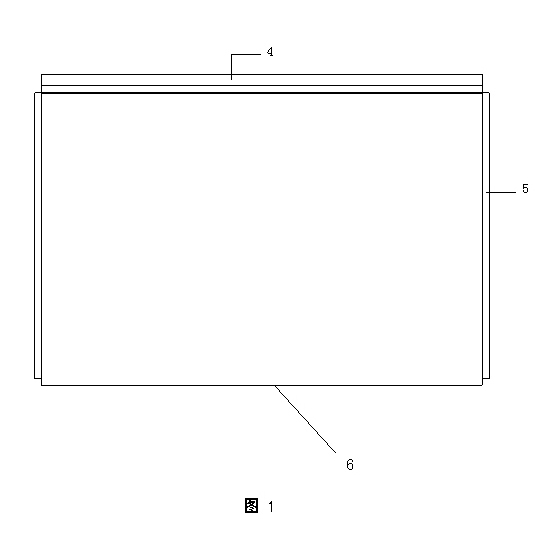

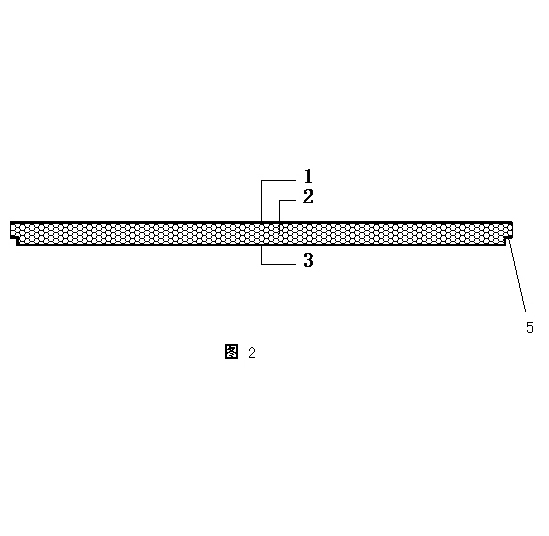

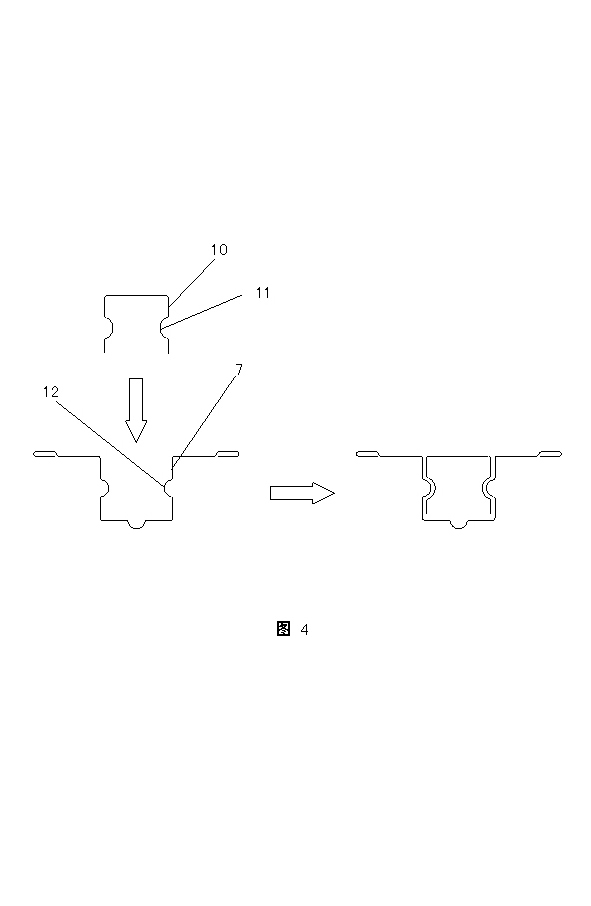

[0019] Such as figure 1 , figure 2 As shown, the embodiment of the composite thermal insulation board of the present invention, the composite thermal insulation board includes an inner panel 1, an outer panel 3, and a core layer 2 between the two panels. For the convenience of description, the direction of the following description is figure 1 The orientation shown has nothing to do with the actual orientation of the product in use. The ends on the upper and lower sides of the composite insulation board are tongue-and-groove 4,6 for overlapping, and the specific structure of the tongue-and-groove is the prior art, so it will not be repeated here.

[0020] The edges of the outer panels 3 on the left and right sides of the composite thermal insulation board are provided with an inward-turned bending structure 5 for docking with the corresponding composite thermal insulation board to form a groove extending along the length direction of the edge. bottom of the panel surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com