Anti-blue-light cover plate glass as well as preparation method and application thereof

A cover glass and anti-blue light technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex process and high cost, achieve broad application prospects, improve strength, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the anti-blue light cover glass contains 70% SiO based on the molar percentage of oxide 2 , 2.7%Al 2 O 3 , 14.8%Na 2 O, 5.5% MgO, 1% K 2 O, 6%CaO;

[0040] The anti-blue light cover glass also contains Pr 3+ , based on the total molar percentage of oxides as described above as 100%, the Pr 3+ The molar percentage of 0.18%.

[0041] The preparation method is as follows: according to the glass components in terms of the molar percentage of oxides in the anti-blue light cover glass, each component is weighed, the glass raw materials are mixed, the temperature is kept at 1560 DEG C for 8 hours to melt, and the molten glass is poured into the glass. Put it into cold water at 20°C, then melt it at 1560°C for 8 hours, cast it on a copper plate, and anneal it at 580°C to obtain a 0.7mm-thick anti-blue light cover glass.

Embodiment 2-8

[0043] The difference between Examples 2-8 and Example 1 is that the anti-blue light cover glass is measured in mole percent of oxide, and its composition ratio is shown in Table 1. Other than that, the preparation method of the anti-blue light cover glass is the same as that in Example 1.

[0044] The anti-blue light cover glass of Examples 1-8 was chemically strengthened, the chemical strengthening temperature was 420°C, and the strengthening time was 4h. The obtained strengthening depth and compressive stress value are shown in Table 1.

[0045] Table 1

[0046]

[0047]

[0048] As can be seen from Table 1, the anti-blue light cover glass of the present invention has sufficient stress layer depth and high surface compressive stress after chemical strengthening.

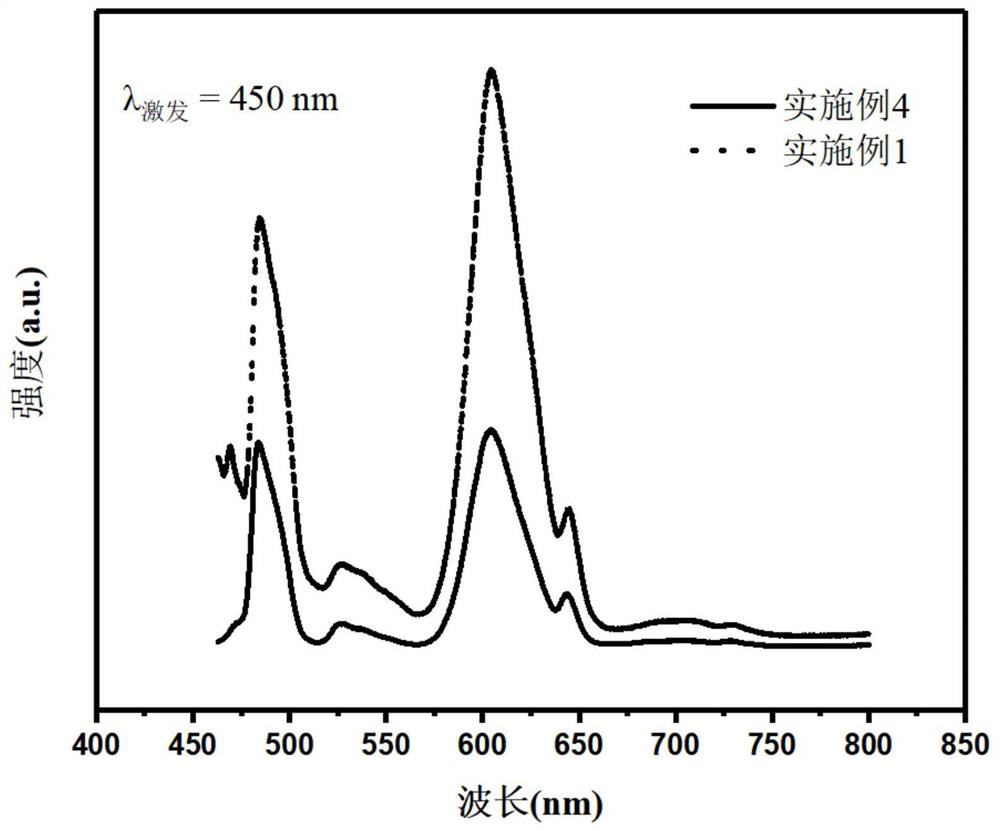

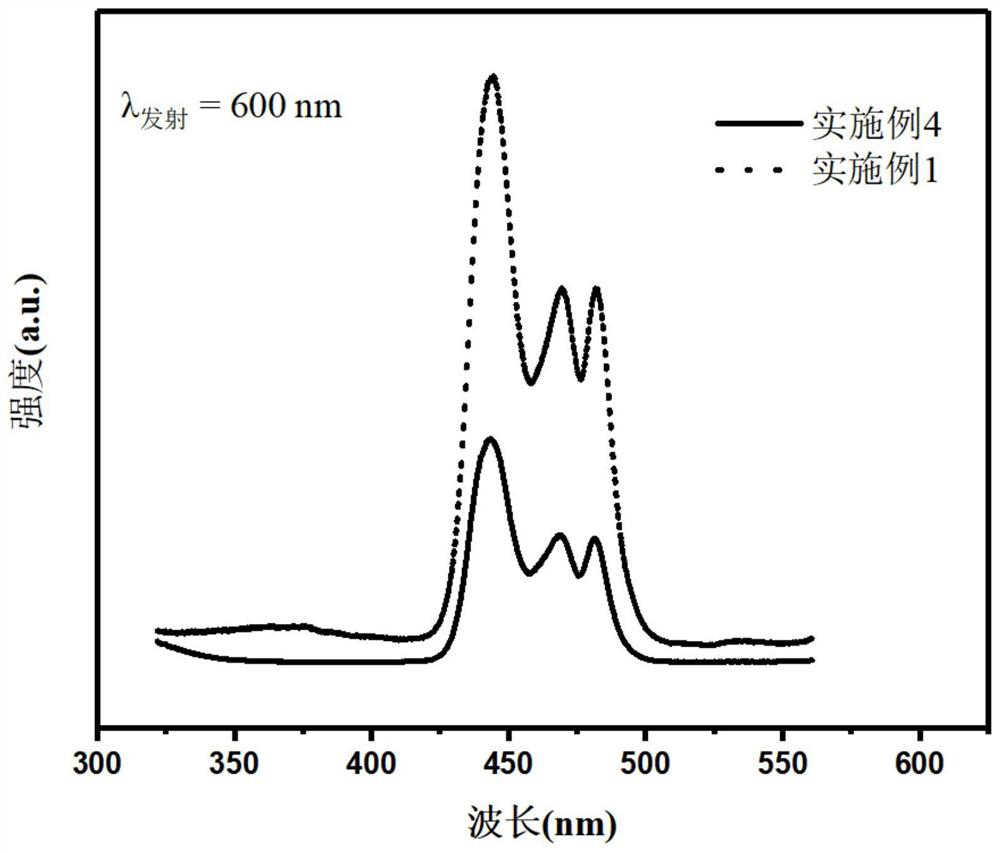

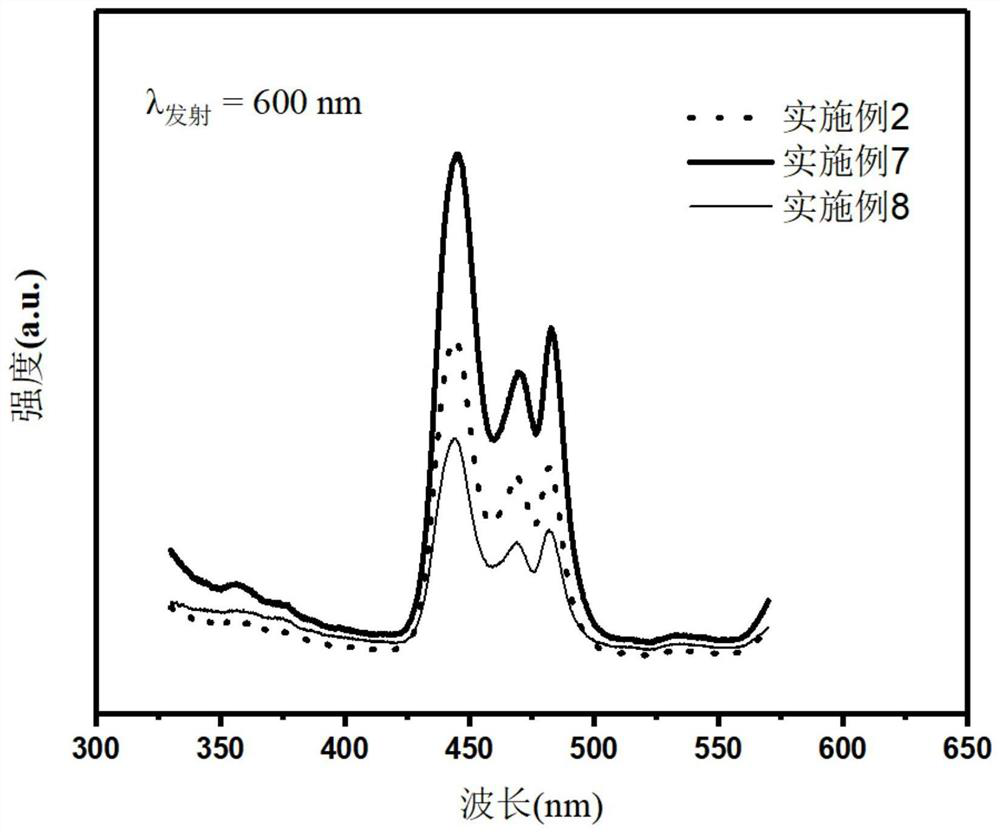

[0049] Fluorescence spectrum test (fluorescence spectrophotometer, model F-4600, Hitachi, Japan) was performed on the anti-blue light cover glass of the embodiment, figure 1 The fluorescence spectra of Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com