A kind of environment-friendly easy demoulding molding device and its application

A technology of compression molding and easy demoulding, which is applied in presses, manufacturing tools, etc., can solve problems affecting application and performance, increase procedures, and uneconomical, etc., and achieve simplified demoulding post-processing, simplified economy and environmental protection, and simple and practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: An environmentally friendly and easy-to-release molding device and its application in the preparation of buoyant materials

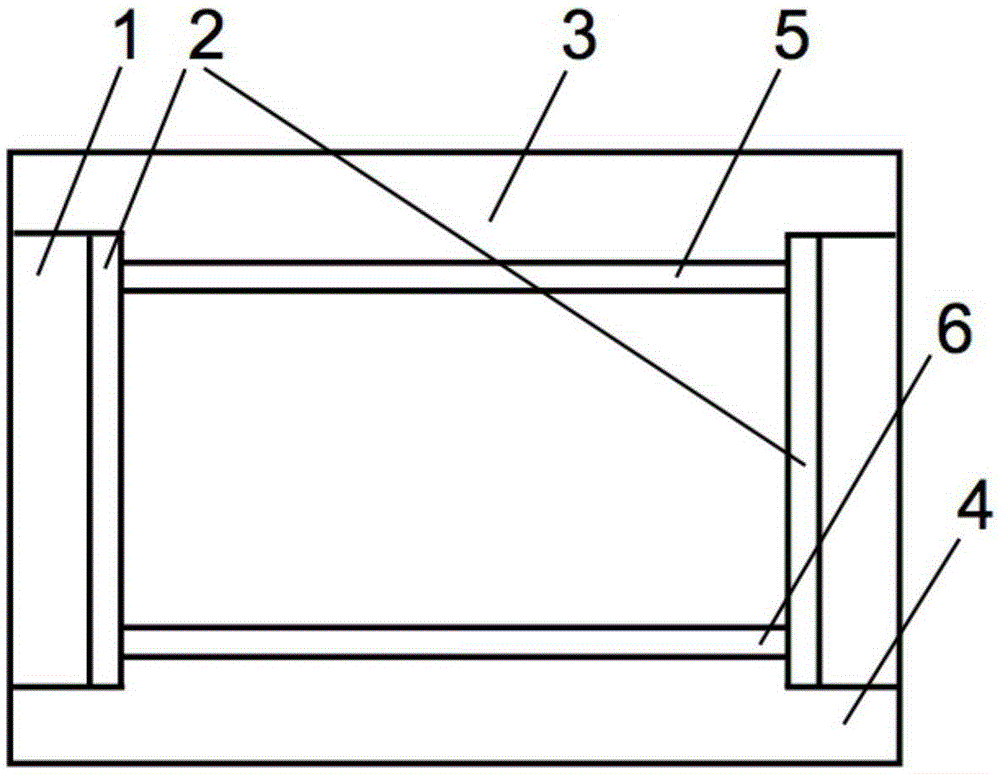

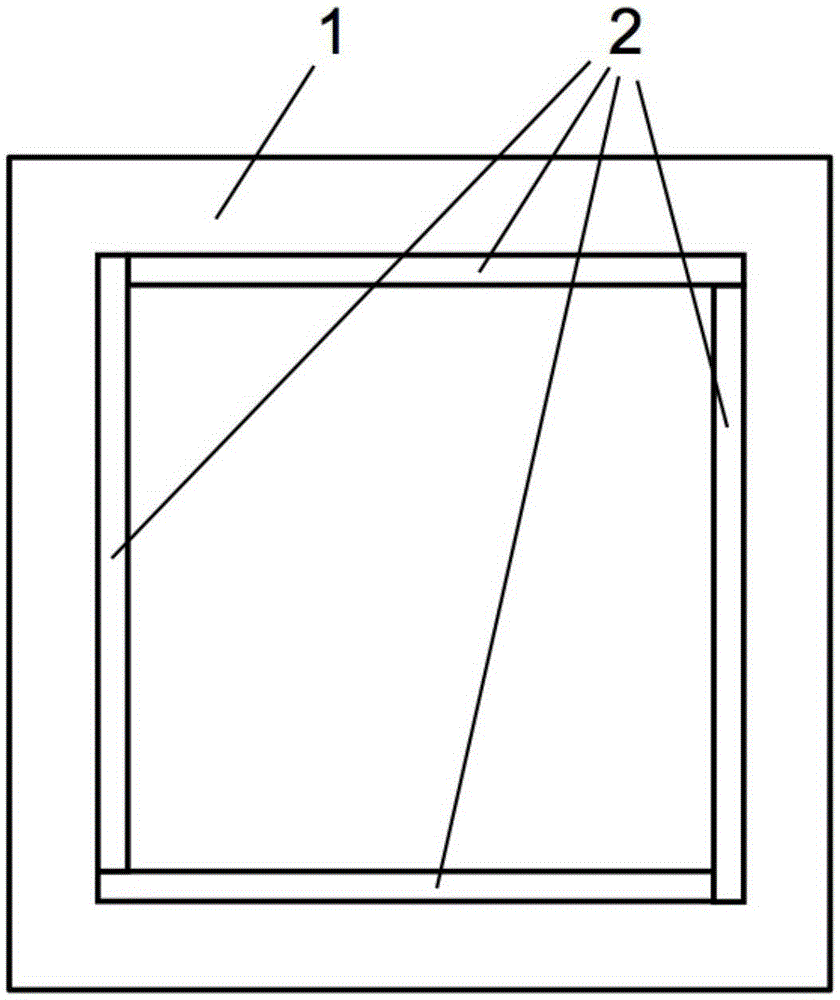

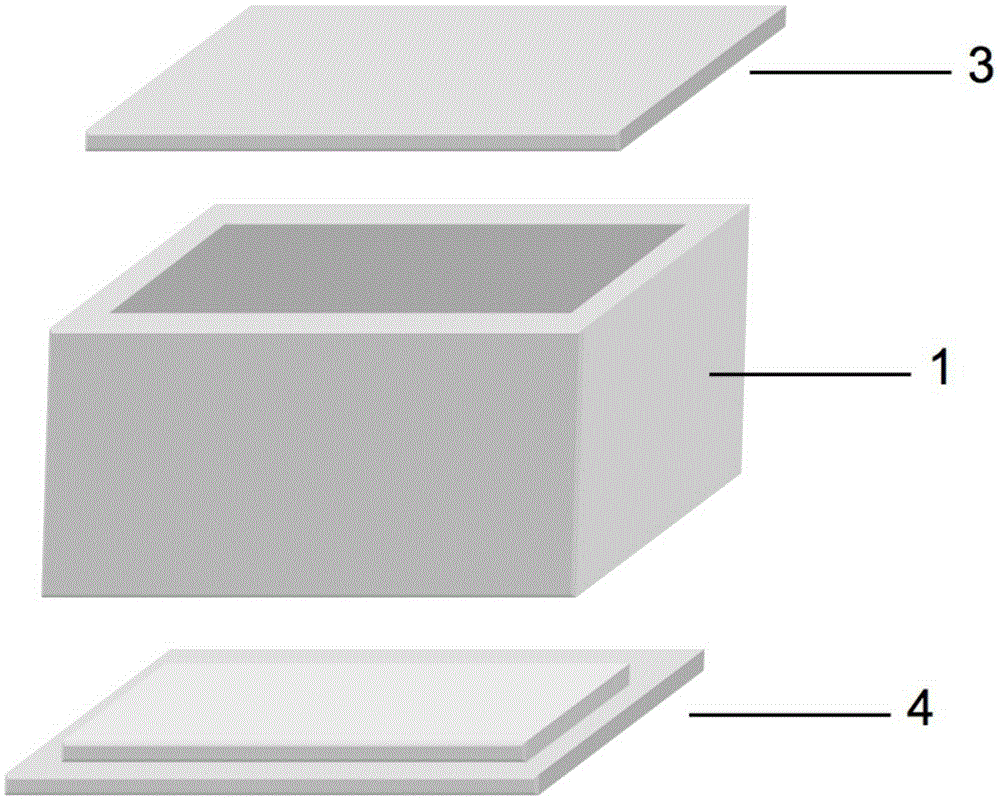

[0035] The molding device includes a square outer mold 1 , an assembled polytetrafluoroethylene liner 2 , an upper cover 3 , a lower cover 4 , an upper sealing sheet 5 and a lower sealing sheet 6 .

[0036] The outer mold 1 has an external dimension (length×width×height) of 320mm×320mm×140mm, and an internal dimension (length×width×height) of 280mm×280mm×140mm.

[0037] The dimensions (length×thickness×height) of the four polytetrafluoroethylene sheets in the assembled polytetrafluoroethylene lining 2 are 270mm×10mm×140mm.

[0038] The size of the top of the upper cover 3 (length×width×height) is 320mm×320mm×20mm, and the size of the raised part of the upper cover 3 (length×width×height) is 260mm×260mm×20mm.

[0039] The size of the bottom of the lower cover 4 (length×width×height) is 320mm×320mm×20mm, and the size of the raised portio...

Embodiment 2

[0044] Example 2: An environment-friendly easy-release molding device and its application in the preparation of buoyant materials

[0045] The molding device includes a rectangular (the ratio of length to width is 2:1) outer mold 1 , assembled polytetrafluoroethylene lining 2 , upper cover 3 , lower cover 4 , upper sealing sheet 5 and lower sealing sheet 6 .

[0046] The outer mold 1 has an external dimension (length×width×height) of 400mm×200mm×140mm, and an internal dimension (length×width×height) of 360mm×160mm×140mm.

[0047] The dimensions (length×thickness×height) of the two polytetrafluoroethylene sheets in the assembled polytetrafluoroethylene lining 2 are 355mm×5mm×140mm, and the dimensions of the other two polytetrafluoroethylene sheets (length×thickness × height) is 155mm × 5mm × 140mm.

[0048] The size of the top of the upper cover 3 (length×width×height) is 400mm×200mm×20mm, and the size of the raised part of the upper cover 3 (length×width×height) is 350mm×150m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com