Cutting method for two-dimensional laser cutting tubular product

A cutting method and two-dimensional laser technology, which are applied to laser welding equipment, tubular objects, manufacturing tools, etc., can solve the problems of the use of two-dimensional cutting heads and other problems, and achieve the purpose of solving the limitations of use, expanding the processing range and improving the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

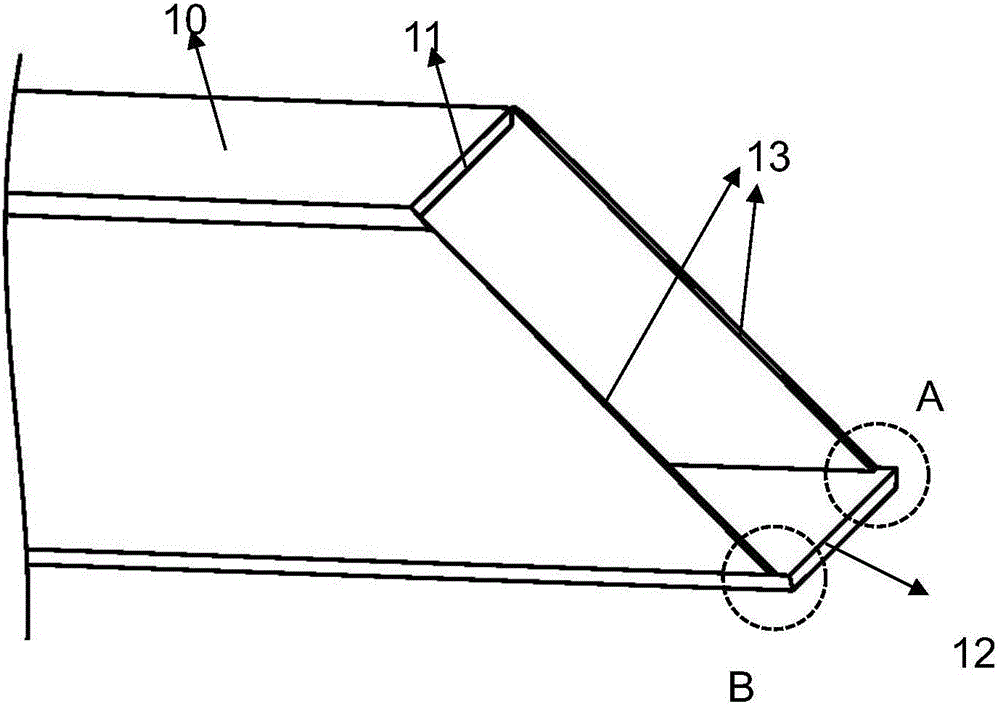

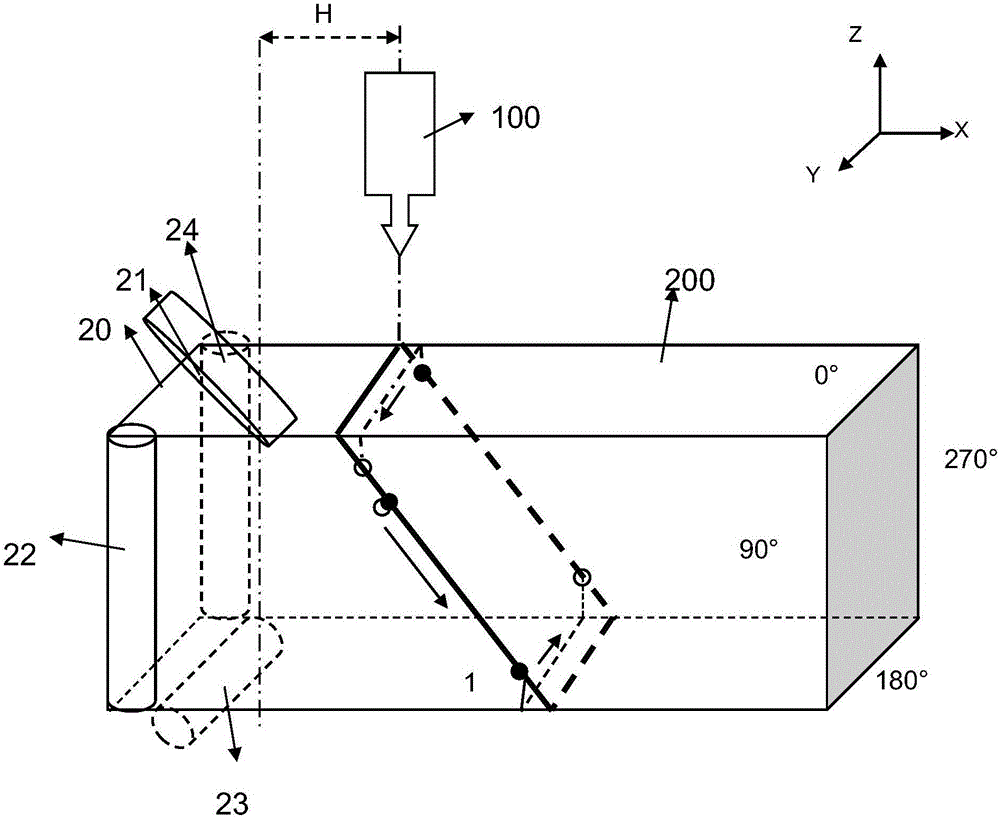

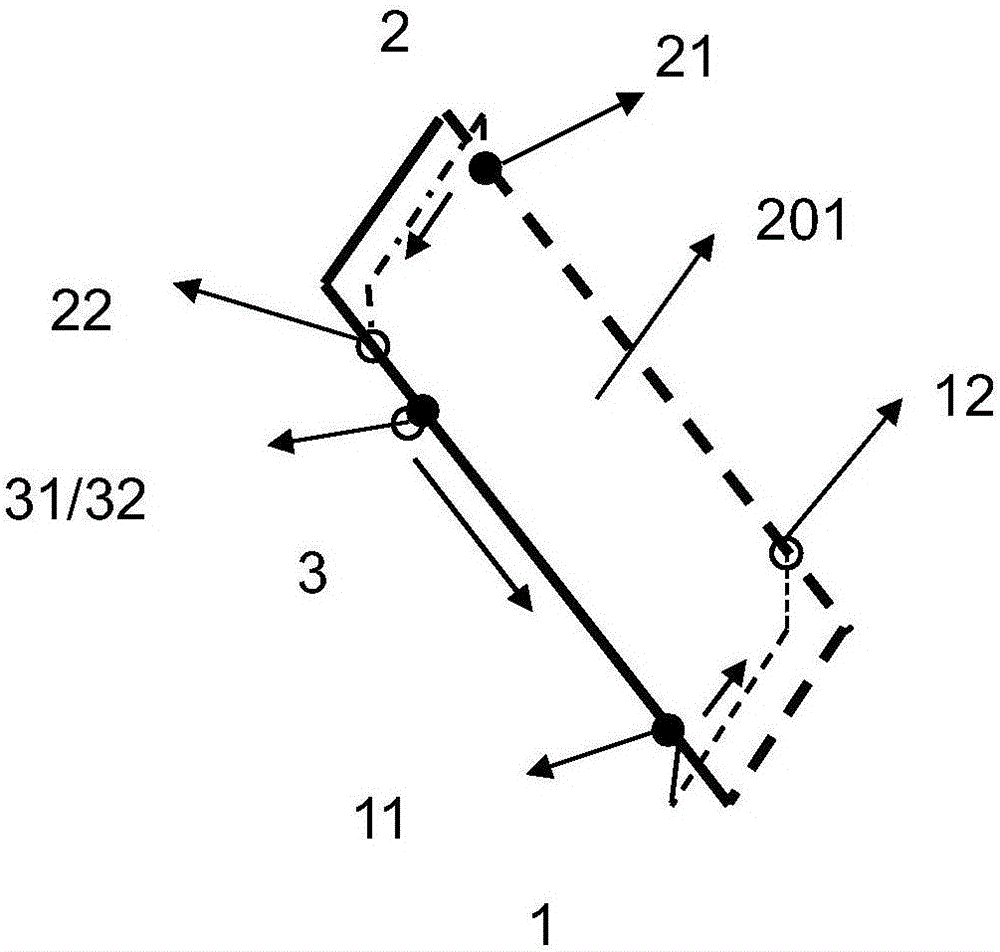

[0024] The invention provides a cutting method for two-dimensional laser cutting pipes. The cutting method adopts a two-dimensional cutting head 100. The two-dimensional cutting head means that the cutting head can only move horizontally in the Y direction and vertically in the Z direction, and is always perpendicular to the pipe. Instead of changing the swing angle with the pipe. Through this cutting method, the two-dimensional cutting head can achieve the effect of three-dimensional pendulum cutting, thereby enhancing its own functions and expanding its processing range, meeting the actual production needs and solving the problem of using the two-dimensional cutting head. The disadvantage of limitations.

[0025] see figure 2 and image 3 As shown, the pipe material 200 of the present invention includes pipe materials such as square pipes, rectangular pipes, and round waist pipes.

[0026] In this embodiment, the pipe 200 refers to a square pipe, one end of the pipe 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com