Stress response type optical hydrogel as well as preparation method and application thereof

A hydrogel and stress technology, which is applied in the field of stress-responsive optical hydrogel and its preparation, can solve the problems of low stretching degree, narrow color range, uneven color development of mechanically responsive materials, etc., and achieve tensile properties Good, good biodegradability, good interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A stress-responsive optical hydrogel, the preparation method of which is as follows:

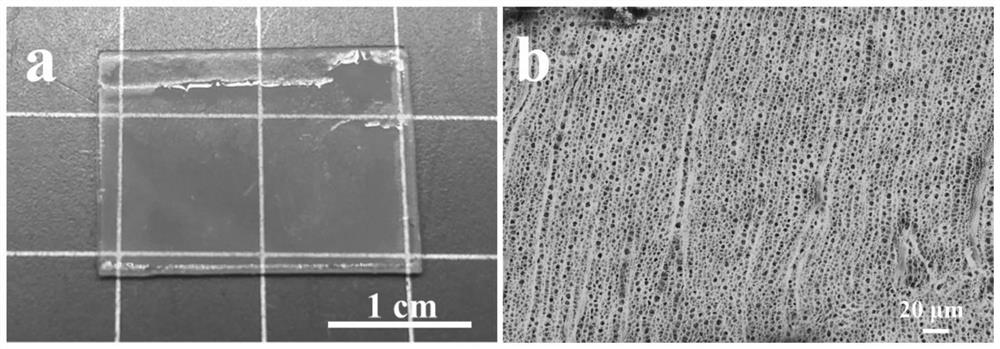

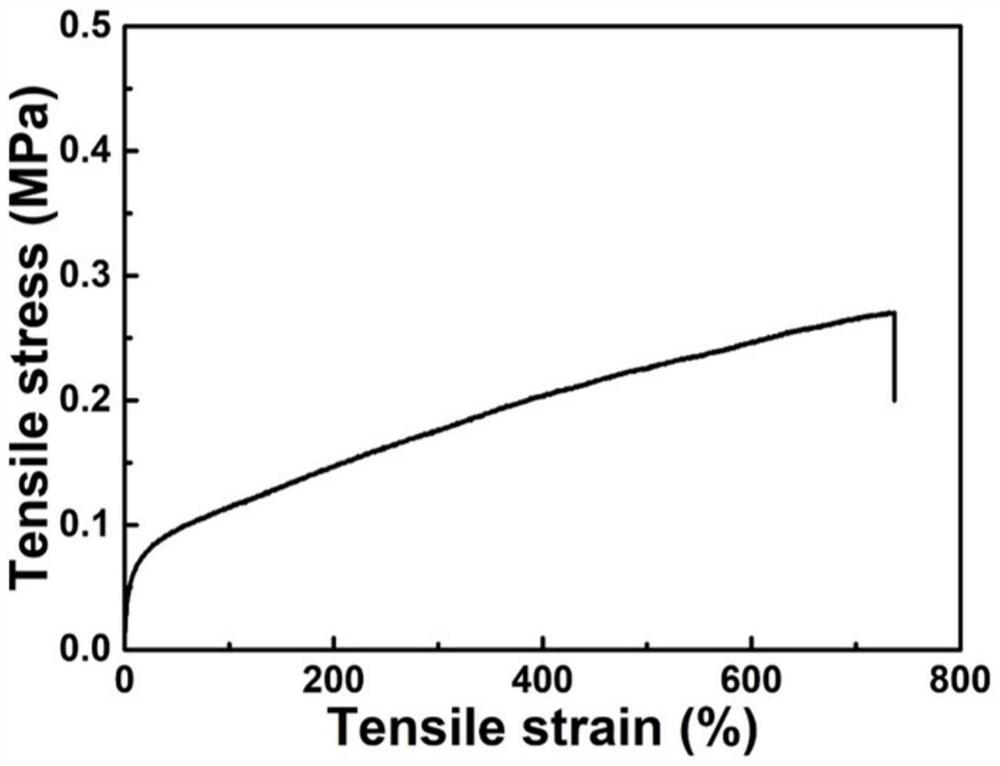

[0029] The cellulose nanocrystal suspension with a concentration of 1wt% was ultrasonically treated at 600W for 10min, and 15mL of the sonicated suspension was taken, and filtered with a nylon filter membrane with a pore size of 0.22μm under a vacuum of 0.6bar to produce chiral cellulose Nanocrystalline film (thickness: 77.5 μm), take a chiral cellulose nanocrystalline film (0.075 g) with a size of 15 mm × 20 mm, sandwich it up and down with two glass slides with a size of 25 mm × 35 mm, soak it in 6 mL of acrylamide and acrylic acid precursor body solution (solution composition and mass percentage are: acrylamide 10%, acrylic acid 10%, N,N-methylenebisacrylamide 0.1%, photoinitiator 2959 0.15%, and the balance is water) for five minutes Then, UV light polymerization was carried out for 2 h under a UV lamp with a power of 40 W and a wavelength of 365 nm to obtain a stress-responsive p...

Embodiment 2

[0035] A stress-responsive optical hydrogel, the preparation method of which is as follows:

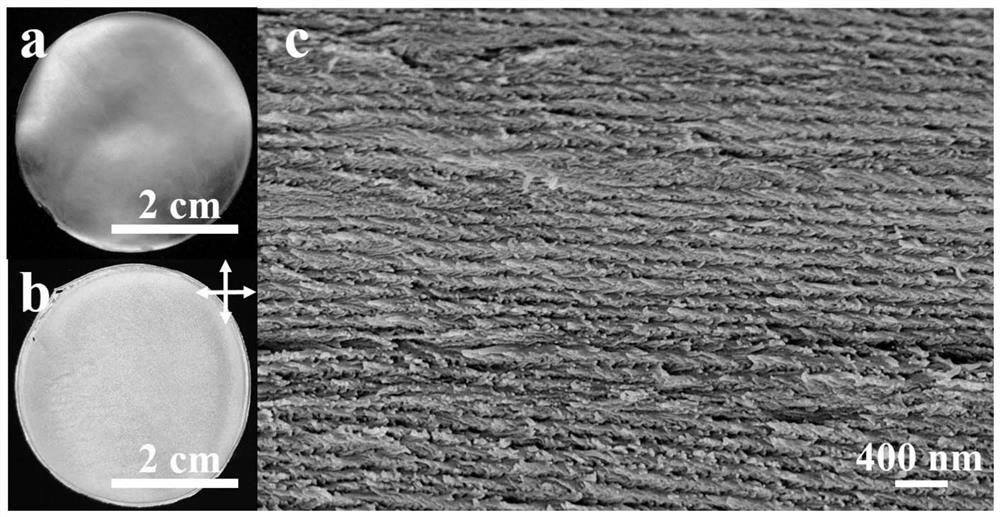

[0036] The cellulose nanocrystal suspension with a concentration of 2wt% was subjected to 600W ultrasonic treatment for 10min, and 15mL of the ultrasonic suspension was taken, and a nylon filter membrane with a pore size of 0.22 μm was suction-filtered under a vacuum of 0.6bar to prepare a 477nm screw pitch. Chiral cellulose nanocrystalline membrane (186.3 μm in thickness), take a 15mm×20mm chiral cellulose nanocrystalline membrane (0.15g) and clamp it up and down with two 25mm×35mm glass slides, soak it in 6mL acrylic Amide and acrylic acid precursor solution (solution composition and mass percentage are: acrylamide 10%, acrylic acid 10%, N,N-methylenebisacrylamide 0.1%, photoinitiator 29590.15%, and the balance is water) After swelling for five minutes, UV light polymerization was carried out for 2 h under a UV lamp with a power of 40 W and a wavelength of 365 nm to obtain a stress-...

Embodiment 3

[0040] A stress-responsive optical hydrogel, the preparation method of which is as follows:

[0041] The cellulose nanocrystal suspension with a concentration of 1wt% was ultrasonically treated at 400W for 10min, and 15mL of the supersonic suspension was taken, and filtered with a nylon filter membrane with a pore size of 0.22μm under a vacuum of 0.6bar to prepare a 477nm screw pitch. Chiral cellulose nanocrystalline membrane (thickness is 83.3 μm), take a chiral cellulose nanocrystalline membrane (0.075g) with a size of 15mm×20mm, clamp it up and down with two glass slides with a size of 25mm×35mm, soak it in 6mL of acrylic Amide and acrylic acid precursor solution (solution composition and mass percentage are: acrylamide 10%, acrylic acid 10%, N,N-methylenebisacrylamide 0.1%, photoinitiator 29590.15%, and the balance is water) After swelling for five minutes, UV light polymerization was carried out for 2 h under a UV lamp with a power of 40 W and a wavelength of 365 nm to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com