Power transmission chain

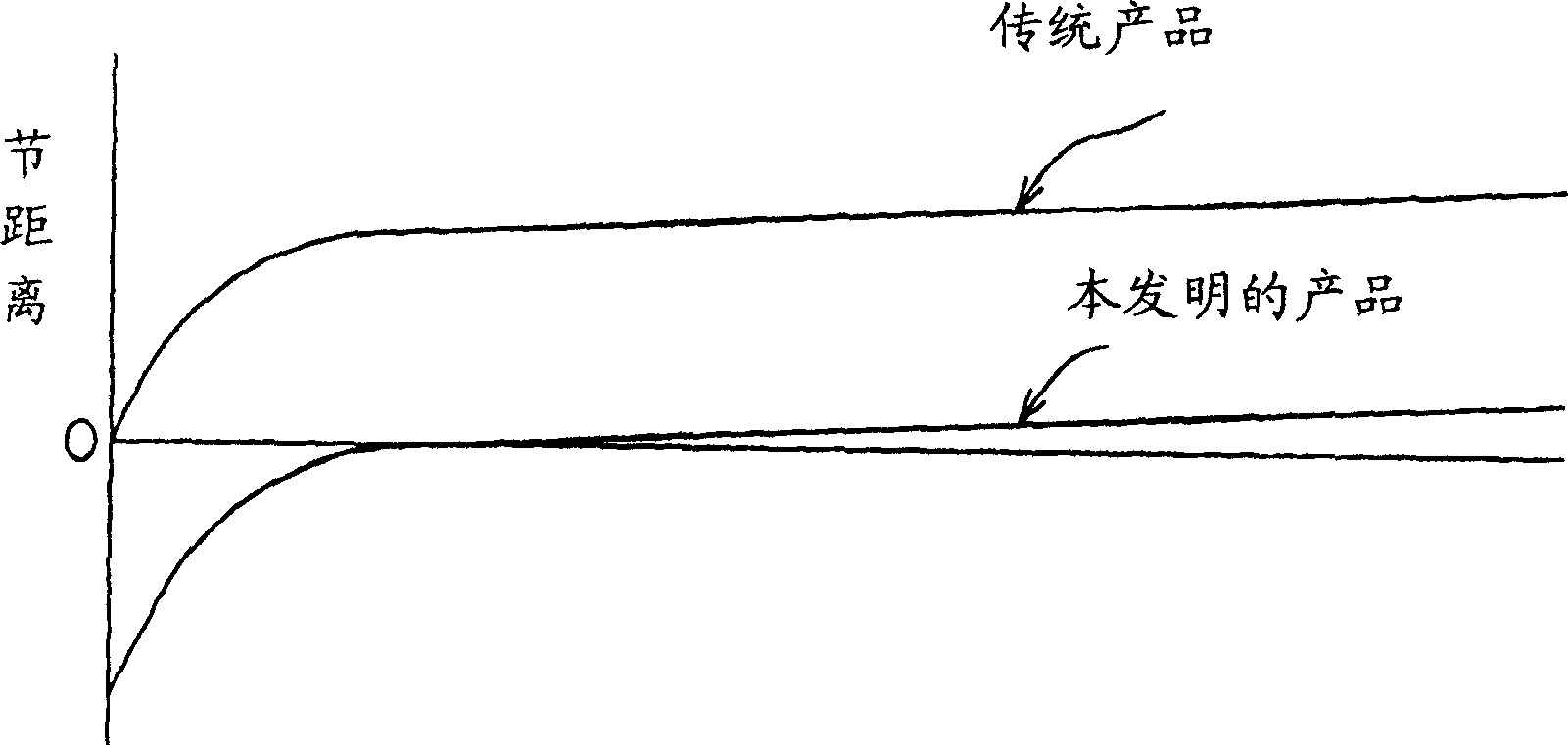

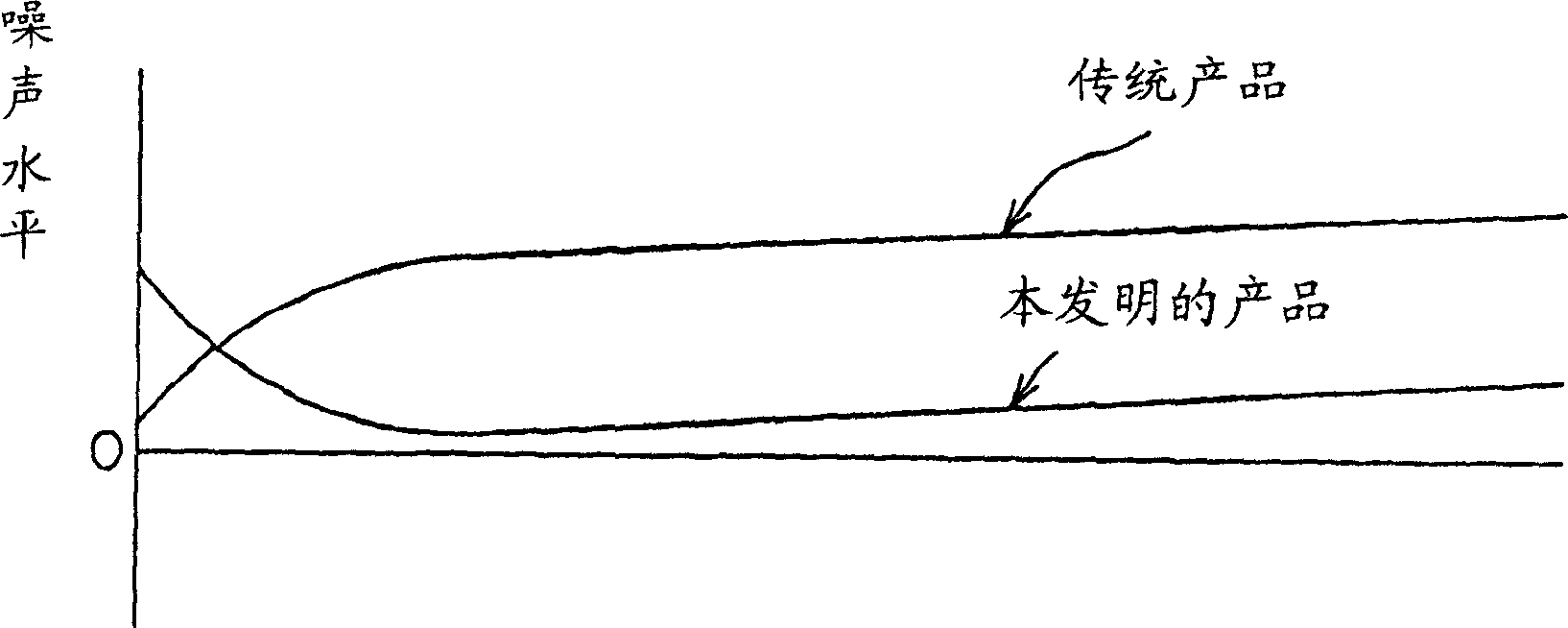

A power transmission and chain technology, applied in the transmission chain and other directions, can solve the problems of sprocket teeth cracks, failures, loud noise of roller chains, etc., and achieve the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

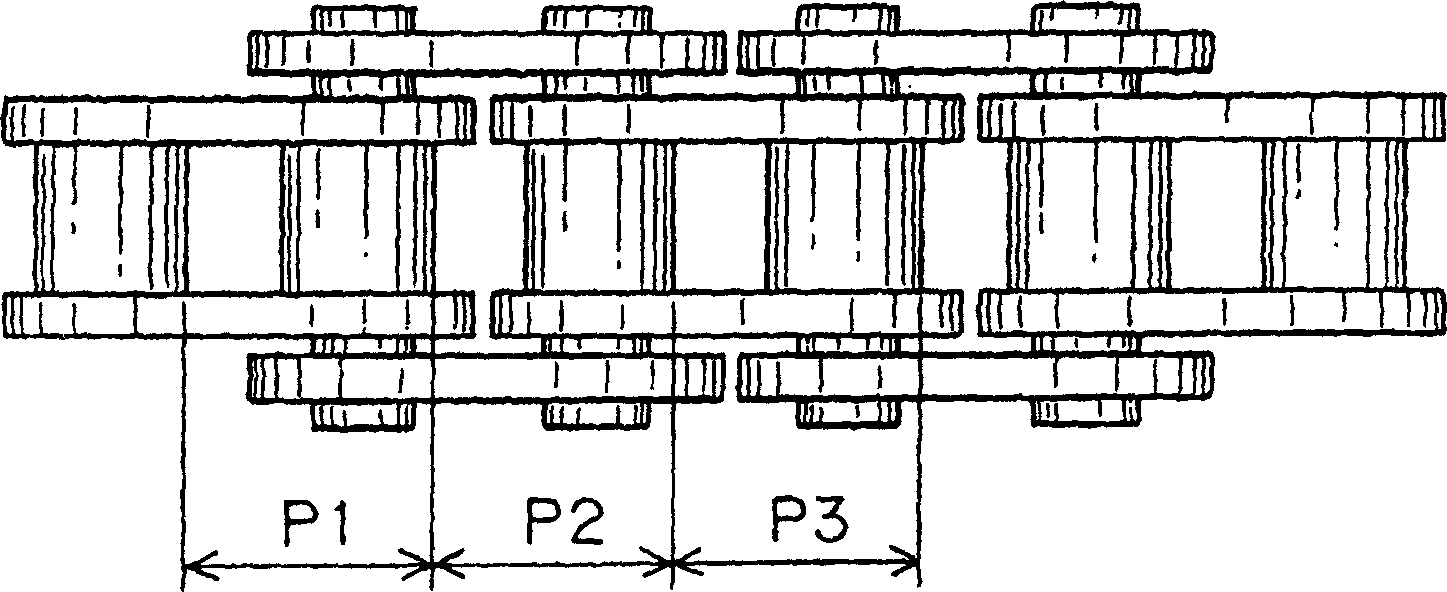

[0013] In the chain 40 according to the present invention, such as Figure 4 Described, the inner and outer links are arranged in overlapping relationship along the length of the chain. Each inner link includes a pair of opposed inner link plates 41 having sleeve holes 41a into which sleeves 42 are press-fitted. The roller 43 is free to rotate on the sleeve. Each outer link includes a pair of opposed outer link plates 44 having pin holes 44a into which pins 45 are press fit. Thus, each inner link comprises two inner links 41 , two bushes 42 and two rollers 43 and each outer link comprises two outer links 44 and two pins 45 . The pin of each outer link extends through the sleeve of the adjacent inner link and is rotatable therein so that the adjacent links can pivot relative to each other.

[0014] Such as figure 2 As shown, in the chain according to the invention, the pitches P1 and P3 are equal to each other. Each of these pitches is measured between corresponding point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com