Method for manufacturing steel strip for central cooling tube and method for winding cooling tube

A manufacturing method and technology for steel strips, which are applied in the field of superconductivity, can solve the problems of failing to meet the control requirements of the central cooling tube winding and poor passability of rectangular steel strips, and achieve the effects of perfect appearance, uniform pitch and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

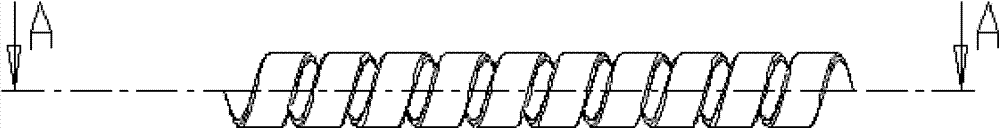

[0032] The central cooling pipe is wound by a stainless steel strip with a rectangular cross-section, and the cross-sectional structure of the steel strip is as follows: figure 1 shown. The structure of the central cooling pipe is as follows figure 2 shown. In order to obtain high-quality finished central cooling pipes, it is necessary to rationally design the production process of the rectangular steel strip, so that the rectangular steel strip has good passability, that is, the thickness, width, and HV hardness are uniform, so that the later winding process of the central cooling pipe is stable and easy to control .

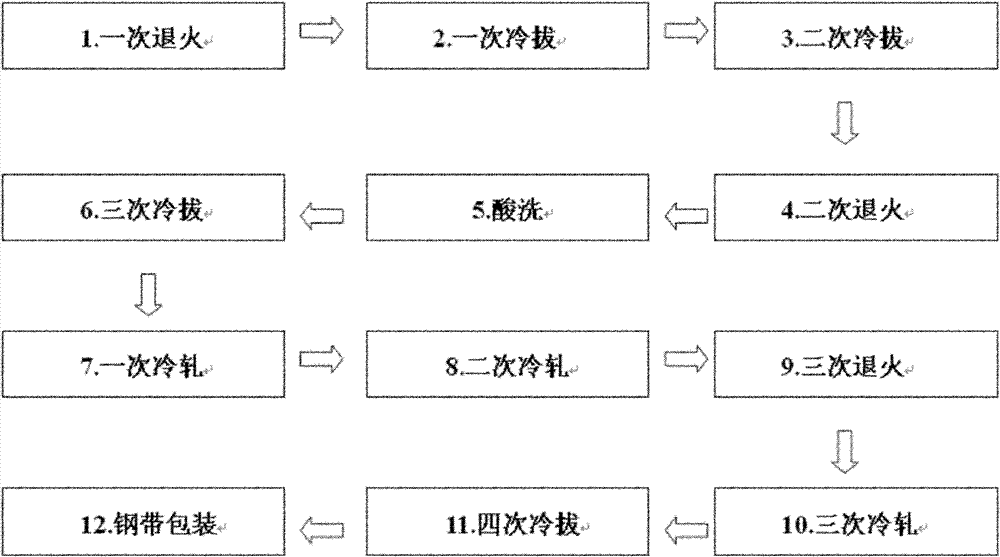

[0033] Such as image 3 shown. In the manufacture of rectangular steel strips, the primary annealing makes the φ1 raw material steel wire into a fully soft state; the primary cold drawing makes the φ1 raw material steel wire into a φ2 steel wire, and the cross section shrinks; the secondary cold drawing makes the φ2 steel wire into a φ3 steel wire, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com