Tapping-free sintering process for internal thread of MIM product

A technology of internal thread and internal thread hole, which is applied in the field of tapping-free sintering technology, can solve the problems that the tapping accuracy cannot be guaranteed, the service life of the tap is affected, and the product qualification rate is low, so as to improve the qualification rate and rework rate and promote it. High utilization value and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

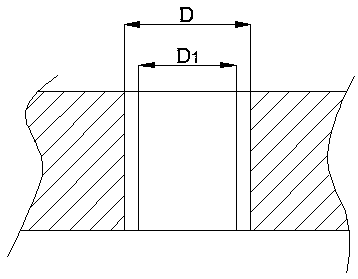

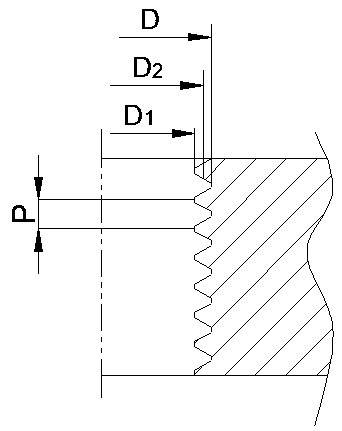

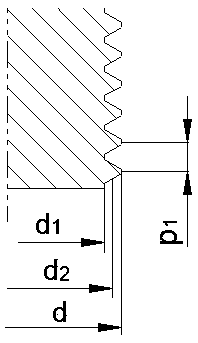

[0027] Such as Figure 1~3 As shown, the tapping-free sintering process of a kind of MIM product internal thread in the present embodiment comprises the following steps

[0028] ①Preparation of POM screw core: According to the mechanical manual, find the internal thread major diameter D and internal thread minor diameter D of the internal thread of the MIM product 1 ,Pitch diameter of internal thread D 2and internal thread pitch p, and then determine the axial expansion rate a of the internal thread according to the material of the MIM product 1 and radial shrinkage a 2 , then according to the known D, D 1 、 D 2 , p, a 1 and a 2 Calculate the major diameter d of the external thread and the minor diameter d of the external thread of the POM screw core respectively 1 , external thread pitch diameter d 2 and external thread pitch p 1 , where d=D×a 2 , d 1 =D 1 ×a 2 , d 2 =D 2 ×a 2 ,p 1 =a 1 ×p, finally according to the calculated d, d 1 、d 2 and p 1 The size ...

Embodiment 2

[0043] Such as Figure 1~3 As shown, the tapping-free sintering process of a kind of MIM product internal thread in the present embodiment comprises the following steps

[0044] ①Preparation of POM screw core: According to the mechanical manual, find the internal thread major diameter D and internal thread minor diameter D of the internal thread of the MIM product 1 ,Pitch diameter of internal thread D 2 and internal thread pitch p, and then determine the axial expansion rate a of the internal thread according to the material of the MIM product 1 and radial shrinkage a 2 , then according to the known D, D 1 、 D 2 , p, a 1 and a 2 Calculate the major diameter d of the external thread and the minor diameter d of the external thread of the new POM screw respectively 1 , external thread pitch diameter d 2 and external thread pitch p 1 , where d=D×a 2 , d 1 =D 1 ×a 2 , d 2 =D 2 ×a 2 ,p 1 =a 1 ×p, finally according to the calculated d, d 1 、d 2 and p 1 The size ...

Embodiment 3

[0059] Such as Figure 1~3 As shown, the tapping-free sintering process of a kind of MIM product internal thread in the present embodiment comprises the following steps

[0060]①Preparation of POM screw core: According to the mechanical manual, find the internal thread major diameter D and internal thread minor diameter D of the internal thread of the MIM product 1 ,Pitch diameter of internal thread D 2 and internal thread pitch p, and then determine the axial expansion rate a of the internal thread according to the material of the MIM product 1 and radial shrinkage a 2 , then according to the known D, D 1 、 D 2 , p, a 1 and a 2 Calculate the major diameter d of the external thread and the minor diameter d of the external thread of the new POM screw respectively 1 , external thread pitch diameter d 2 and external thread pitch p 1 , where d=D×a 2 , d 1 =D 1 ×a 2 , d 2 =D 2 ×a 2 ,p 1 =a 1 ×p, finally according to the calculated d, d 1 、d 2 and p 1 The size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com