An all-in-one machine for processing parts with internal threads

An all-in-one machine, internal thread technology, used in manufacturing tools, metal processing equipment, thread trimmers, etc., can solve the problems of occupying space, incompetence, time-consuming and labor-intensive, and achieve the effect of uniform pitch and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

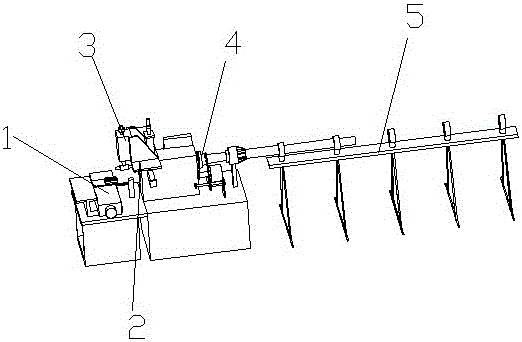

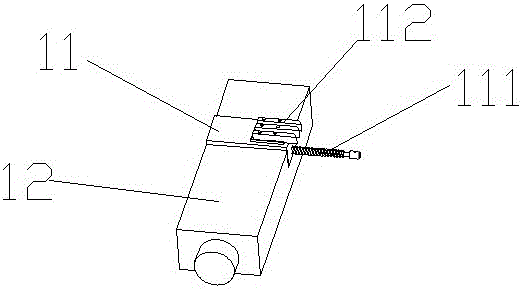

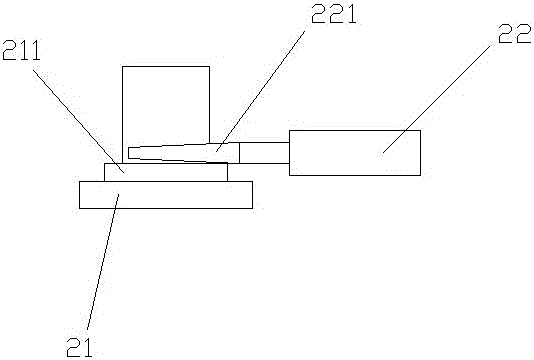

[0030] Example 1, such as Figure 1-9 , an all-in-one machine for processing parts with internal threads, including a frame, the frame includes a cutting mechanism 1, a clamping mechanism 2, a measuring and positioning mechanism 3 arranged above the clamping mechanism 2, and a rotating mechanism arranged in front of the clamping mechanism 2 Mechanism 4, the cutting mechanism 1 includes a horizontally adjustable workbench 11 and a longitudinally adjustable workbench 12, the horizontally adjustable workbench 11 is connected with a lead screw 111 through a motor, and the upper surface is also provided with a tool mounting frame 112, and the tool is installed The frame 112 is provided with several cutter grooves, and the longitudinally adjustable workbench 12 is connected with the motor. The clamping mechanism 2 includes a fixed workbench, clamping blocks 21 arranged in a circle and a first cylinder 22, and the fixed workbench is provided with a transverse hole. The clamping block...

Embodiment 2

[0031] Example 2, such as Figure 1-10 , the machining direction of machining parts with internal threads is Figure 10 In the direction indicated by the arrow, metal pipe fittings enter from the support guide mechanism 5, pass through the rotating part 41 and the speed measuring part 42 in the rotating mechanism 4, and enter the clamping mechanism 2 to clamp the pipe fittings, wherein the rotating part 41 provides a power , the speed measuring part 42 is to measure the rotational speed of the rotating pipe fitting, to ensure a certain rotational speed so as to meet the cutting requirements, and the measuring and positioning mechanism 3 is to locate the length of the pipe fitting, which can be manually adjusted. Before each cutting, a measurement and positioning will be done. Afterwards, the cutting mechanism 1 is adjusted to a suitable position for internal thread processing, and this equipment has a numerical control function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com