Cross thermal transfer ribbon patterning machine for fishing rod

A technology of punching machines and carbon ribbons, which is applied in applications, household appliances, household components, etc., can solve problems such as easy formation of broken ribbons, delay in the production cycle of fishing rods, and affect the production efficiency of fishing rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

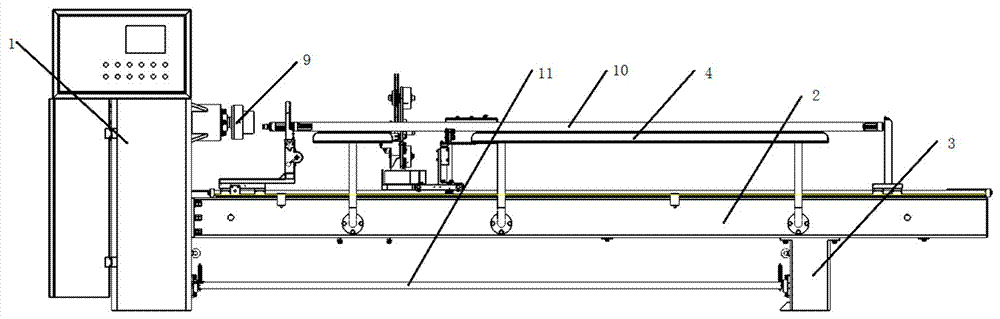

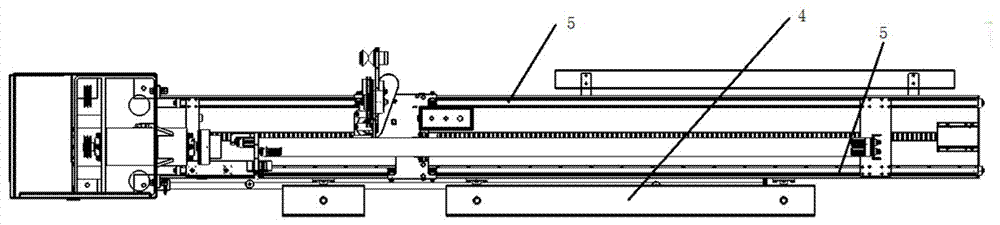

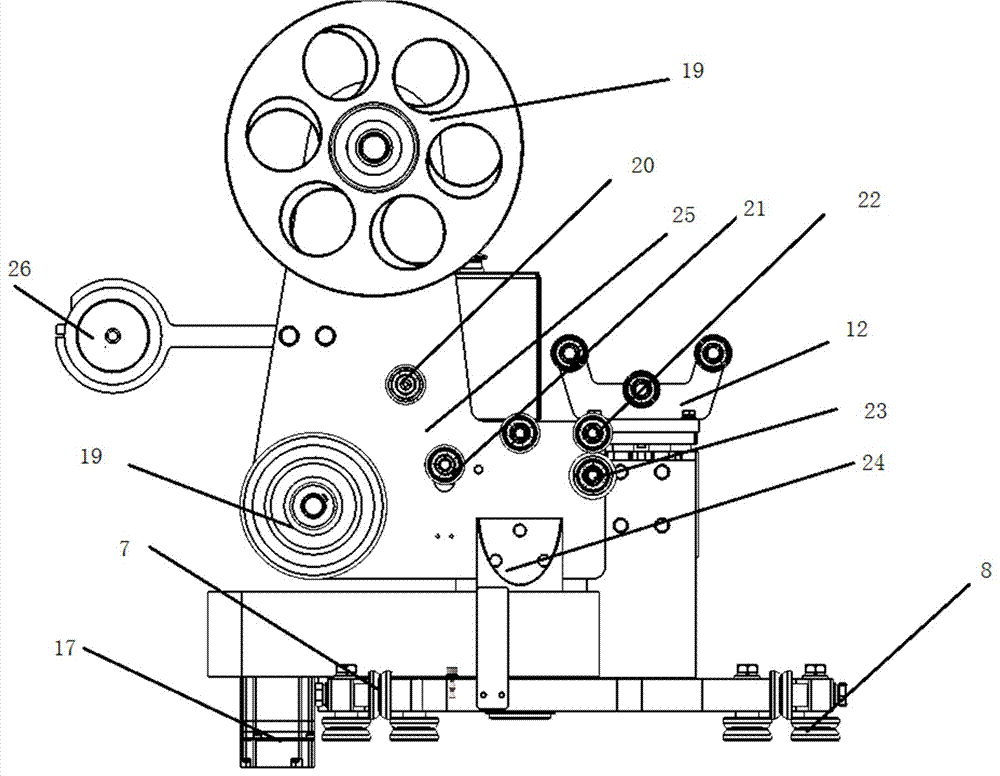

[0026] As shown in the figure, a cross-ribbon punching machine for fishing rods includes a body, a chuck unit and a slide assembly. The body is provided with a bedside box 1 and a frame, and the frame includes a workbench 2 and a workbench support 3 , one side of the workbench is provided with a rod putting groove 4, and the rod putting groove 4 is fixedly connected with one side of the workbench through the rod putting groove frame so as to facilitate the placement of fishing rods and improve the processing efficiency. Guide rails 5 are respectively provided on the front and rear sides of the upper side of the workbench. The slide plate assembly is provided with a slide plate. The lower end of the slide plate is provided with a guide unit that matches the guide rail. The guide unit includes a longitudinal V-shaped wheel 7 and a horizontal V-shaped wheel 8, the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com