High-speed high-performance data communication cable for network and manufacturing method thereof

A data communication, high-performance technology, applied in the direction of cable/conductor manufacturing, with twisted/quad twisted cables, circuits, etc., can solve the problems of difficulty, return loss, cable concentricity and cable core Problems such as poor cylindricity, to achieve the effect of consistent arrangement sequence, excellent performance and stable pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

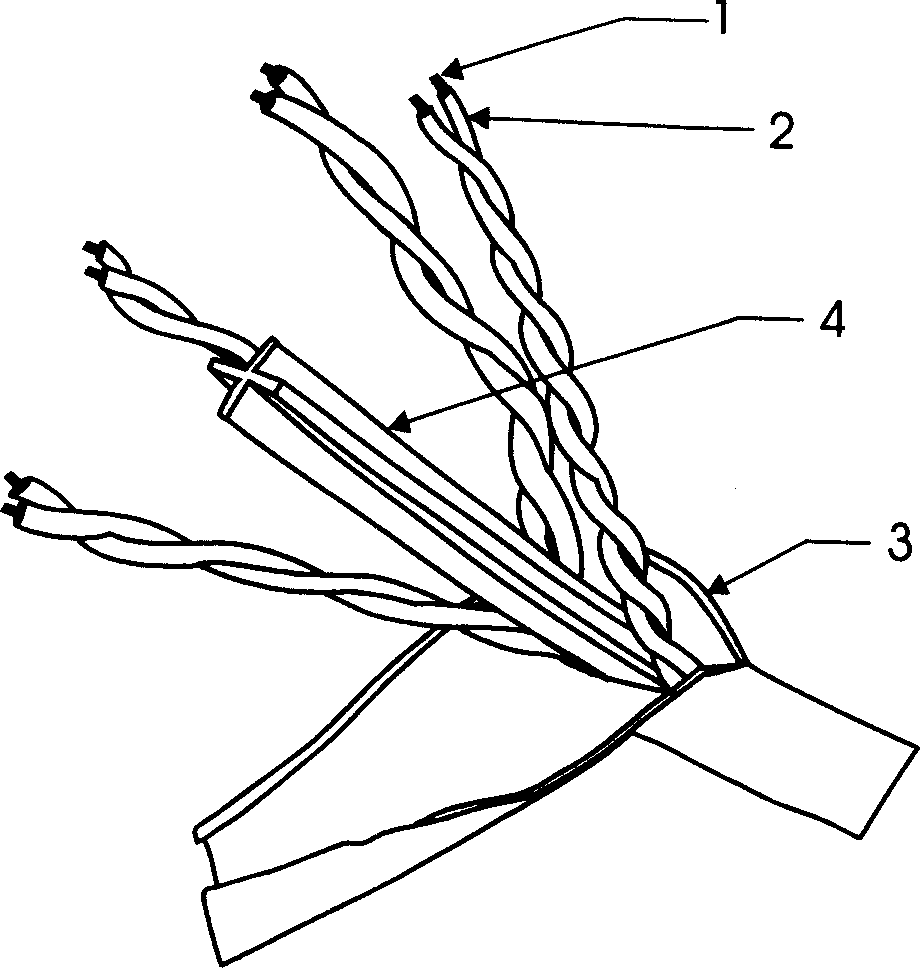

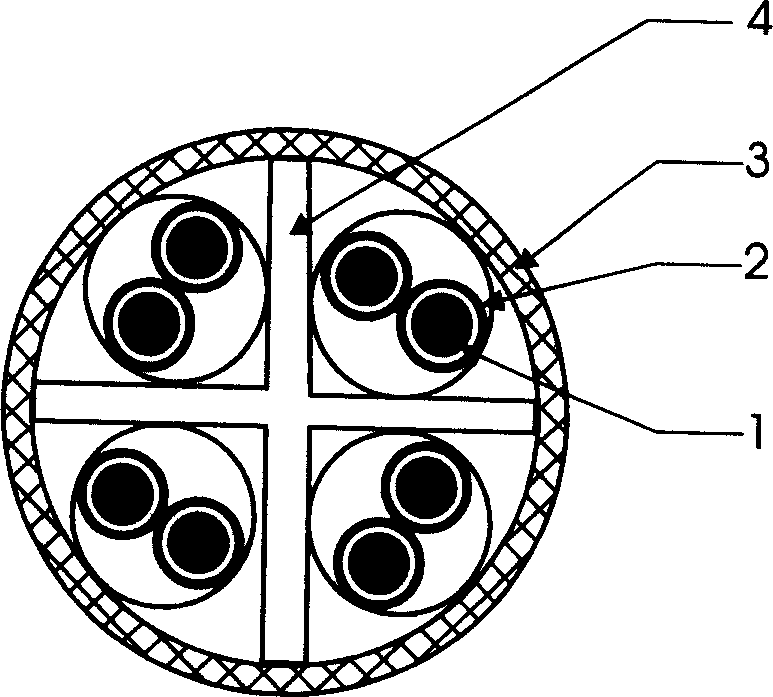

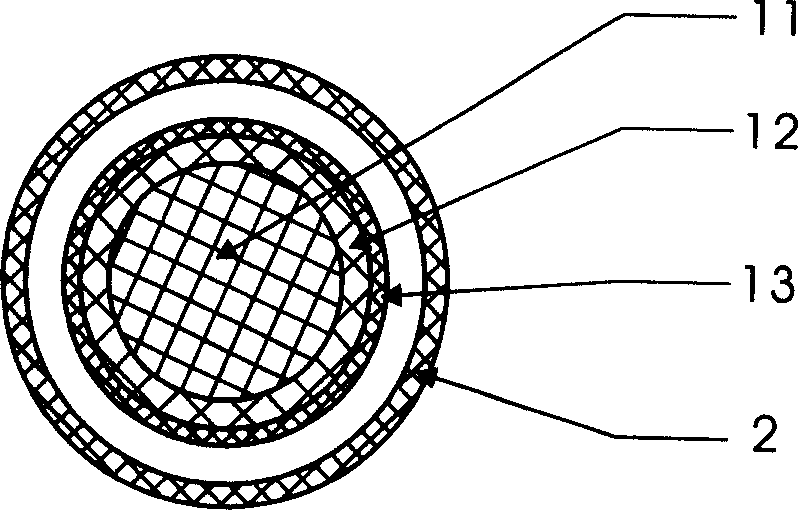

[0034] Implementation mode one: if figure 1 As shown, the Teflon (Teflon) insulating sheath 3 with an outer diameter of 6.2±0.3mm is composed of four pairs of cables twisted together to form a pair and each pair has a different twist distance. The wires are all composed of a conductor cable core 1 with an outer diameter of 0.58 mm and an insulating sheath 2 with an outer diameter of 0.95 mm. The conductor cable core 1 is made of a stretched steel core 11 coated with a copper coating layer 12 and then plated with a silver layer 13 ( see image 3 ), the insulation sheath is also equipped with cross-section foamed Teflon (Teflon) packing, which separates each pair of twisted signal lines from each other; the total lay length is 130±5mm; the insulation sheath 2 is made of Teflon Dragon (Teflon) made.

Embodiment approach 2

[0035] Embodiment 2: Except that the cable core is replaced by silver-plated copper, other structures and materials are the same.

Embodiment approach 3

[0036] Embodiment 3: Except that the cable core is replaced by bare copper, other structures and materials are the same; the surface roughness of the bare copper is relatively low.

[0037] The aforementioned cables can be made by the following processes:

[0038] 1. The production process of silver-plated copper-clad steel cable core:

[0039] 1) Stretch φ6.0mm billet into φ2.2mm steel bar;

[0040] 2) Stretching the φ2.2mm steel bar and simultaneously annealing it to obtain a stretched steel core 11 with an outer diameter of 0.5mm;

[0041] 3) Copper-clad steel continuous extrusion cladding (refer to the paper "Research on continuous extrusion cladding of copper-clad steel contact wire billet" 10006 Yun Xinbing 116028 Song Baoyun Liu Yuanwen) The basic principle of continuous extrusion cladding is to use friction as the driving force Carry out extrusion; on the basis of the continuous extrusion process method, the shoe seat is placed on the upper part of the extrusion whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com