Single fire rolling method for tc4 titanium alloy plate

A titanium alloy, 1.TC4 technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of poor formability of single-fire rolling alloys, and achieve good surface quality, good structure uniformity, Effect of Simplified Rolling Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

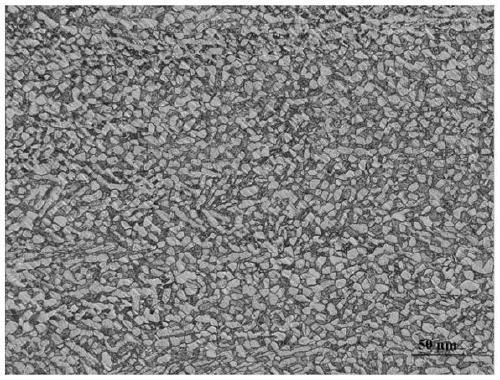

Embodiment 1

[0038] Embodiment 1 adopts the method of the present invention to carry out rolling to TC4 titanium alloy

[0039] The specific operation steps are as follows:

[0040] ①Use a walking heating furnace to heat the TC4 slab with a thickness of 151mm. The preheating section is <800°C for 90 minutes, the heating section is 930°C for 60 minutes, and the soaking section is 980°C for 90 minutes;

[0041] ② After soaking for 90 minutes in the soaking section, increase the temperature of the soaking section to 1000°C, continue holding for 30 minutes, and then roll out of the furnace;

[0042] ③ Turn off the cooling water and descaling water of the roller table, and quickly transfer the billet to the rolling mill for rolling;

[0043] ④ Change direction before starting rolling, that is, cross rolling is carried out in the first pass, and cross rolling is used in subsequent passes;

[0044] ⑤The starting rolling temperature is 955°C, the deformation in the first three passes is 24%, 29%...

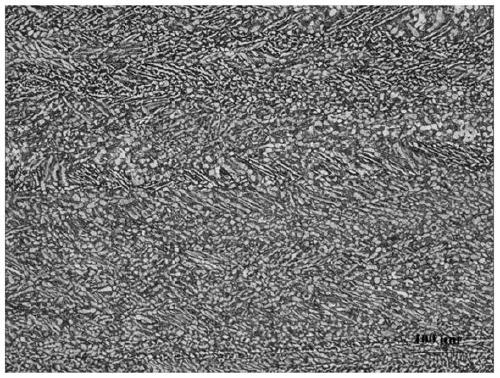

Embodiment 2

[0048] Embodiment 2 adopts the method of the present invention to carry out rolling to TC4 titanium alloy

[0049] The specific operation steps are as follows:

[0050] ① Use a walking heating furnace to heat the TC4 slab with a thickness of 140mm. The preheating section is <800°C for 90 minutes, the heating section is 950°C for 60 minutes, and the soaking section is 980°C for 90 minutes;

[0051] ② After soaking for 90 minutes in the soaking section, increase the temperature of the soaking section to 1020°C, continue holding for 30 minutes, and then roll out of the furnace;

[0052] ③ Turn off the cooling water and descaling water of the roller table, and quickly transfer the billet to the rolling mill for rolling;

[0053]④ Change direction before starting rolling, that is, cross rolling is carried out in the first pass, and cross rolling is used in subsequent passes;

[0054] ⑤The starting rolling temperature is 960°C, the deformation in the first three passes is 25%, 28%...

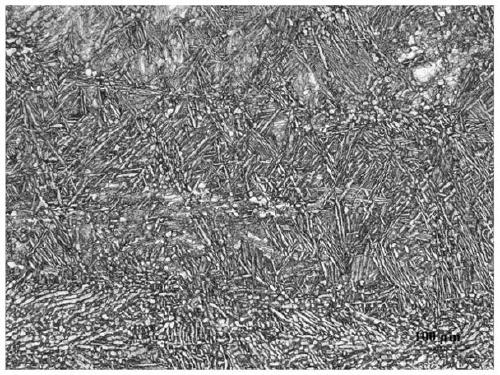

Embodiment 3

[0058] Embodiment 3 adopts the method of the present invention to carry out rolling to TC4 titanium alloy

[0059] The specific operation steps are as follows:

[0060] ①Use a walking heating furnace to heat the TC4 slab with a thickness of 150mm. The preheating section is <800°C for 90 minutes, the heating section is 950°C for 60 minutes, and the soaking section is 980°C for 90 minutes;

[0061] ② After soaking for 90 minutes in the soaking section, increase the temperature of the soaking section to 1020°C, continue holding for 30 minutes, and then roll out of the furnace;

[0062] ③ Turn off the cooling water and descaling water of the roller table, and quickly transfer the billet to the rolling mill for rolling;

[0063] ④ Change direction before starting rolling, that is, cross rolling is carried out in the first pass, and cross rolling is used in subsequent passes;

[0064] ⑤The starting rolling temperature is 958°C, the deformation in the first three passes is 24%, 29%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com