Production method of fused AZS hanging wall brick

A production method and technology of hanging wall bricks, which are applied in the field of refractory materials, can solve problems such as shrinkage cavities at necks, stress cracks of electro-fused AZS hanging wall bricks, etc., and achieve reduced processing losses, good brick regularity, and reduced model volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

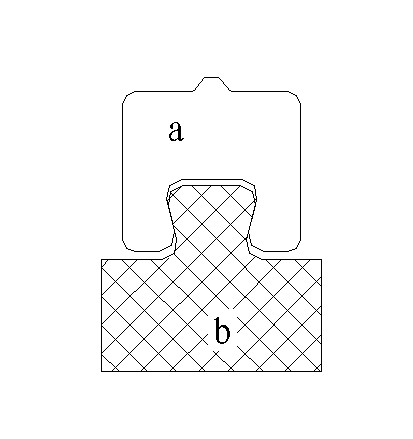

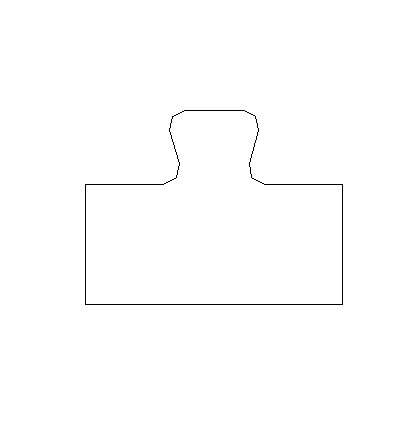

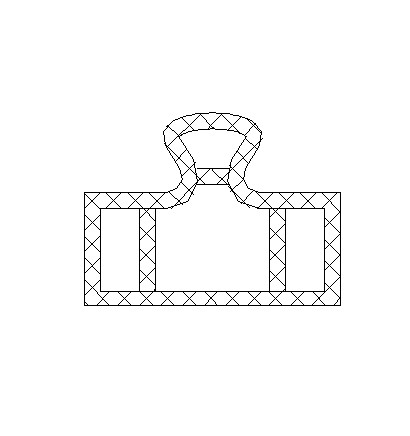

Image

Examples

Embodiment 1

[0024] A kind of production method of electrofusion AZS hanging wall brick, utilizes lost foam technology to produce, and its steps are as follows:

[0025] (1) The model is made of polystyrene foam, and the density of the model is 0.03g / cm 3 , compressive strength 15kg / cm 2 , the interior is a hollow structure with ribs;

[0026] (2) The model is filled with sand in a box. The size of the insulating sand box for casting is 1200mm×1200mm×1000mm, and 9 sets of models are placed in each box. The bottom of the sand mold is laid with insulating bricks to strengthen the heat preservation. After putting in dry quartz sand, shake it on the vibration platform. Place a square riser on the upper part of each model after scraping with a ruler, and seal the contact gap between the riser and the model with fine sand;

[0027] (3) Ingredients: The ingredients contain 30% synthetic fused AZS brick clinker, and the balance is fused cast zirconia corundum brick raw material; the synthetic fu...

Embodiment 2

[0031] A kind of production method of electrofusion AZS hanging wall brick, utilizes lost foam technology to produce, and its steps are as follows:

[0032] (1) The model is made of polystyrene foam, and the density of the model is 0.03g / cm 3 , compressive strength 10kg / cm 2 , the interior is a hollow structure with ribs;

[0033] (2) The model is filled with sand in a box. The size of the insulating sand box for casting is 1200mm×1200mm×1000mm, and 9 sets of models are placed in each box. The bottom of the sand mold is laid with insulating bricks to strengthen the heat preservation. After putting in dry quartz sand, shake it on the vibration platform. Place a square riser on the upper part of each model after scraping with a ruler, and seal the contact gap between the riser and the model with fine sand;

[0034] (3) Ingredients: The ingredients contain 20% synthetic fused AZS brick clinker, and the balance is fused cast zirconia corundum brick raw material; the synthetic fu...

Embodiment 3

[0038] A kind of production method of electrofusion AZS hanging wall brick, utilizes lost foam technology to produce, and its steps are as follows:

[0039] (1) The model is made of polystyrene foam, and the density of the model is 0.04g / cm 3 , compressive strength 15kg / cm 2 , the interior is a hollow structure with ribs;

[0040] (2) The model is filled with sand in a box. The size of the insulating sand box for casting is 1200mm×1200mm×1000mm, and 9 sets of models are placed in each box. The bottom of the sand mold is laid with insulating bricks to strengthen the heat preservation. After putting in dry quartz sand, shake it on the vibration platform. Place a square riser on the upper part of each model after scraping with a ruler, and seal the contact gap between the riser and the model with fine sand;

[0041] (3) Ingredients: The ingredients contain 50% synthetic fused AZS brick clinker, and the balance is fused cast zirconia corundum brick raw material; the synthetic fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com