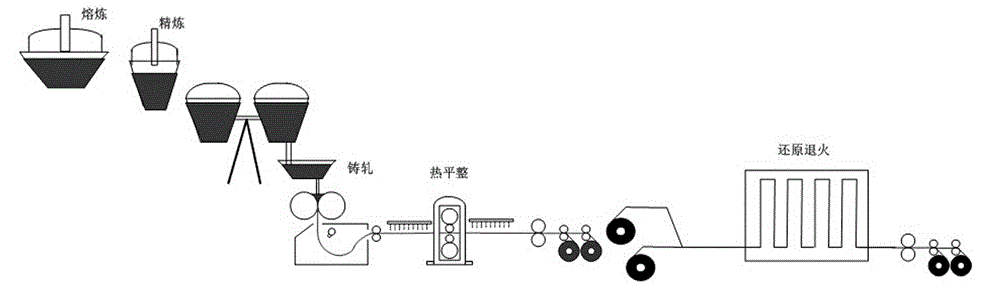

A method for producing hot-rolled pickling-free plates by strip continuous casting combined with reduction annealing

A pickling-free, thin-strip technology, applied in the field of material metallurgy, can solve the problems of increasing the difficulty of scale reduction, thick scale thickness on the strip steel surface, and low production efficiency, so as to save high energy consumption process and reduce production cost , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Smelting and refining:

[0029] According to the composition ratio of the thin strip, by weight percentage, it is C: 0.003%, Si: 0.03%, Mn: 0.22%, Al: 0.02%, S: 0.004%, P: 0.007%, and the rest is Fe ingredients, put into the smelting furnace Smelting in the smelting furnace, when the temperature of the molten steel in the smelting furnace is 1590°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0030] (2) Preparation of cast-rolled strip:

[0031] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll thin strip casting and rolling of the refined molten steel. The pouring temperature of the refined molten steel is 1550°C, the casting and rolling speed is 40m / min, and the preset roll gap is 0.9 mm, protected by inert gas argon during the flow of molten steel to obtain a cast-rolled strip with a thickness of 1.1 mm, and the oxide scale on the surface of the cast-rolled strip is contr...

Embodiment 2

[0037] (1) Smelting and refining:

[0038] According to the composition ratio of the strip, by weight percentage C: 0.04%, Si: 0.04%, Mn: 0.3%, Al: 0.025%, S: 0.006%, P: 0.009%, the balance is Fe ingredients, put into the smelting furnace Smelting in the smelting furnace, when the temperature of the molten steel in the smelting furnace is 1560°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0039] (2) Preparation of cast-rolled strip:

[0040] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll strip casting and rolling of the refined molten steel. The starting temperature of the refined molten steel is 1520°C, the casting and rolling speed is 25m / min, and the preset roll gap is 2mm. , inert gas argon protection is used during the flow of molten steel to obtain a cast-rolled strip with a thickness of 2.1 mm, and the oxide scale on the surface of the cast-rolled strip is controlled at 7 μm...

Embodiment 3

[0047] (1) Smelting and refining:

[0048] According to the composition ratio of thin strip, by weight percentage C: 0.004%, Si: 2.91%, Mn: 0.2%, Al: 0.01%, S: 0.016%, the balance is Fe batching, puts into smelting furnace and smelts, when When the temperature of molten steel in the smelting furnace is 1650°C, add a slag remover, and then carry out refining to obtain refined molten steel;

[0049] (2) Preparation of cast-rolled strip:

[0050] The beryllium copper casting roll with coating protection on the surface is used to carry out twin-roll thin strip casting and rolling of the refined molten steel. The pouring temperature of the refined molten steel is 1600 ℃, the casting and rolling speed is 10m / min, and the preset roll gap is 2.0 mm, protected by inert gas argon during the flow of molten steel to obtain a cast-rolled strip with a thickness of 2.1 mm, and the oxide scale on the surface of the cast-rolled strip is controlled at 7 μm;

[0051] (3) Thermal leveling:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com