Integrated forming process of high-power wind power motor cabin cover

A technology for wind turbines and molding processes, applied in sustainable manufacturing/processing, climate sustainability, and final product manufacturing, etc., can solve the problem of reducing the strength of the motor compartment cover, affecting the normal use of high-power wind turbines, and hiding the residual motor compartment cover. Defects and other problems, to achieve the effect of increasing strength, meeting stiffness strength, and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

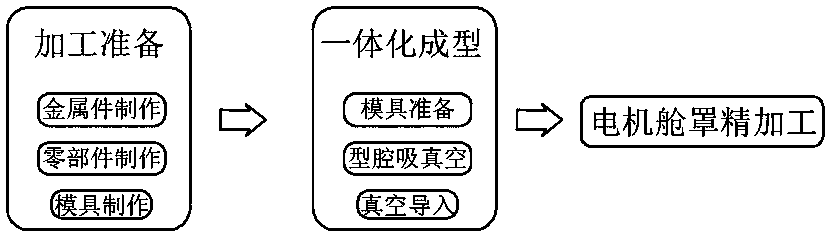

[0043] see figure 1 , an integrated molding process for a high-power wind turbine cover, the main steps of which are:

[0044] S1. Production of metal parts. Make corresponding metal parts according to the pre-designed drawings. The metal parts mainly include metal connectors, screws, etc., and after the metal parts are prepared, the surface of the metal parts is polished and anti-rust. The surface of metal parts is not easy to rust;

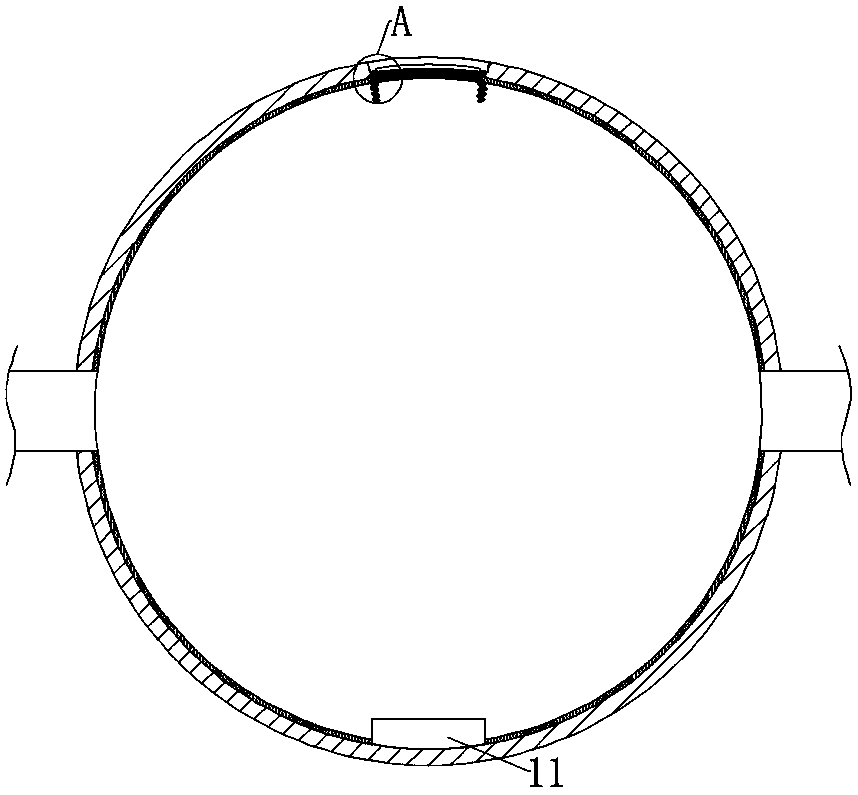

[0045] S2. Parts production: make corresponding non-metallic parts according to the pre-designed drawings, among which non-metallic parts mainly include the sealing device of the motor cabin cover, etc., and polish and deburr the surface after the parts are prepared deal with;

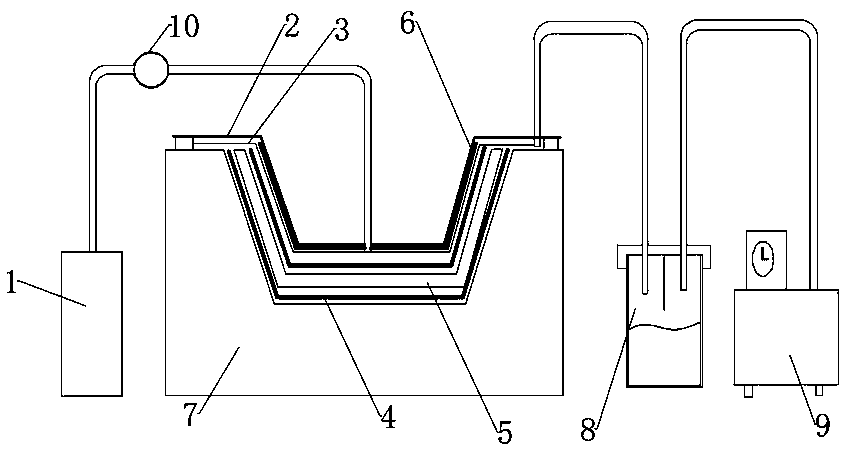

[0046] S3, mold making, according to the drawings designed in advance, make the integrally formed mold body 7 corresponding to the motor cabin cover, wherein the mold body 7 is a vacuum introduction mould;

[0047] S4, mold preparation, after cleaning the inside of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com