Patents

Literature

36results about How to "Good impact energy absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

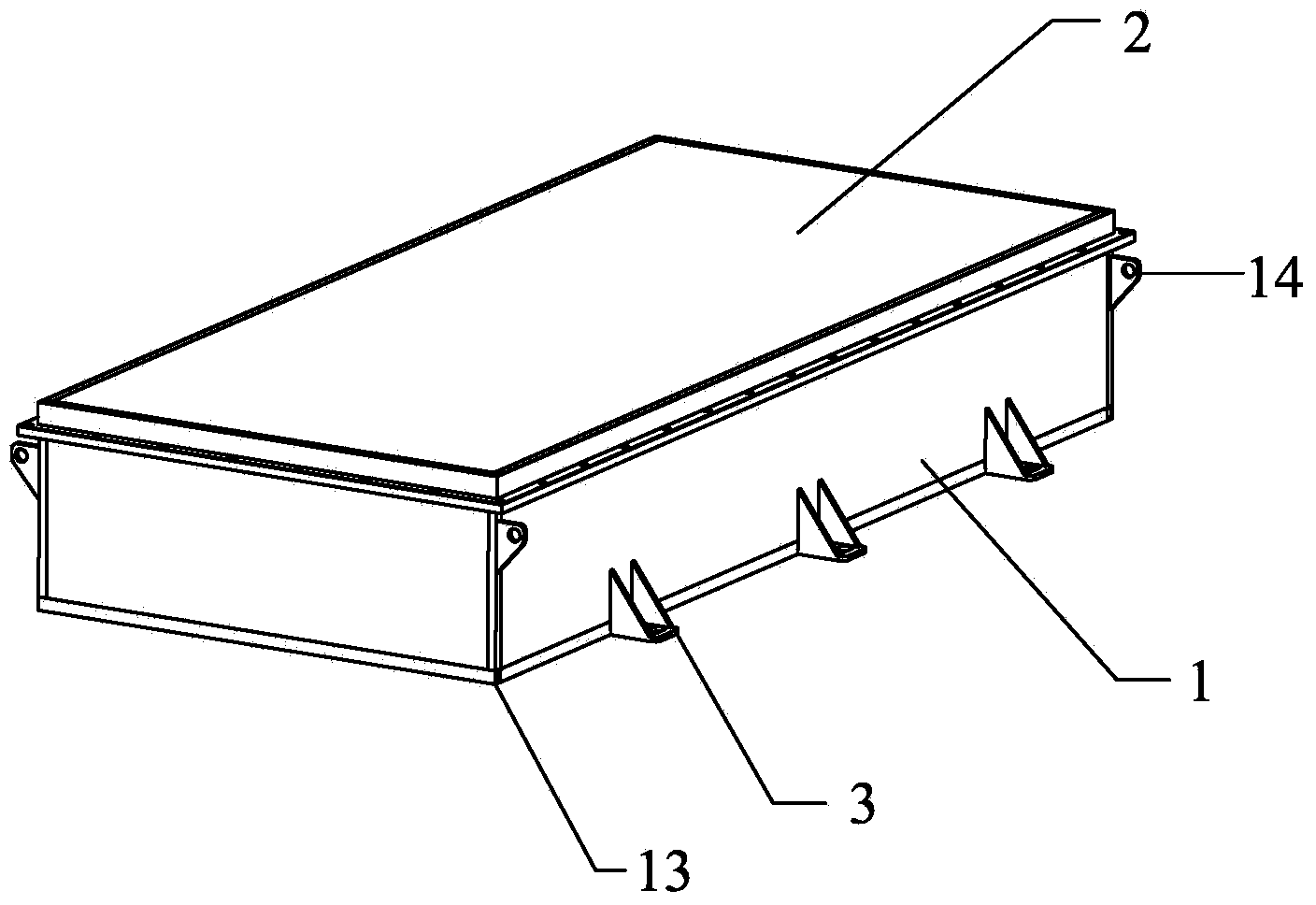

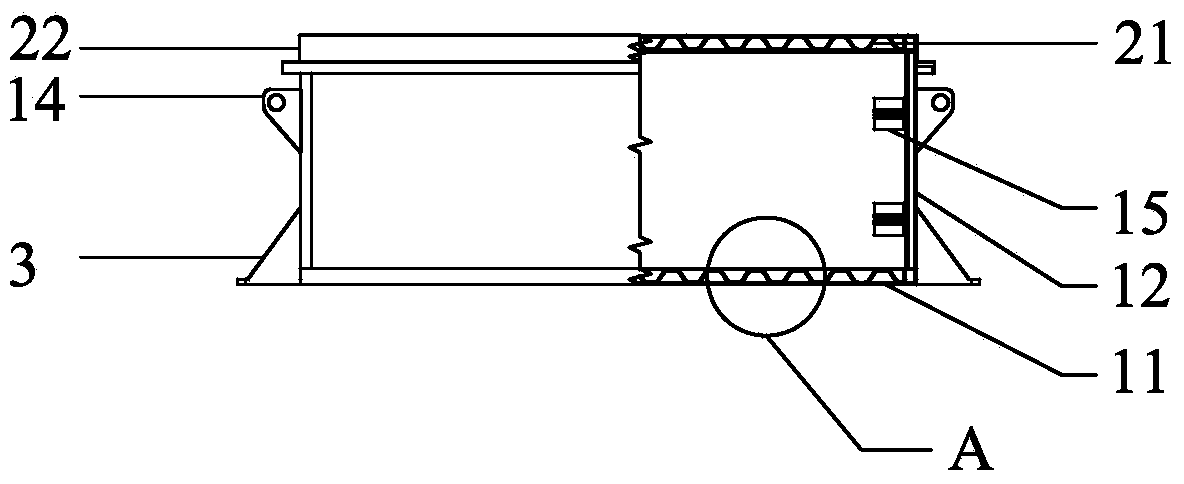

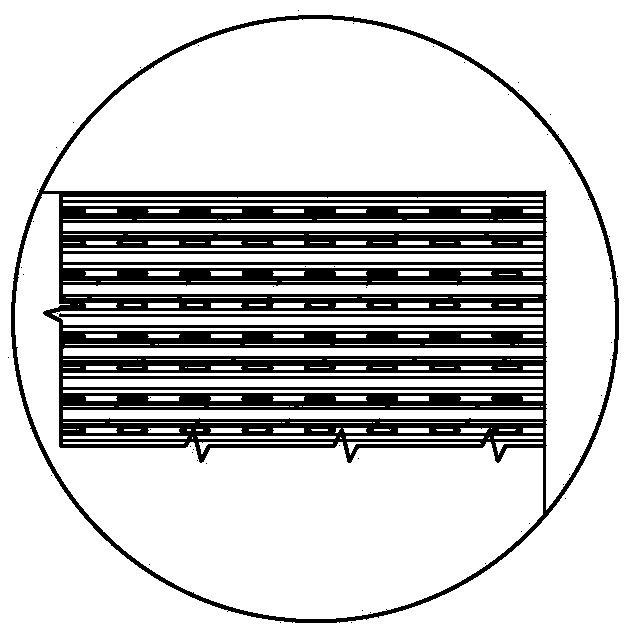

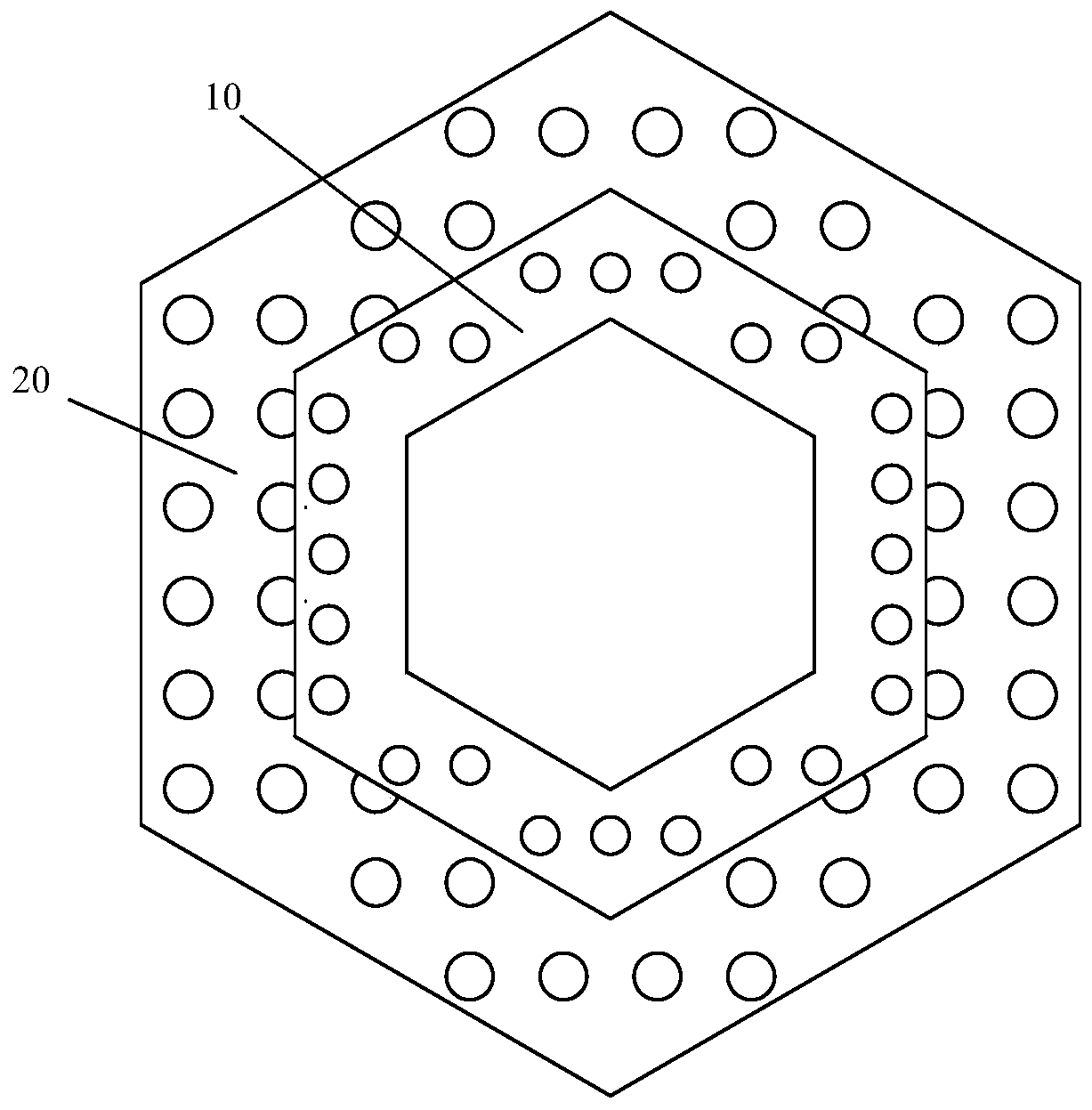

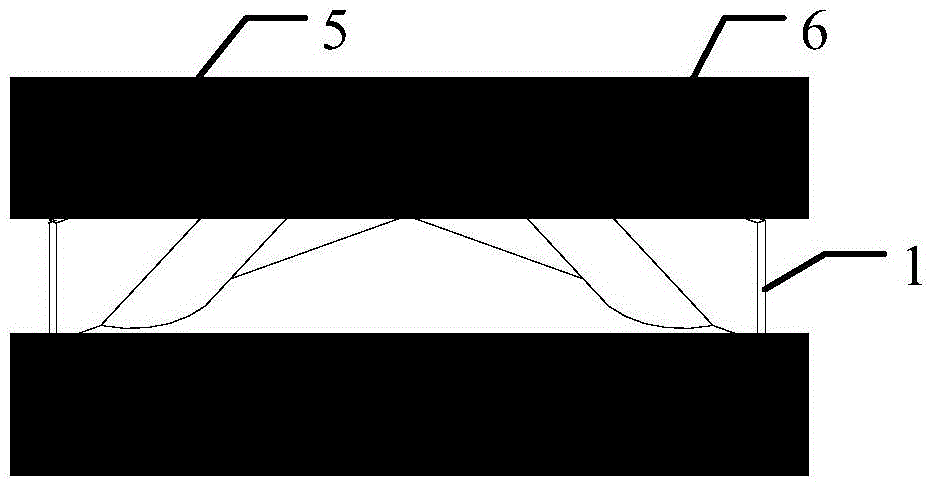

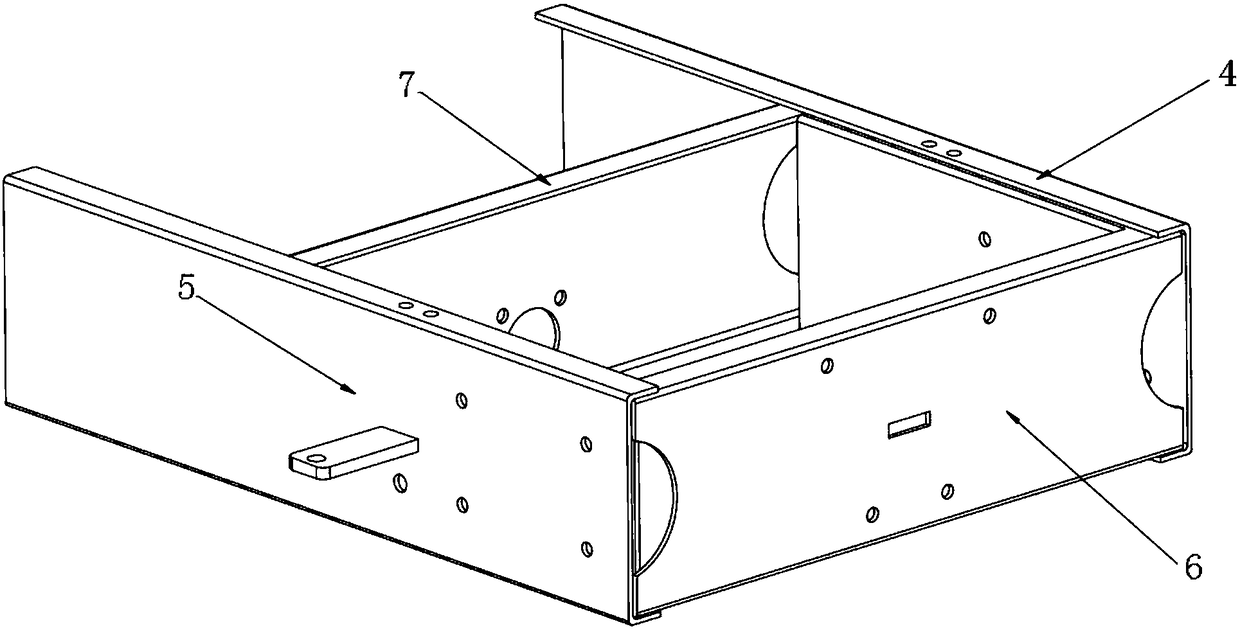

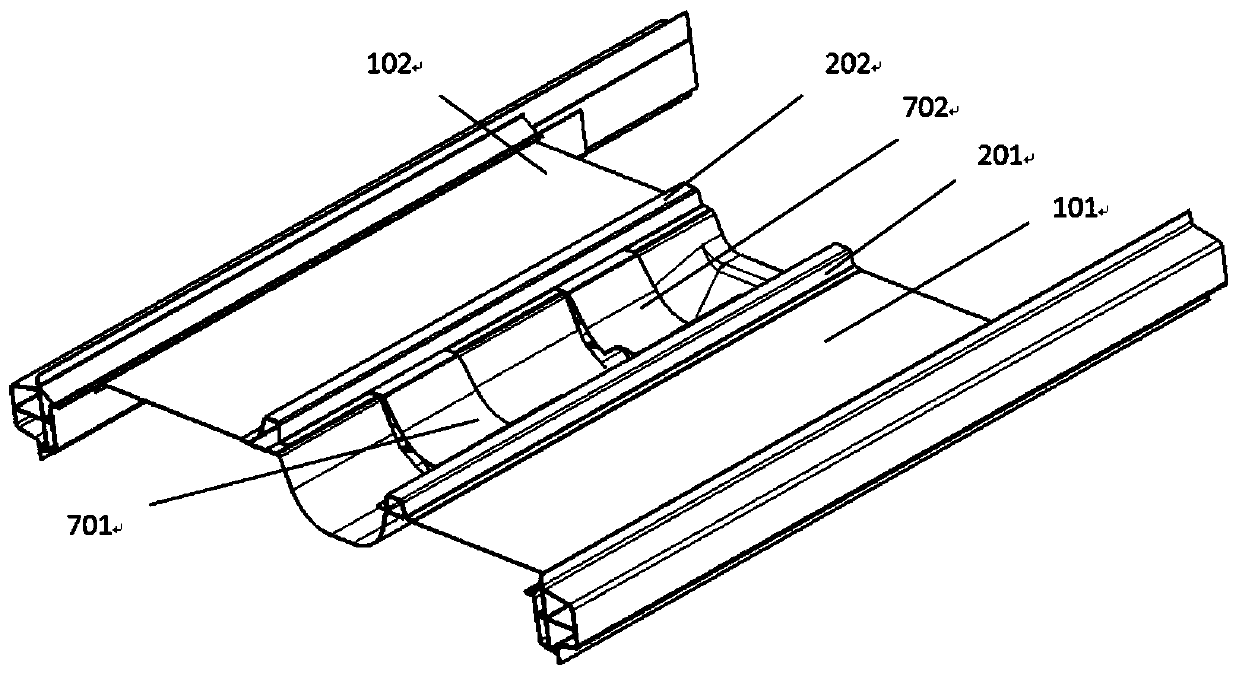

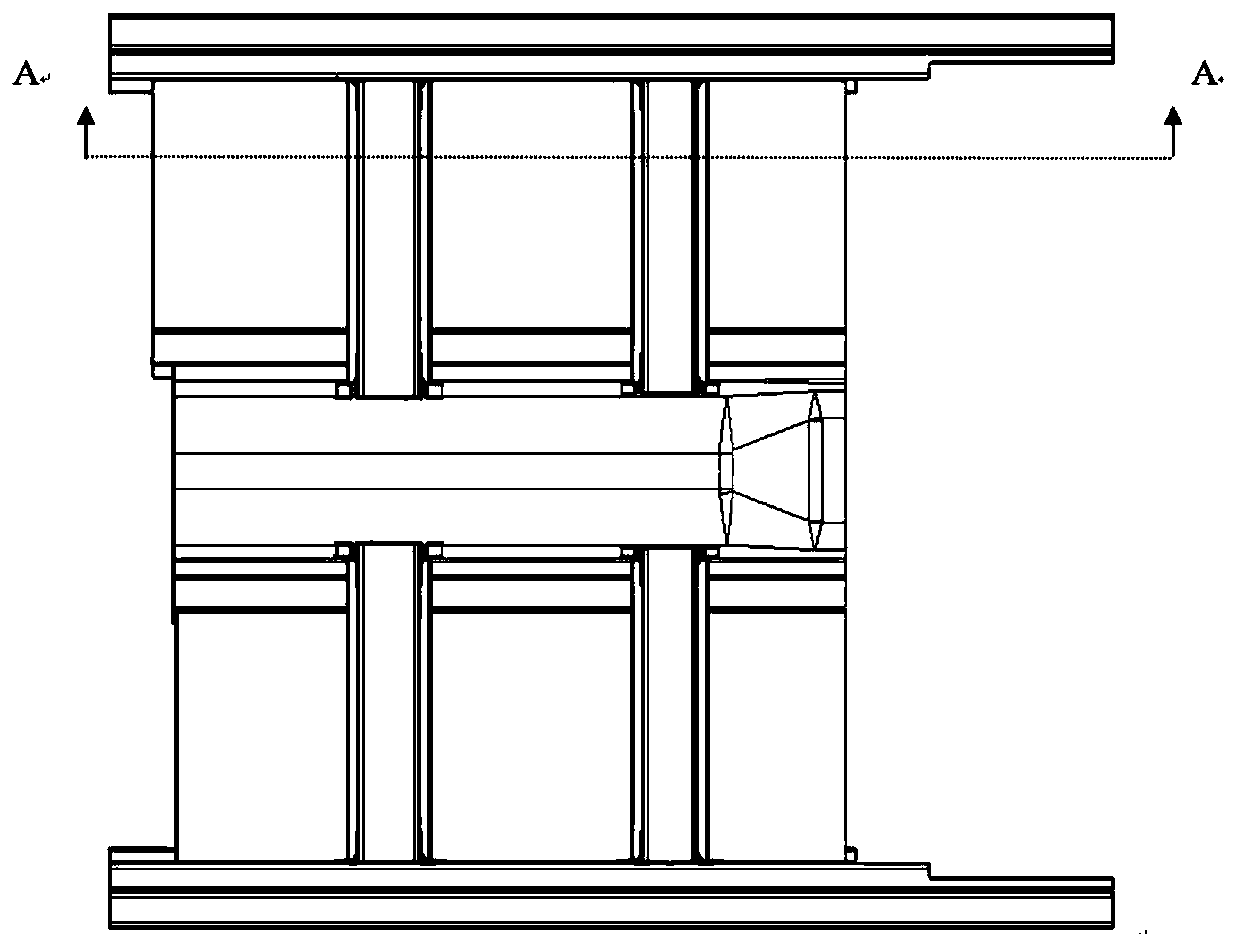

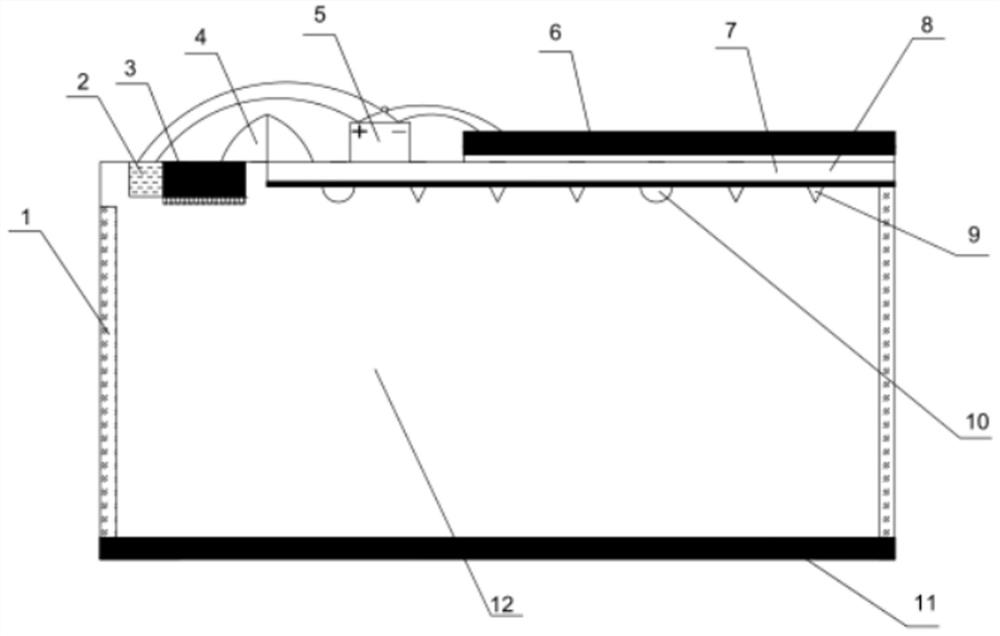

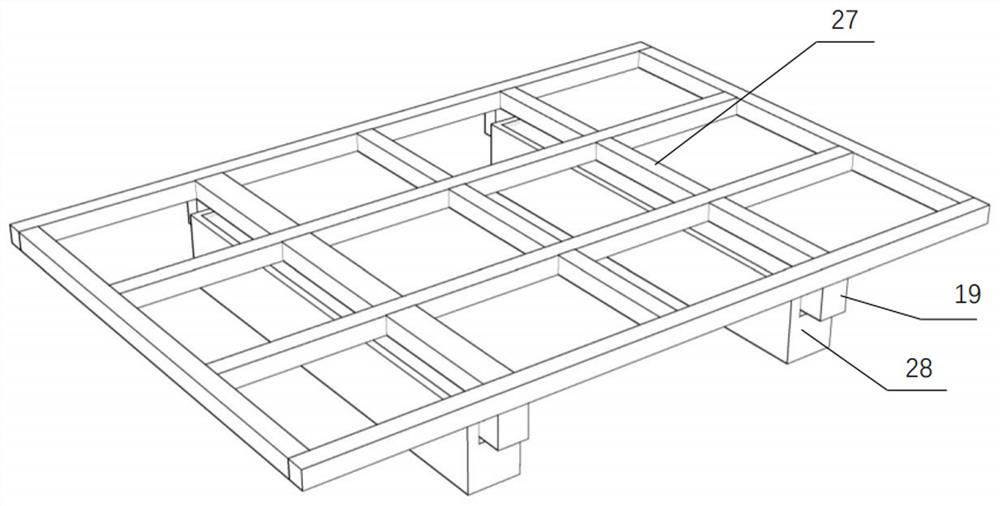

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

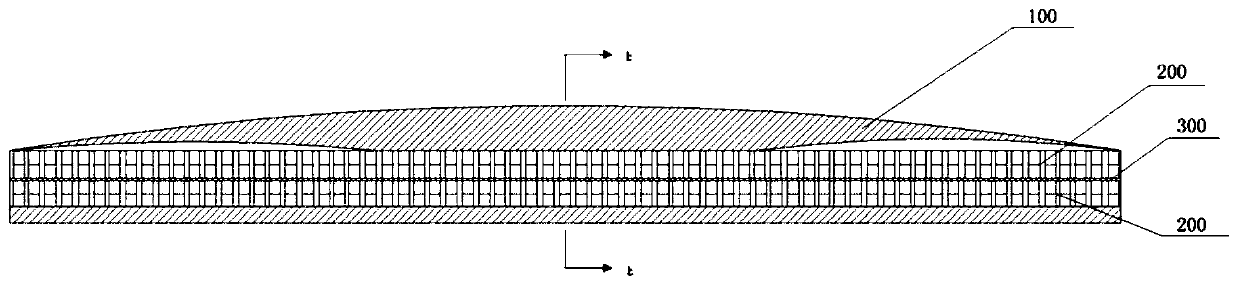

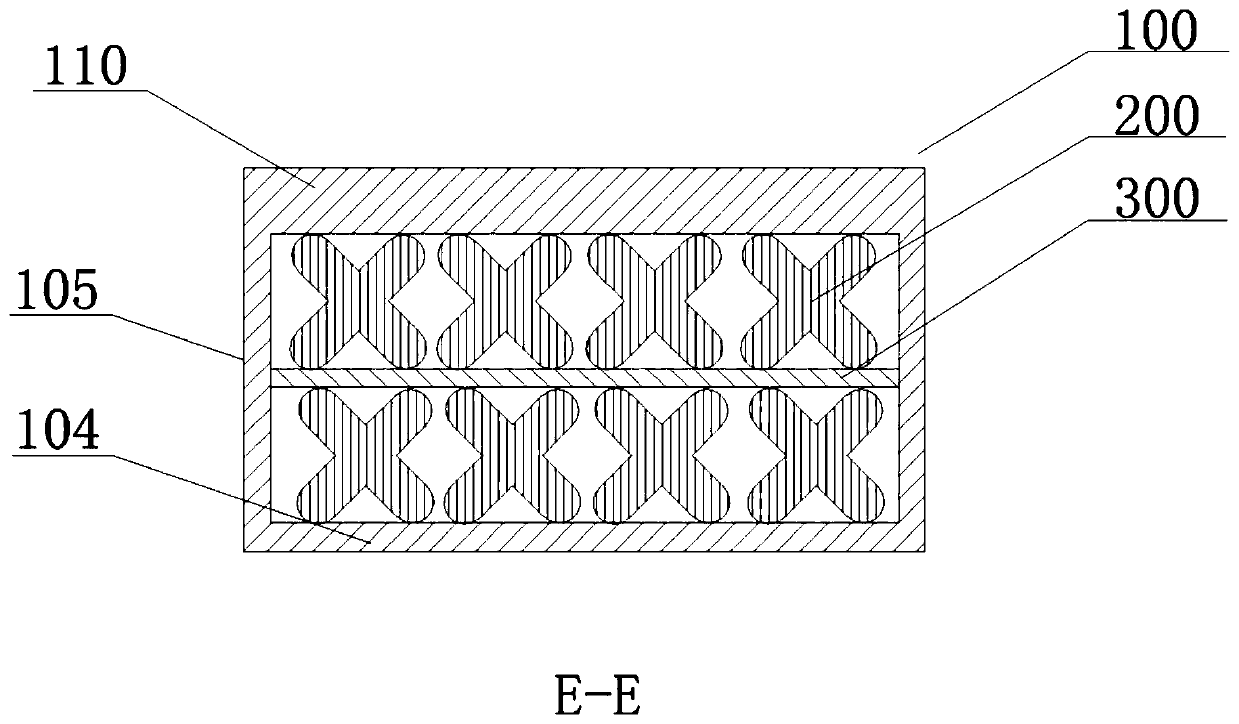

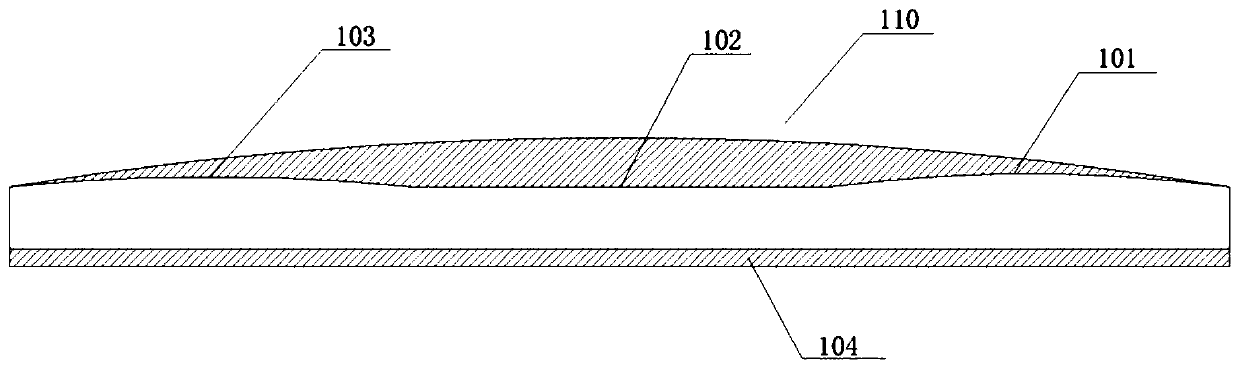

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

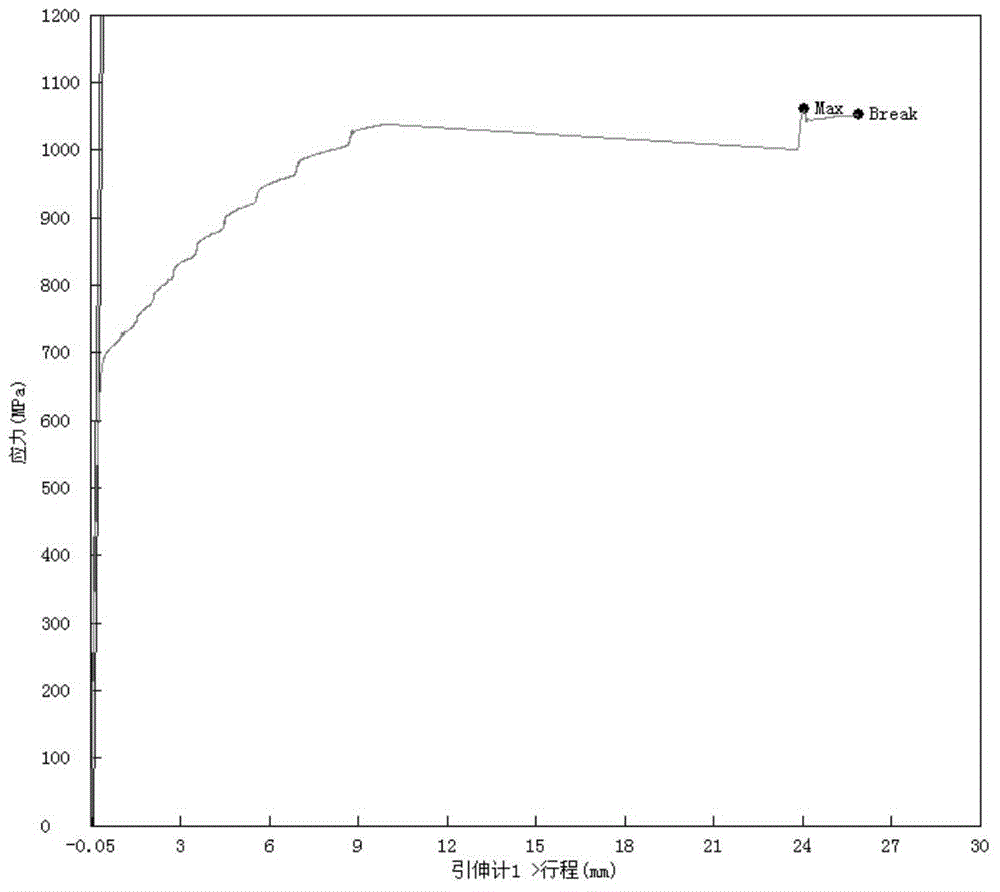

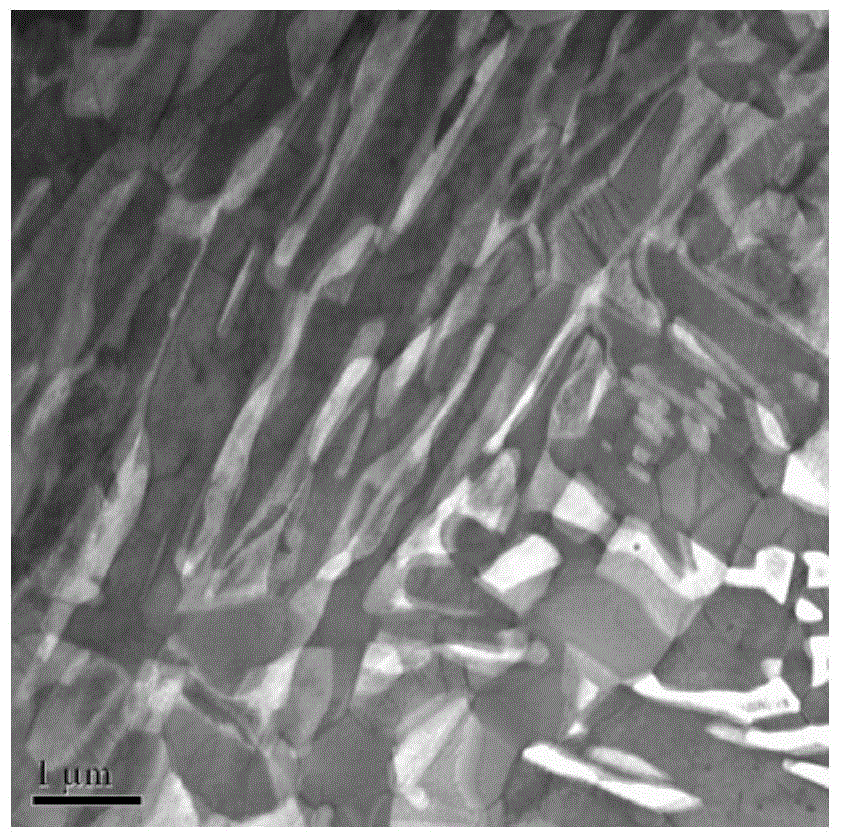

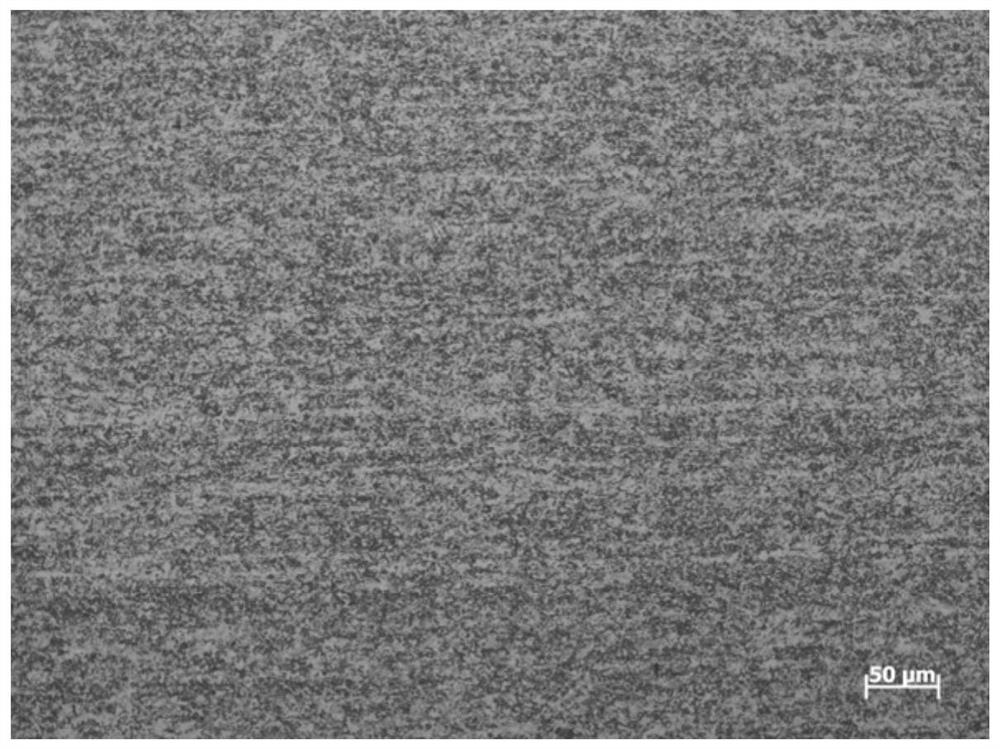

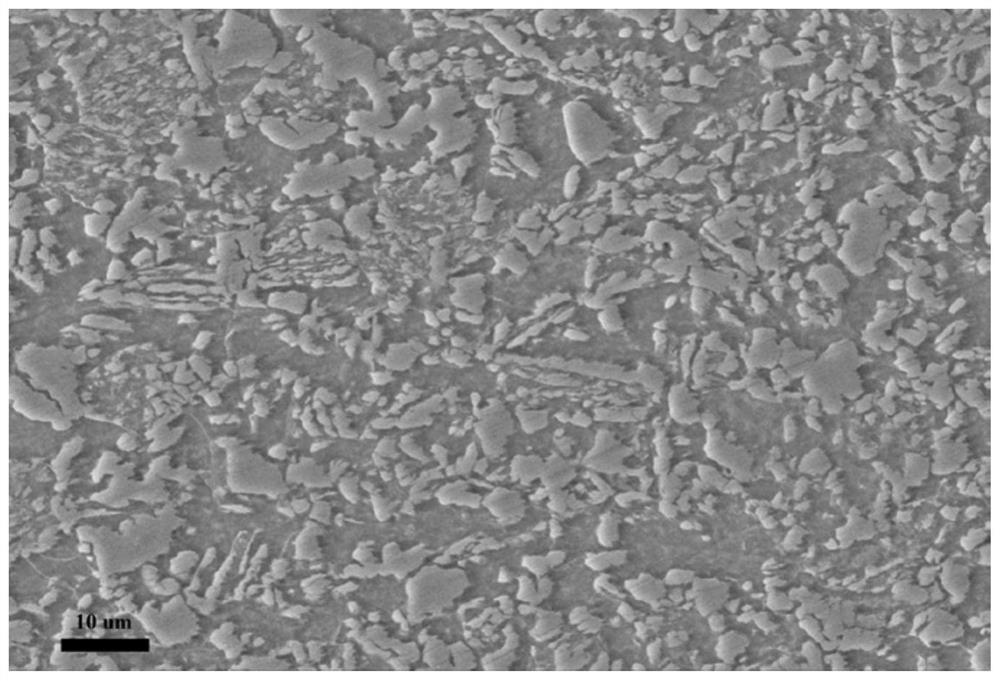

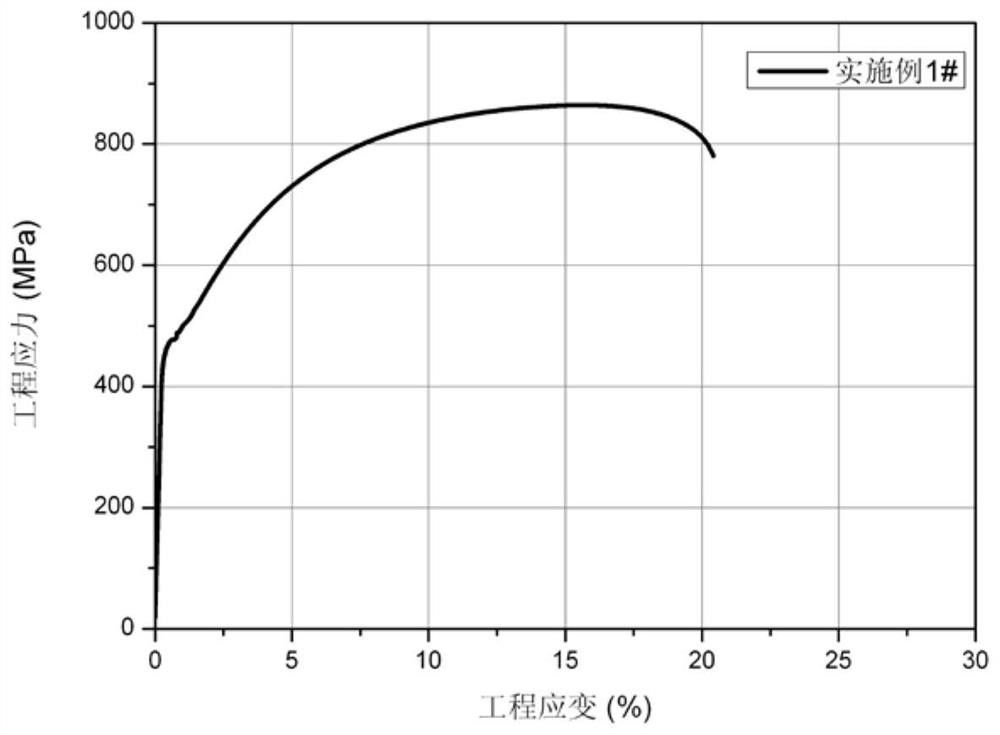

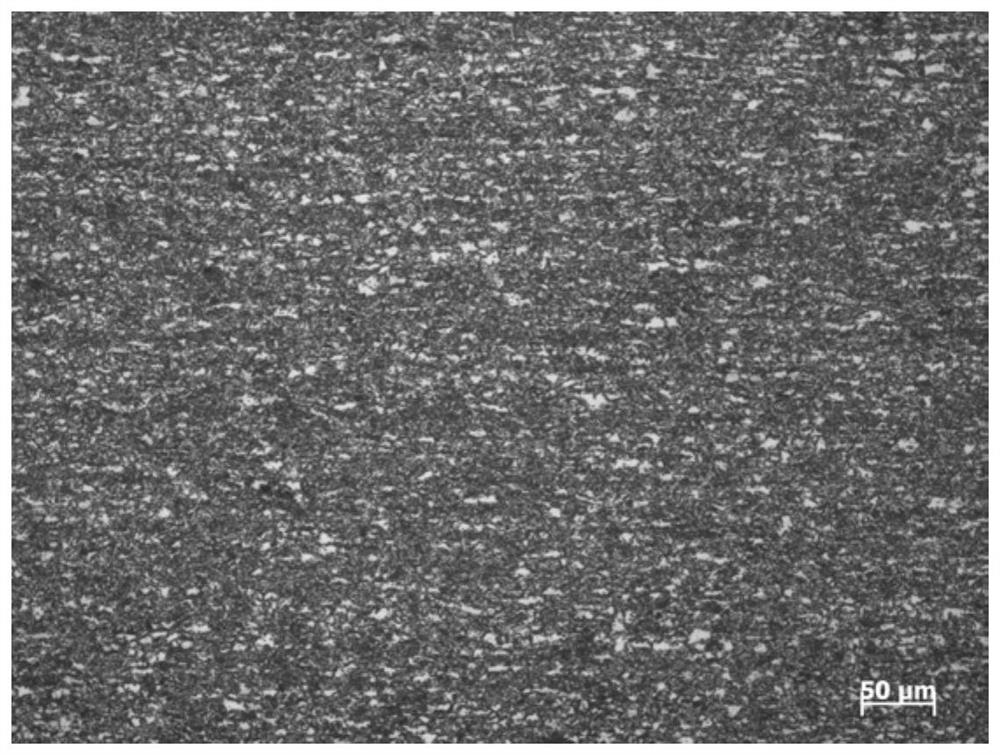

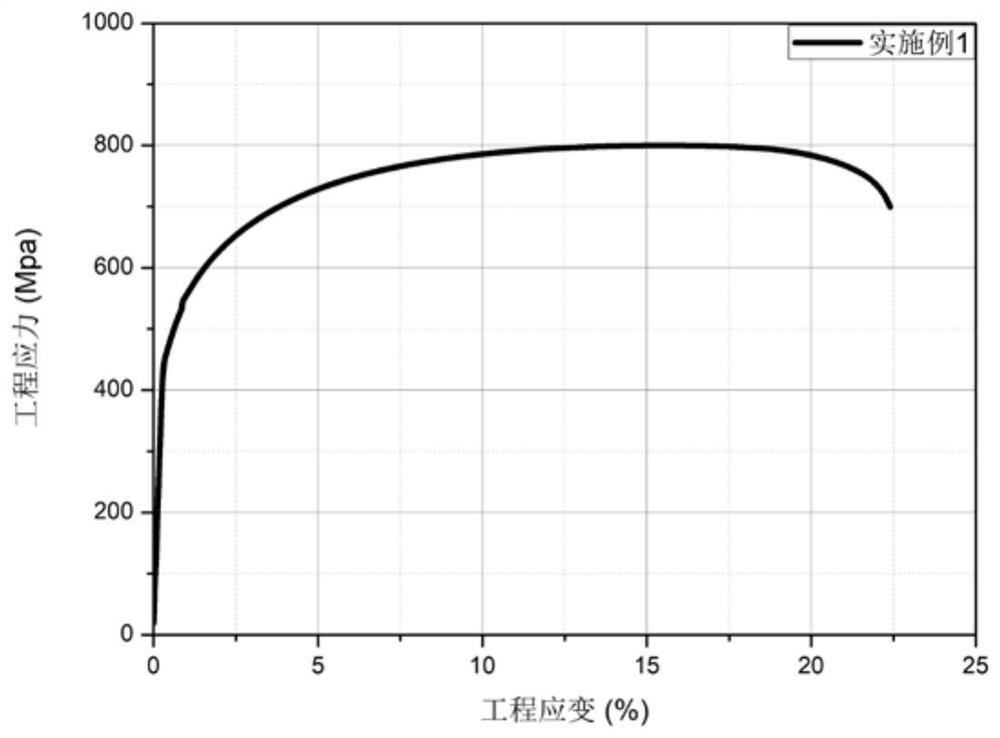

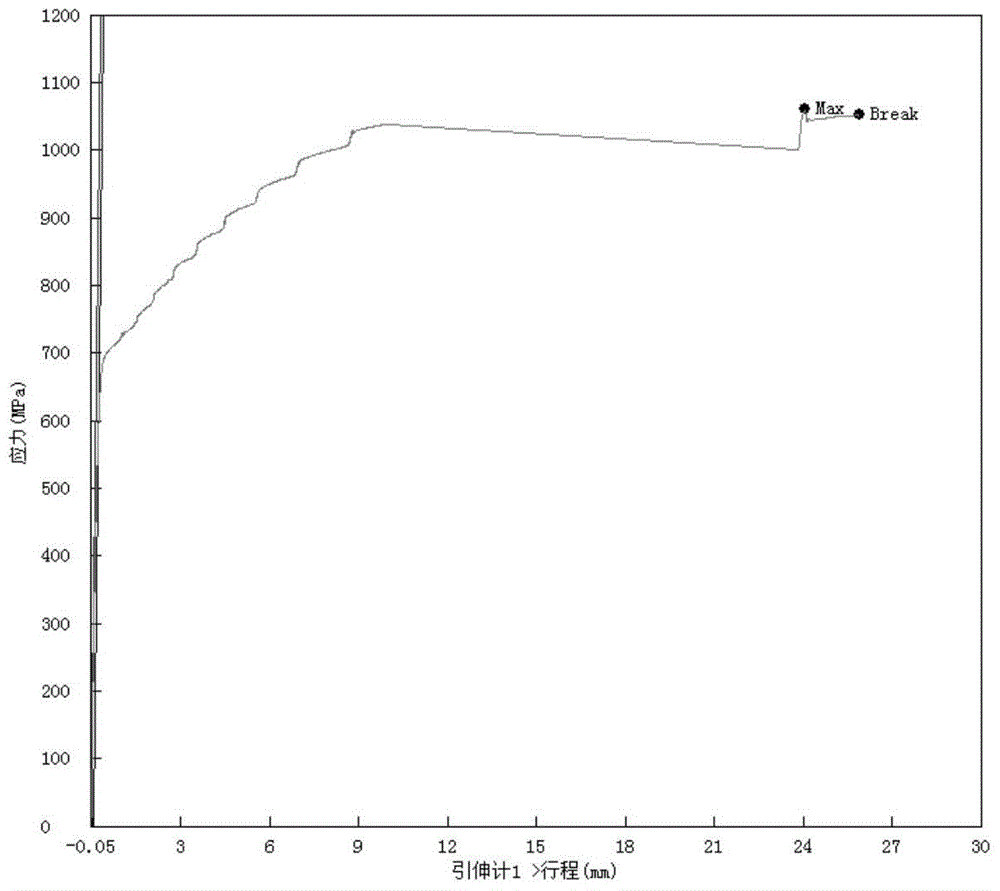

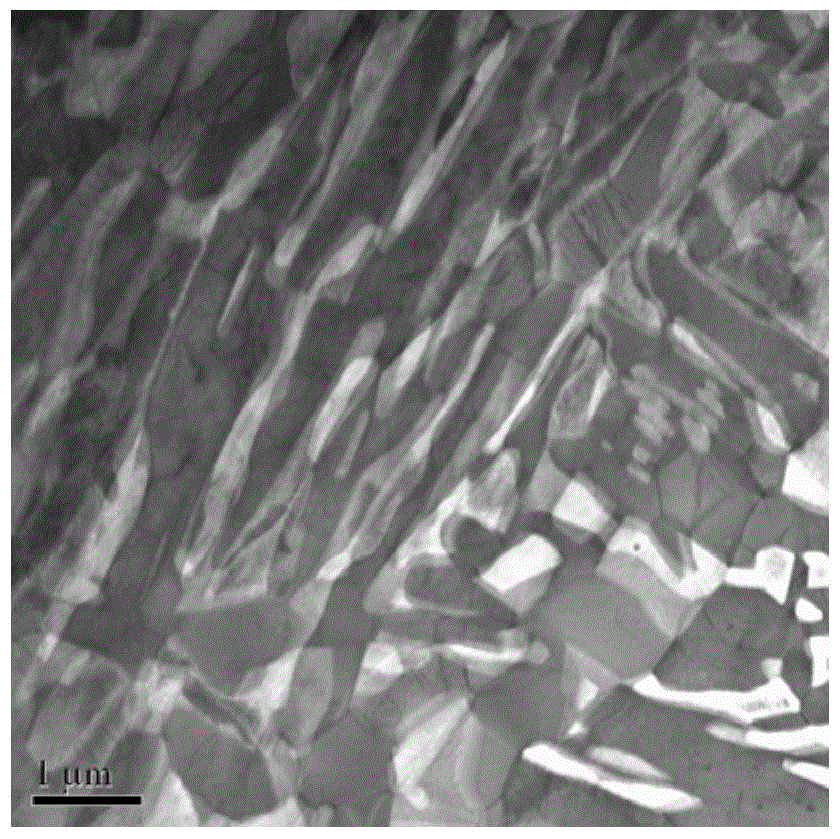

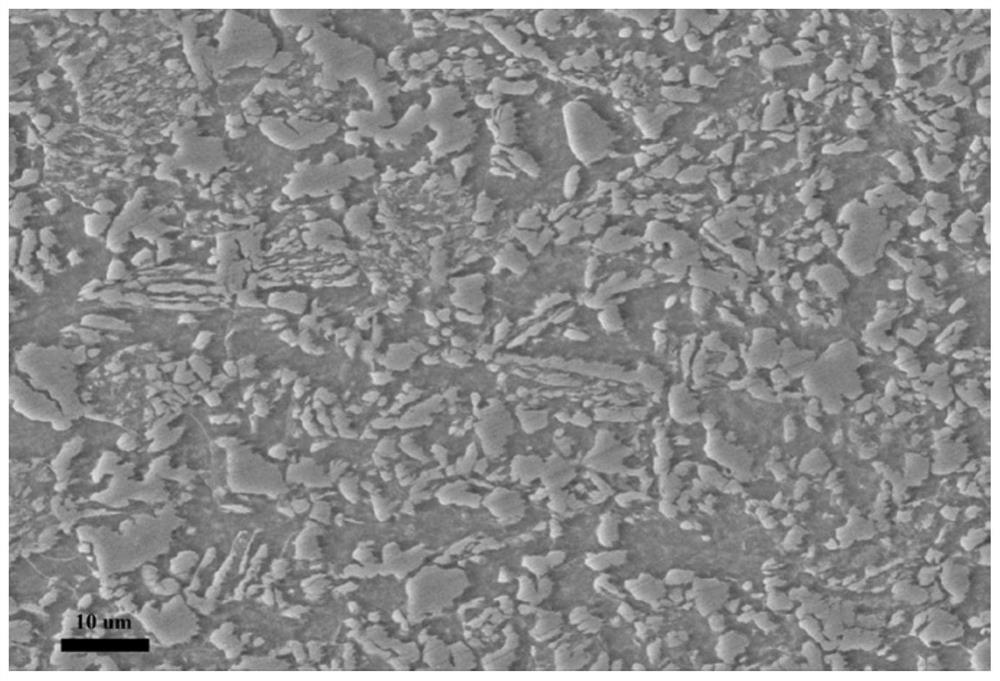

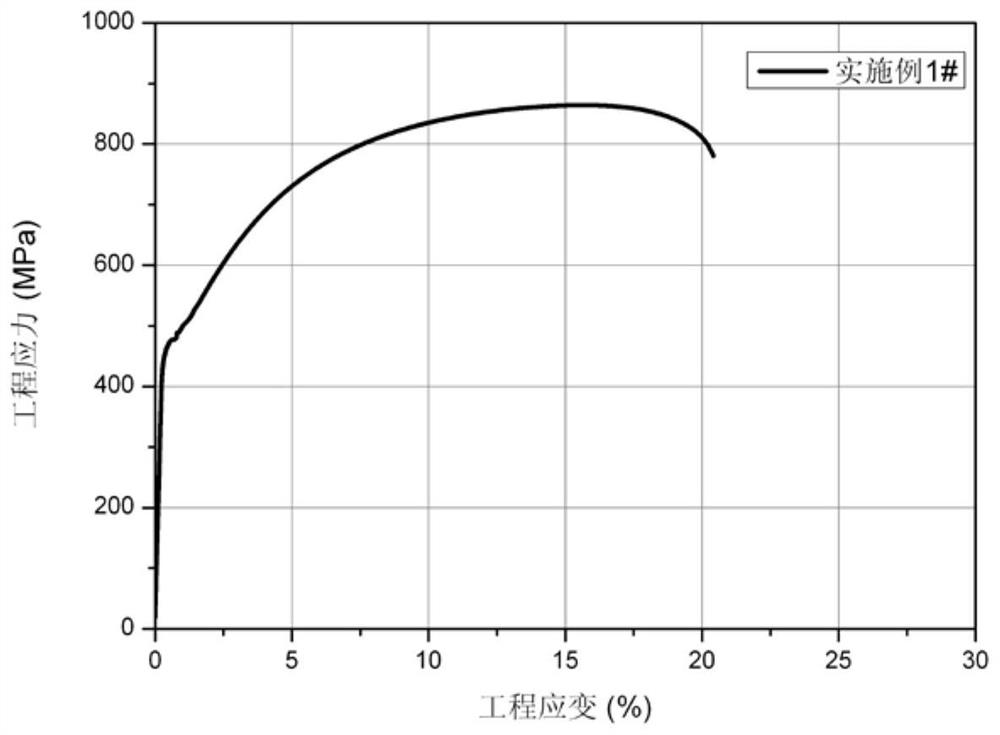

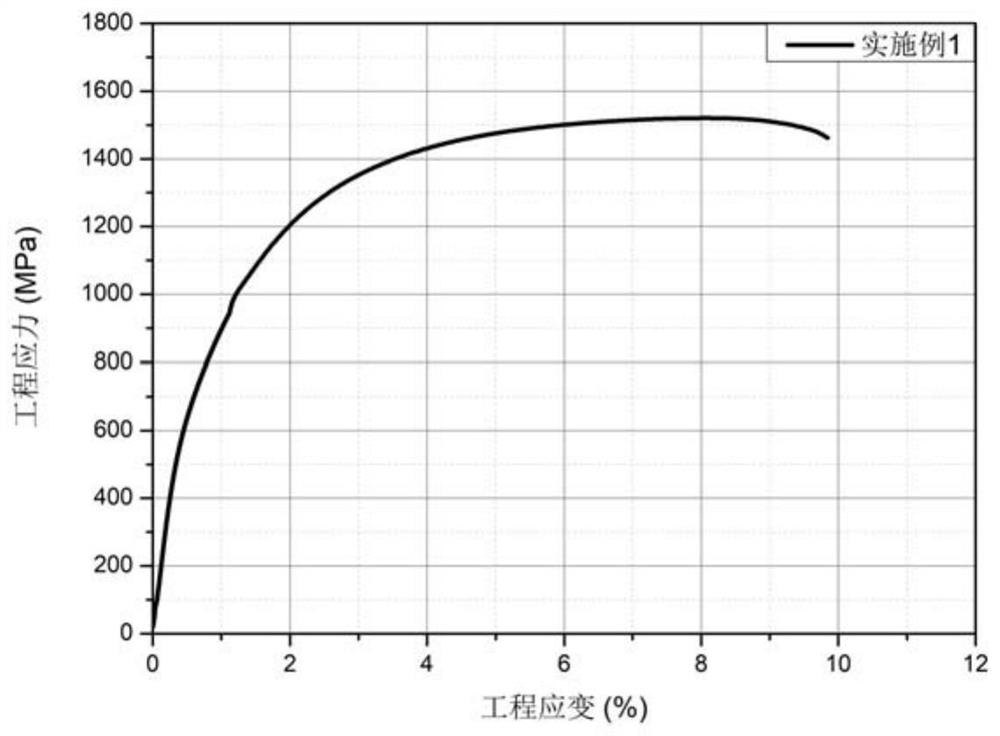

1000 MPa-level high-strength high-plasticity aluminum-containing medium manganese steel and manufacturing method thereof

The invention discloses 1000 MPa-level high-strength high-plasticity aluminum-containing medium manganese steel and a manufacturing method thereof. The steel comprises the following chemical components by mass percent: 0.05-0.25% of C, 0.02-0.40% of Si, 7.0-11% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, 1.50-3.50% of Al, 0.02-0.60% of Cr, smaller than or equal to 0.50% of Cu, smaller than or equal to 0.40% of Mo, smaller than or equal to 0.10% of Nb, smaller than or equal to 0.010% of N and the balance of Fe and unavoidable impurities. The manufacturing method of the steel comprises the steps of smelting, continuous casting, hot continuous rolling, cover annealing, acid pickling cold rolling, cover annealing or continuous annealing and finishing packing. The steel disclosed by the invention has high strength, excellent cold stamping forming performance and impacting energy absorption performance.

Owner:武汉钢铁有限公司

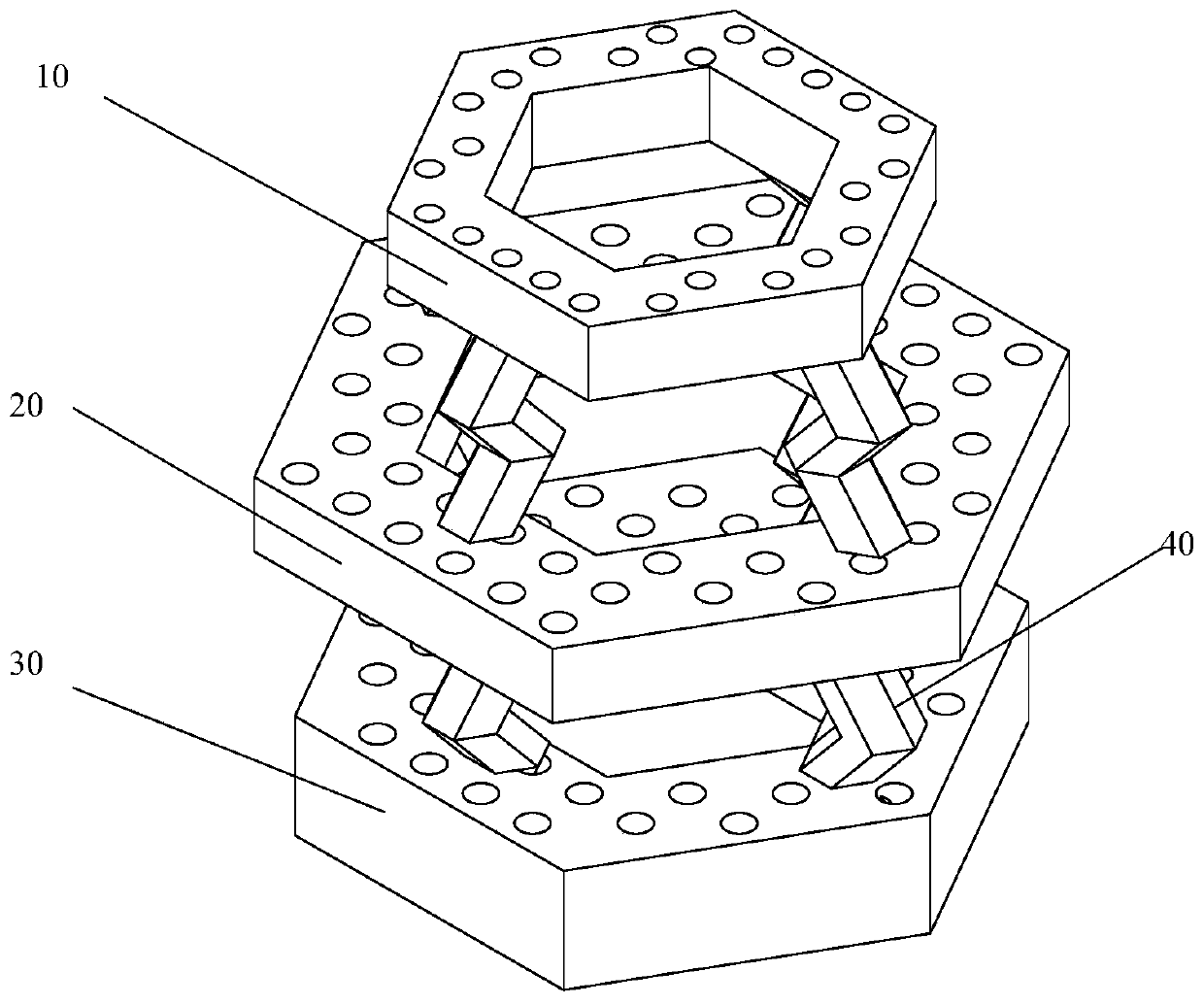

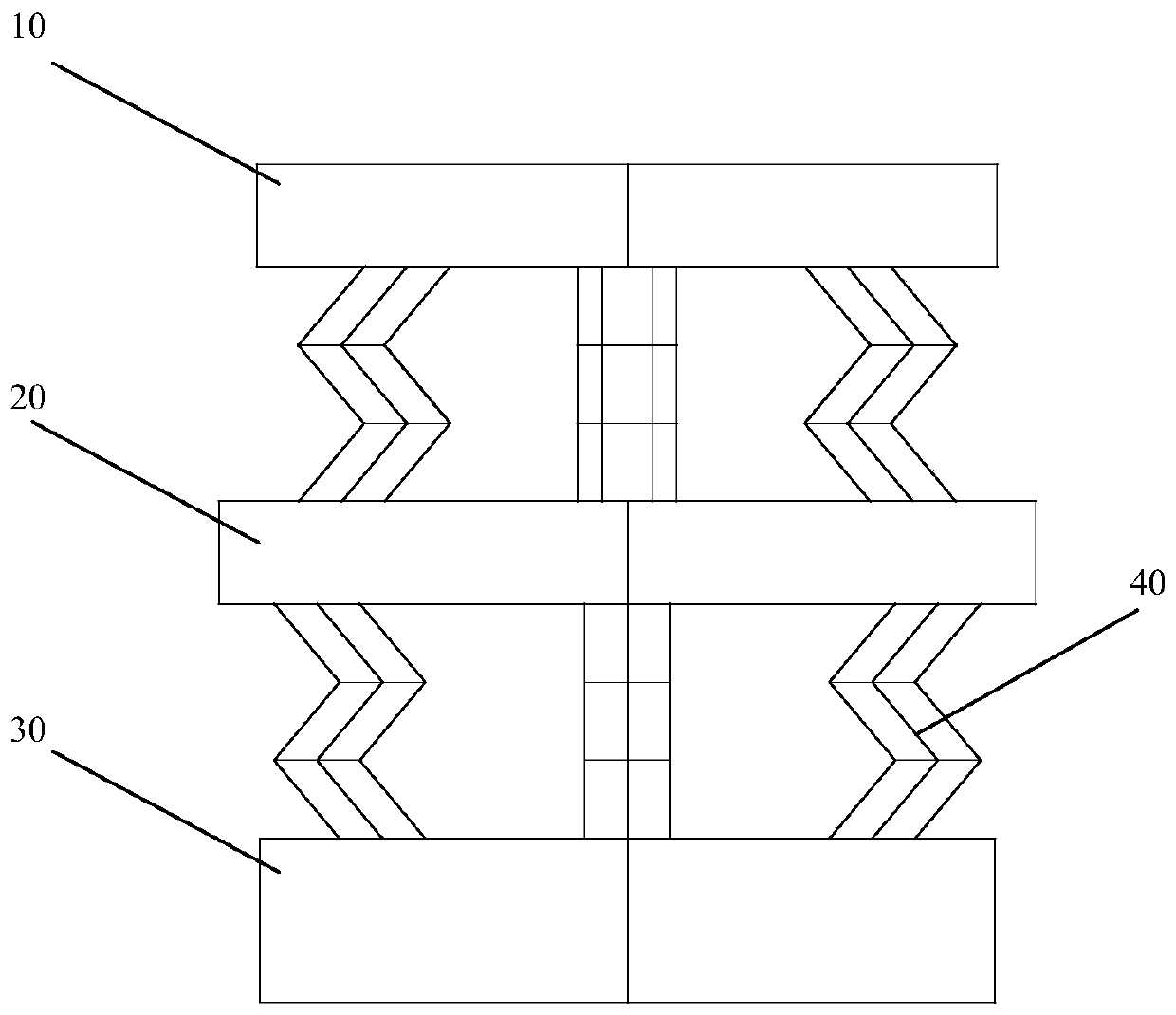

Hierarchical origami-shaped automobile collision energy-absorbing structure

PendingCN110641403AIncrease dynamicsImprove dynamic performanceBumpersMetal layered productsTitanium metalMetallic materials

The invention discloses a hierarchical origami-shaped automobile collision energy-absorbing structure. The hierarchical origami-shaped automobile collision energy-absorbing structure comprises a plurality of energy-absorbing layers and an origami-shaped induction tube, wherein the origami-shaped induction tube is a Z-shaped folded metal tube formed by folding a metal sheet through a Miura foldingmethod; adjacent energy-absorbing layers are connected with each other through the folded paper-shaped induction tubes; the plurality of energy-absorbing layers comprise a honeycomb energy-absorbing layer and a porous material energy-absorbing layer coaxially distributed from top to bottom; the honeycomb energy-absorbing layer comprises two first metal plates and a metal material with a special-shaped honeycomb structure filled between the two first metal plates; and the porous material energy-absorbing layer comprises two second metal plates and a porous metal material filled between the twosecond metal plates. The hierarchical origami-shaped automobile collision energy-absorbing structure has good dynamic performance and safety; and sufficient strength and energy-absorbing are ensured by using aluminum alloy, titanium metal and porous metal while having very light weight

Owner:HUAQIAO UNIVERSITY

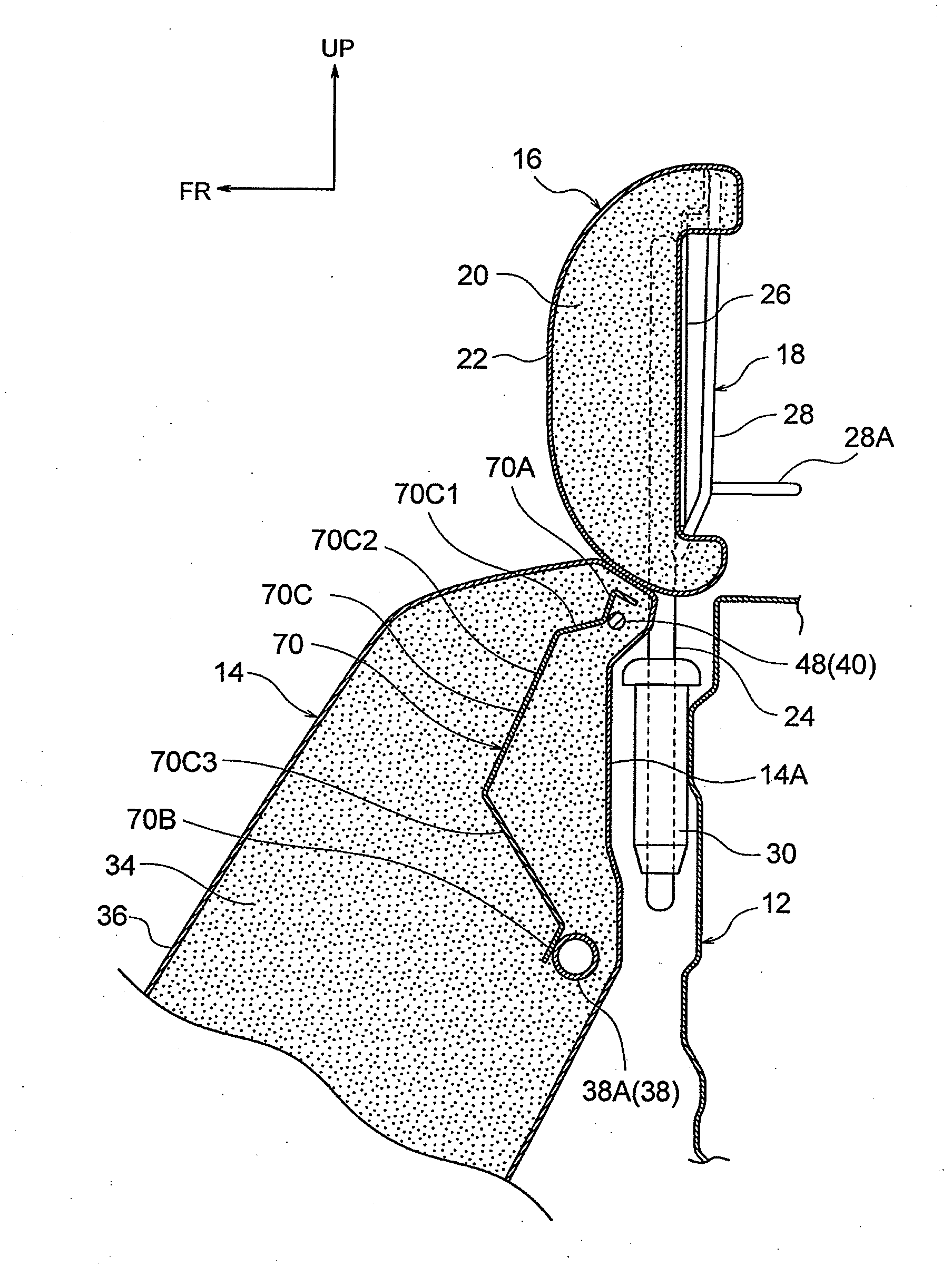

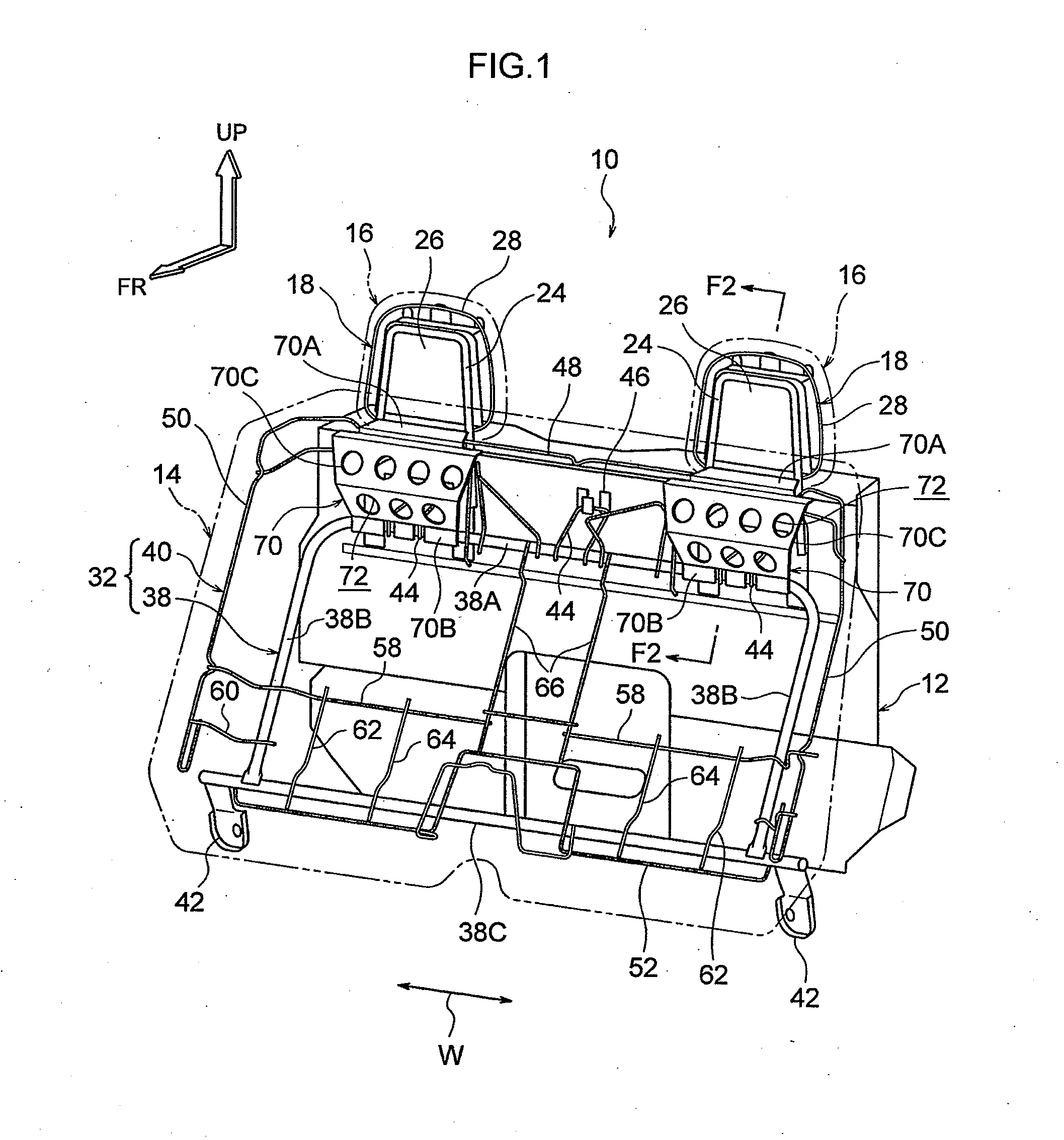

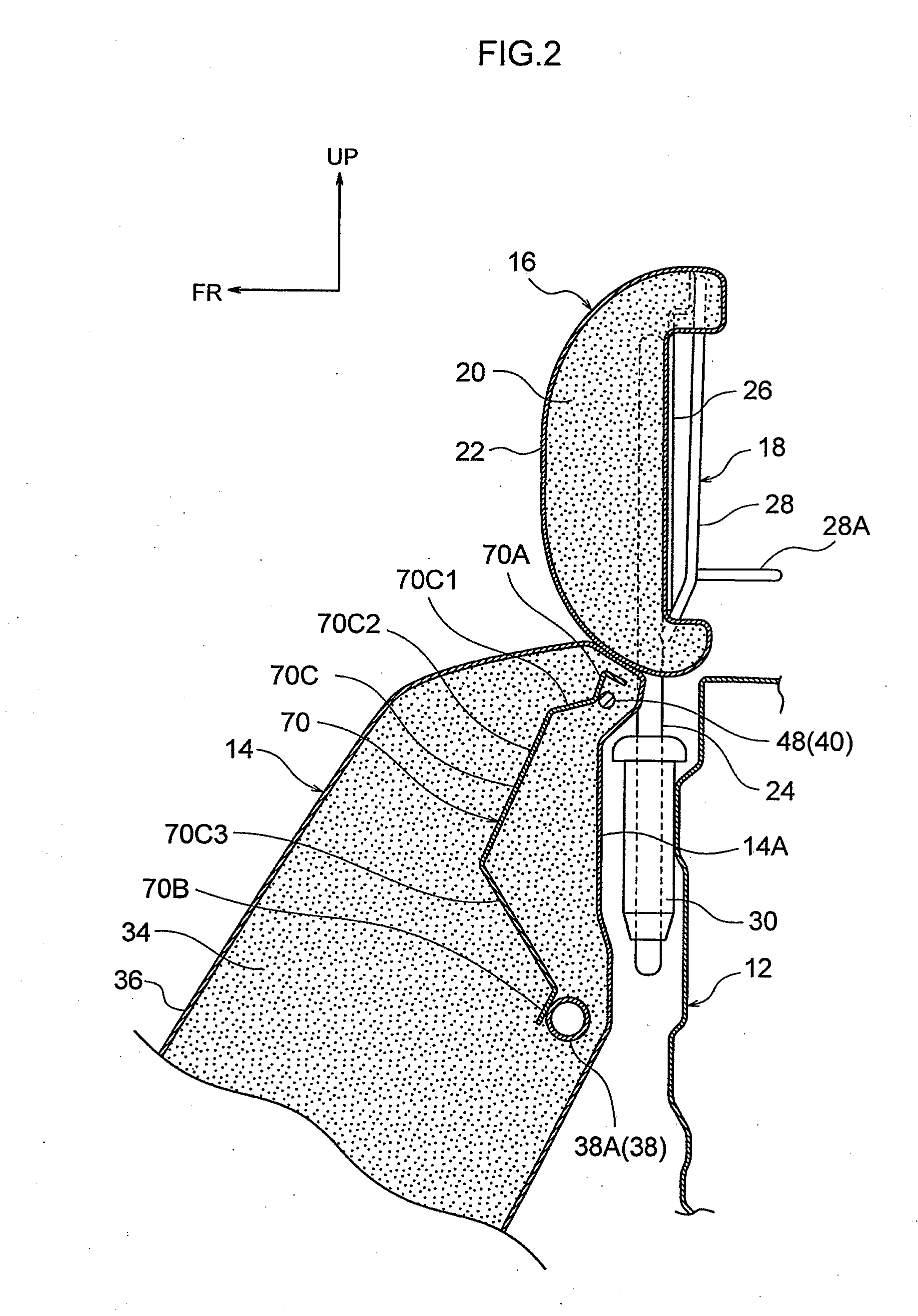

Vehicle Seat

InactiveUS20120001462A1Improve shock absorptionRigid enoughPedestrian/occupant safety arrangementSeat framesEngineeringHead holder

There is provided a vehicle seat including: a seatback including a seatback frame skeleton member covered by a seatback pad cushion member on at least a front side of the seatback frame; a headrest including a headrest frame skeleton member disposed above the seatback; and a shock absorbing member disposed further to the front side than the headrest frame and being at a top portion of the seatback, attached to the seatback frame and absorbing impact energy by plastic deformation when an impact is imparted to the top portion of the seatback from the front side.

Owner:NHK SPRING CO LTD

Aluminum alloy crash box for automobile

ActiveCN105235617ASmooth connectionGood impact energy absorptionBumpersEnergy absorptionLong-fiber-reinforced thermoplastic

The invention discloses an aluminum alloy crash box for an automobile. The aluminum alloy crash box for the automobile comprises an aluminum alloy crash box body, wherein the aluminum alloy crash box body is filled with long fiber reinforced thermoplastic composite material blocks; and connecting plates are arranged at the two ends of the aluminum alloy crash box body. Preferably, two types of long fiber reinforced thermoplastic composite material blocks with different densities are arranged in the aluminum alloy crash box body at intervals. According to the invention, as the aluminum alloy crash box body is combined with the long fiber reinforced thermoplastic composite material blocks, the energy absorption properties of the aluminum alloy crash box body and the long fiber reinforced thermoplastic composite material blocks are organically combined and composite materials with a plurality of densities are arranged in the aluminum alloy crash box body at intervals to control the deformation mode of the crash box; therefore, the energy absorption potential of the crash box is maximized. Automobile crash damage and personal injury can be effectively reduced.

Owner:重庆凯瑞特种车有限公司 +1

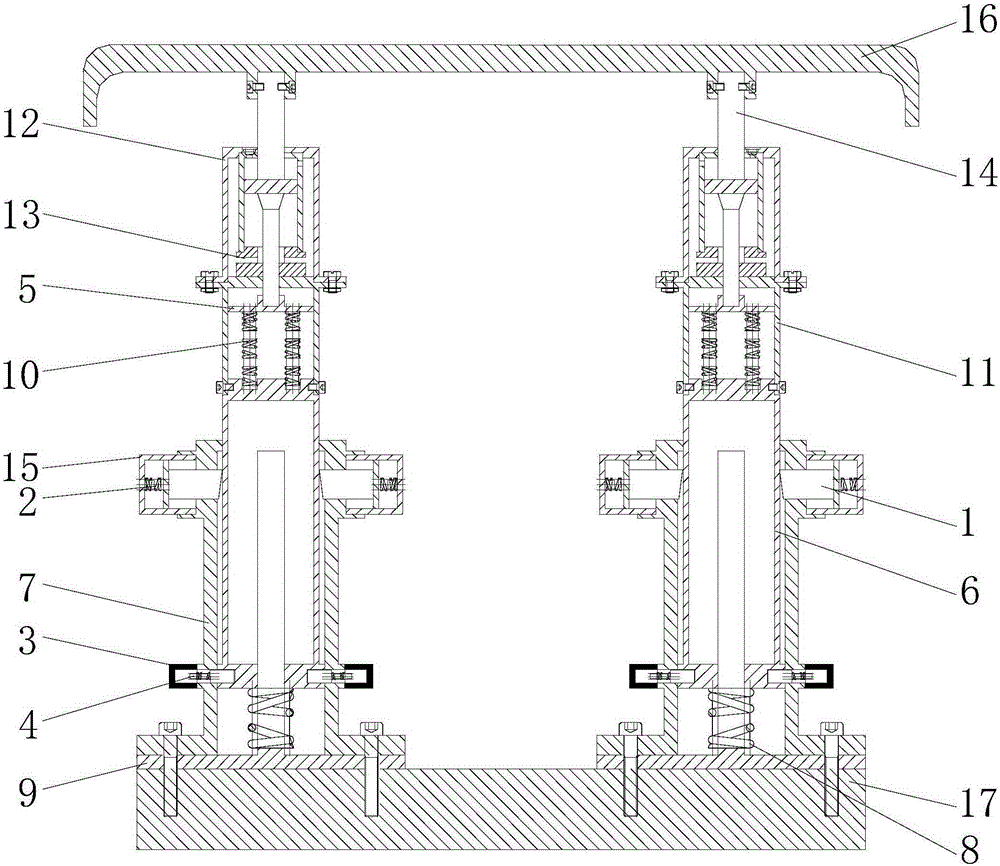

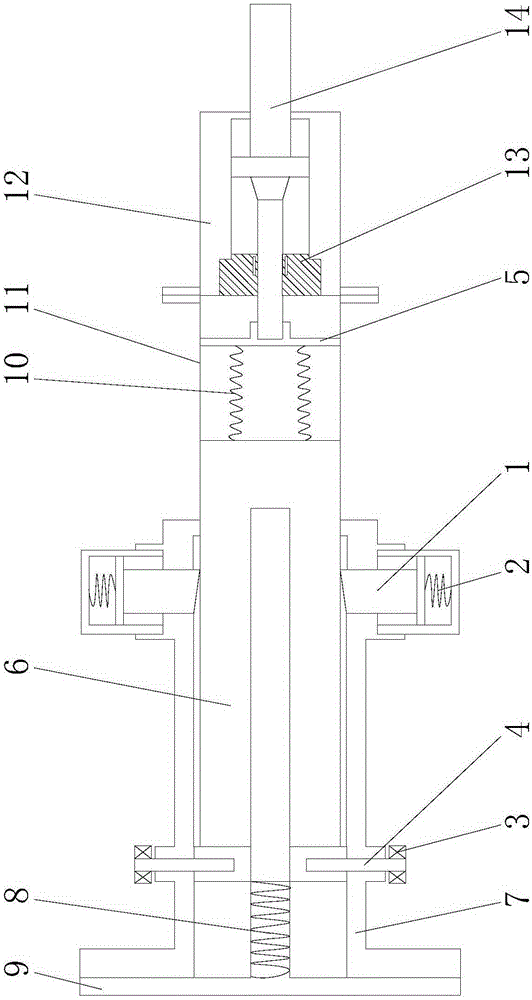

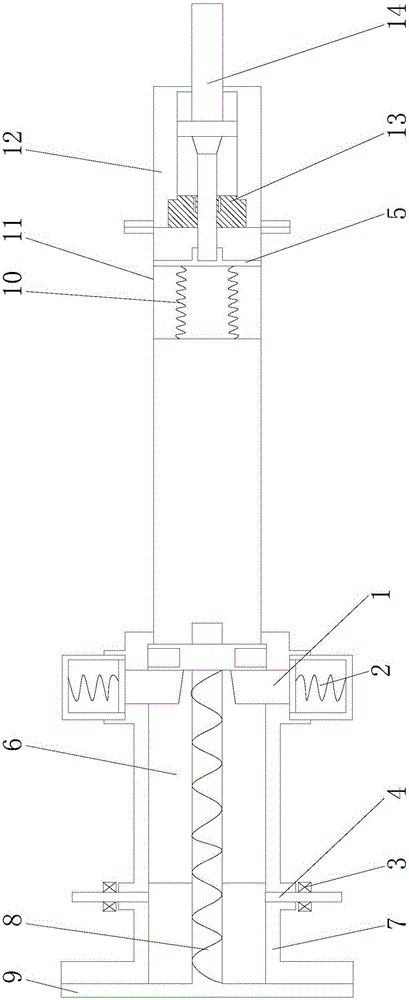

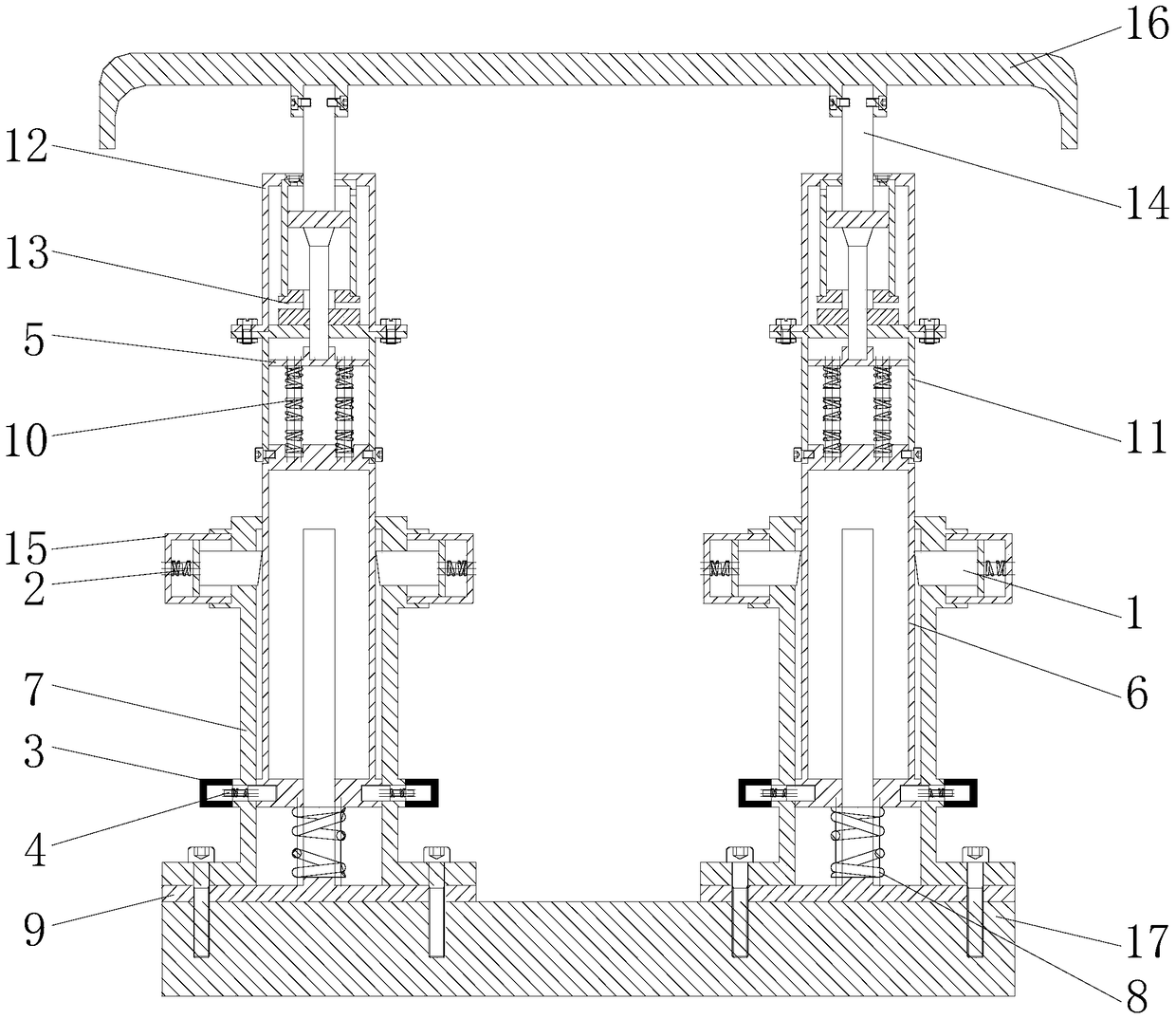

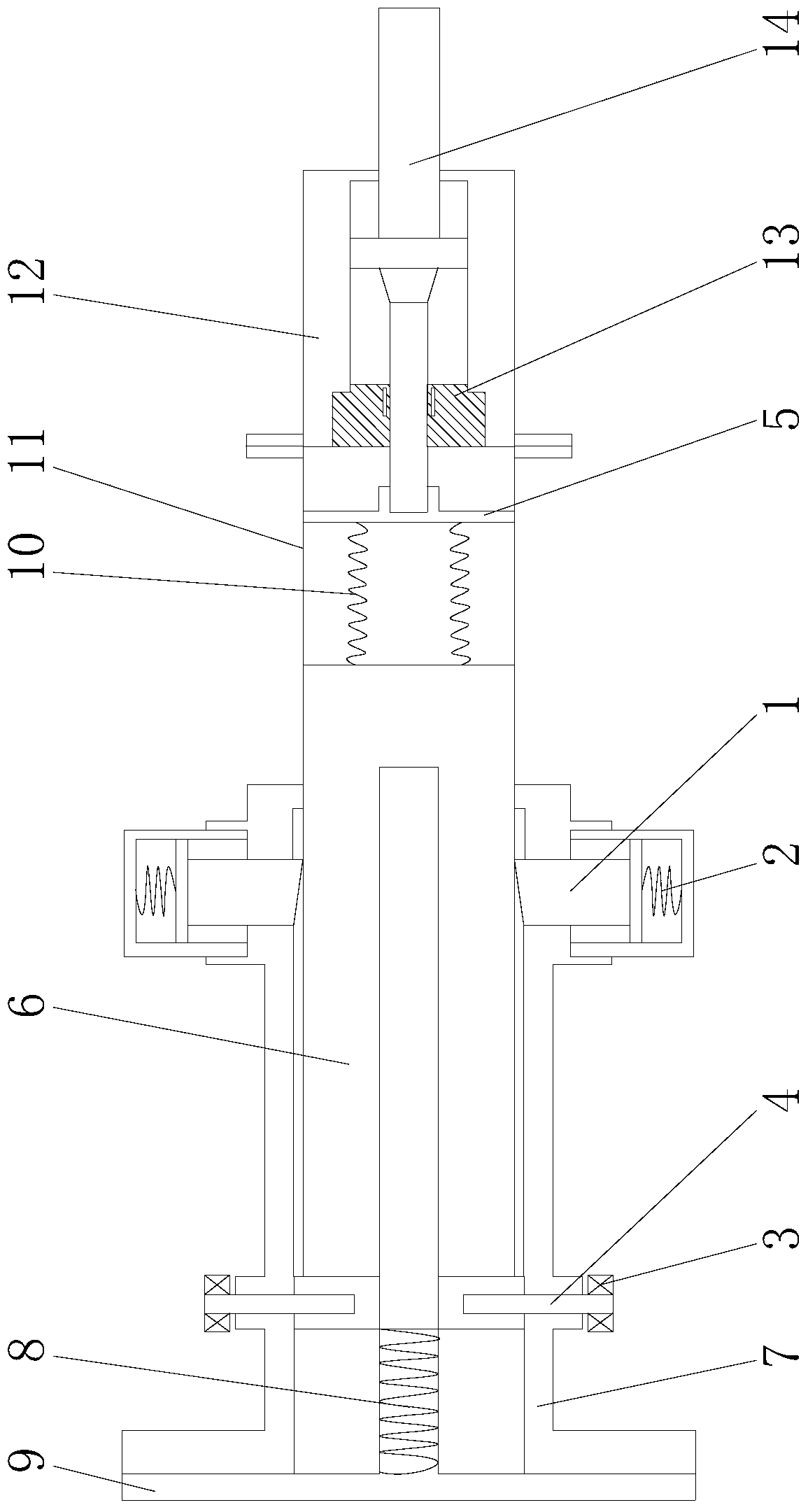

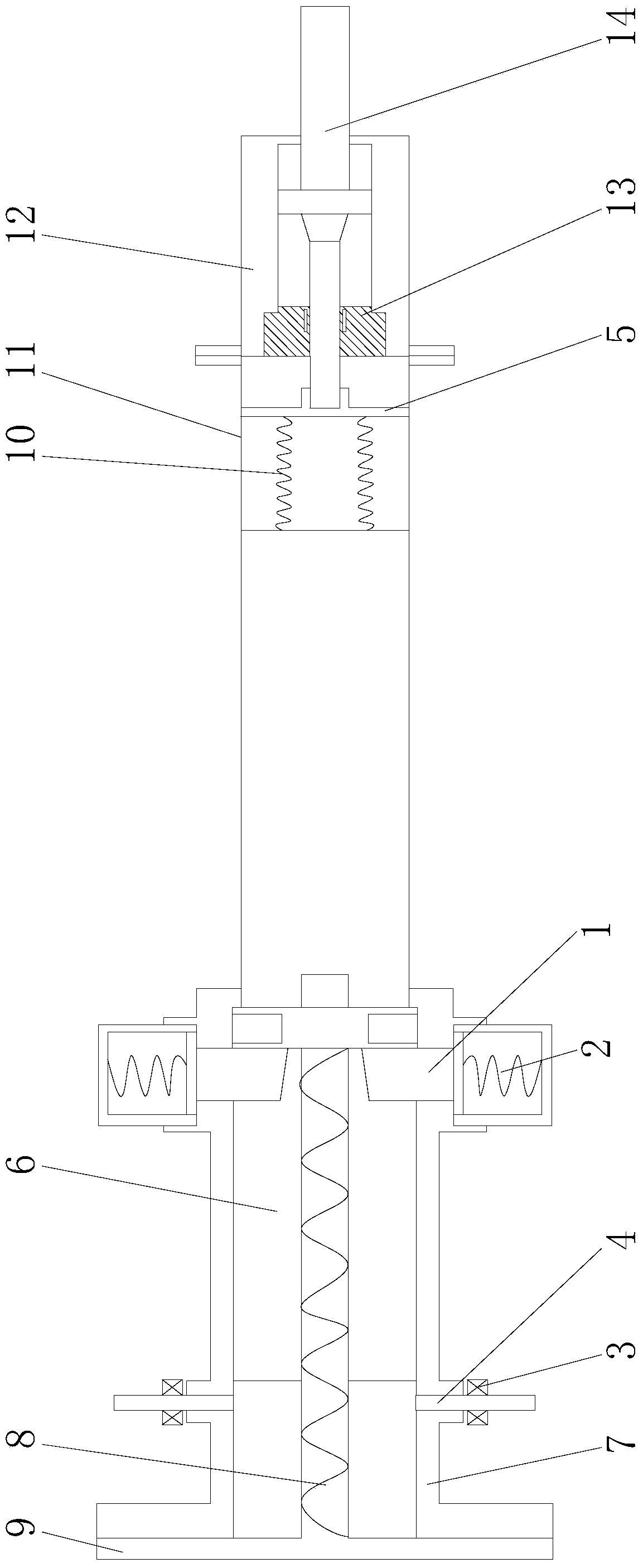

Automobile collision buffer device

InactiveCN105216724AGood impact energy absorptionReduce casualtiesBumpersHydraulic cylinderEngineering

The invention discloses an automobile collision buffer device, and relates to the technical field of automobiles. Each energy-absorbing cylinder is connected to a spring energy-absorbing cylinder in a clearance fit manner; the spring energy-absorbing cylinder is connected to a hydraulic cylinder sleeve; the energy-absorbing cylinder is disposed in an energy-absorbing beam sleeve in a sliding manner; a spring limit rod is arranged at the bottom end of the energy-absorbing beam sleeve; the ends of the spring limit rod penetrate the energy-absorbing cylinder; push springs are arranged on the portion, under the energy-absorbing cylinder, of the spring limit rod in a penetrating manner; the bottom end of the energy-absorbing cylinder is in plugging connection with bolts; the bolts cooperate with electromagnets; limit pin sleeves are arranged on the upper side wall of the energy-absorbing beam sleeve; each limit pin sleeve is internally provided with a limit pin; a pressure spring is cooperatively arranged between each limit pin and the wall of the corresponding limit pin sleeve; the spring energy-absorbing cylinder is internally provided with energy-absorbing springs which are fixed to a spring positioning disc; and a piston rod is disposed in the hydraulic cylinder sleeve in a penetrating manner. The automobile collision buffer device improves automobile collision energy-absorbing effects, protects an automobile and pedestrians, reduces the damage to the front structure of the automobile, is low is cost, and is high in practicality.

Owner:GUANGDONG UNIV OF TECH

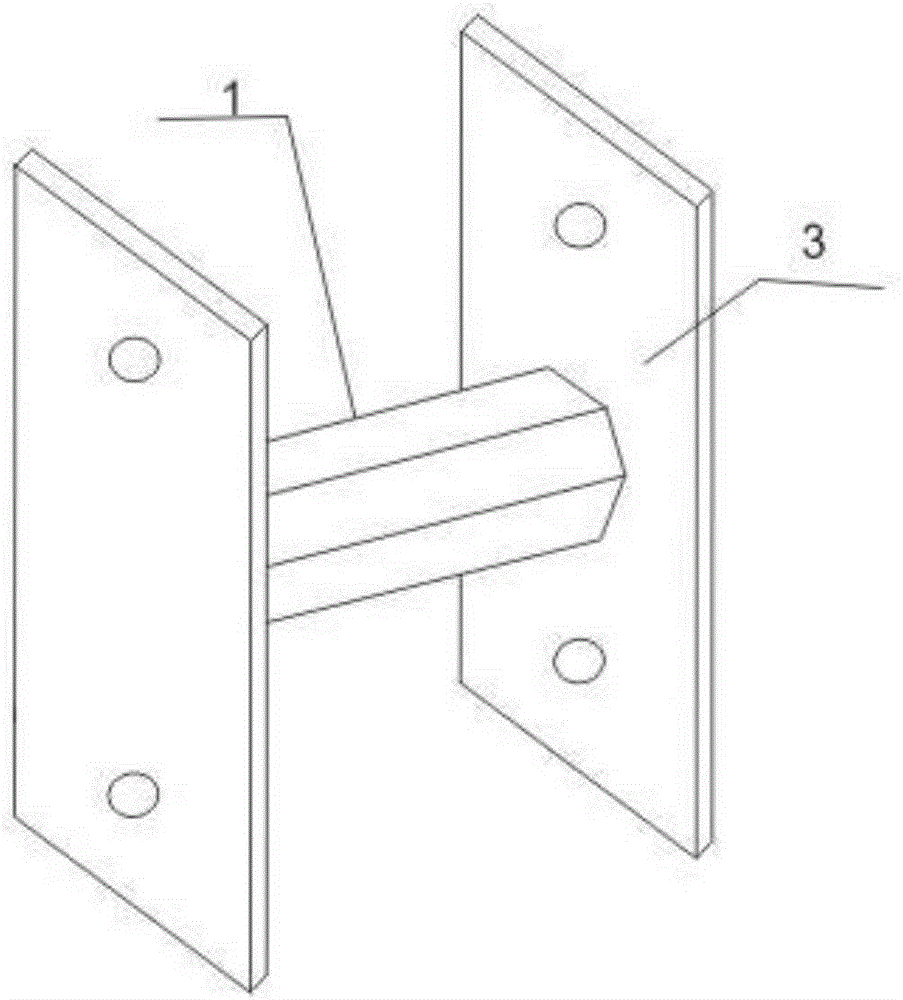

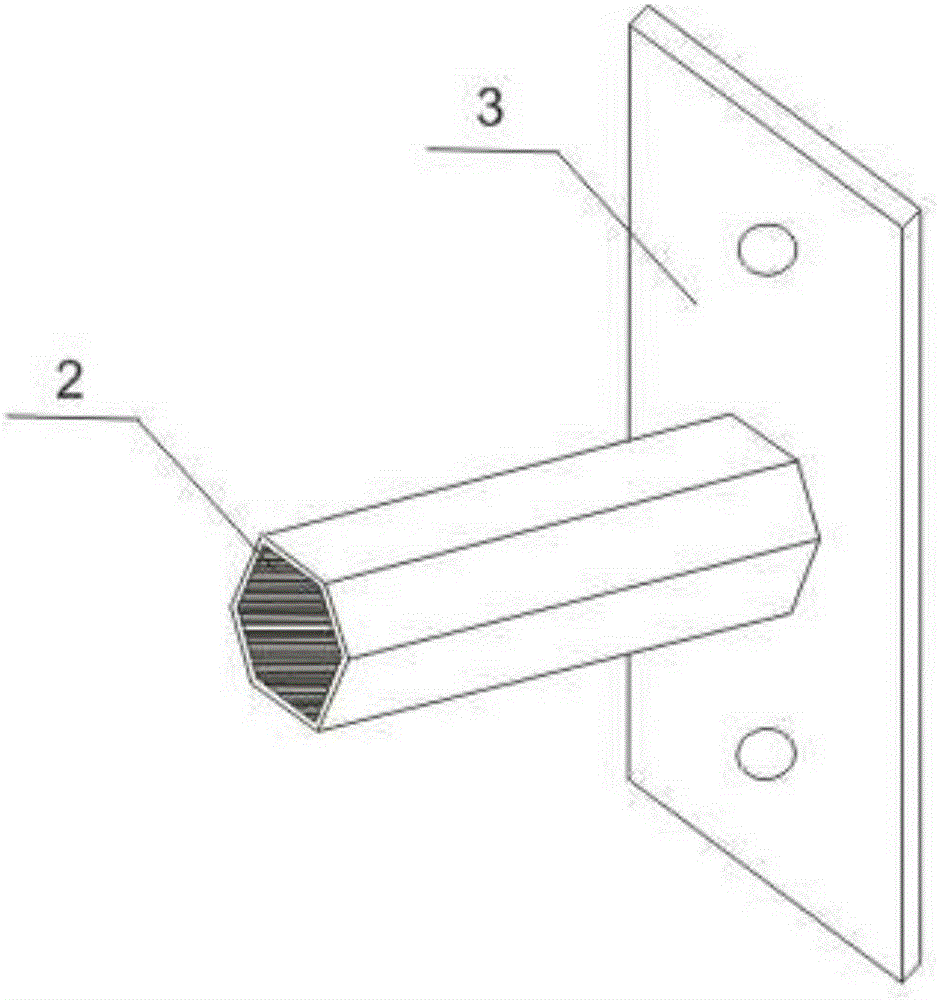

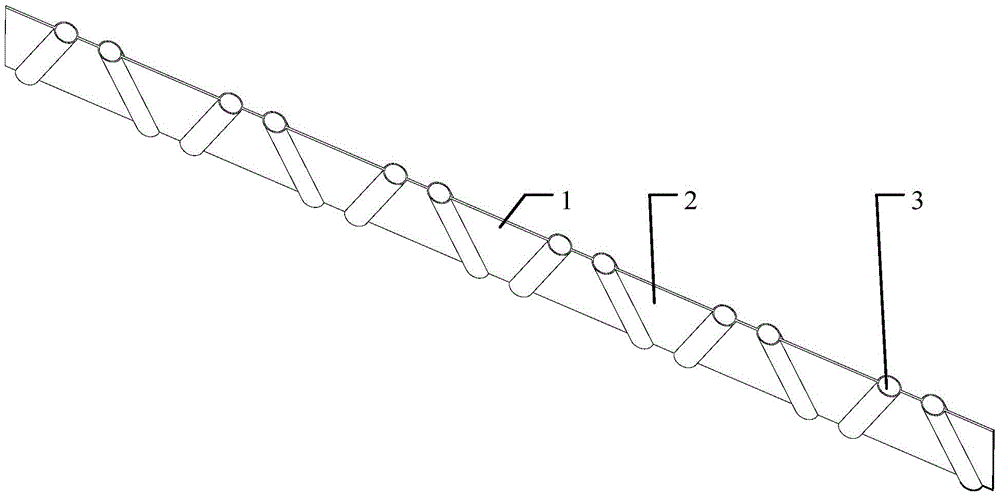

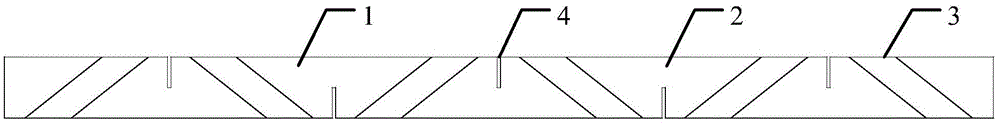

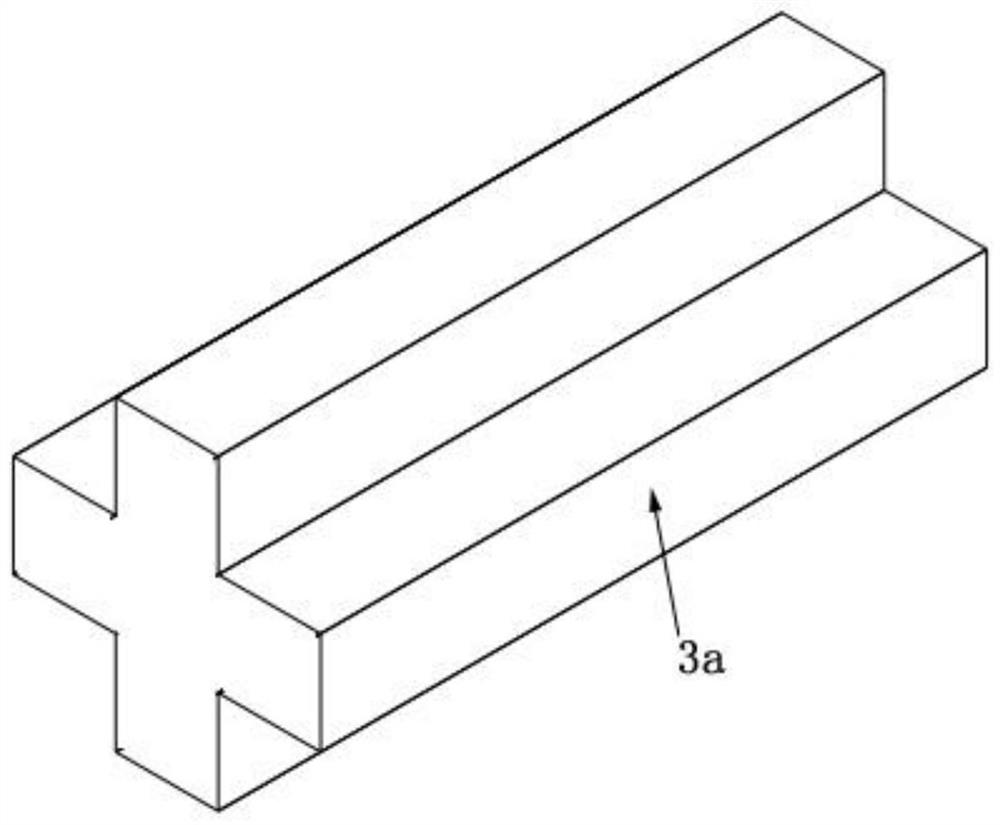

Single bar structure, lattice single-cell honeycomb structure and preparation method of single bar structure

ActiveCN105526488AGood impact energy absorptionHigh strengthSheets/panelsInstabilityShock resistance

The invention provides a single bar structure, a lattice single-cell honeycomb structure and a preparation method of the single bar structure. The single bar structure comprises a batten which is tabulate. At least one pair of round pipes is arranged on the batten. The central axes of the round pipes are located on the plane of the batten. The two ends of each round pipe are located at the two ends, in the width direction, of the batten respectively. Due to the fact that the single bar structure is provided with the at least one pair of round pipes, the strength of the single bar structure applied to a core material of a sandwich structure is improved, and the shock resistance of the single bar structure is improved; when the single bar structure is applied to the sandwich structure, a dynamic impact load can be well borne, the good instability resistance is achieved, and thus the sandwich structure can well absorb impact energy.

Owner:常熟常春汽车零部件有限公司

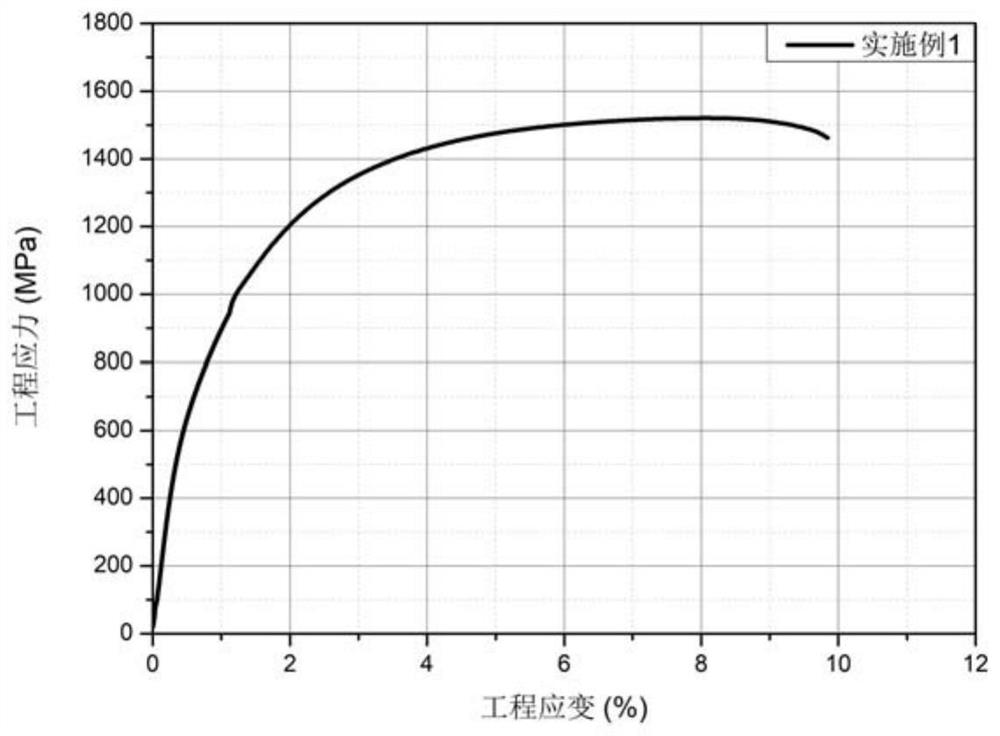

1.5 GPa-grade ultrahigh-strength high-plasticity high-reaming DH steel plate and preparation method thereof

ActiveCN113388779AReduce manufacturing costRealize industrial productionFurnace typesHeat treatment furnacesThin slabContinuous annealing

The invention provides a 1.5 GPa-grade ultrahigh-strength high-plasticity high-reaming DH steel plate and a preparation method thereof. The steel plate comprises the following components in percentages by weight: 0.20%-0.26% of C, 1.8%-2.8% of Mn, 1.0%-2.0% of Si, 0.02%-0.08% of Al, 0.20%-0.80% of Cr, less than or equal to 0.01% of P, less than or equal to 0.01% of S, 0.02%-0.15% of Nb, 0.02%-0.15% of V, 0-0.10% of Ti and the balance of Fe and inevitable impurities. The preparation method comprises the steps of smelting, medium and thin slab continuous casting, hot continuous rolling, acid pickling and cold rolling, continuous annealing and finishing. The yield strength of the steel plate produced by the method is 1000-1350 MPa, the tensile strength is 1470-1650 MPa, the A80 percentage elongation after fracture is greater than or equal to 9.0%, and the hole expansion rate is greater than or equal to 15%.

Owner:ANGANG STEEL CO LTD

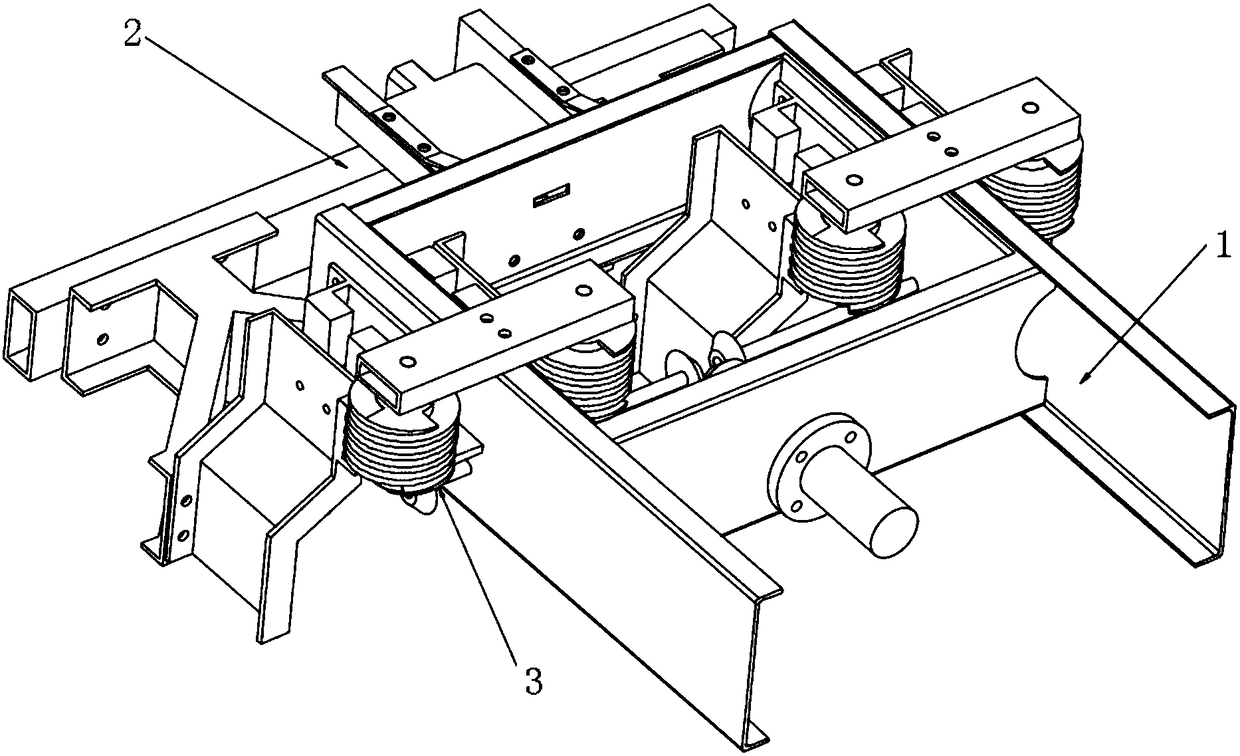

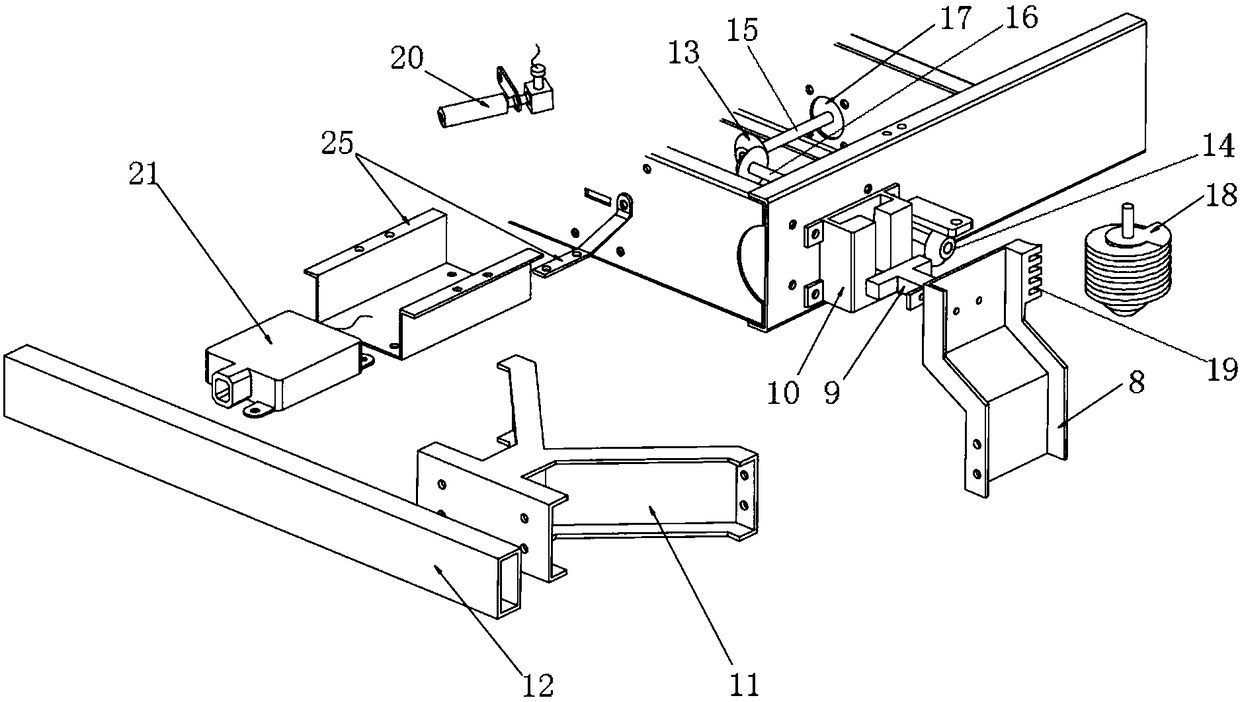

Automatic emergency rear protective device and method

ActiveCN108482287ANot easy to damageEnsure safetyInternal combustion piston enginesSignalling/lighting devicesRear-end collisionVehicle frame

The invention discloses an automatic emergency rear protective device and method. The automatic emergency rear protective device comprises a frame, a driving mechanism, a rear bumper and a control device. The driving mechanism is mounted on the frame and in transmission connection with the rear bumper, and the control device is electrically connected with the driving mechanism. By adoption of an electromechanical integration technology, trafficability can be improved while safety of rear vehicles in collision can be guaranteed, and less proneness to damages of the rear protective device is guaranteed when the vehicle runs normally; when rear-end collision is possibly caused by the fact that own vehicle slows down or stops or the vehicle behind runs at a high speed or accelerates suddenly,the automatic emergency rear protective device is started, a danger warning of collision with the vehicle behind is provided for a driver, then the driver can lower the rear bumper to an operating position, and accordingly the damage degree of collision accidents can be decreased.

Owner:JILIN UNIV

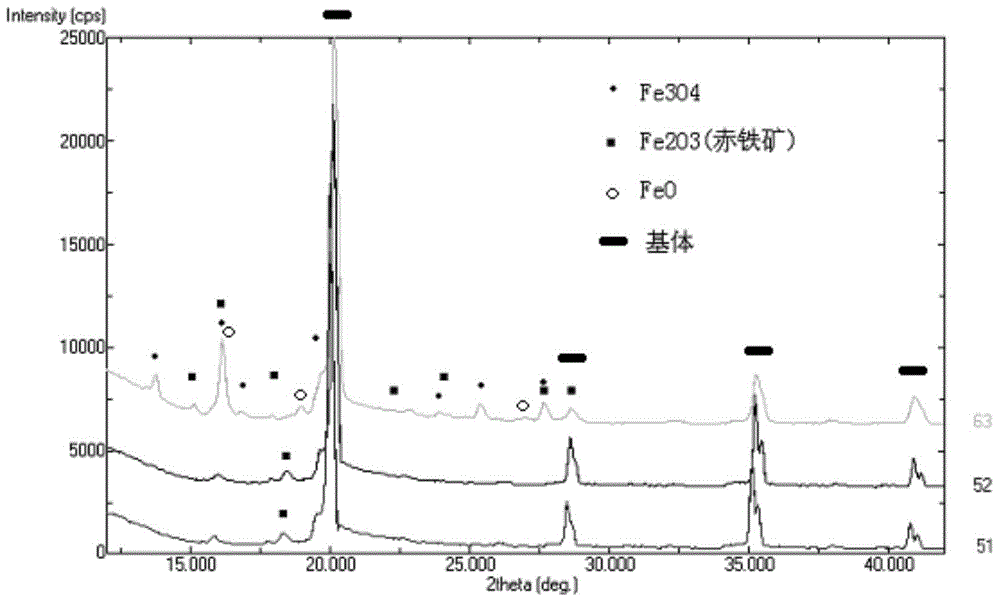

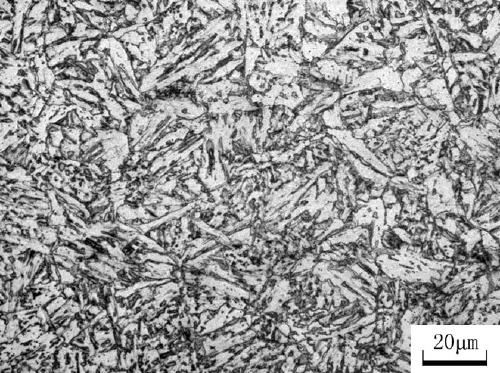

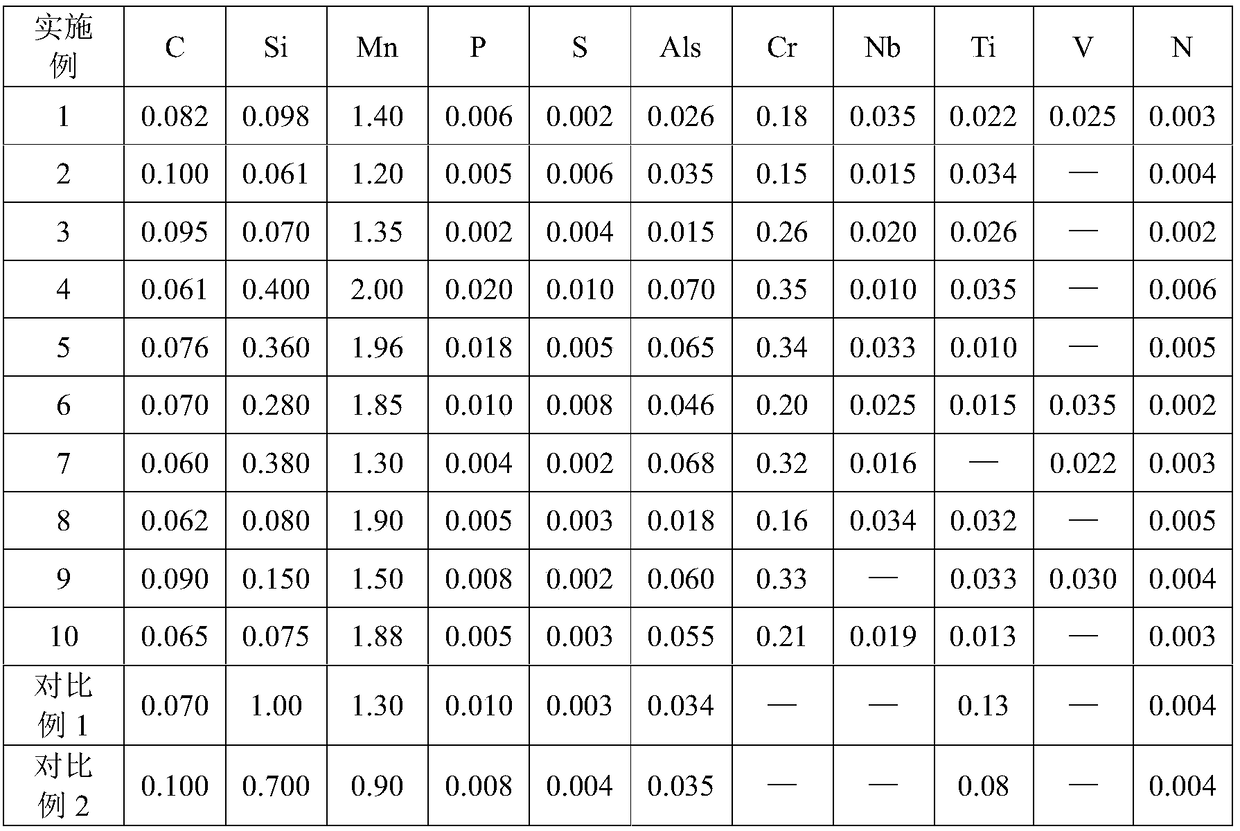

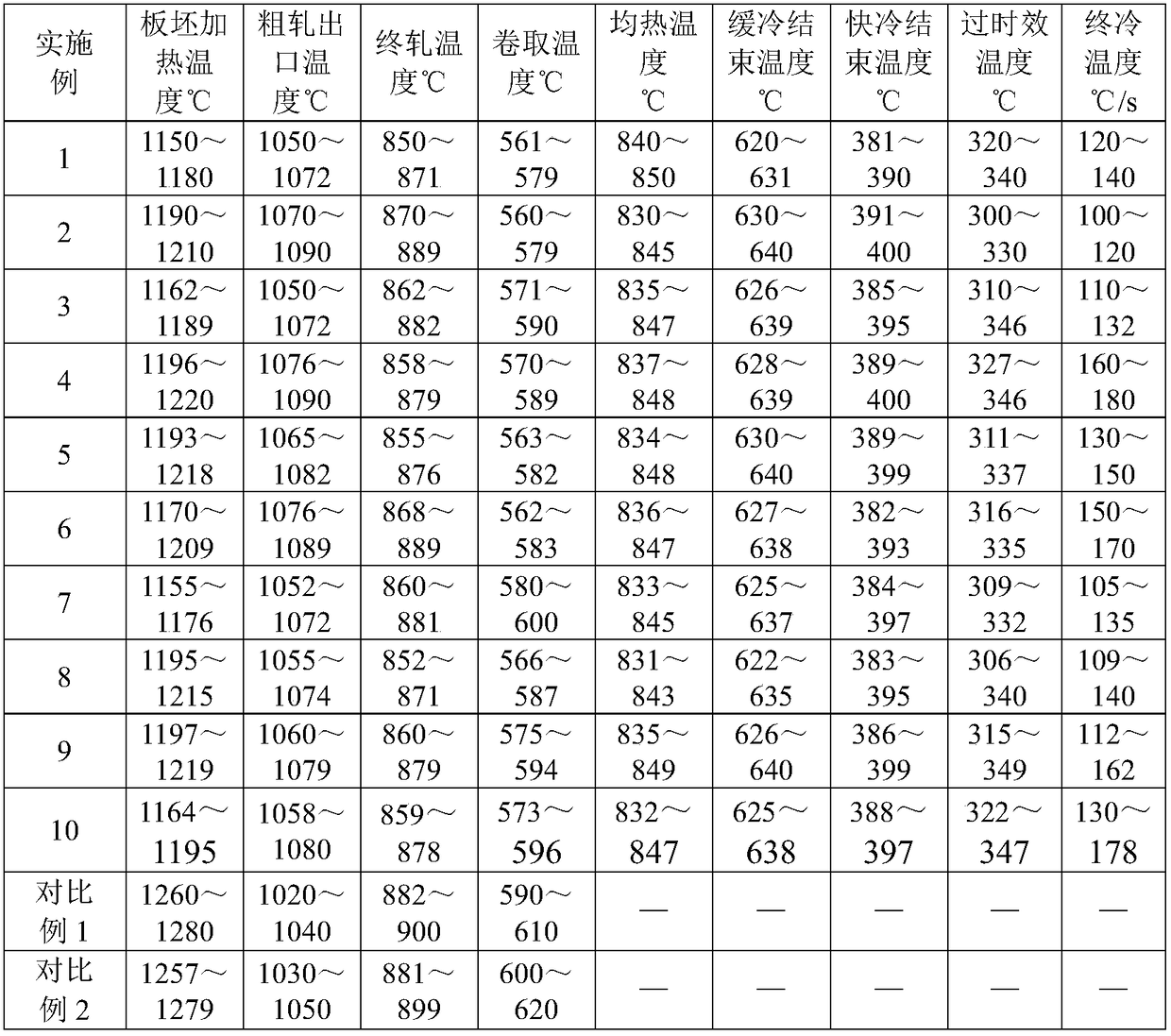

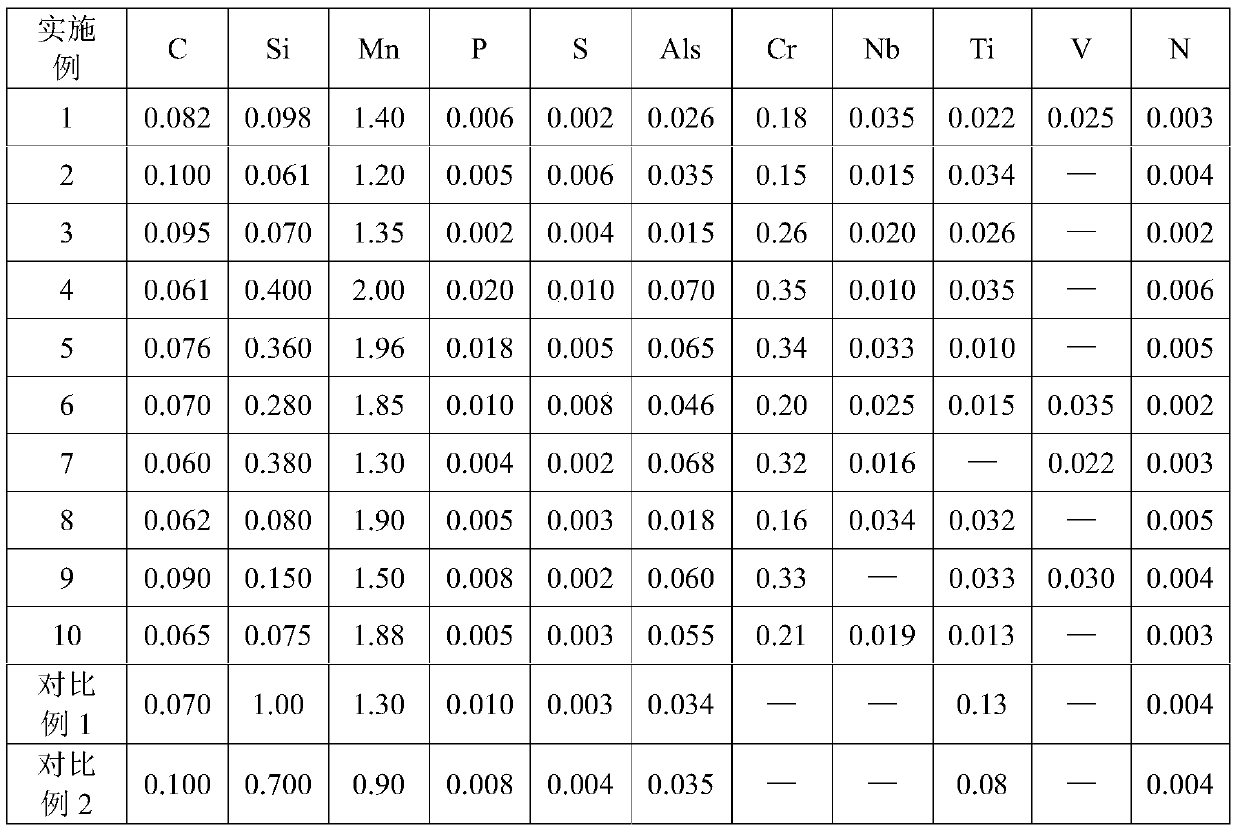

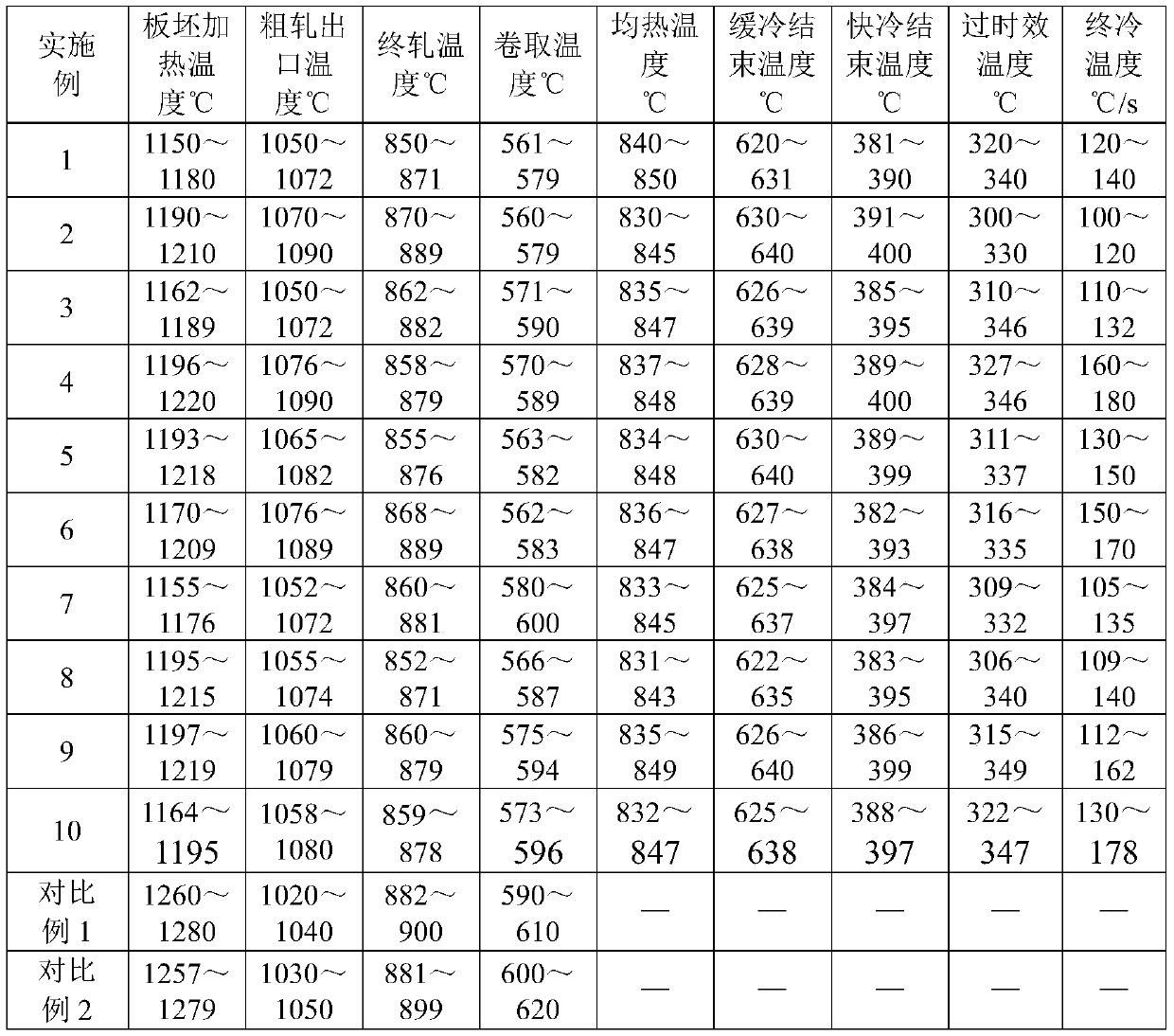

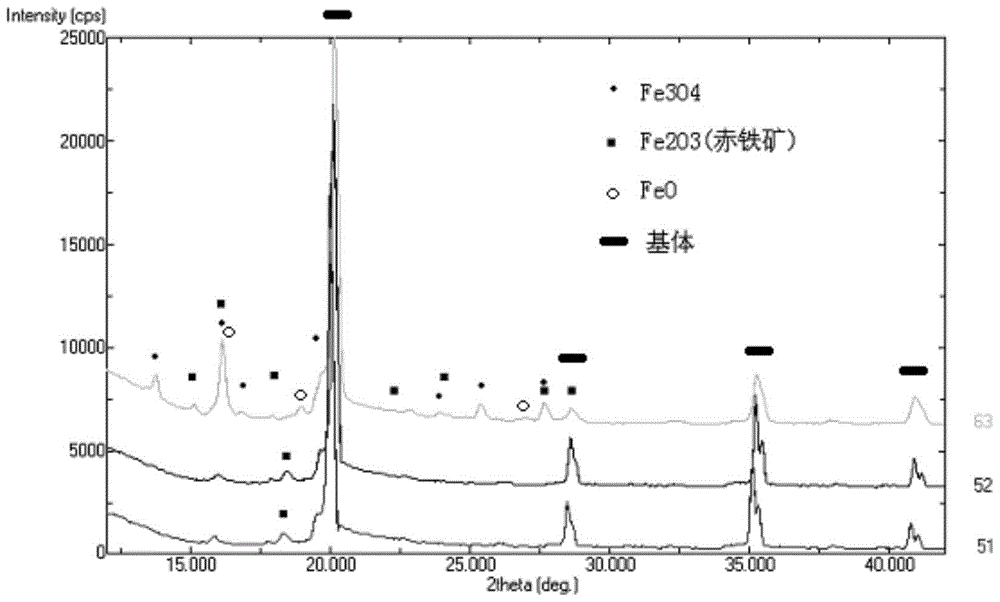

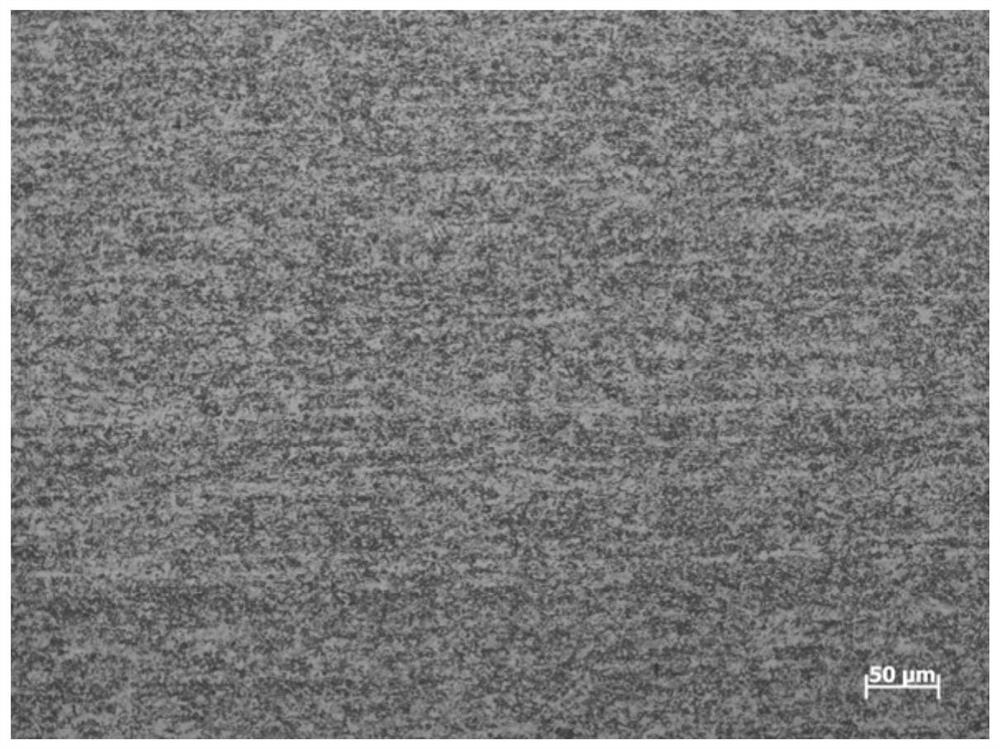

600 MPa grade multiphase steel with good flanging performance and production method thereof

ActiveCN109023053AGood reaming and flanging performanceGood crash energy absorption performanceFlangingPearlite

The invention relates to a 600 MPa grade multiphase steel with good flanging performance, and the 600 MPa grade multiphase steel with the good flanging performance comprises the compositions of, by weight, 0.060-0.100% of C, 0.060-0.400% of Si, 1.20-2.00% of Mn, 0.020% or less of P, 0.010% or less of S, 0.015-0.070% of Als, 0.15-0.35% of Cr, 0.010-0.035% of Ti, 0.010-0.035% of Nb and 0.006% or less of N; A production process comprises the steps that according to the composition setting, blank casting is conducted after conventional smelting is conducted; hot rolling process is performed; coldrolling process is performed; the blank casting is naturally cooled to room temperature, and the blank casting is waiting for used. Yield strength is 360 - 440 MPa, tensile strength is 600 ~ 700 MPa,elongation is 19% or above, the hole expansion rate is 45% or above. The microstructure of the 600 MPa grade multiphase steel is pearlite, bainite, ferrite, a small amount of martensite and residual austenite, thus it is ensured that the good forming performance, flanging performance and collision energy absorption performance are achieved while the high strength is achieved.

Owner:武汉钢铁有限公司

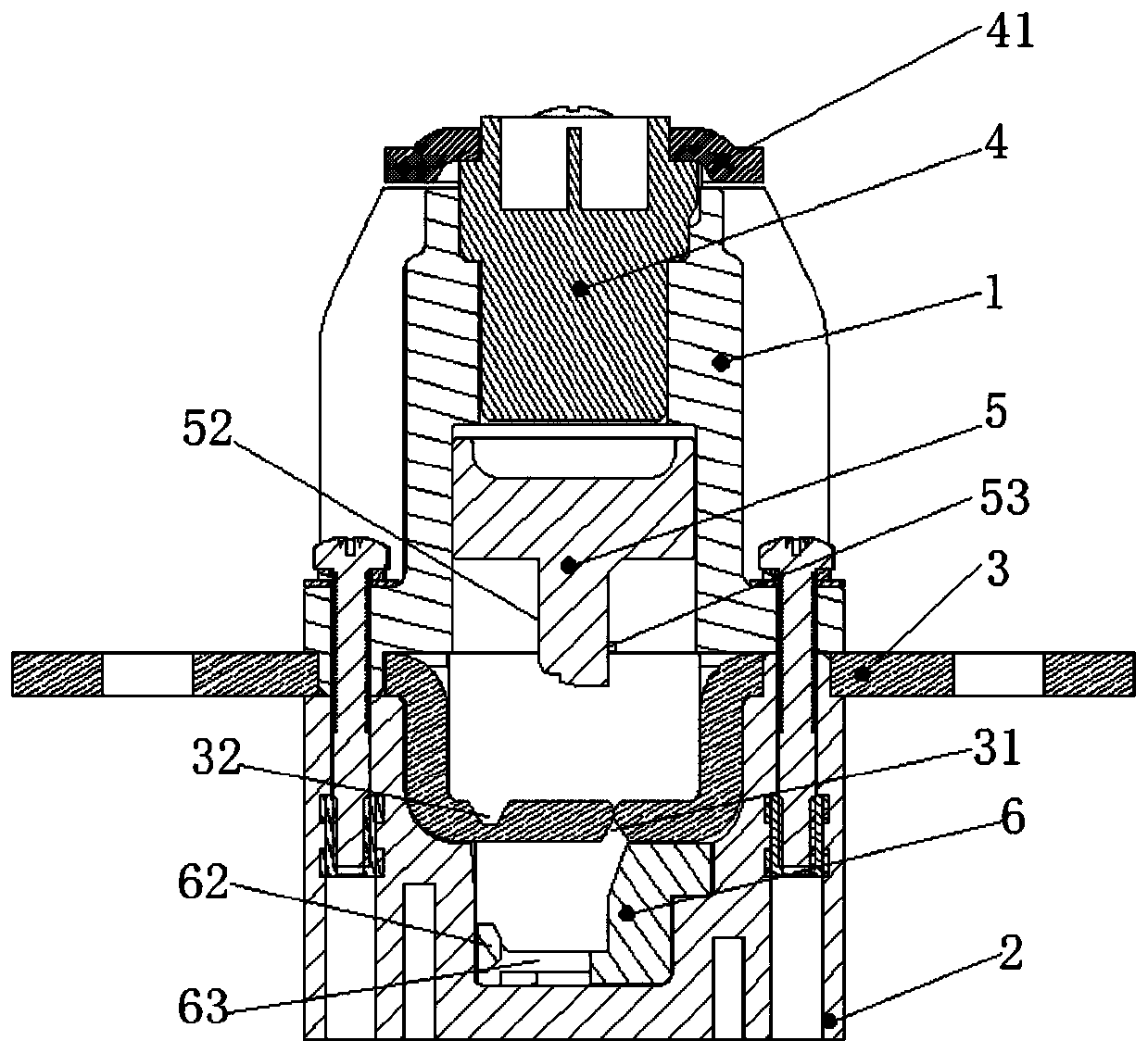

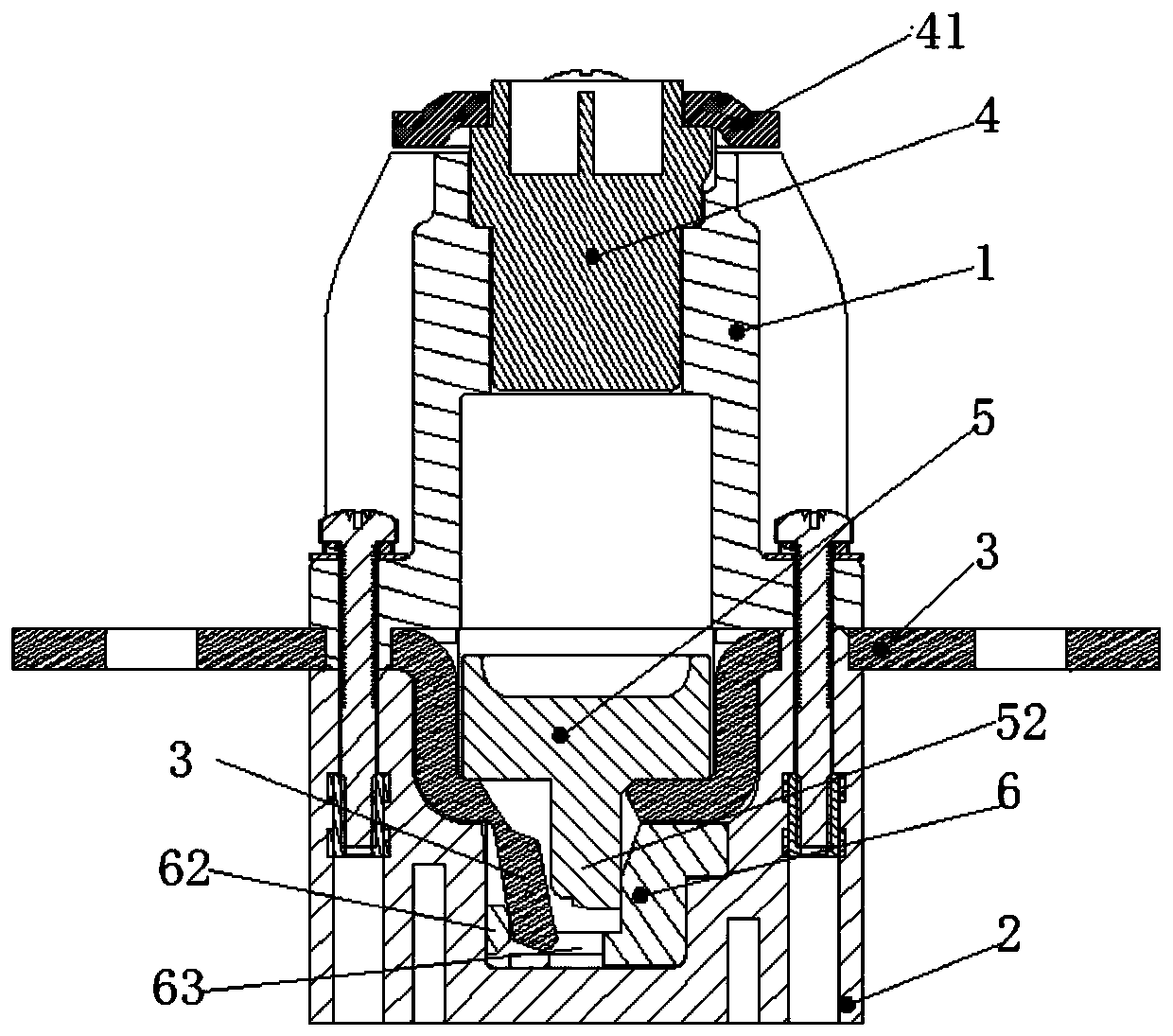

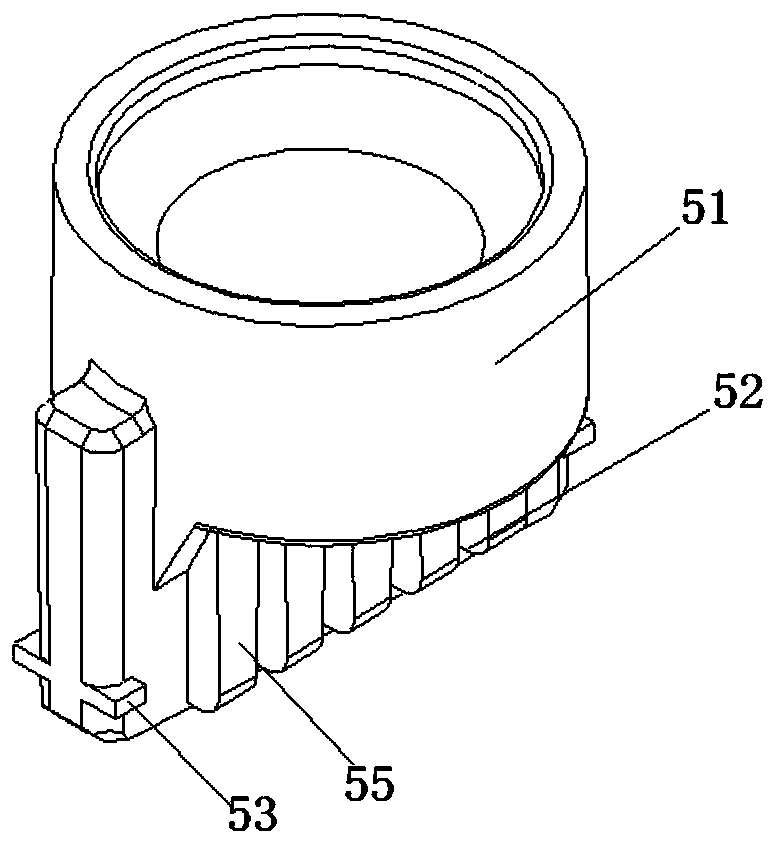

External driving type quick switch structure

PendingCN110491749AAvoid compromising electrical performanceGood impact energy absorptionExplosion operated switchesEmergency protective devicesEnergy absorptionEngineering

An external driving type quick switch structure comprises an upper shell, a lower shell and a conductive plate arranged between the upper shell and the lower shell. An electronic ignition device and apiston are sequentially arranged in the accommodating cavity of the upper shell from top to bottom, and an accommodating cavity is formed in the lower shell below the piston and the conductive plate;the switch structure is characterized in that the conductive plate is recessed towards the accommodating cavity of the lower shell, and a flat-bottomed notch is formed in the accommodating cavity; abreaking notch and a bending notch are formed in the flat bottom of the notch at intervals, and the lower end of the piston is located above the breaking notch. The accommodating cavities in the uppershell and the lower shell meet the requirement that the piston can move into the lower shell from the upper shell. The conductive plate is broken at the breaking notch and falls down along the side wall of a cushion block by taking the bending notch as a rotating shaft, so that a main circuit is disconnected. Impact energy is absorbed through an energy absorption structure arranged between the piston and the cushion block.

Owner:XIAN ZHONGRONG ELECTRIC CO LTD

780 MPa-grade alloying hot galvanizing DH steel and preparation method thereof

ActiveCN111979488AImprove hole expansion performanceLow costHot-dipping/immersion processesSteel platesHeat conservation

The invention discloses 780 MPa-grade alloying hot galvanizing DH steel and a preparation method thereof. The steel comprises 0.11-0.17% of C, 1.4-2.4% of Mn, 0.15-0.60% of Si, 0.02-1.0% of Al, 0.20-0.70% of Mo, 0-0.03% of P, 0-0.03% of S, 0-0.005% of B, 0-0.05% of V, 0-0.05% of Ti and the balance iron and inevitable impurities. The heating temperature of casting blank is 1170-1280 DEG C, the rolling temperature is 1020-1140 DEG C, the final rolling temperature is higher than or equal to 910 DEG C, the coiling temperature is 550-700 DEG C, the cold rolling reduction ratio is 40-80%, the annealing temperature is 770-870 DEG C, the annealing time is 30-300 seconds, the galvanizing temperature is 450-470 DEG C, the alloying temperature is 470-530 DEG C, the heat preservation time is 5-60 seconds, A50 of a steel plate finished product is 20-25%, the hole expansion rate is larger than or equal to 25%, and the requirements of automobile steel for high formability and high hole expansion performance are met.

Owner:ANGANG STEEL CO LTD

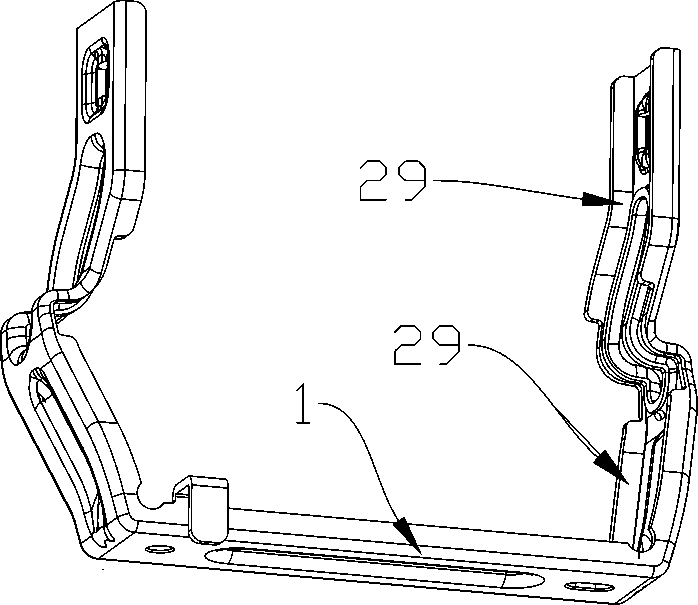

Metal energy absorbing bracket for a dashboard of an automobile

ActiveCN109018019AGood impact energy absorptionGood cushioning for oblique collisionsSuperstructure subunitsDashboardsRear quarterDashboard

Provided is A metal energy absorbing bracket for a dashboard of an automobile. the metal energy absorbing bracket is installed between a rear end of the dashboard and a body sheet metal, the metal energy absorbing bracket comprises a lateral panel and side panels arranged on both sides of the lateral panel, the side panels comprises lower side panels and upper side panels connected together by bending portions, the lower side panels is connected on both sides of the lateral panel; The side plates are symmetrically arranged, and the lower side plates on both sides are provided with an opening angle of 25 DEG to 35 DEG, the upper side plates on both sides are arranged in parallel, and the lower side plates on the same side and the upper side plates are provided with an included angle of 100DEG to 110 DEG. The metal energy-absorbing bracket of the invention changes the straight strip direct structure in the prior art, adopts the bending structure and the open angle structure, and has good collision energy-absorbing effect. The angle between the lower side plate and the upper side plate is 100-110 degrees, and the angle between the lower side plate and the upper side plate is 25 -35degrees, which can well cushion the impact force in the vertical direction.

Owner:FUCHENG AUTO PARTS

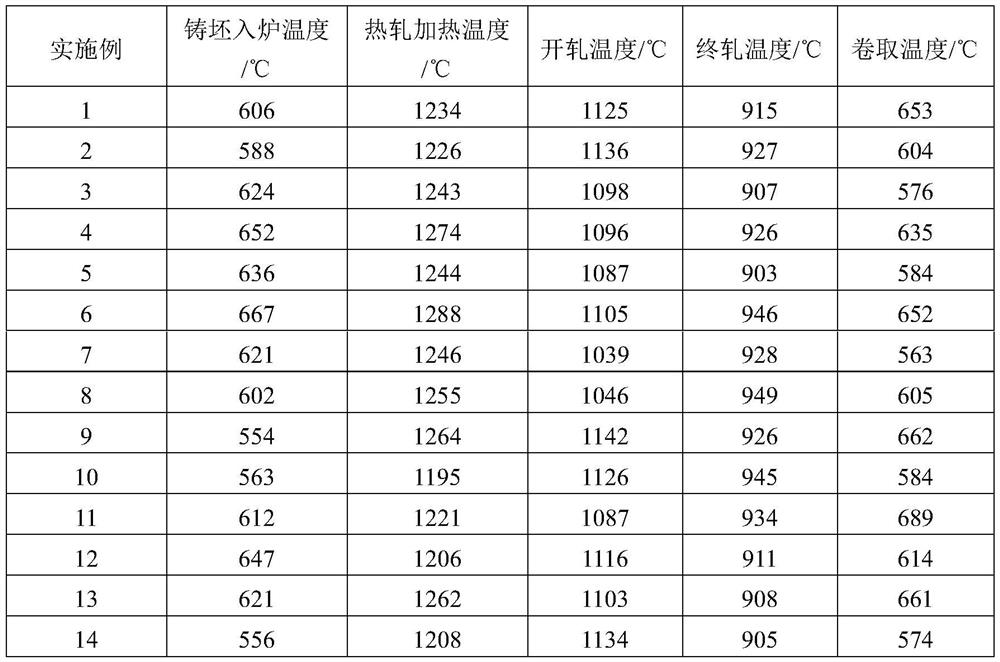

A kind of 780MPa grade high ductility cold-rolled DH steel and its preparation method

The invention discloses a 780MPa high-plasticity cold-rolled DH steel and a preparation method thereof. Steel contains C: 0.10%~0.18%, Mn: 1.5%~2.5%, Si: 0.4%~0.8%, Al: 0.02%~0.7%, Cr: 0.02%~0.50%, P≤0.01%, S≤ 0.01%, Nb≤0.1%, Ti≤0.1%, and Si+Al: 0.5%~1.5%, the balance is iron and unavoidable impurities. The starting rolling temperature is 1050~1150℃, the final rolling temperature is ≥900℃, the coiling temperature is 550~700℃; the cold rolling reduction rate is 40%~80%; the continuous annealing preheating temperature is 200~600℃, and the annealing temperature is 760~880℃ , annealing time 10-600s, slow cooling outlet temperature 660-760°C, rapid cooling rate>20°C / s, overaging temperature 300-420°C, overaging time 30-3600s; skin elongation 0.3%-0.7%. For parts in the automotive industry that require high formability.

Owner:ANGANG STEEL CO LTD

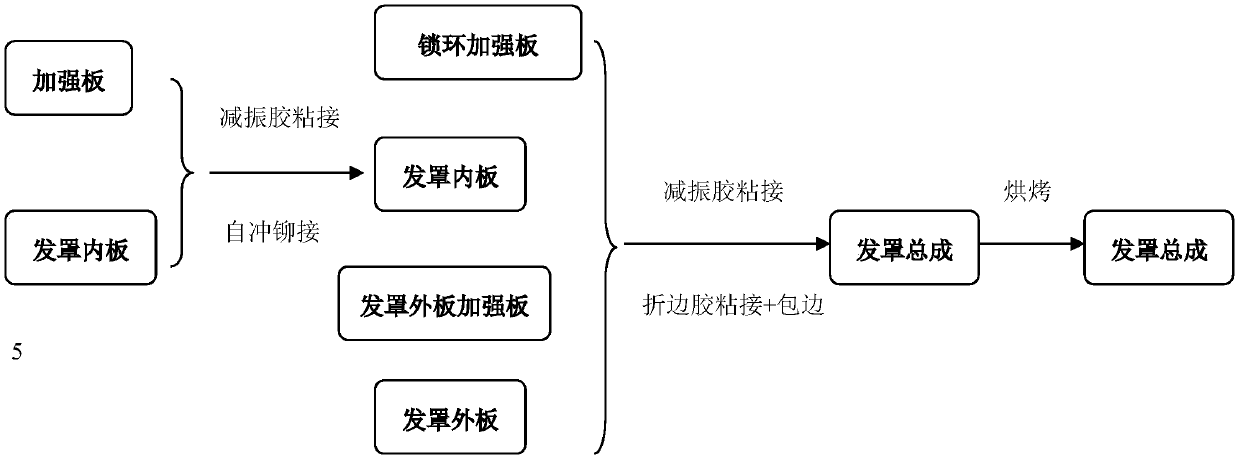

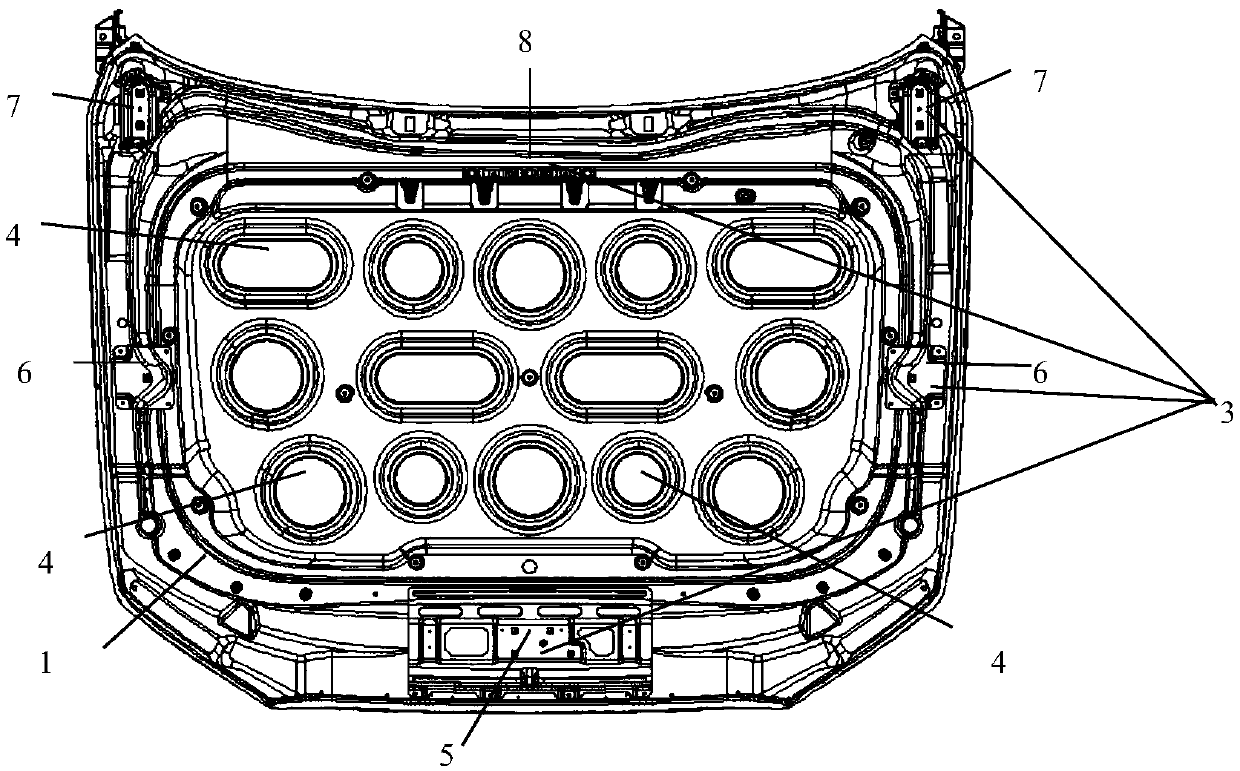

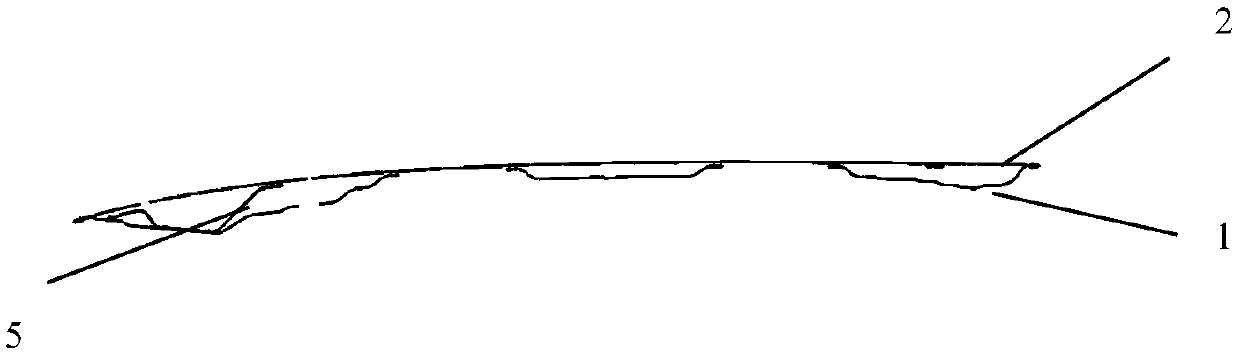

Passenger car aluminum alloy engine cover riveting and bonding composite connection method

InactiveCN109513868AGuaranteed stiffnessGuaranteed StrengthFastening meansEngineeringWrapping procedure

The invention provides a passenger car aluminum alloy engine cover riveting and bonding composite connection method. The method comprises the steps that an engine cover reinforcing plate is pre-fixedto an engine inner plate through a vibration reduction glue bonding manner, reinforcing plates are completely fixed to the engine cover inner plate through a self-piercing riveting manner; a protruding edge of a lightening hole of the engine cover inner plate, a lock ring reinforcing plate and an engine outer plate reinforcing plate are coated with vibration reduction glue, and an engine cover outer plate of the engine cover falls down to finish bonding; the edge of the engine cover inner plate is coated with folding glue, the edge of the engine cover outer plate is subjected to side wrappingtowards the engine cover inner plate, the side wrapping procedure of the engine cover can be finished, and an engine cover assembly can be obtained; the engine cover assembly is baked, vibration reduction glue and folding glue are cured, and connection of the engine cover can be achieved. The self-piercing riveting and bonding composite process is used for replacing the welding process, connectionof the aluminum alloy engine cover is achieved, and whole rigidity, whole strength and size precision of connection of the aluminum alloy engine cover can be better ensured.

Owner:CHINA FIRST AUTOMOBILE

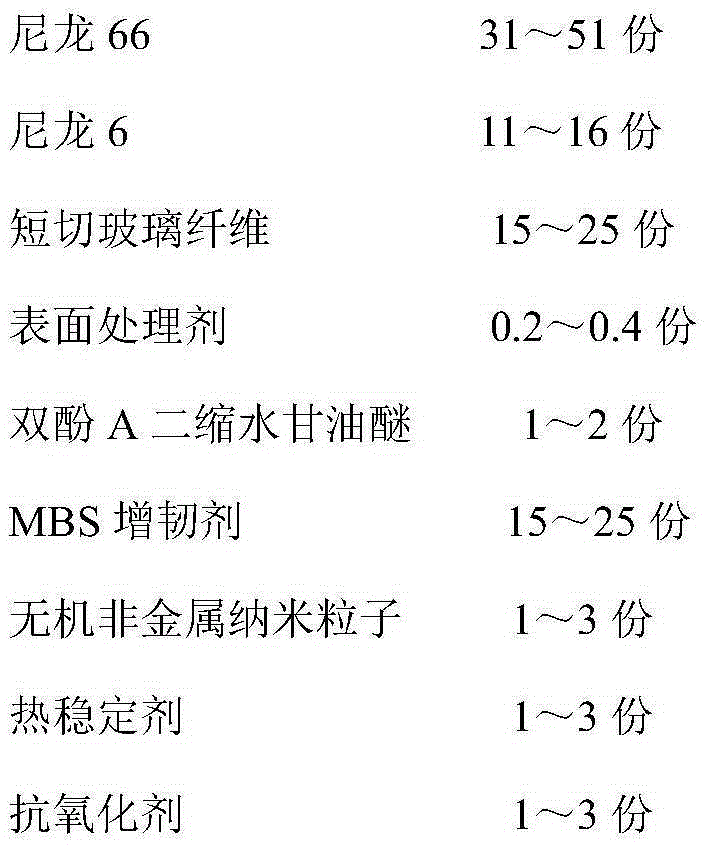

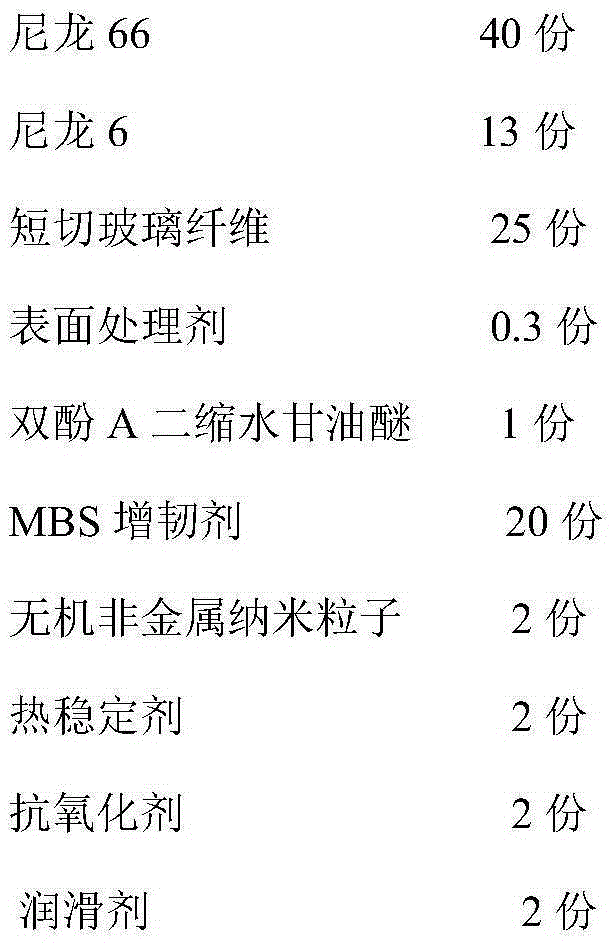

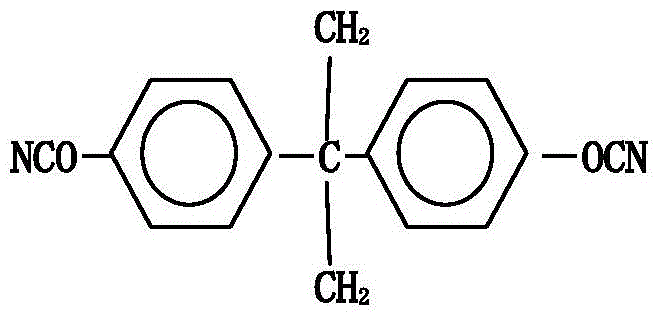

Nylon plastic bearing retainer for draw-bar box and preparation method of nylon plastic bearing retainer

The invention discloses a nylon plastic bearing retainer for a draw-bar box and a preparation method of the nylon plastic bearing retainer. According to the formula of the nylon plastic bearing retainer, nylon 66 and nylon 6 are taken as a compound basic material, through adding materials of short-cut glass fibers, a surface treating agent, bisphenol A diglycidyl ether, an MBS flexibilizer, inorganic nonmetal nano particles, a heat stabilizer, an antioxidant, a lubricating agent and the like, the notch impact strength, the tensile strength and the bending strength of the nylon plastic of the bearing retainer provided by the invention are all higher than those of common nylon plastic, more importantly, the nylon plastic has very high low-temperature-resistant capability, and the lowest using temperature can reach more than subzero 20 DEG C, so the requirements of the nylon plastic bearing retainer for the draw-bar box in a cold region are greatly met.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

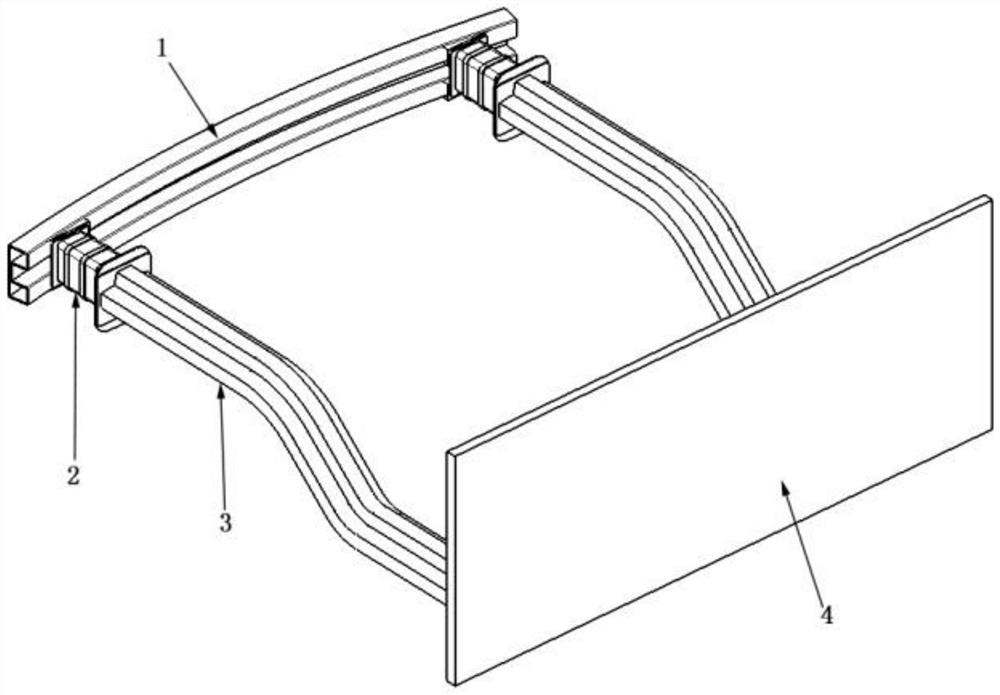

Automobile roof beam with bending resistance and manufacturing method thereof

InactiveCN109703624AGood impact energy absorptionHigh strengthAdditive manufacturing apparatusSuperstructure subunitsFiberEngineering

The invention relates to an automobile roof cover beam with bending resistance. The automobile roof cover beam with bending resistance includes a hollow beam made of carbon fibers, microstructured fillers and a carbon fiber laminate, wherein the microstructured fillers are bonded to the carbon fiber laminate and are arranged in the hollow beam; the hollow beam is a variable diameter square tube, and comprises an upper wall, a lower wall and left and right side walls; the upper wall is curved with a thick intermediate portion and two thin end portions; the cross section of the microstructured filler has a structure in which columnar bodies are intersected at one point, and two ends of the columnar body are semicircular; the microstructure is filled in the roof beam, so as to improve the impact energy absorption effect of the roof beam; and in order to enhance the rigidity of the roof beam, the carbon fiber composite material with high specific strength and high specific modulus is adopted, and is combined with the loading feature of the roof beam, the hollow beam adopts the structure with two thick sides and a thick intermediate portion, thus optimizing distribution of the material, improving the strength of the roof beam, thereby further obtaining a good safety effect.

Owner:JILIN UNIV

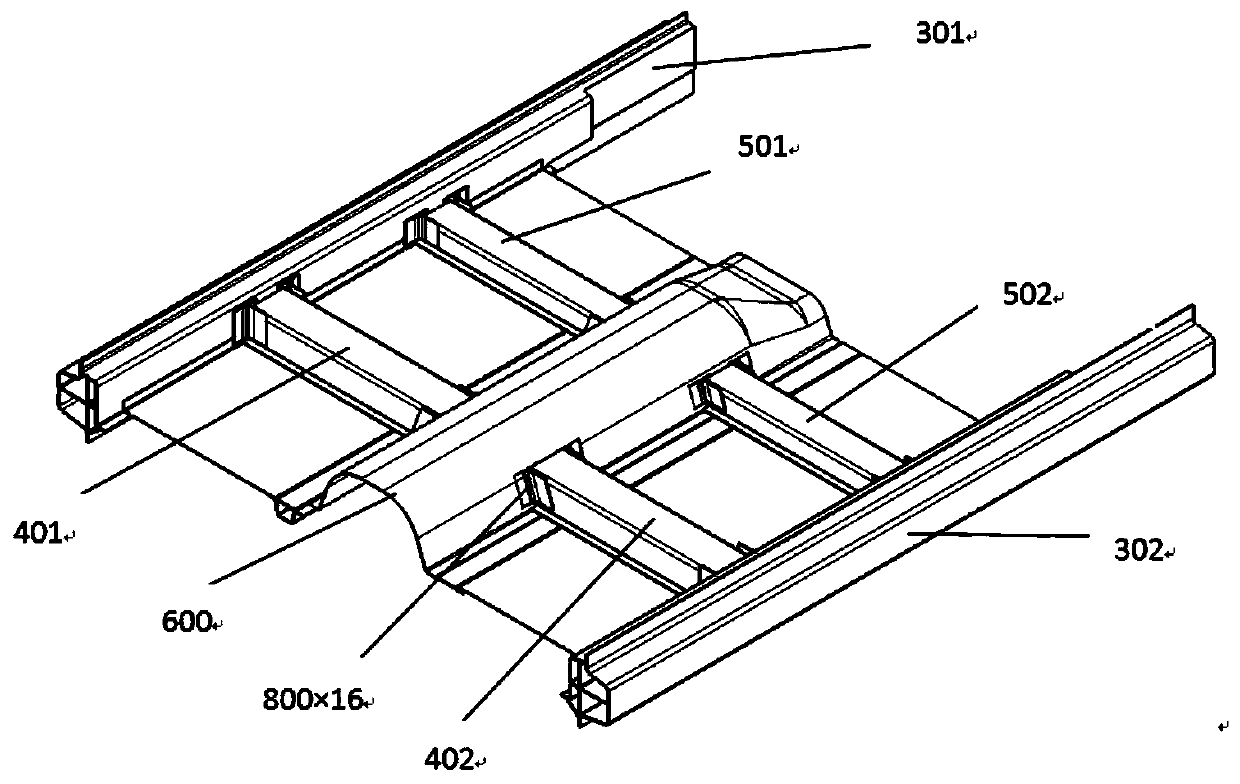

All aluminum alloy front floor assembly for automobile

InactiveCN110001792ALight in massImprove NVH performanceSuperstructure subunitsEngineeringInverted u

The invention discloses an all aluminum alloy front floor assembly for an automobile. The all aluminum alloy front floor assembly for the automobile comprises a front floor, an omega-shaped middle passage stamping panel, a multi-cavity inverted U-shaped middle through plate piece with a wing arm-shaped section, a front floor longitudinal beam with an extending wing arm and a square-shaped section,a threshold beam with a wing wall and an irregular four-square-shaped section and an irregular seat cross beam with an extending wing arm and an irregular square-shaped section. According to the allaluminum alloy front floor assembly for the automobile, each member adopts an aluminum alloy material, and the integral mass of the assembly is light; compared with a steel front floor, the the all aluminum alloy front floor assembly for the automobile has the advantages that the integral weight loss reaches up to 25-35%, the manufacturing is simple, the cost is saved, and the assembly can be completely recycled. According to the all aluminum alloy front floor assembly for the automobile, each member adopts a cementing and riveting mixed connecting mode so that the structural strength of the integral structural frame is high; and moreover, the integral NVH performance of the automobile is improved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

A kind of 600mpa grade multi-phase steel with good flanging performance and its production method

Owner:武汉钢铁有限公司

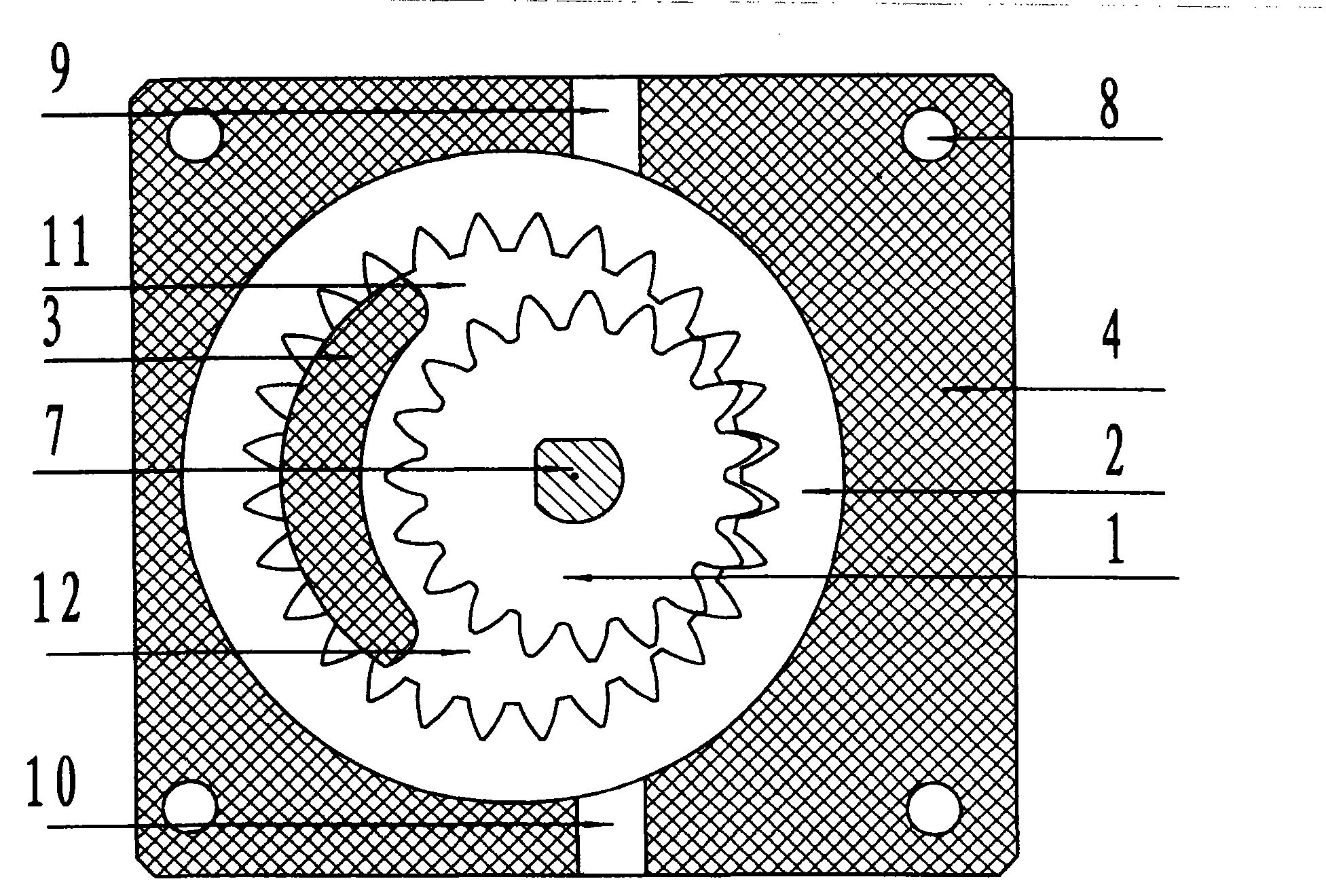

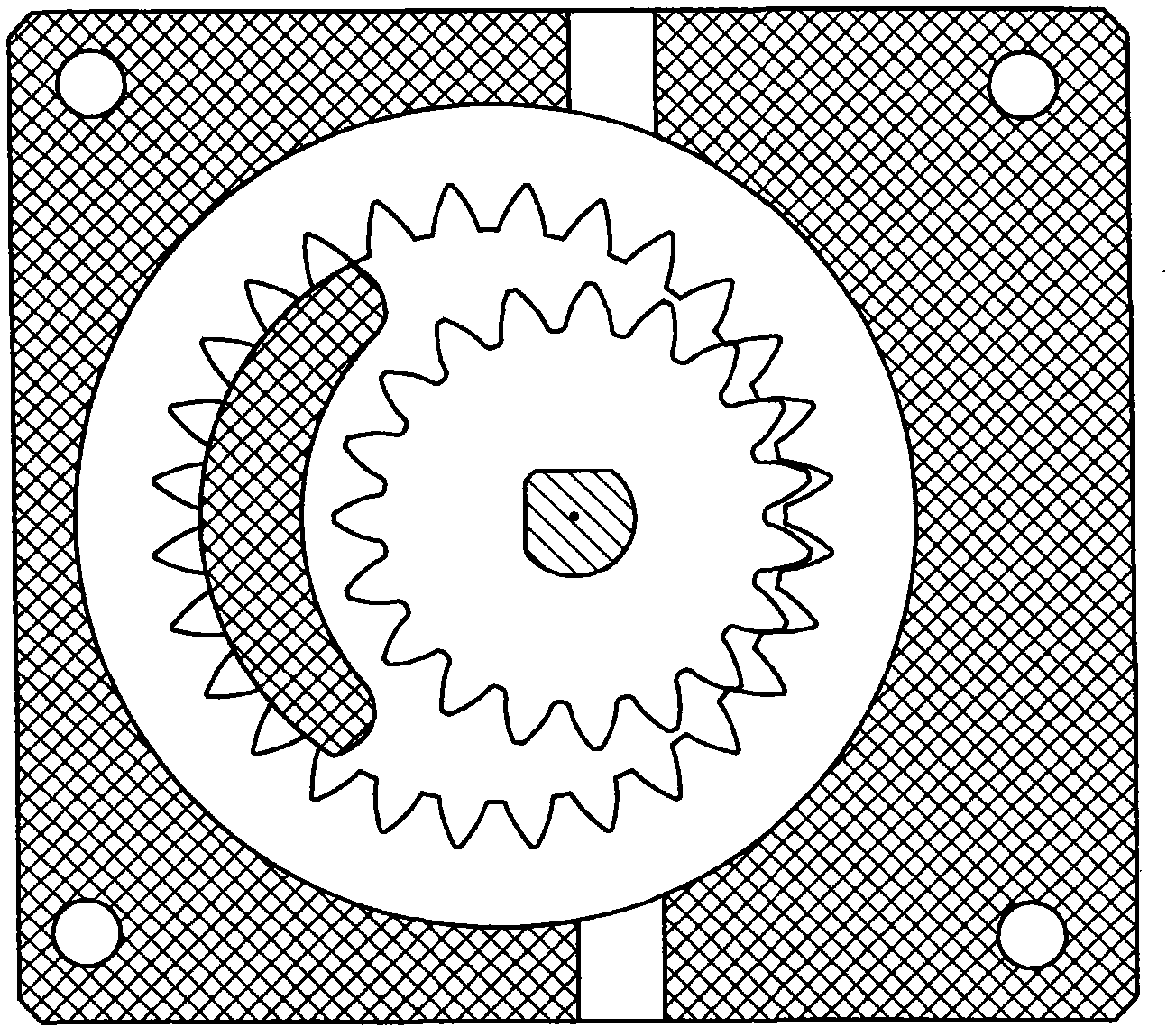

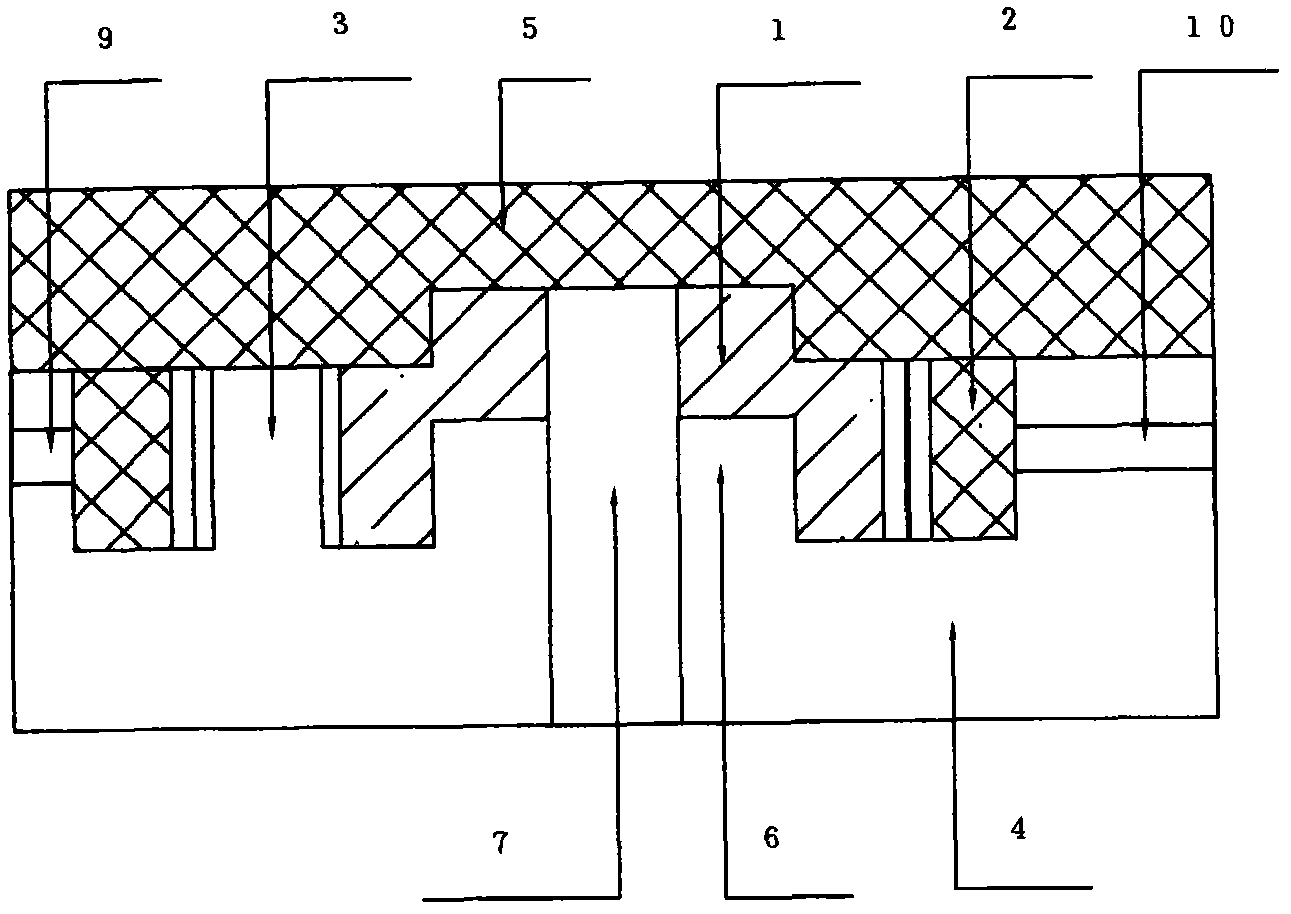

Ultra-high molecular polyethylene gear pump

InactiveCN102865224AWeak surface adsorptionNot easy to stickRotary piston pumpsRotary piston liquid enginesDrive wheelNoise reduction

The invention relates to an ultra-high molecular polyethylene gear pump, which is composed of a pump body with an ultra-high molecular polyethylene material, a driven wheel, a gland, a main wheel body with a metal material and the like. A driving wheel is positioned on a boss of the pump body, and is engaged with the driven wheel, the wall of the driven wheel can be thickened properly, the boss, a crescent shaped lever and the pump body are combined as an integral body, a manufacture method can employ a machine tooling device to process and shape, or employ a molding and sintering process. The pump body, the driven wheel, the gland and the driving wheel are in soft and hard duality relation, and can preventing the driving wheel from damaging, the ultra-high molecular polyethylene gear pump has the excellent performances of wear resistance, health and nontoxicity, vibration and noise reduction and no adhesion, and is suitable for the gear pump delivered by the high viscosity liquids, foods, medicines and chemical mediums. The ultra-high molecular polyethylene gear pump has the advantages that the components of the ultra-high molecular polyethylene material can replace the metal material components in the prior art, the service life of the gear pump can be increased, the ultra-high molecular polyethylene gear pump has the active effects of no pollution, no vibration, no noisy, self-cleanness, simple treatment and the reduced cost.

Owner:冀珂

1000mpa grade high-strength and high-plasticity aluminum-containing medium-manganese steel and manufacturing method thereof

The invention discloses 1000 MPa-level high-strength high-plasticity aluminum-containing medium manganese steel and a manufacturing method thereof. The steel comprises the following chemical components by mass percent: 0.05-0.25% of C, 0.02-0.40% of Si, 7.0-11% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, 1.50-3.50% of Al, 0.02-0.60% of Cr, smaller than or equal to 0.50% of Cu, smaller than or equal to 0.40% of Mo, smaller than or equal to 0.10% of Nb, smaller than or equal to 0.010% of N and the balance of Fe and unavoidable impurities. The manufacturing method of the steel comprises the steps of smelting, continuous casting, hot continuous rolling, cover annealing, acid pickling cold rolling, cover annealing or continuous annealing and finishing packing. The steel disclosed by the invention has high strength, excellent cold stamping forming performance and impacting energy absorption performance.

Owner:武汉钢铁有限公司

Automobile collision buffer device

InactiveCN105216724BGood impact energy absorptionReduce casualtiesBumpersHydraulic cylinderEngineering

The invention discloses an automobile collision buffer device, and relates to the technical field of automobiles. Each energy-absorbing cylinder is connected to a spring energy-absorbing cylinder in a clearance fit manner; the spring energy-absorbing cylinder is connected to a hydraulic cylinder sleeve; the energy-absorbing cylinder is disposed in an energy-absorbing beam sleeve in a sliding manner; a spring limit rod is arranged at the bottom end of the energy-absorbing beam sleeve; the ends of the spring limit rod penetrate the energy-absorbing cylinder; push springs are arranged on the portion, under the energy-absorbing cylinder, of the spring limit rod in a penetrating manner; the bottom end of the energy-absorbing cylinder is in plugging connection with bolts; the bolts cooperate with electromagnets; limit pin sleeves are arranged on the upper side wall of the energy-absorbing beam sleeve; each limit pin sleeve is internally provided with a limit pin; a pressure spring is cooperatively arranged between each limit pin and the wall of the corresponding limit pin sleeve; the spring energy-absorbing cylinder is internally provided with energy-absorbing springs which are fixed to a spring positioning disc; and a piston rod is disposed in the hydraulic cylinder sleeve in a penetrating manner. The automobile collision buffer device improves automobile collision energy-absorbing effects, protects an automobile and pedestrians, reduces the damage to the front structure of the automobile, is low is cost, and is high in practicality.

Owner:GUANGDONG UNIV OF TECH

Anti-collision structure device at front end of automobile

The invention discloses an anti-collision structure device at a front end of an automobile. The anti-collision structure device comprises a front anti-collision beam, two absorption boxes, front longitudinal beams in one-to-one correspondence with the absorption boxes and a supporting plate. Each front longitudinal beam is of a closed dodecagon frame structure formed by combining four U-shaped frames, and the cross section of each front longitudinal beam has a hollow cross frame structure; the two absorption boxes are fixedly arranged on the inner sides of the two ends of the front anti-collision beam respectively, one end of each front longitudinal beam is fixedly connected to the front anti-collision beam through one absorption box, and the other end of the front longitudinal beam is fixedly connected to the supporting plate. According to the anti-collision structure device, the mass of an automobile body is reduced. According to the device, the section shape of the front longitudinal beam is changed, a more reasonable layout scheme is selected, the dodecagon has a better collision energy absorption effect by being compared with a quadrangle, a hexagon and an octagon, the anti-collision performance of a vehicle can be enhanced; and casualties of passengers are reduced as much as possible when traffic accidents happen.

Owner:ZHEJIANG UNIV OF TECH

A kind of 780mpa grade alloyed hot-dip galvanized dh steel and preparation method thereof

ActiveCN111979488BExcellent hole expandabilityRealize industrial productionHot-dipping/immersion processesSteel platesGalvanization

The invention discloses a 780MPa grade alloyed hot-dip galvanized DH steel and a preparation method thereof. Contained in steel, C: 0.11% to 0.17%, Mn: 1.4% to 2.4%, Si: 0.15% to 0.60%, Al: 0.02% to 1.0%, Mo: 0.20% to 0.70%, P≤0.03%, S ≤0.03%, B≤0.005%, V≤0.05%, Ti≤0.05%, the balance is iron and unavoidable impurities. Slab heating temperature 1170-1280°C, starting rolling temperature 1020-1140°C, finishing rolling temperature ≥910°C, coiling temperature 550-700°C; cold rolling reduction 40%-80%; annealing temperature 770-870°C, The annealing time is 30-300s, the galvanizing temperature is 450-470°C, the alloying temperature is 470-530°C, and the holding time is 5-60s. Finished steel plate A 50 20% to 25%, hole expansion rate ≥ 25%, meeting the requirements of high formability and high hole expansion performance of automotive steel.

Owner:ANGANG STEEL CO LTD

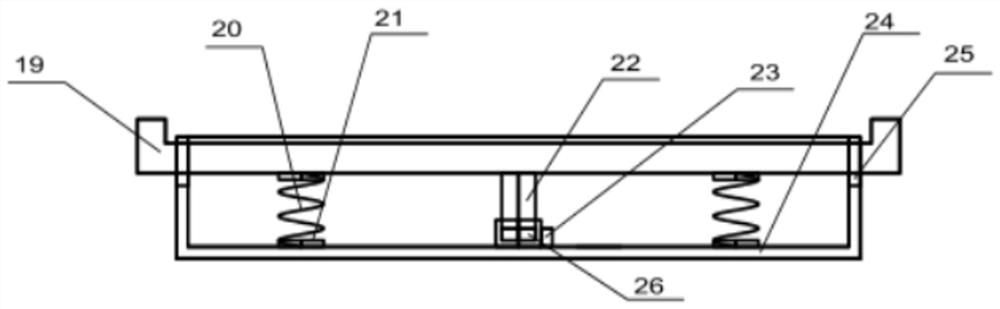

A multi-functional logistics compartment

ActiveCN112758196BSave energyPlay the role of cushioning and dampingBatteries circuit arrangementsAir-treating devicesEngineeringDrive motor

A multifunctional logistics carriage, comprising a carriage body, a buffer and vibration reduction device, a ventilation and cooling device, a solar power generation energy storage device, and a disinfection and sterilization device; the bottom of the carriage is provided with a buffer and vibration reduction device, and the buffer and vibration reduction device includes a hollow shell Body, pressure bearing plate, spring, hydraulic push rod, hydraulic drive motor, hydraulic cylinder; the side walls of the box body are respectively equipped with air bag plates, and there are multiple cavities evenly in the air bag plates, and the ventilation between the two cavities The pipes are connected; the top of the box body is equipped with a ventilation and cooling device and a solar energy storage device. The ventilation and cooling device includes a refrigerant, an evaporator, an overflow channel, and an air inlet; the solar energy storage device includes a solar panel and a battery; The bottom of the flow channel is equipped with a disinfection and sterilization device; the invention has good functions of buffering and vibration reduction, ventilation and cooling, solar power generation and energy storage, disinfection and sterilization, high functional integration, strong practicability, and more in line with modern logistics transportation requirements.

Owner:HENAN UNIV OF SCI & TECH

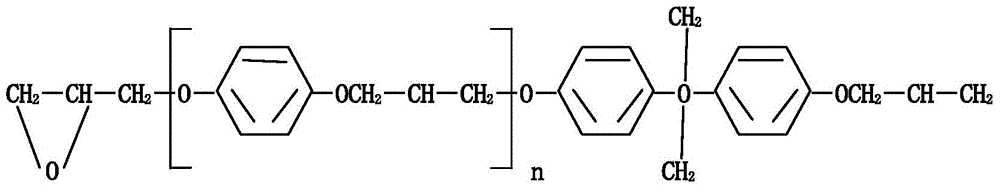

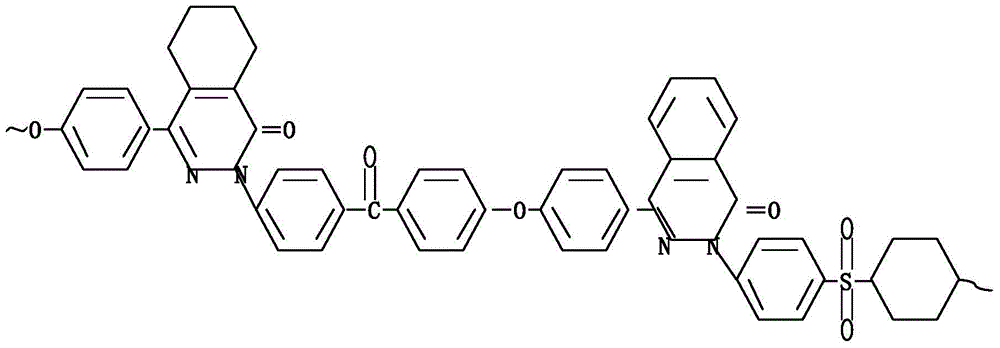

A kind of manufacturing method of high-frequency characteristic copper-clad laminate

ActiveCN104908400BGood dispersionHigh impact strengthLamination ancillary operationsLaminationEpoxyEther

The invention relates to a high frequency-characteristic copper-clad plate manufacturing method. The method comprises the following steps: 1)a poly phthalazinone ether / epoxy resin blend is prepared; 2)a sol is prepared; 3)a prepreg is manufactured; and 4)the copper-clad plate is manufactured. As the epoxy resin is modified by poly phthalazinone ether, the manufactured poly phthalazinone ether resin-based high-frequency copper-clad plate overcomes defects such as high moisture absorption, poor processing property, poor impact-resisting property and high price of the existing high-frequency plate. In addition, the manufactured high-frequency copper-clad plate has the following advantages of excellent dielectric property and high glass transition temperature, excellent mechanical property and dimensional stability, excellent heat-resisting property, good processing property, and excellent flame-retardant property. The high-frequency copper-clad plate of the invention can meet requirements of manufacturing a high-frequency, high-speed and high-property circuit board.

Owner:PUTIAN HANJIANG YD PCB CO LTD

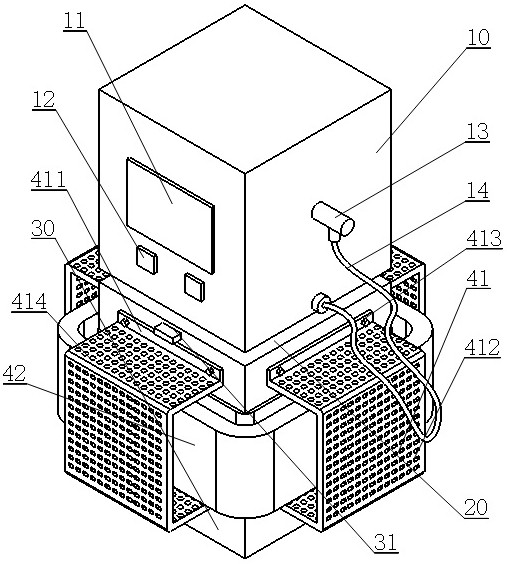

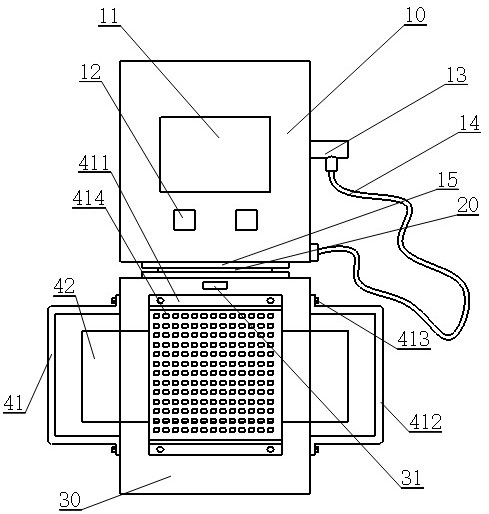

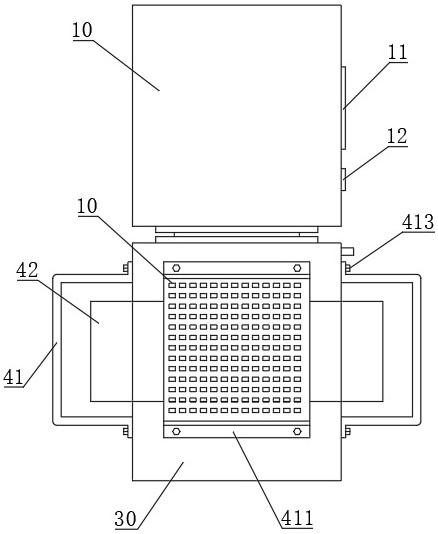

A new energy charging pile with buffer and protection functions

ActiveCN112140929BAvoid damageAvoid spreadingCharging stationsNon-rotating vibration suppressionNew energyAirbag

The invention discloses a new energy charging pile with buffering and protection functions, which includes a box body, a connecting part and a base body; The charging gun and the charging cable are connected, and the base is hollow at the bottom; the connecting part is located in the middle of the charging pile, and the connecting part has a shell and an inner cavity, and the inner cavity of the connecting part is placed with an airbag; the base is located at the lower part of the charging pile, and the There are pressure sensor, gas generator, power controller and three anti-collision parts; when the pressure of the first anti-collision part exceeds the threshold value, the pressure sensor sends a gas release signal to the gas generator, and the second anti-collision part sends a signal to the third anti-collision part. The collision part conducts pressure, and when the pressure of the third anti-collision part exceeds a threshold value, the pressure sensor sends a signal to cut off the power supply to the power controller. The invention not only saves materials, is convenient for replacement, but also realizes multi-directional protection for charging piles and collision vehicles.

Owner:浙江晨泰科技股份有限公司

1.5gpa grade ultra-high-strength, high-plasticity, and high-hole-expansion DH steel plate and preparation method

ActiveCN113388779BReduce manufacturing costRealize industrial productionFurnace typesHeat treatment furnacesThin slabContinuous annealing

Owner:ANGANG STEEL CO LTD

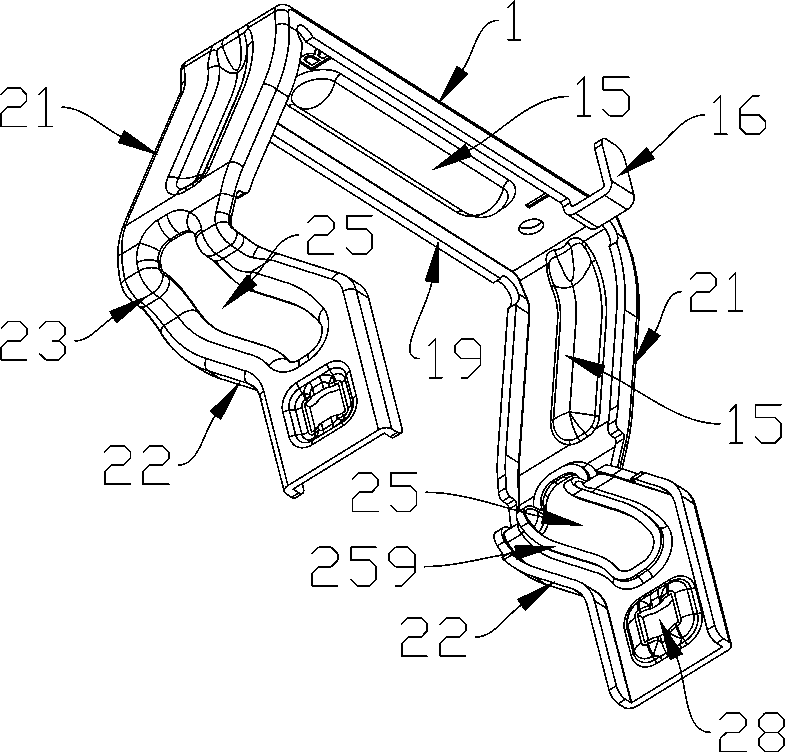

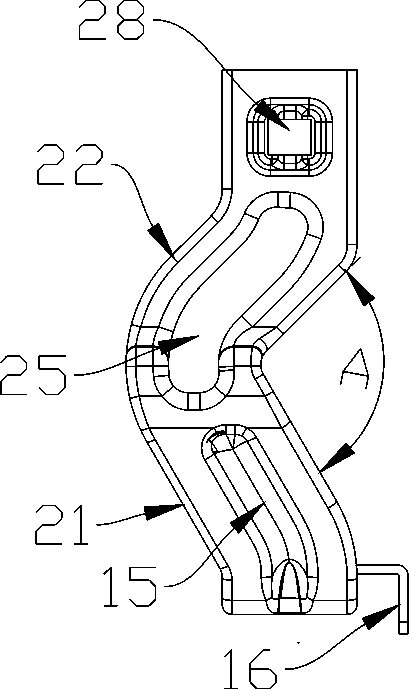

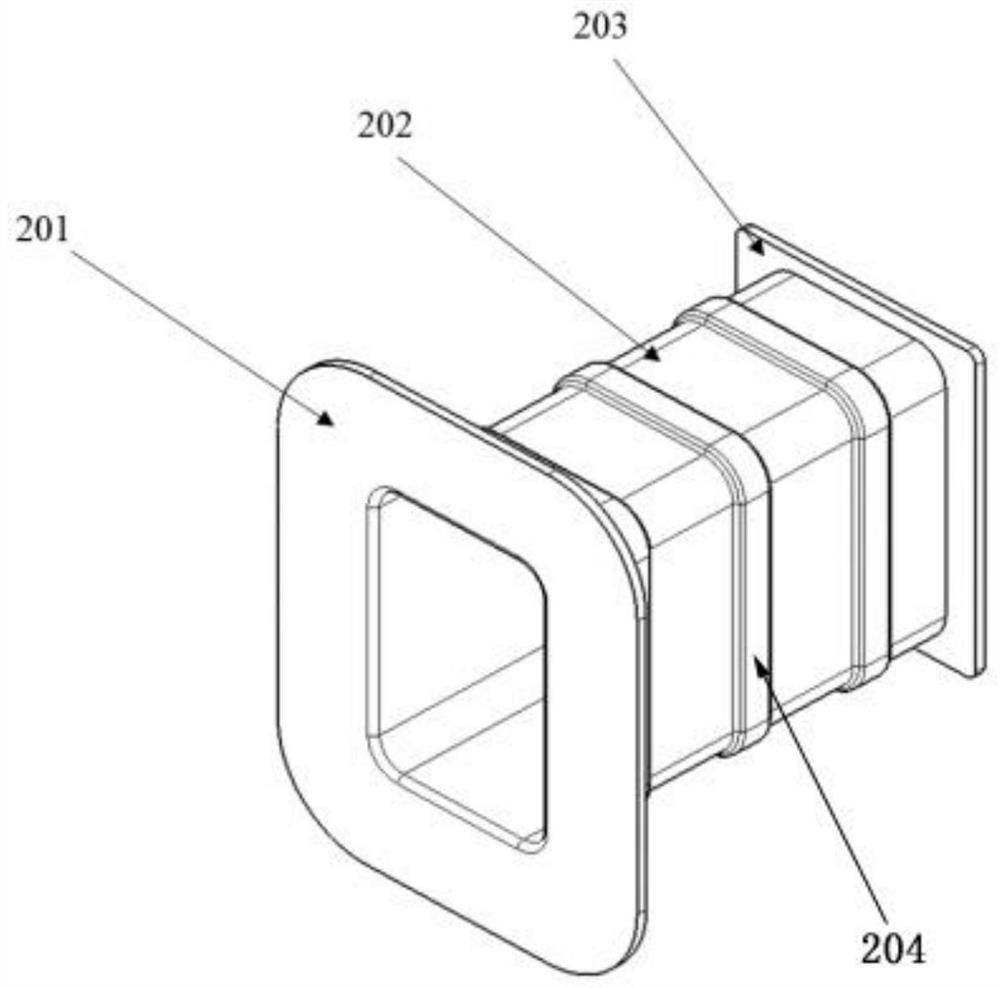

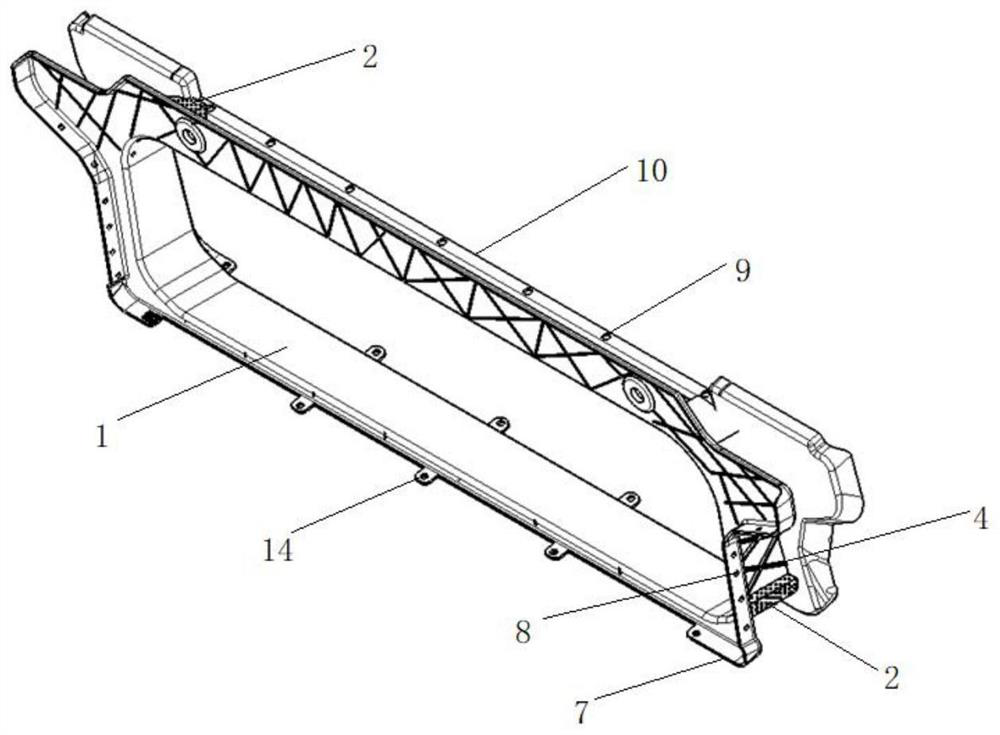

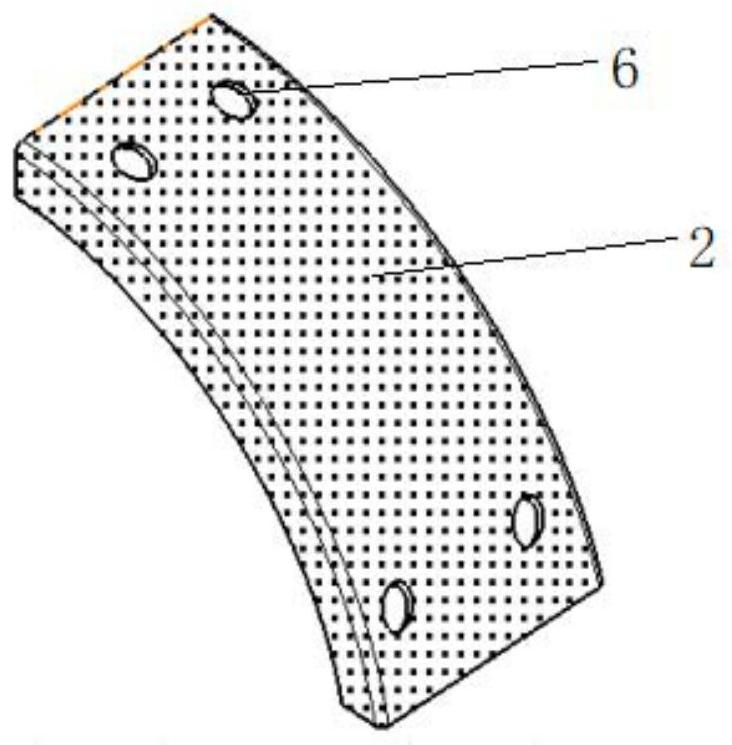

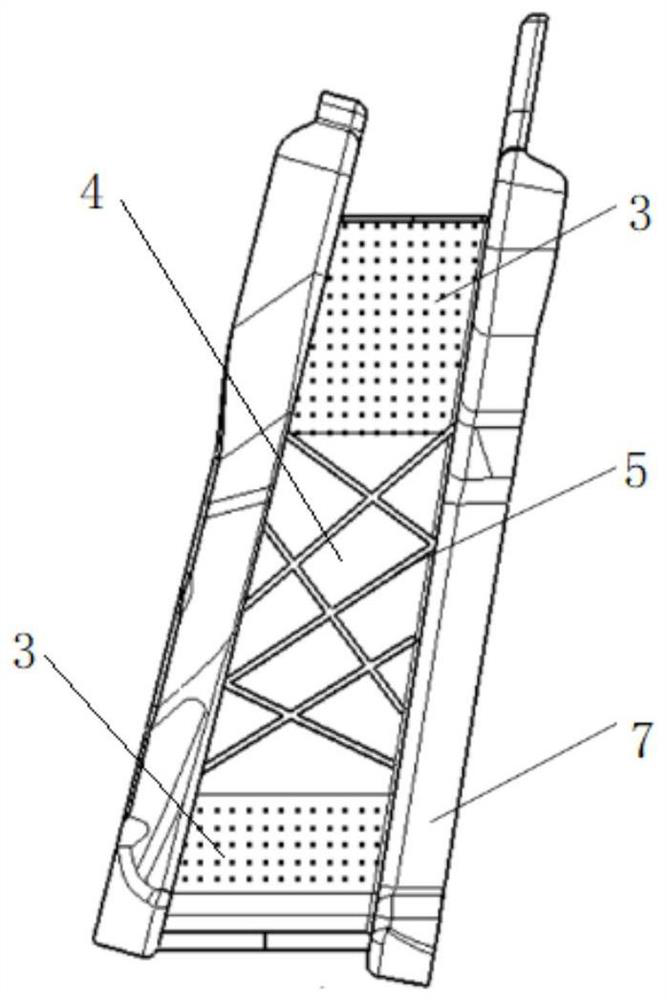

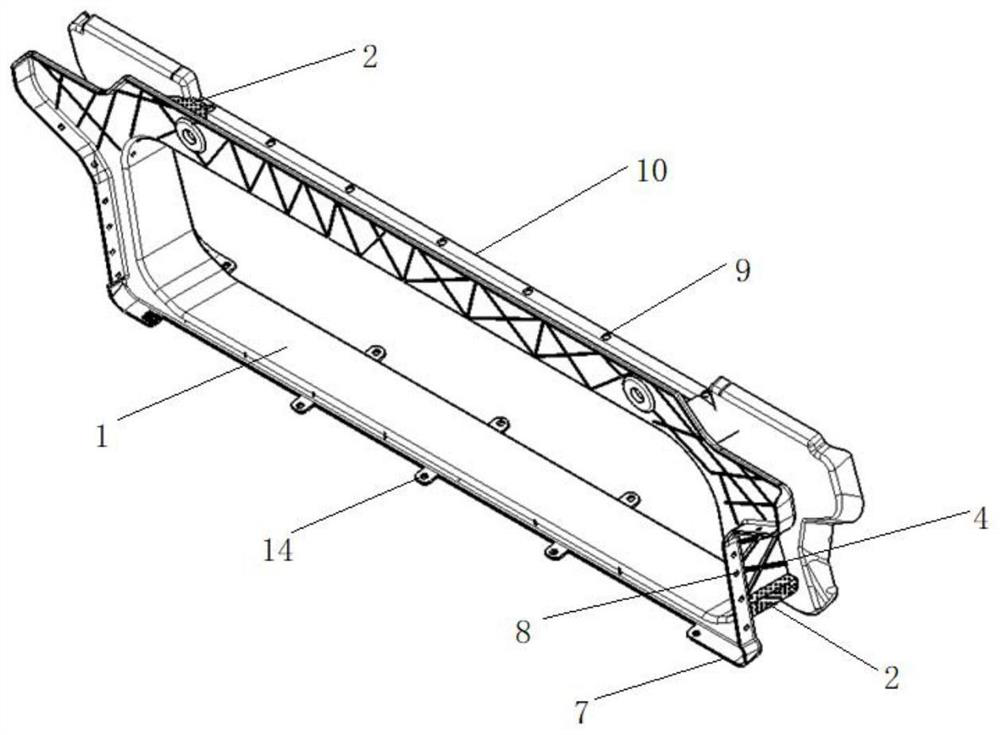

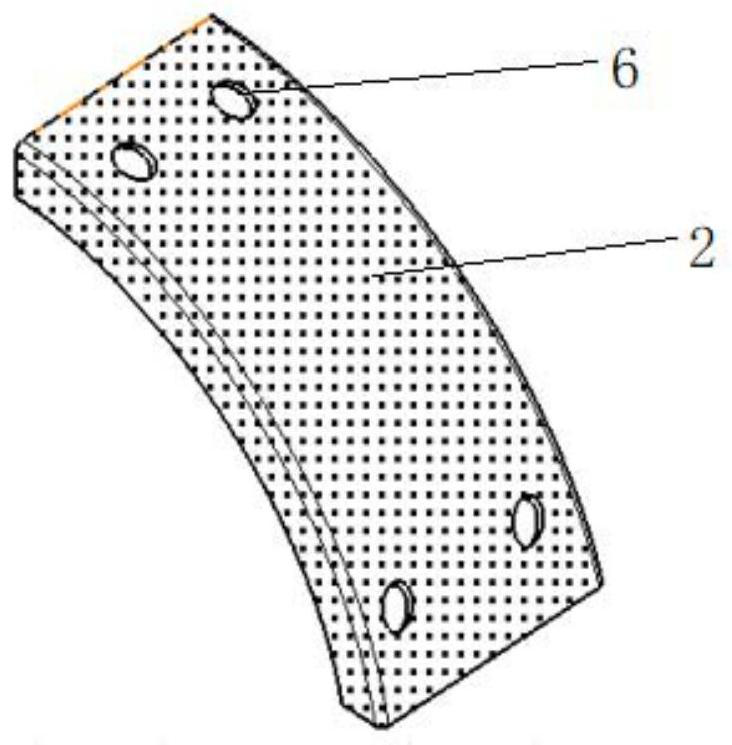

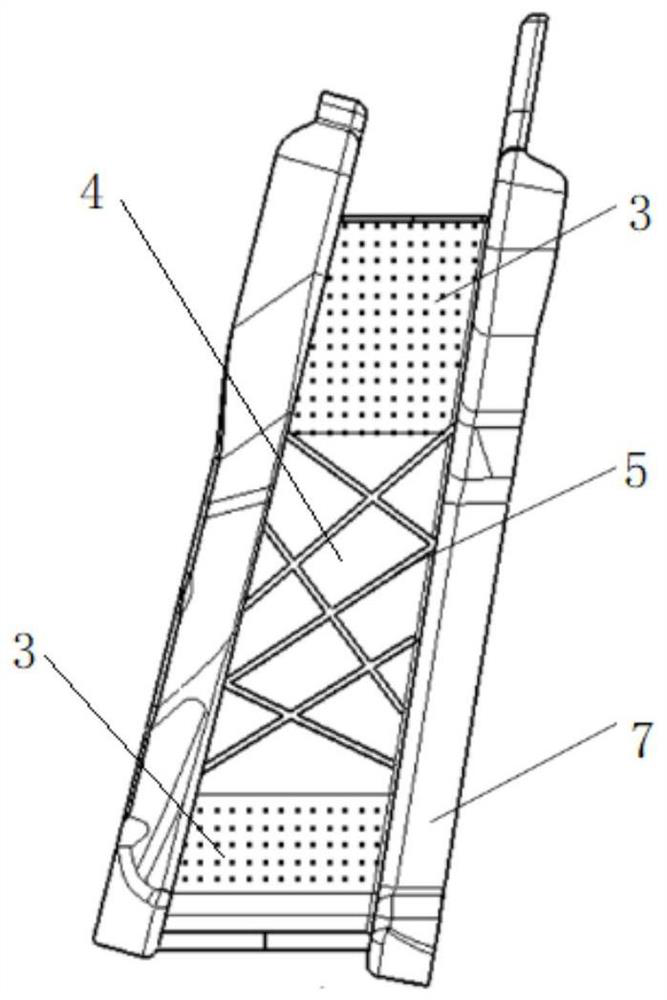

Integrated C-ring structure

ActiveCN112172936AIncreased torsional stiffnessSolve complexitySuperstructuresGlass fiberClassical mechanics

An integrated C-ring structure comprises a framework and foamed aluminum, the framework is integrally formed by nylon 66 and 50% of a glass fiber material through injection molding, the interior of the framework is hollow, and the foamed aluminum comprises foamed aluminum plates arranged at the corners of the framework and detachably and fixedly connected with the framework and foamed aluminum blocks arranged in the framework in a filling mode. The foamed aluminum blocks are filled in the framework, and the torsional rigidity of the C-ring structure can be increased and the degree of freedom of torsional rigidity adjustment can be improved by replacing the foamed aluminum plates with different foaming rates. The framework further comprises side wall vertical plates which are arranged in abilateral symmetry mode, cavities are formed in the side wall vertical plates, and foamed aluminum blocks and reinforcing ribs are arranged in the cavities to further improve the torsional rigidity ofthe C-ring structure. According to the integrated C-ring structure, a plurality of part welding and riveting structures of an original C-ring structure are replaced, the lightweight requirement is met, and meanwhile the torsional rigidity of the C-ring structure can be improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

An integrated c-ring structure

An integrated C-ring structure, including skeleton and aluminum foam, the skeleton is integrally formed by injection molding of nylon 66 and 50% glass fiber material, the interior of the skeleton is hollow, the foam aluminum is set at the corner of the skeleton and is detachable with the skeleton The fixedly connected foam aluminum plates and the foam aluminum blocks filled inside the frame, the frame is filled with foam aluminum blocks and the torsional stiffness of the C-ring structure can be increased by replacing the foam aluminum plates with different foaming rates and the degree of freedom of torsional stiffness adjustment can be improved. The skeleton also includes side wall vertical plates arranged symmetrically on the left and right. A cavity is formed inside the side wall vertical plate, and foam aluminum blocks and reinforcing ribs are arranged inside the cavity to further increase the torsional rigidity of the C-ring structure. The integrated C-ring structure of the present invention replaces the welding and riveting structure of many parts of the original C-ring structure, meets the requirement of light weight and can increase the torsional rigidity of the C-ring structure.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com