A kind of manufacturing method of high-frequency characteristic copper-clad laminate

A production method and high-frequency characteristic technology, which is applied in the field of high-frequency characteristic copper clad laminates, can solve the problems of poor PCB processing performance, low glass transition temperature, brittle polyphenylene ether material, etc., and achieve excellent flame retardancy and excellent mechanical properties Performance, Effect of High Glass Transition Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a high-frequency characteristic copper clad laminate includes the following steps:

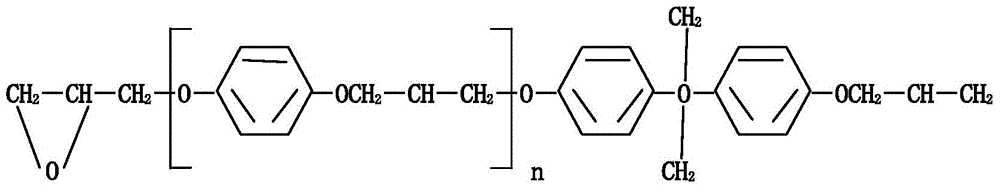

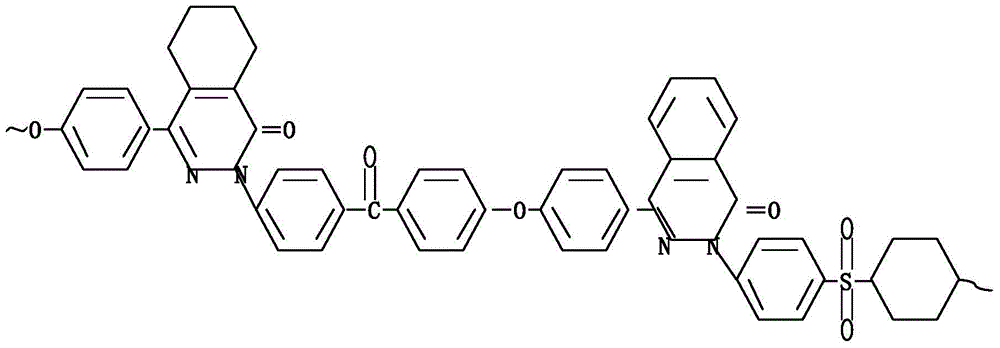

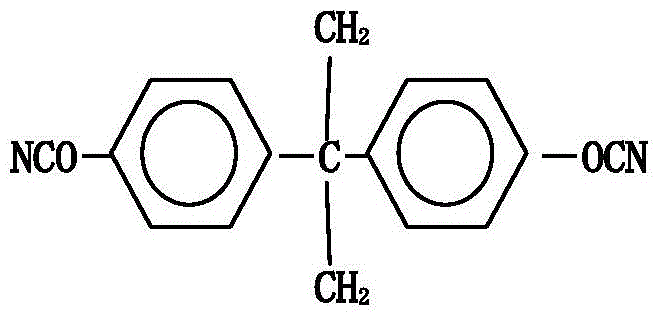

[0031] 1. First add 100 parts by weight of bisphenol A type bifunctional novolac epoxy resin and 22 parts by weight of bisphenol A type cyanate resin into the reactor, and then add 10 parts by weight of miscellaneous Biphenyl polyaryl ether, hetero narbiphenyl polyaryl ether is dissolved in dimethyl formamide before adding, and then the temperature of the reaction kettle is heated to about 100 ℃, and the mixture is uniformly stirred for 3 hours to prepare the poly nararyl biphenyl polyaryl ether. Ether / epoxy blend.

[0032] 2. Take 30 parts by weight of diaminodiphenyl sulfone (DDS) curing agent and 0.09 parts by weight of dimethylimidazole curing accelerator into the dissolving tank, then add 35 parts by weight of acetone as solvent, and stir to diaminodiphenyl After the sulfone and dimethylimidazole were completely dissolved, they were added to the reaction kett...

Embodiment 2

[0036] A method for manufacturing a high-frequency characteristic copper clad laminate includes the following steps:

[0037] 1. First add 105 parts by weight of bisphenol A type bifunctional novolac epoxy resin and 27 parts by weight of bisphenol A cyanate resin into the reactor, and then add 12 parts by weight of miscellaneous naphthalene Biphenyl polyaryl ether, hetero narbiphenyl polyaryl ether is dissolved in dimethyl formamide before adding, and then the temperature of the reactor is heated to about 100 ℃, and the mixture is uniformly stirred for 3 hours. Ether / epoxy blend.

[0038] 2. Take 33 parts by weight of diaminodiphenyl sulfone (DDS) curing agent and 0.06 parts by weight of 2-ethylimidazole curing accelerator into the dissolving tank, then add 40 parts by weight of methyl ethyl ketone as a solvent, and stir to diamino After the diphenyl sulfone and 2-ethylimidazole were completely dissolved, they were added to the reactor containing 135 parts by weight of the polyary...

Embodiment 3

[0042] A method for manufacturing a high-frequency characteristic copper clad laminate includes the following steps:

[0043] 1. First add 110 parts by weight of bisphenol A type bifunctional novolac epoxy resin and 20 parts by weight of bisphenol A cyanate resin into the reactor, and then add 15 parts by weight of miscellaneous Biphenyl polyaryl ether, hetero narbiphenyl polyaryl ether is dissolved in dimethyl formamide before adding, and then the temperature of the reaction kettle is heated to about 100 ℃, and the mixture is uniformly stirred for 3 hours to prepare the poly nararyl biphenyl polyaryl ether. Ether / epoxy blend.

[0044] 2. Take 27 parts by weight of diaminodiphenyl sulfone (DDS) curing agent and 0.075 parts by weight of dimethylimidazole curing accelerator into the dissolving tank, then add 45 parts by weight of acetone as a solvent, and stir to diaminodiphenyl After the sulfone and dimethylimidazole were completely dissolved, they were added to the reactor contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com