A kind of 600mpa grade multi-phase steel with good flanging performance and its production method

A multi-phase steel and performance technology, which is applied in the field of 600MPa grade multi-structured steel for automotive safety structural parts, can solve the problems of being unsuitable for industrial production, prone to cracking, poor formability, etc., and achieve good hole expansion and flanging performance. The effect of good forming performance and good collision energy absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below:

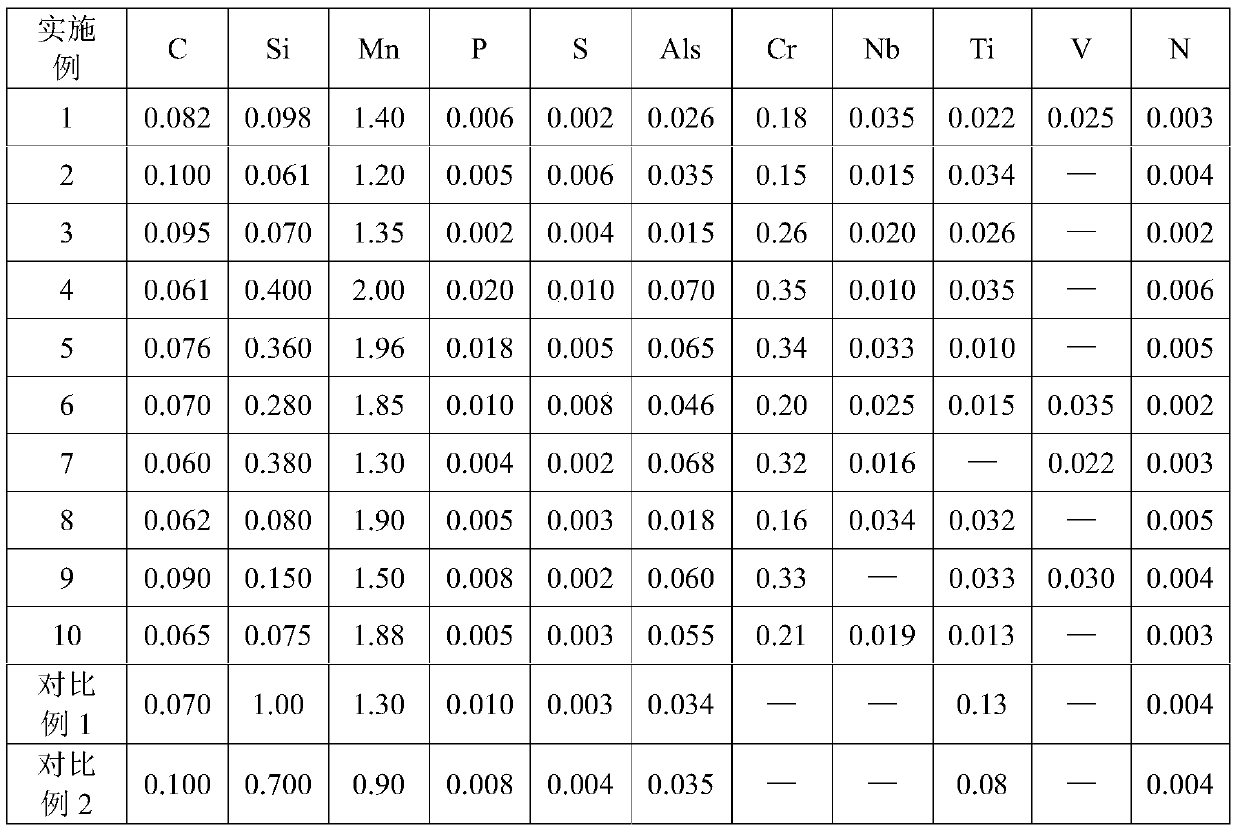

[0044] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

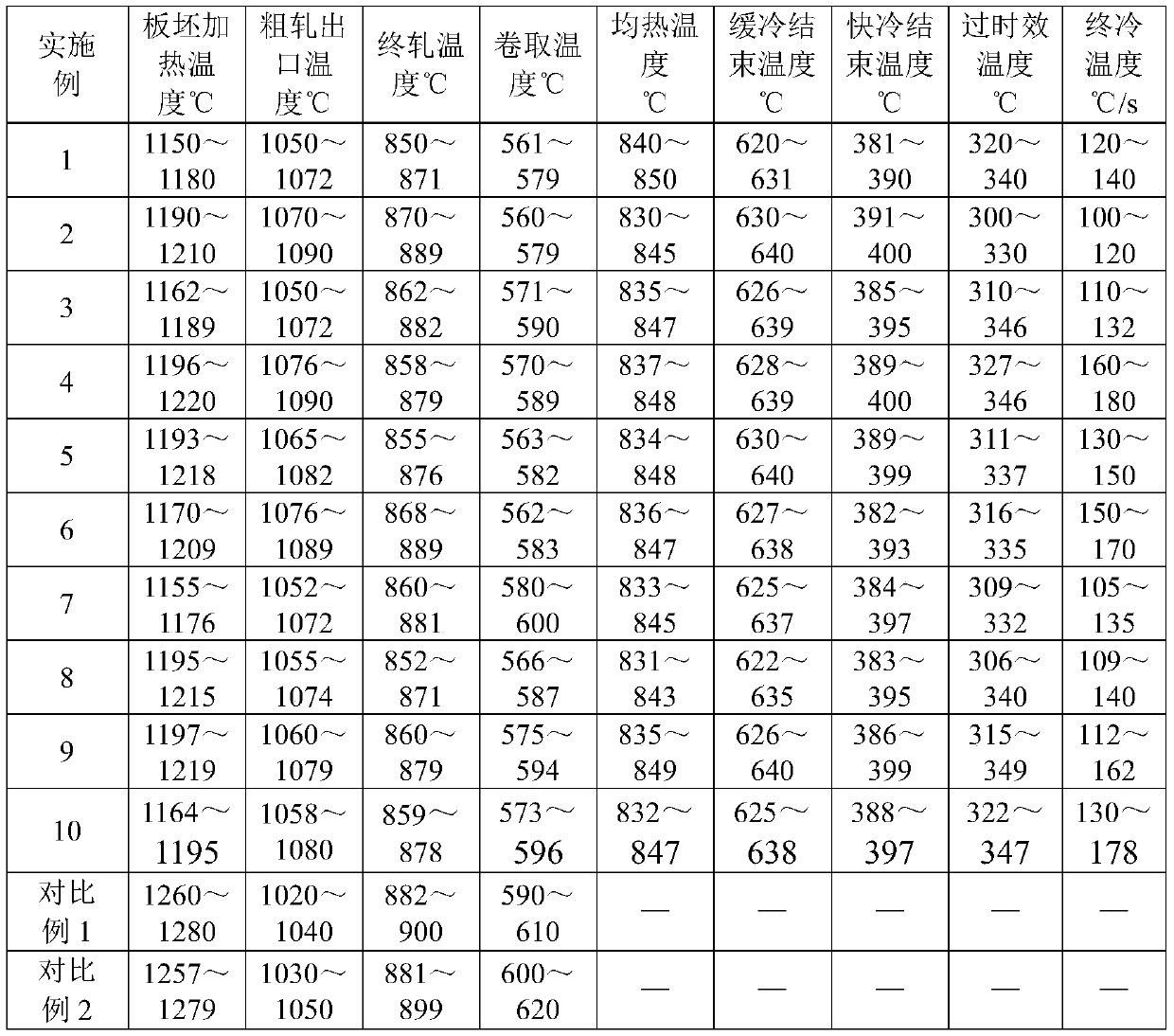

[0045] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative examples;

[0046] Table 3 is a list of performance testing conditions of each embodiment of the present invention and comparative examples.

[0047] Each embodiment of the present invention all produces according to the following steps:

[0048] 1) Set the slab after conventional smelting according to the composition, and control the superheat of the slab to 25-40°C;

[0049] 2) Carry out hot rolling process:

[0050] A. First, heat the slab, and control the heating temperature at 1150-1220°C;

[0051] B. Rough rolling is carried out, and the phosphorus removal pass of rough rolling is controlled not less than 3 times, and the exit temperature of rough rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com