Ultra-high molecular polyethylene gear pump

An ultra-high polymer, polyethylene technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of sticky materials, complex processing, high noise, etc., to achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

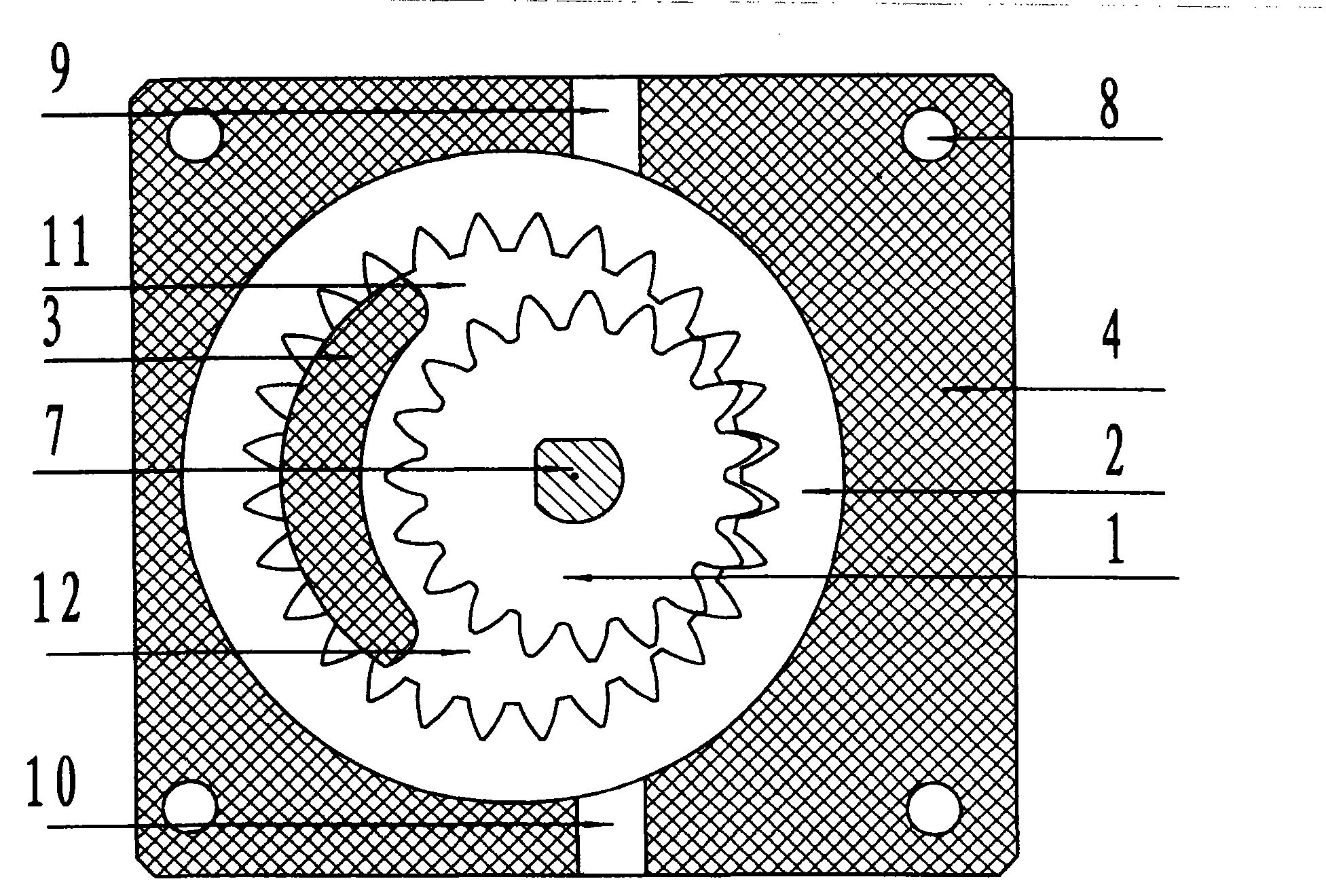

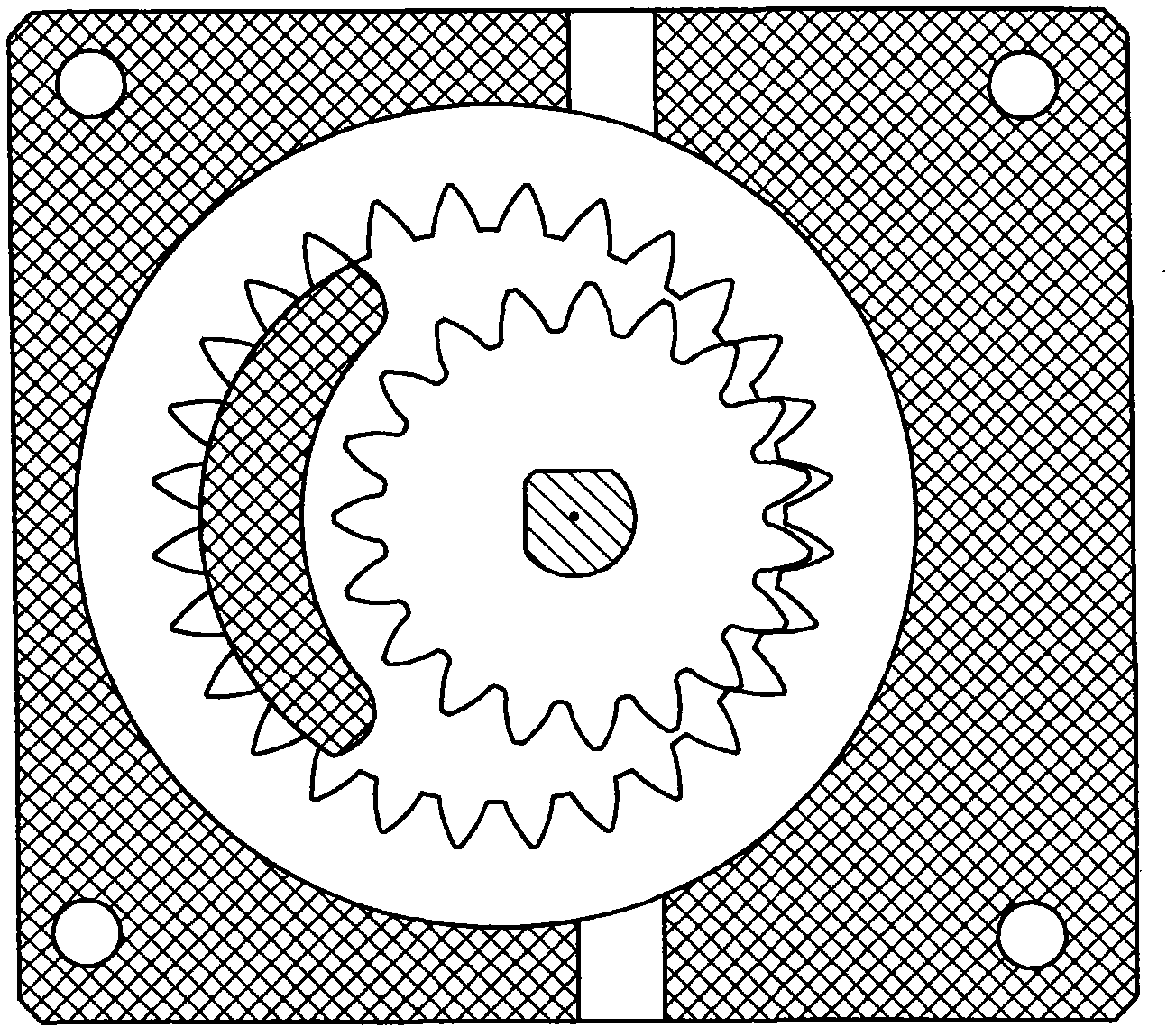

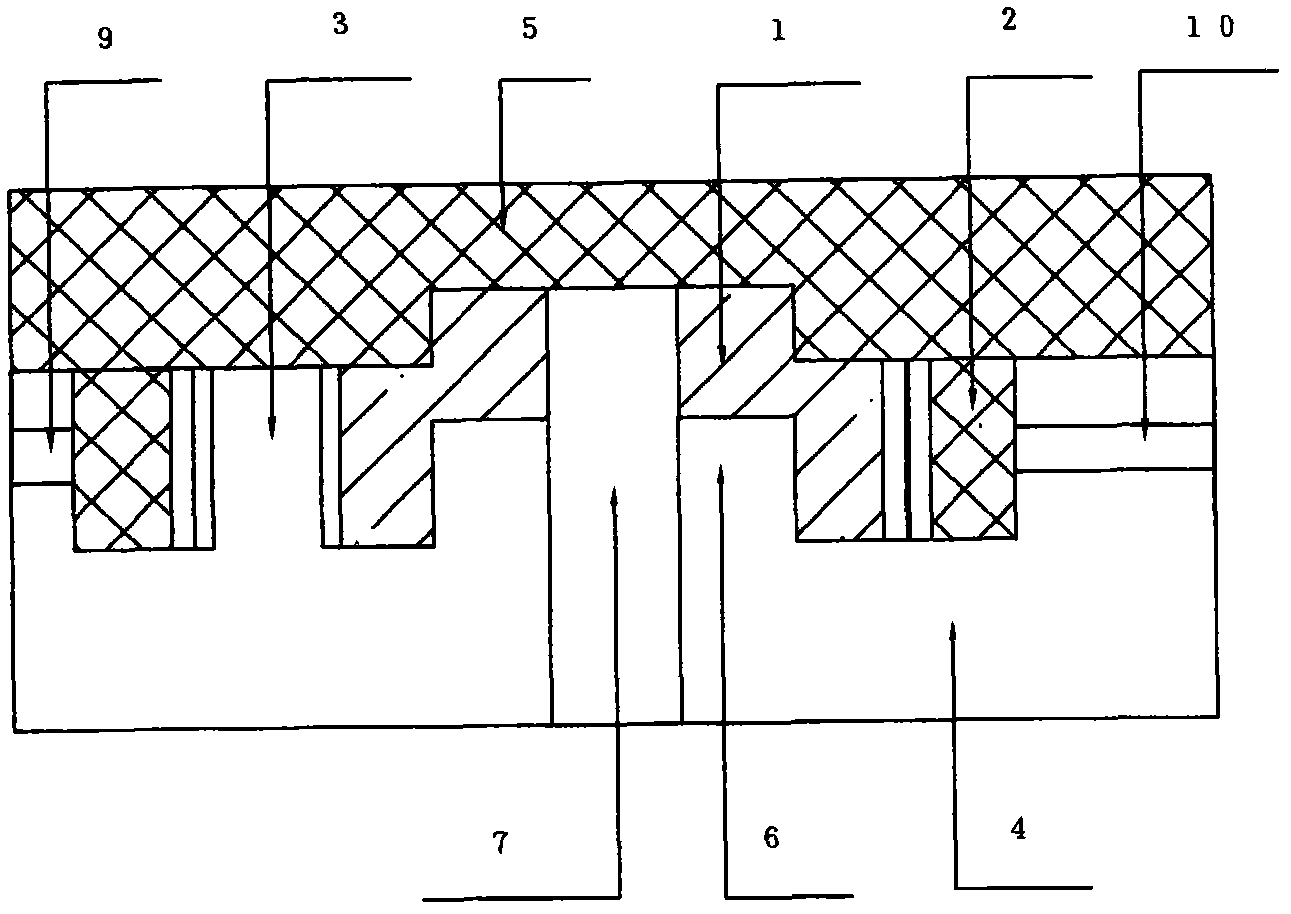

[0016] figure 1 , 3 represents the embodiment of the ultra-high molecular polyethylene gear pump of the present invention, the driving wheel 1 is processed and formed by metal materials, the driven wheel 2 is processed and formed by ultra-high molecular polyethylene profiles, the modulus is the same as that of the driving wheel 1, and the pump body 4. The gland 5 is formed by ultra-high molecular polyethylene profiles in CNC equipment milling, or molded and sintered. The crescent plate 3, the boss 6 and the pump body 4 are integrally formed. The driving wheel 1 is positioned on the boss 6 and the drive shaft 7 The driven wheel 2 is eccentrically installed in the gear compartment of the pump body 4, and meshes with the driving wheel 1 to form a gear pair. The crescent plate 3 is located between the driving wheel 1 and the driven wheel 2 to separate the oil suction chamber 11 and the pressure oil chamber 12. The gland 5 is fixed on the end face of the pump body 4 with bolts 8. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com