External driving type quick switch structure

A fast switch and external drive technology, applied in the direction of electric switches, explosive switches, electrical components, etc., can solve the problems of large heat generation, large internal resistance, poor current impact resistance, etc., and achieve the effect of absorbing impact energy well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

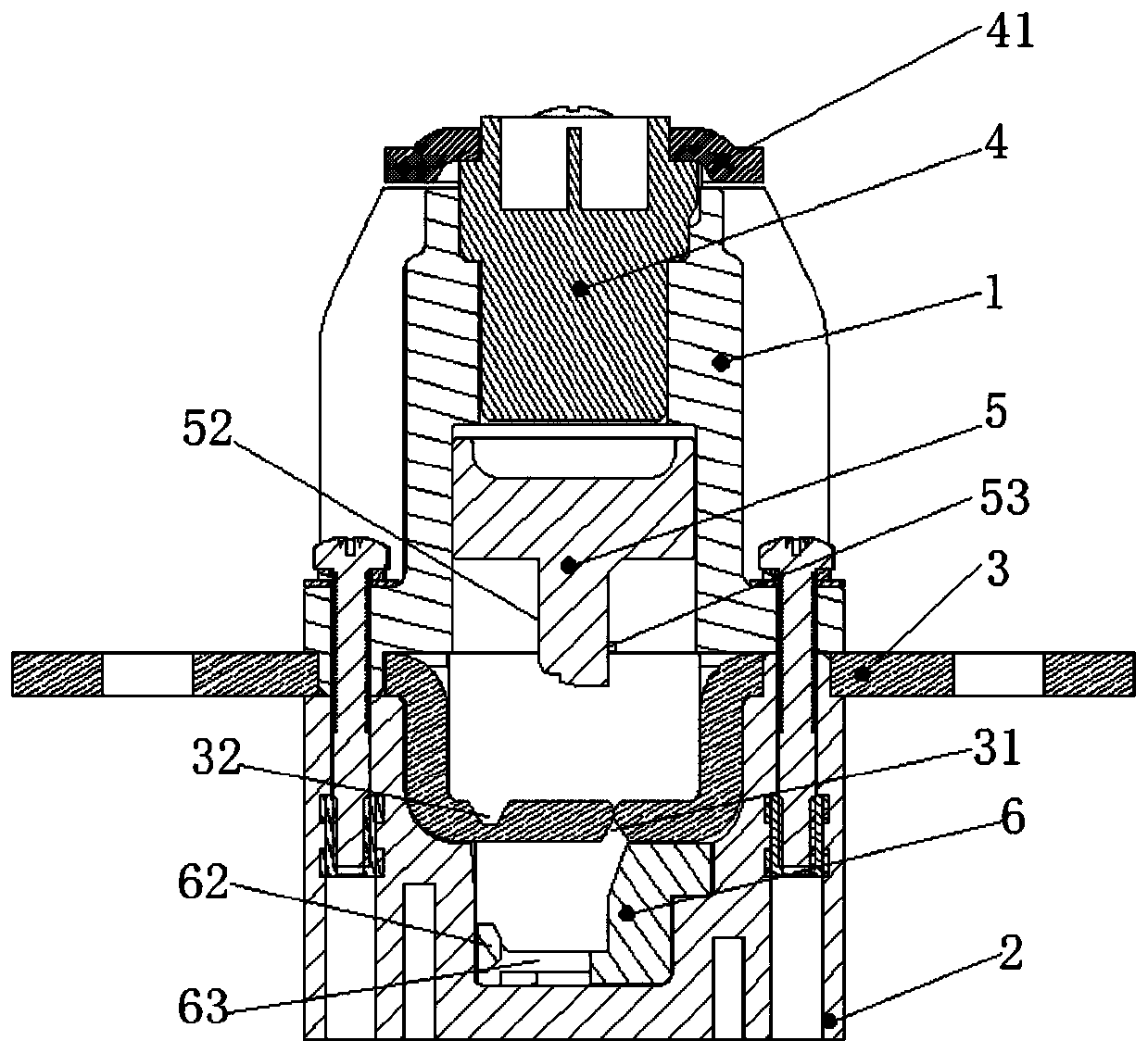

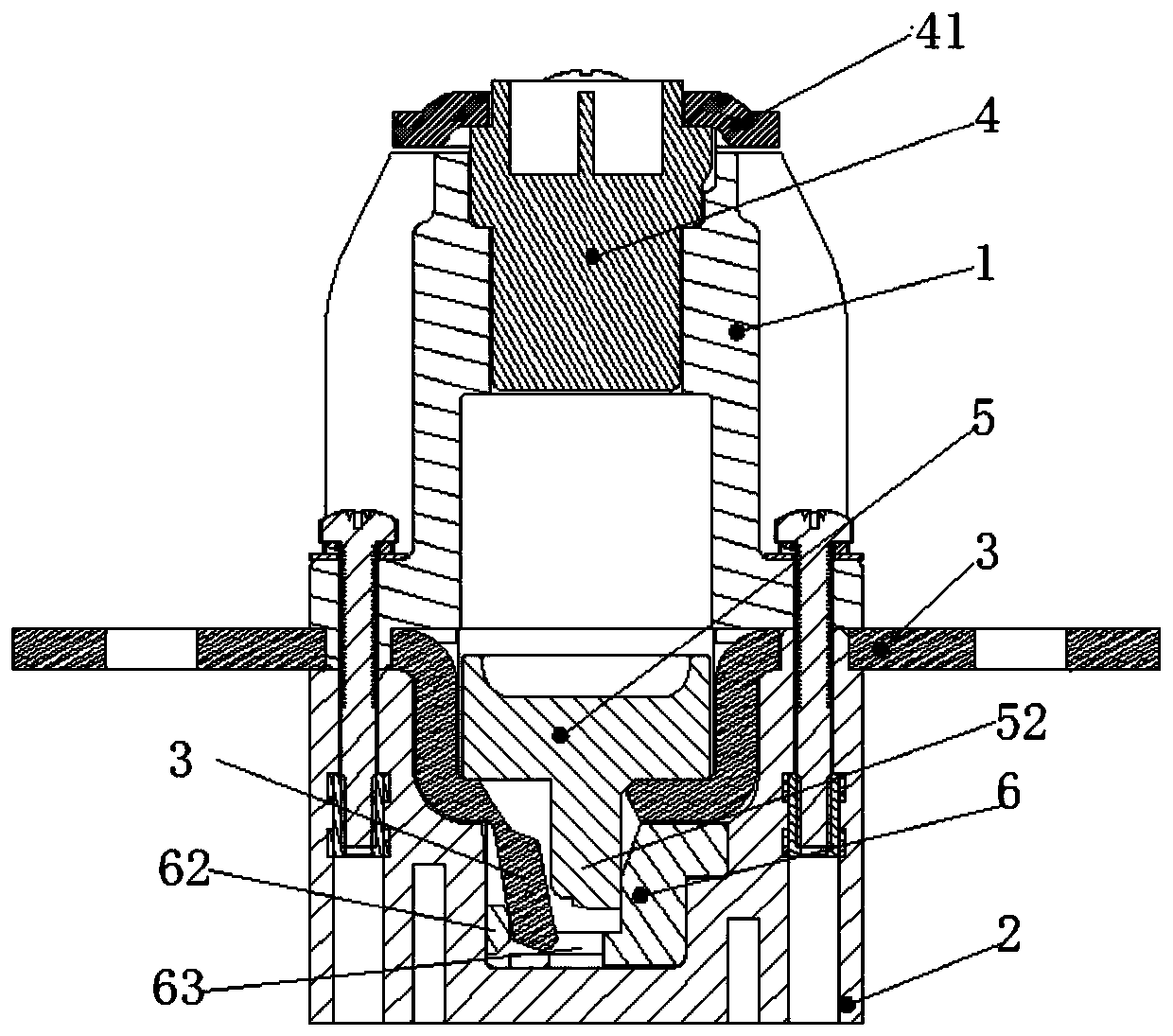

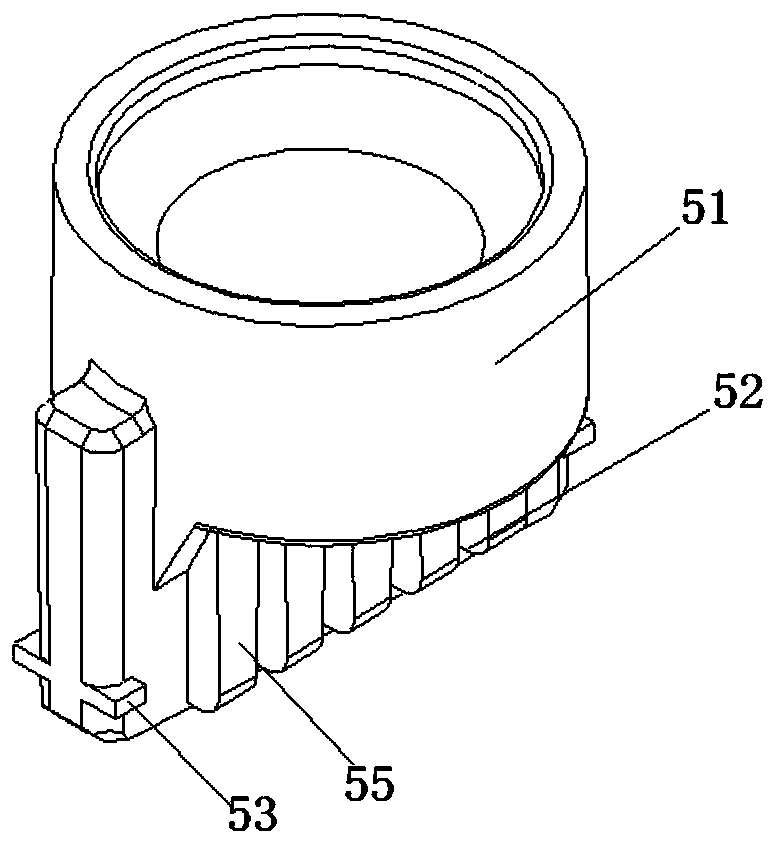

[0029] With regard to the above technical solutions, embodiments are given and described in detail in combination with figures. The fast current cut-off device of the present invention mainly includes an upper casing, a conductive plate, a lower casing, a gas generating device, etc., see Figure 1 to Figure 6 ,in.

[0030] The casing, in this embodiment, is composed of an upper casing 1 and a lower casing 2 spliced together. A conductive plate 3 is arranged between the contact surface of the upper shell and the lower shell, and the upper shell, the lower shell and the conductive plate are fixed together by screws between the upper shell and the lower shell. The contact parts between the conductive plate and the upper casing and the lower casing are sealed.

[0031] An accommodating cavity is opened in the upper housing. In this embodiment, the accommodating cavity is divided into upper and lower parts and arranged through. An electronic ignition and explosive device 4 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com