Waterproof detection method for battery pack

A detection method and a technology of a battery pack, which are applied in the direction of detecting the appearance of fluid at the leakage point, measuring the increase and decrease rate of the fluid, and using liquid/vacuum to measure the liquid tightness, etc., can solve the problem of time-consuming, labor-intensive, and high-efficiency Inefficient and other problems, to achieve the effect of convenient detection, high detection efficiency, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

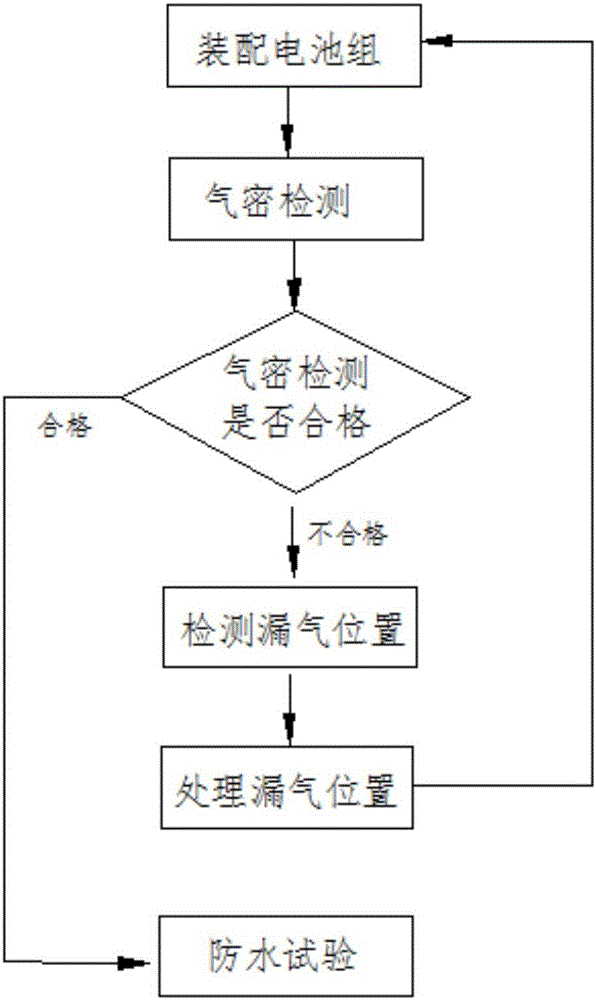

[0025] The battery pack waterproof detection method of this embodiment includes the following steps:

[0026] S1. Assemble the battery pack according to the waterproof level of IPX7;

[0027] S2. Connect the air tightness detector to the battery pack and the air source, and the relative humidity of the air source is 75%, to obtain a battery pack that has passed the air tightness test and a battery pack that has failed the air tightness test;

[0028] S3, using the humidity card detection step S2 to airtightly detect the leaking position of the unqualified battery pack, and process the leaking position of the battery pack;

[0029] S4. Repeat steps S1-S3 for the battery pack processed in step S3 until the airtight test is qualified;

[0030] S5. Perform a waterproof test on the battery packs that pass the airtight test in step S2.

[0031] In step S2, the air tightness detector is connected to the battery pack and the air source, and the air source with a relative humidity of...

Embodiment 2

[0033] The battery pack waterproof detection method of this embodiment includes the following steps:

[0034] S1. Assemble the battery pack according to the waterproof level of IPX7;

[0035] S2. Connect the air tightness detector to the battery pack and the air source, and the relative humidity of the air source is 80%, the air source is charged into the battery pack, the detected air pressure is 5KPa, the pressure is maintained for 90s, the air leakage rate is 92Pa, and the air leakage rate is tested If it is less than 150Pa, the result is qualified, and the battery pack that passes the airtight test is obtained;

[0036] S3. Conduct the waterproof test on the battery pack that passed the airtight test in step S2. Put the battery pack in 1m deep water and let it stand for 30 minutes. Then, take it out of the water, open the box, and find that there is no water leakage, that is, the waterproof test is qualified.

Embodiment 3

[0038] The battery pack waterproof detection method of this embodiment includes the following steps:

[0039] S1. Assemble the battery pack according to the waterproof level of IPX7;

[0040] S2. Connect the air tightness detector to the battery pack and the air source, and the relative humidity of the air source is 85%, the air source is charged into the battery pack, the detected air pressure is 4.2KPa, the pressure is maintained for 90s, the air leakage rate is 160Pa, and the air leakage is checked rate is greater than 150Pa, the result is unqualified, and the battery pack that fails the air tightness test is obtained;

[0041] S3. For the battery pack that fails the air tightness test, use the humidity card to detect the leak position, and find that there is a screw position on the flange side of the battery pack box, the humidity card shows the color, open the box cover and find that the sealing ring here has been damaged , replace the sealing ring;

[0042] S4. Repeat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com