Differential signal cable

A differential signal and cable technology, applied in the field of high-speed data transmission, can solve the problems of increasing the effective dielectric constant, increasing the diameter of high-speed digital signal transmission cables, etc., to achieve fast signal propagation, light weight, and good bending stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

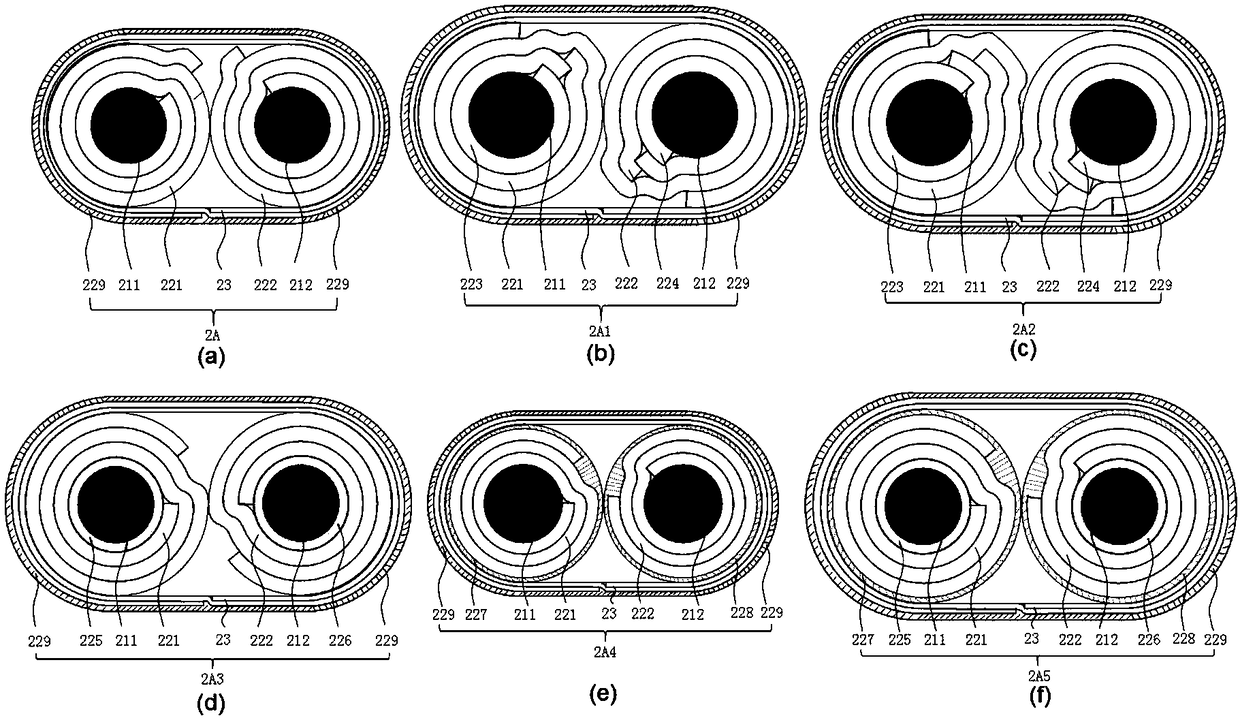

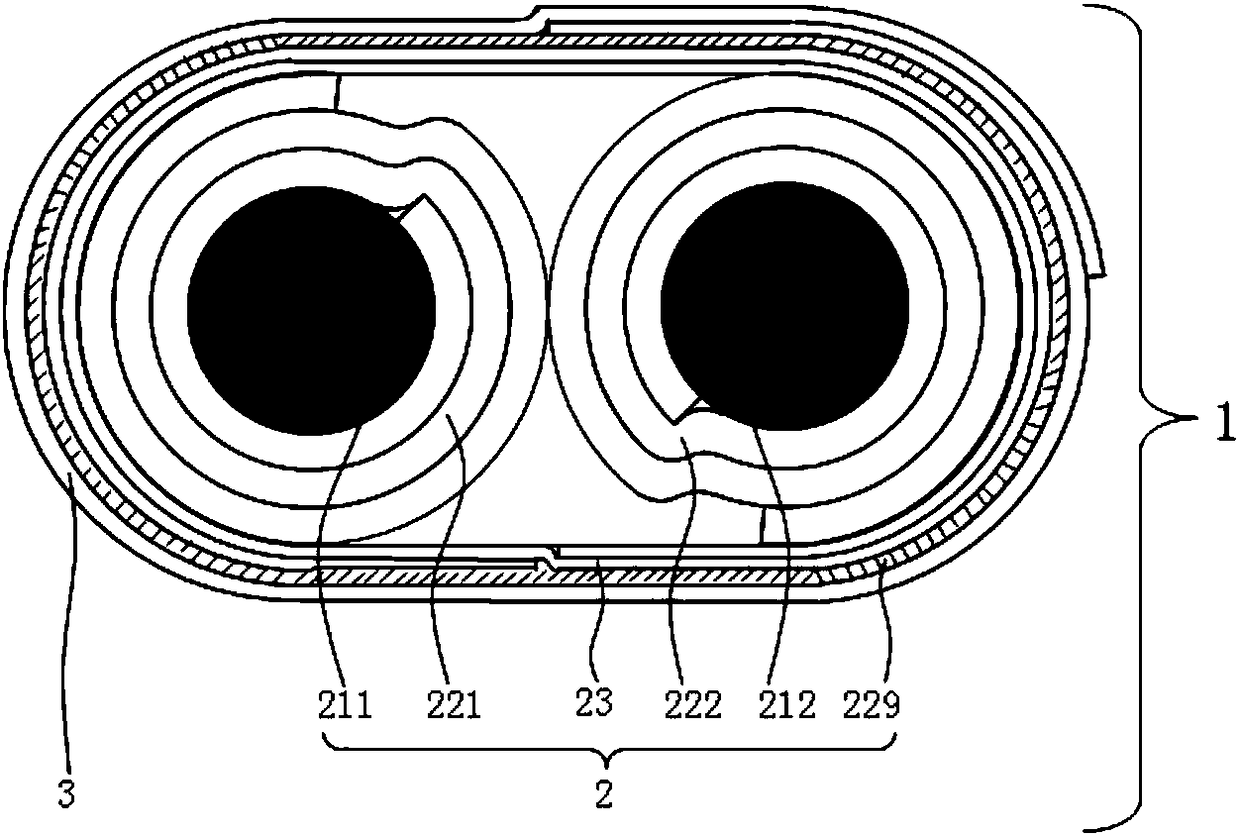

[0075] figure 2 It shows the cross-sectional structure diagram of Embodiment 1 of the differential signal cable of the present invention. Depend on figure 2 It can be seen that the differential signal cable 1 of the present invention is composed of an insulating core wire 2 and a shielding layer 3 . The insulated core wire 2 is composed of a pair of double conductors 211, 212 placed in parallel, first insulating dielectric tapes 221, 222 respectively wrapped on the double conductors 211, 212, and the first insulating dielectric tapes 221, 222 and the insulating stable layer 23 formed by co-wrapping the insulating stable layer 23 and the extruded third extruded insulating medium 229 covered outside the insulating stable layer 23. The insulation stabilization layer 23 tightly wraps the double conductors 211, 212 wrapped by the first insulating dielectric strips 221, 222 and the first insulating dielectric strips 221, 222 as a whole to enhance the fastening stability of the c...

Embodiment 2

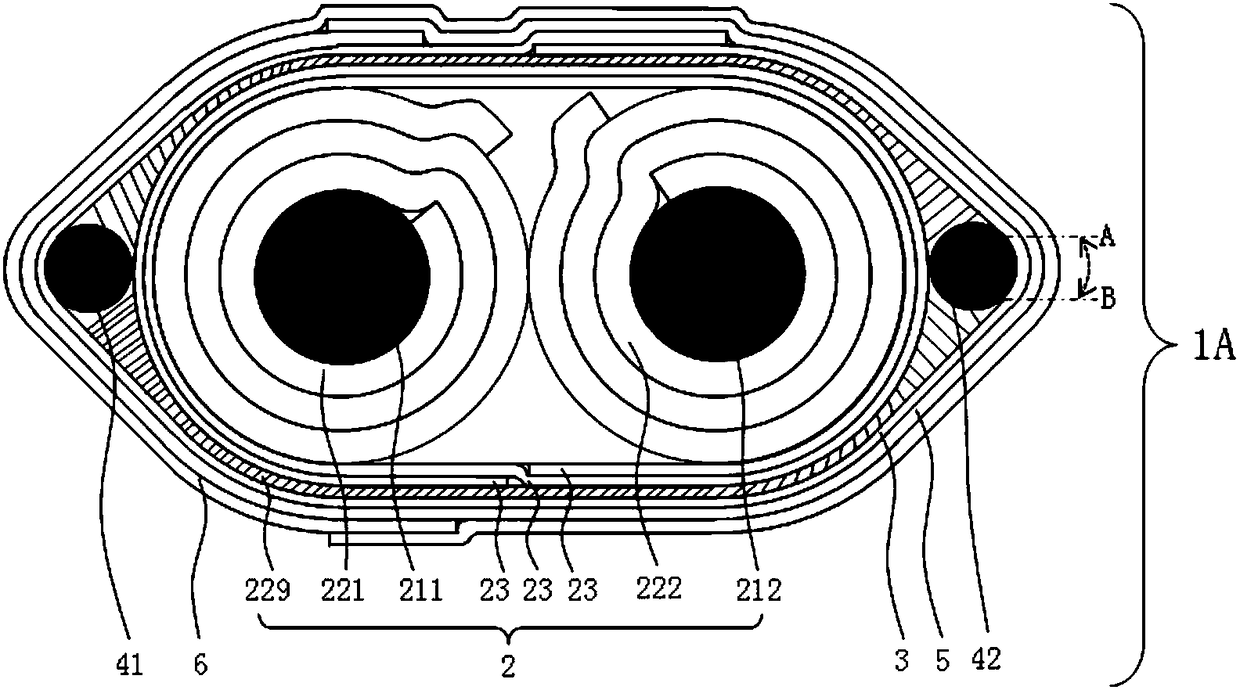

[0082] image 3 It shows the cross-sectional schematic diagram of Embodiment 2 of the differential signal cable of the present invention (the view perpendicular to the length direction of the conductor). Depend on image 3It can be seen that the differential signal cable 1A of the present invention is composed of an insulating core wire 2 , a shielding layer 3 , a first stable layer 5 , a second stable layer 6 and drain wires 41 and 42 . The insulated core wire 2 is composed of a pair of double conductors 211, 212 placed in parallel, first insulating dielectric tapes 221, 222 respectively wrapped on the double conductors 211, 212, and the first insulating dielectric tapes 221, 222 and the insulating stable layer 23 formed by co-wrapping the insulating stable layer 23 and the extruded third extruded insulating medium 229 covered outside the insulating stable layer 23. The insulation stabilization layer 23 tightly wraps the double conductors 211, 212 wrapped by the first insul...

Embodiment 3

[0092] Figure 4 Represents a schematic structural view of Embodiment 3 of the differential signal cable of the present invention, wherein Figure 4 (a) is a schematic structural diagram of a metal foil strip with a width difference between the two ends of the metal foil 31 and the carrier 32, Figure 4 (b) is a schematic diagram of the cross-sectional structure of the differential signal cable 1B (a view perpendicular to the length direction of the conductor). Depend on Figure 4 It can be seen that the differential signal cable 1B of the present invention is composed of an insulating core wire 2 , a shielding layer 3 , a first stable layer 5 , a second stable layer 6 and drain wires 41 and 42 . The insulated core wire 2 is composed of a pair of double conductors 211, 212 placed in parallel, first insulating dielectric tapes 221, 222 respectively wrapped on the double conductors 211, 212, and the first insulating dielectric tapes 221, 222 and the insulating stable layer 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com