A connection method and structure of a seal inspection pup joint and a test and adjustment pup joint

A technology of sealing sub-joints and measuring and adjusting sub-joints, which is applied to fixed/insulating contact components, earthwork drilling, drilling equipment, etc., can solve the problems of inconvenient maintenance of sealing sub-joints, improve convenience and improve wiring Multiple, simple maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

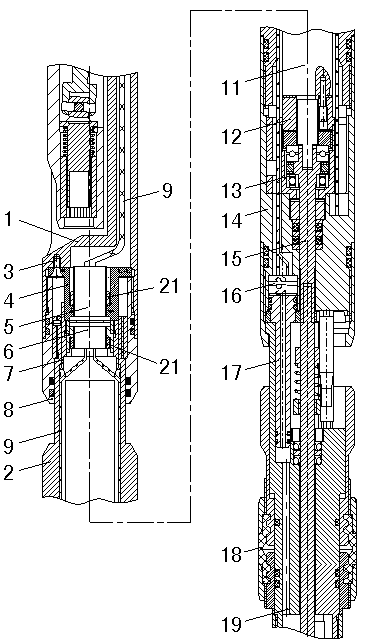

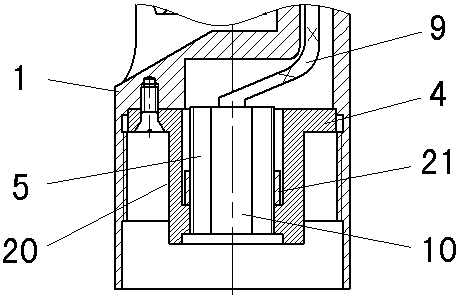

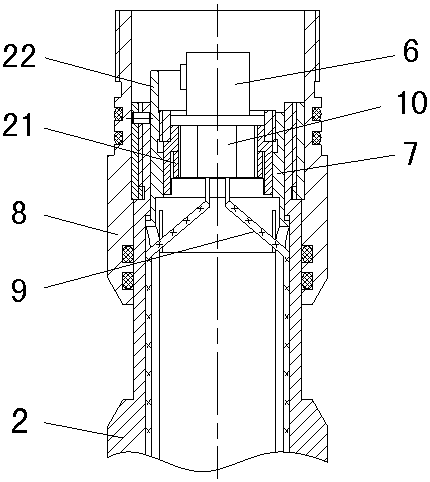

[0024] This example figure 1 As shown, due to the long length of the graph, figure 1 The picture is divided into two parts. Depend on figure 1 It can be seen that this example consists of a test and adjustment nipple 1, a seal inspection nipple 2, a screw 3, a socket bracket 4, a socket 5, a plug 6, a positioning outer tube 7, a free-cut screw plug 8, a wire harness 9, a seal inspection motor 11, Flange assembly 12, bearing assembly 13, installation head 14, transmission shaft 15, formation pressure sensor 16, pressure induction pipe 17, leather cup 18, pressure induction port 19, whole well pressure sensor ( figure 1 Not shown in), nut 21, semicircle boss 22, semicircle groove 20 etc. composition. Installation head 14, formation pressure sensor 16, full well pressure sensor ( figure 1 Not shown in ), the pressure induction pipe 17, the transmission shaft 15, the seal inspection motor 11, the leather cup 18, etc. are the components of the seal inspection nipple 2. The for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com