Nylon plastic bearing retainer for draw-bar box and preparation method of nylon plastic bearing retainer

A technology of bearing cage and nylon plastic, which is applied in the field of nylon plastic bearing cage for trolley case and its preparation, which can solve the problems of affecting the service life of the product, poor low temperature resistance, easy breakage, collapse, etc., and achieve improved fluidity and cold resistance The effect of increasing sexuality and avoiding reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

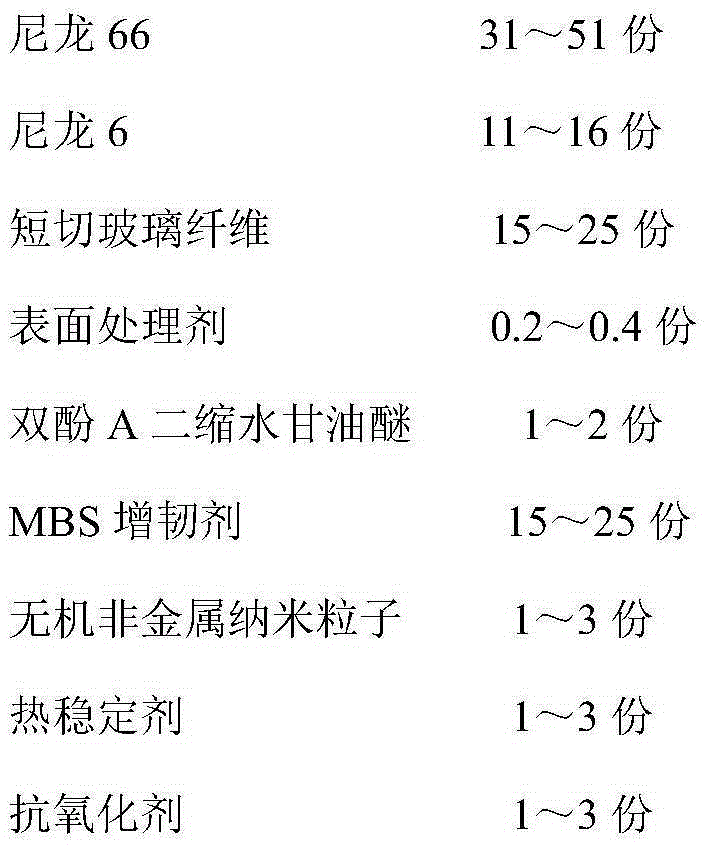

preparation example Construction

[0032] Described preparation method comprises the steps:

[0033] 1) Mix the nylon 66 and nylon 6 in the weight portion, and bake continuously at 80°C to 90°C for 12h to 24h to prepare composite nylon;

[0034] 2) Add the said parts by weight of inorganic non-metallic nanoparticles and 0.01 to 0.1 parts by weight of surface treatment agent into a high-speed mixer, and perform surface activation treatment at 125°C to 130°C for 10 to 15 minutes to obtain activated inorganic non-metallic nanoparticles;

[0035] 3) Add the chopped glass fibers in the parts by weight and the surface treatment agent in the remaining parts by weight into a high-speed mixer, and perform surface activation treatment at 125° C. to 130° C. for 10 to 15 minutes to obtain activated chopped glass fibers ;

[0036] 4) The composite nylon obtained in step 1), the activated inorganic non-metallic nanoparticles obtained in step 2), and MBS toughening agent, bisphenol A diglycidyl ether, heat stabilizer, antio...

Embodiment 1

[0040] A nylon plastic bearing cage for a trolley case, the raw material of which is composed of the following components by weight:

[0041]

[0042] Described preparation method comprises the steps:

[0043] 1) Mix the nylon 66 and nylon 6 in the said parts by weight, and dry continuously at 80° C. for 12 hours to prepare composite nylon;

[0044] 2) adding the calcium carbonate of the described weight part and the silane coupling agent of 0.01 weight part in the high-speed mixer, carry out the surface activation treatment at 125 ℃ for 10 minutes, obtain the activated calcium carbonate;

[0045] 3) Adding the chopped glass fibers in the parts by weight and the silane coupling agent in the remaining parts by weight into a high-speed mixer, and performing surface activation treatment at 125° C. for 10 minutes to obtain activated chopped glass fibers;

[0046] 4) The composite nylon obtained in step 1), the activated calcium carbonate obtained in step 2), and the MBS toughe...

Embodiment 2

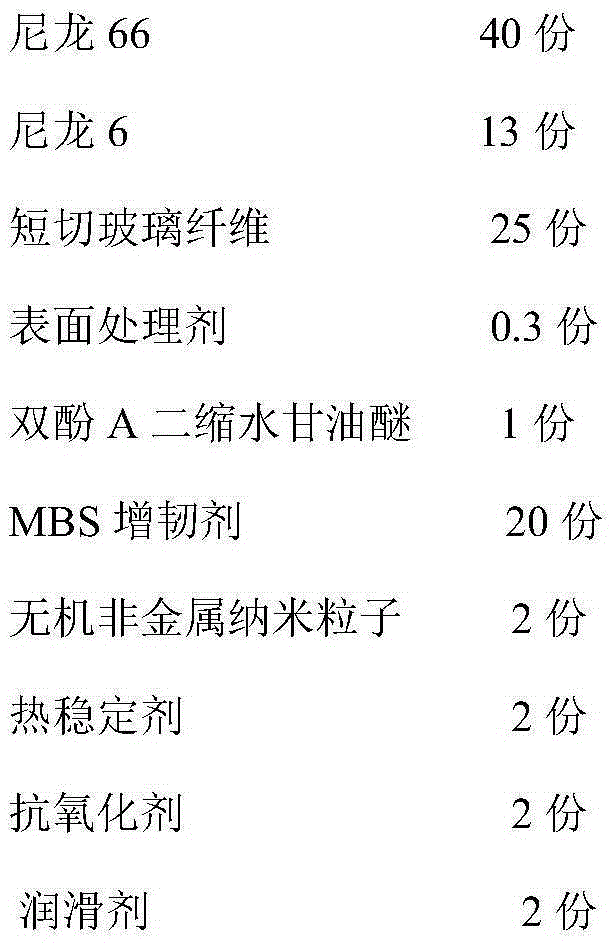

[0050] A nylon plastic bearing cage for a trolley case, the raw material of which is composed of the following components by weight:

[0051]

[0052] Described preparation method comprises the steps:

[0053] 1) mixing the nylon 66 and nylon 6 in the weight parts, and continuously drying at 90° C. for 24 hours to prepare composite nylon;

[0054] 2) adding the barium sulfate in the parts by weight and 0.1 parts by weight of the aluminate coupling agent into a high-speed mixer, and performing surface activation treatment at 130° C. for 15 minutes to obtain activated barium sulfate;

[0055] 3) adding the chopped glass fibers in the parts by weight and the aluminate coupling agent in the remaining parts by weight into a high-speed mixer, and performing surface activation treatment at 130° C. for 15 minutes to obtain activated chopped glass fibers;

[0056] 4) The composite nylon obtained in step 1), the activated barium sulfate obtained in step 2), and the MBS toughening ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com