Hierarchical origami-shaped automobile collision energy-absorbing structure

A collision energy-absorbing, paper-like technology, applied in the direction of metal layered products, vehicle parts, layered products, etc., can solve the problems of not meeting the lightweight design requirements of automobiles, high production costs and maintenance costs, and unsatisfactory safety , to achieve excellent dynamic performance, reduce maintenance costs, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

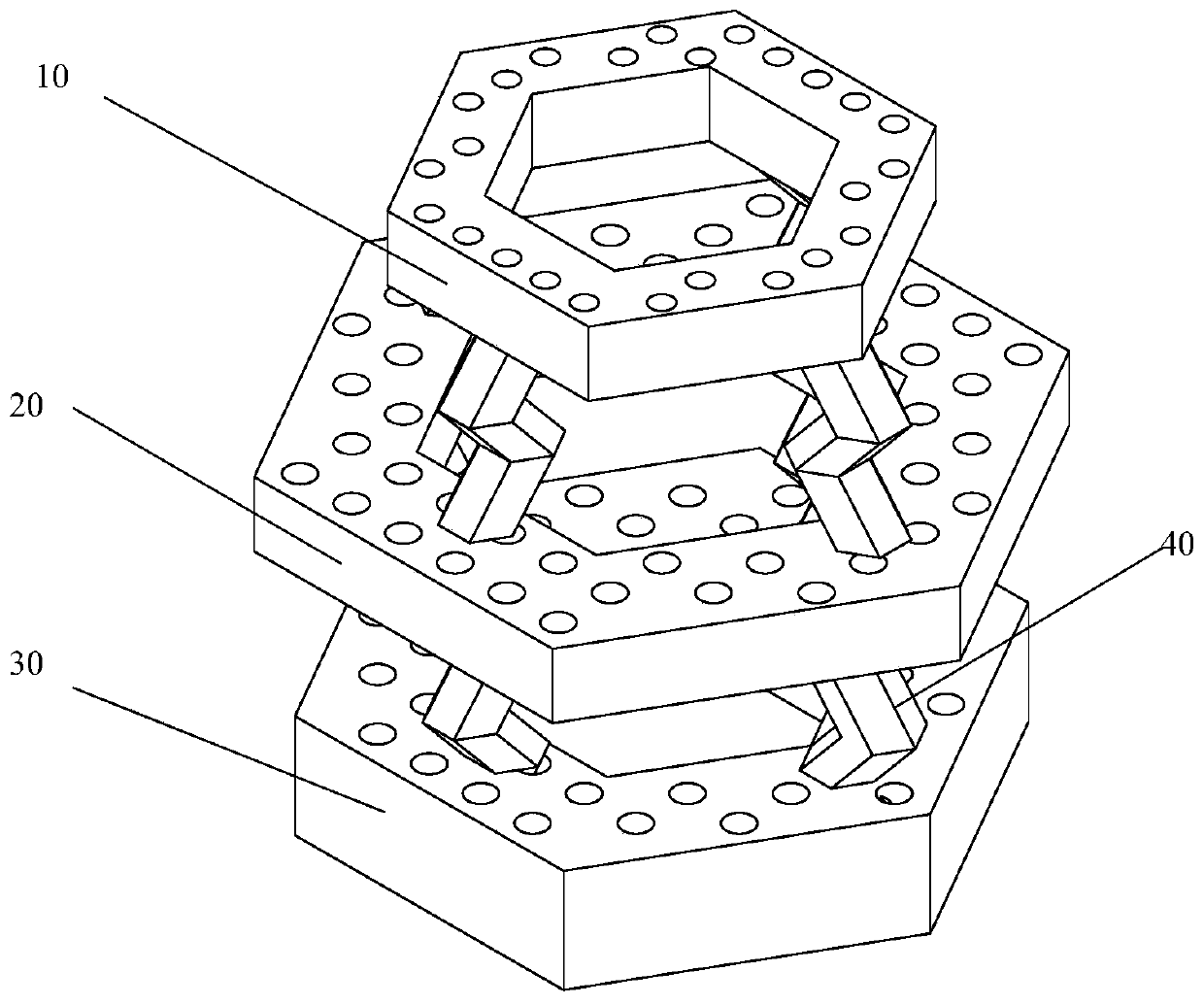

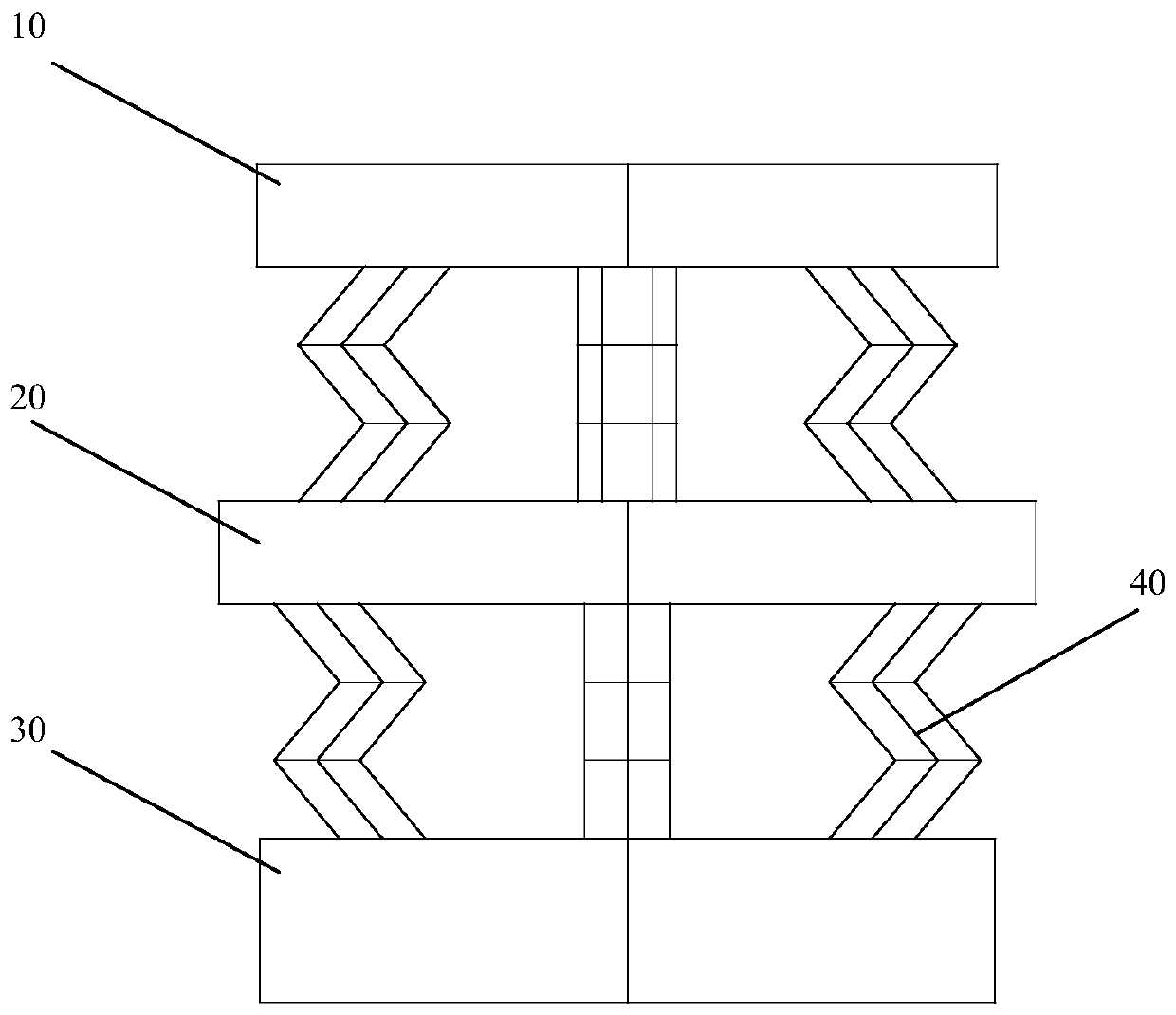

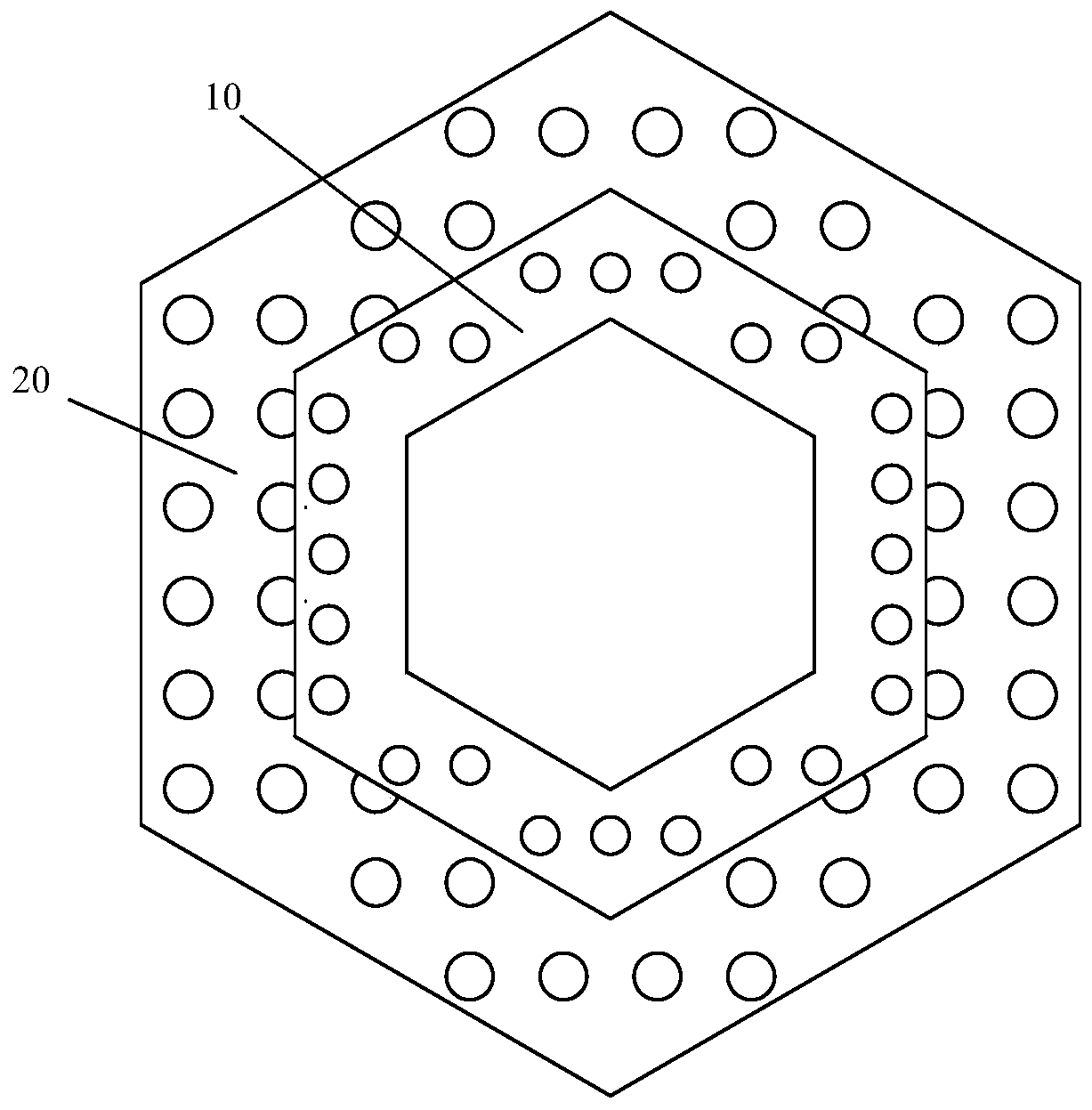

[0037] Examples, see Figure 1 to Figure 12 As shown, a hierarchical origami-like automobile crash energy-absorbing structure of the present invention includes a first honeycomb energy-absorbing layer 10, a second honeycomb energy-absorbing layer 20 and a porous material energy-absorbing layer 30 distributed coaxially from top to bottom , each energy-absorbing layer is connected to each other through four origami-like induction tubes 40, and the origami-like induction tubes 40 are made of aluminum alloy metal sheets through the steps of cutting, modeling, stamping, gluing, trimming, etc. Three sections of hexagonal prism-shaped aluminum alloy metal tube 41 connected in sequence, the angle between the bottom surface of the hexagonal prism and the side edge β=50°; the first honeycomb energy-absorbing layer 10, the second honeycomb energy-absorbing layer 20 and the porous The material energy-absorbing layer 30 is a regular hexagonal ring column, and the outer diameter of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com