1000 MPa-level high-strength high-plasticity aluminum-containing medium manganese steel and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of high-strength steel production, can solve the problems that it is difficult to meet the requirements of low cost, affect the application of steel plate processing, and cannot guarantee the structure of hot-rolled room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

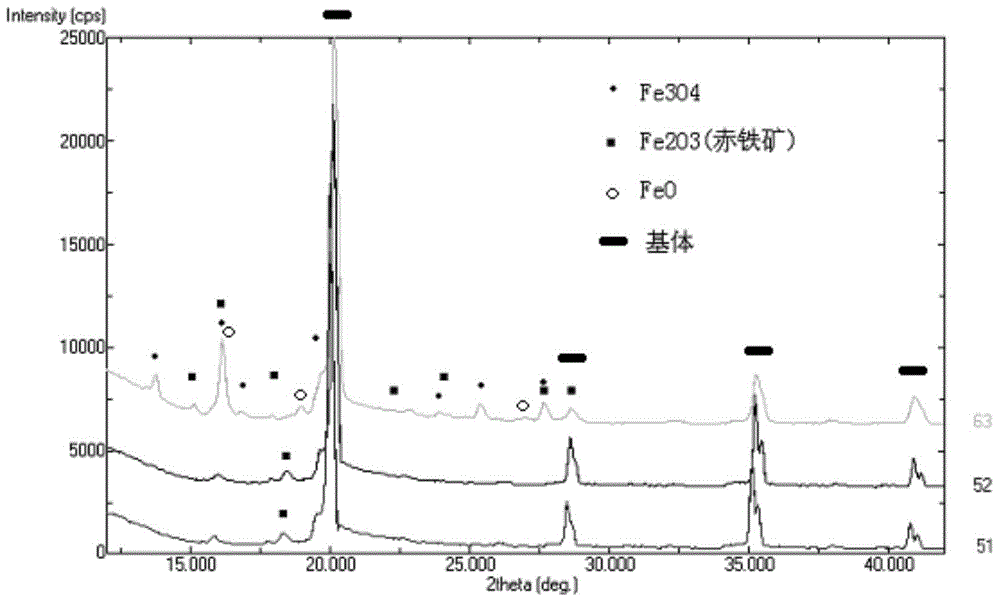

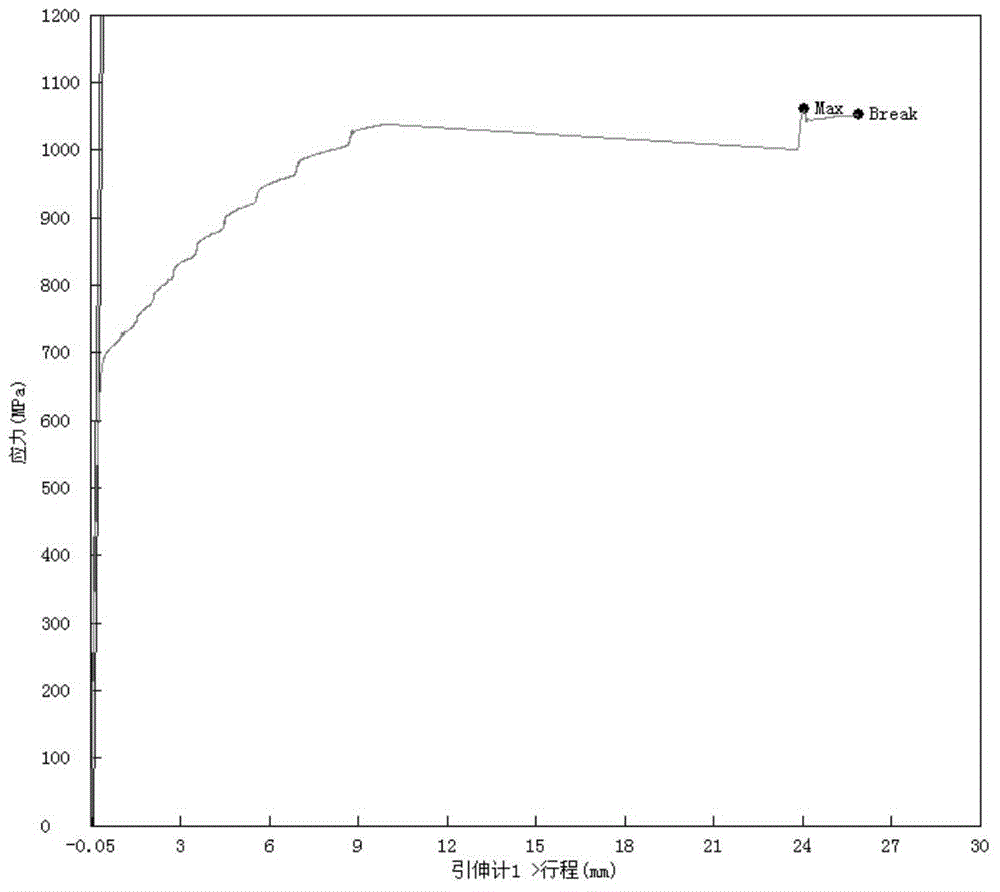

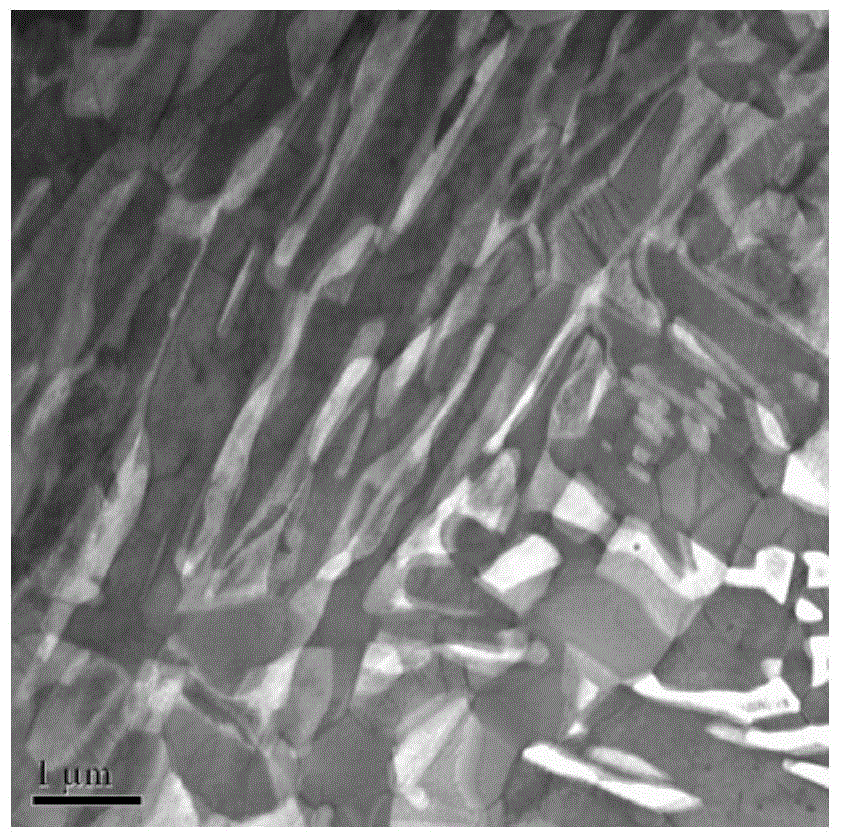

[0028] Four kinds of 1000MPa-grade high-strength and high-plasticity aluminum-containing medium-manganese steels were manufactured, and their chemical compositions are shown in Table 1 in terms of mass percentages.

[0029] Chemical composition of molten steel in table 1 (surplus is Fe and unavoidable impurity) / wt%

[0030] Example

C

Si

mn

P

S

Al

Cr

Cu

Mo

Nb

N

1

0.12

0.15

10.3

0.02

0.008

1.8

0.08

0.4

0.2

0.1

0.006

2

0.18

0.08

10.4

0.03

0.009

2.2

0.1

0.3

0.3

0.08

0.008

3

0.15

0.12

9.3

0.009

0.01

3.3

0.4

0.2

0.1

0.06

0.007

4

0.20

0.13

8.4

0.01

0.012

3.2

0.5

0.2

0.4

0.1

0.009

[0031] The manufacturing method of steel in the above-mentioned embodiments 1 to 4 includes the steps of smelting, continuous casting, hot continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com