Aluminum alloy crash box for automobile

A technology of aluminum alloy and energy-absorbing box, which is applied to bumpers and other directions, can solve problems such as poor energy-absorbing performance, achieve light weight, reduce car collision damage and personnel injuries, and improve energy-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

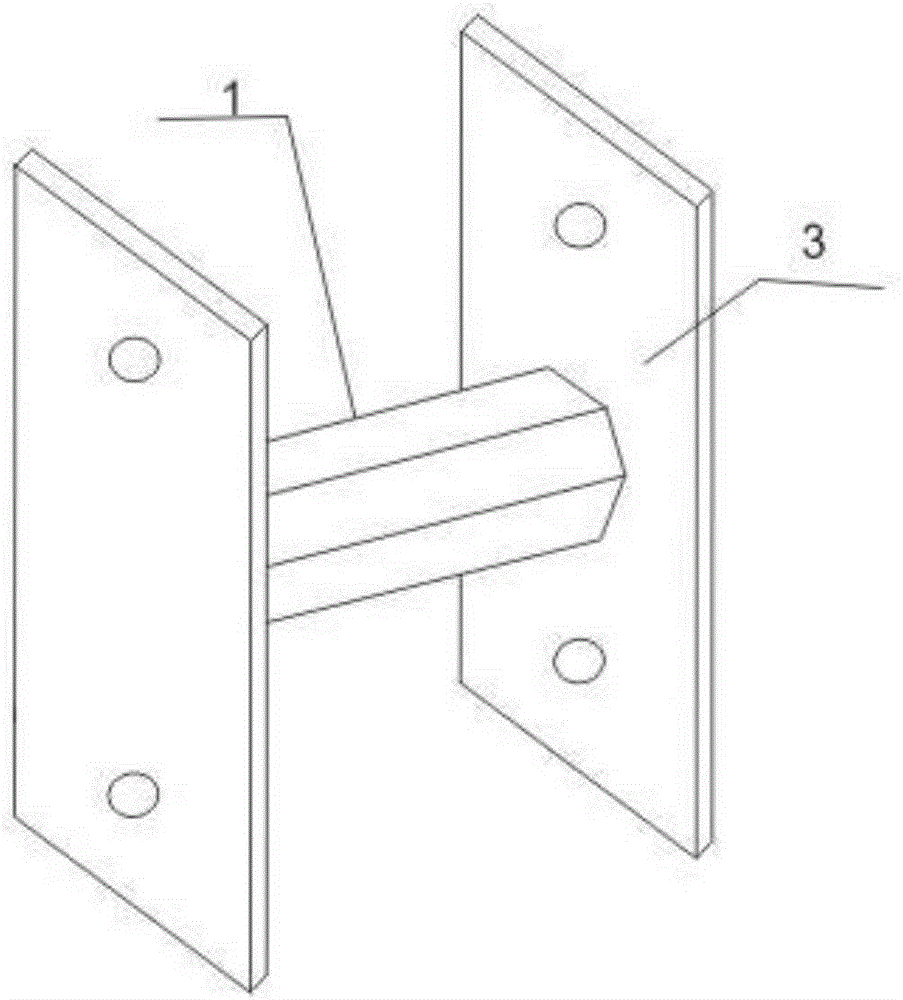

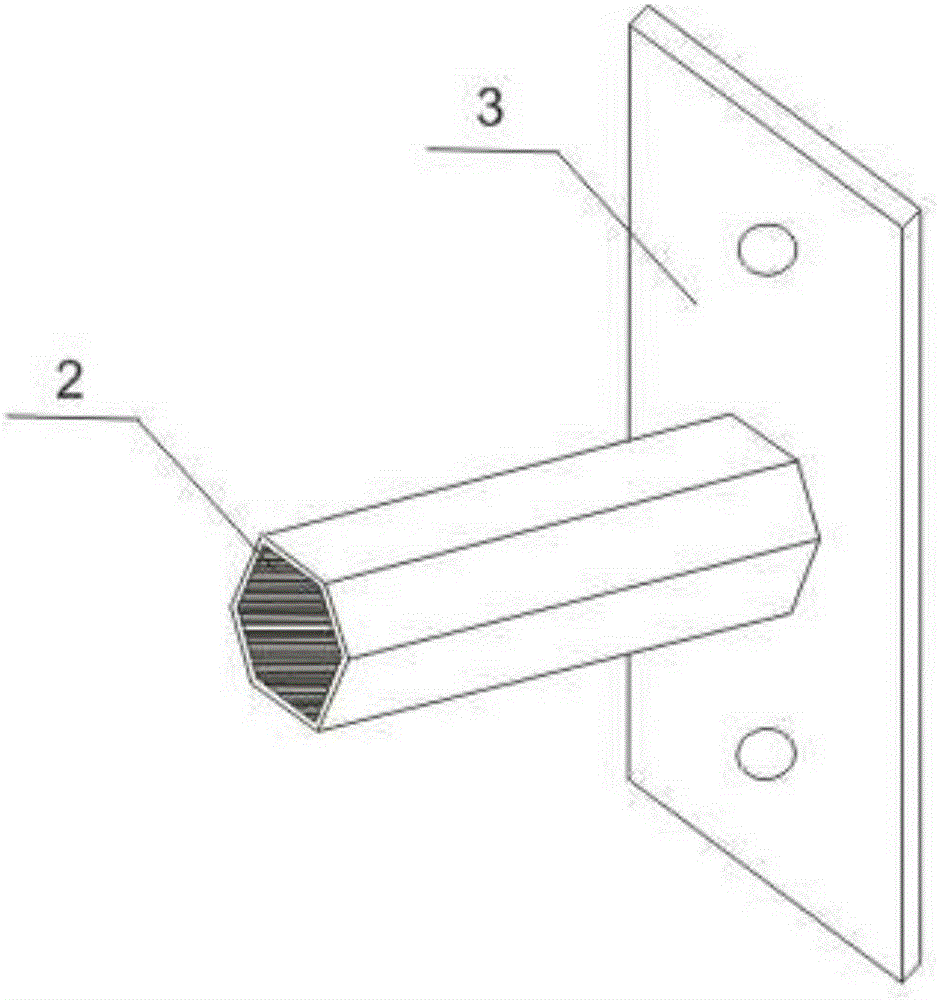

[0027] The aluminum alloy energy-absorbing box for automobiles of the present invention comprises an aluminum alloy energy-absorbing box body 1, the aluminum alloy energy-absorbing box body 1 is a regular polygonal sleeve, and the cross-section of the aluminum alloy energy-absorbing box body 1 is a regular polygon, preferably Regular hexagon, regular octagon or regular dodecagon, figure 1 The middle is a regular hexagon, the side length of the aluminum alloy energy-absorbing box body 1 is 15mm-50mm, the wall thickness is 1.5-3.0mm, and the height is 140-240mm. The edges are connected by arc transitions, and the transition arc radius is 10mm -20mm. Ensure that the edge does not crack during the compression process. The aluminum alloy energy-absorbing box body 1 is extruded. And heat treatment is carried out under certain process conditions, so that it has excellent impact energy absorption performance and compression deformation mode.

[0028] The aluminum alloy energy-absor...

Embodiment 2

[0030] Others are the same as in Example 1, except that: the aluminum alloy energy-absorbing box body 1 is filled with at least two long-fiber-reinforced thermoplastic composite material blocks 2 of different densities, and the long-fiber-reinforced thermoplastic composite material blocks 2 of different densities are radially Space padding. That is, the cross-section of the long fiber reinforced thermoplastic composite material block 2 is the same as that of the aluminum alloy energy-absorbing box body 1, and the central axis of the long fiber reinforced thermoplastic composite material block 2 is on the same line as the central axis of the aluminum alloy energy-absorbing box body 1 superior.

[0031] Preferably: the aluminum alloy energy-absorbing box body 1 is filled with two kinds of long-fiber-reinforced thermoplastic composite material blocks 2 with different densities at intervals. Three blocks each of long fiber reinforced thermoplastic composites of two different dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com