An experimental setup for acoustic metamaterial plate structure

A technology of acoustic metamaterials and experimental devices, which is applied in the direction of material analysis, measuring devices, and analytical materials using sound waves/ultrasonic waves/infrasonic waves. Effect of prestressing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

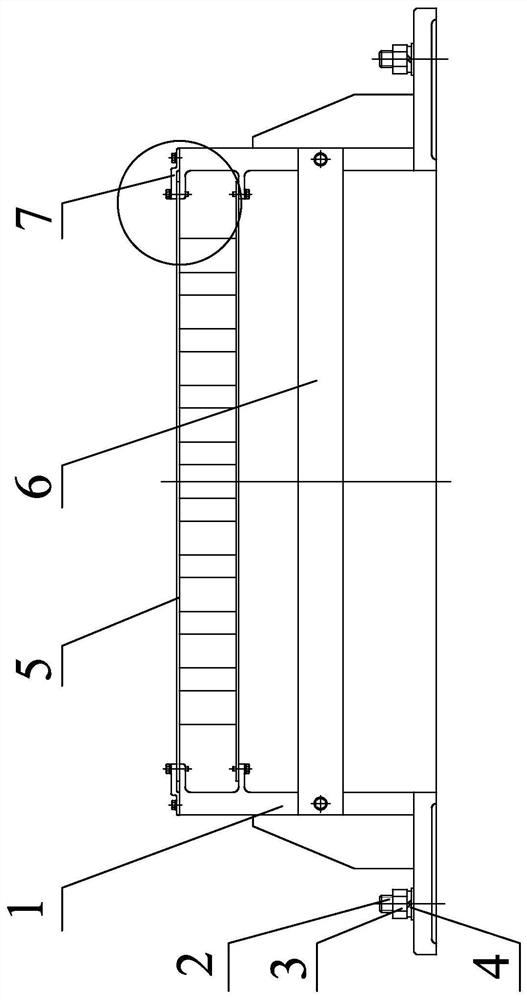

[0021] Specific implementation method 1: Combination figure 1 and Image 6 Explain that this implementation method, an experimental device of an acoustic super material board structure in this implementation method, the experimental device includes ultra -material board 5, two fixture brackets 1. Two positioning rods 6, two fixed pressure plate 7 and 2Ns 2n. Connect, n is a positive integer;

[0022] The two fixture brackets 1 is relatively set on both sides of the super material board 5, each fixing board 7 is installed on the top of a fixture bracket 1, a substrate 51 in the super material board 5 is set on the fixture bracket 1 and the fixed pressure plate 7 7 In between, and the super material board 5 is fixed on the fixture bracket 1, each positioning rod 6 is set on one side of the two fixture bracket 1, and each positioning rod 6 is connected to the two fixture brackets 1, each one, each of which The fixture bracket 1 is fixed to the base orbit of the vibration ground throug...

specific Embodiment approach 2

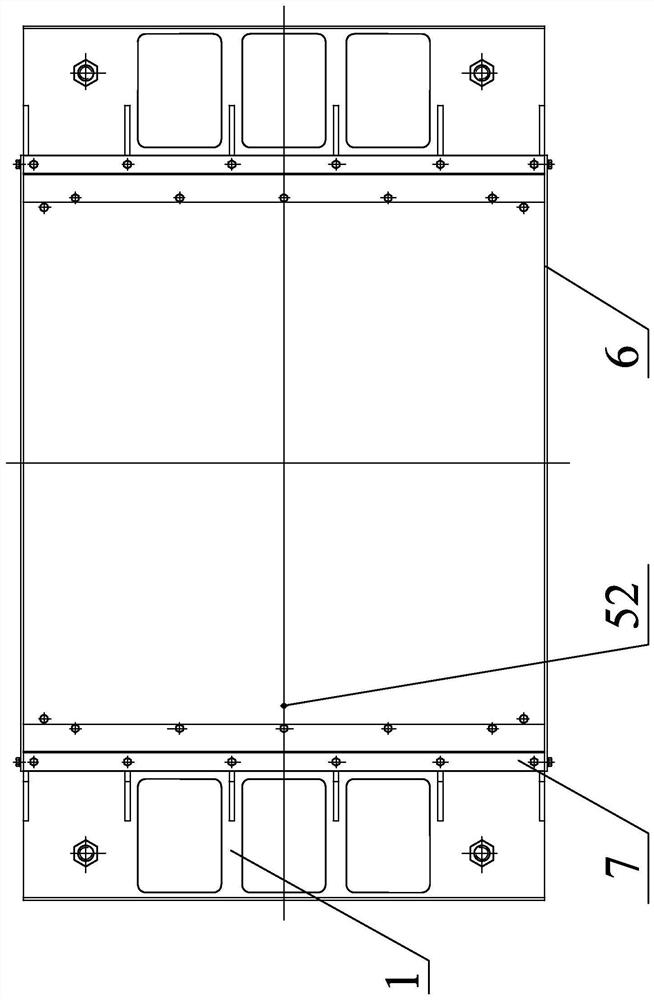

[0024] Specific implementation method 2: Combination Image 6 and Figure 7 Explain that this implementation method, this implementation method is further limited to the ultra -material board 5 of the specific embodiment. In this embodiment, the super material board 5 includes two substrate 51 and Z single rods 53, Z is the as the Positive integer, two substrates 51 parallel settings, Z one straight rod 53 evenly distributed between two substrate 51, and one end of each straight rod 53 is fixed with a substrate 51. A excitement hole 52. Other composition and connection methods are the same as the specific embodiments.

[0025] In this embodiment, the super material board 5 includes two substrate 51, one of the substrate 51 is set between the fixture bracket 1 and the fixed pressure plate 7, which is used to hold the fixing. Double fixation to ensure that the installation is more stable. The substrate 51 and the controllers 53 are made of controllable positions. The materials of the ...

specific Embodiment approach 3

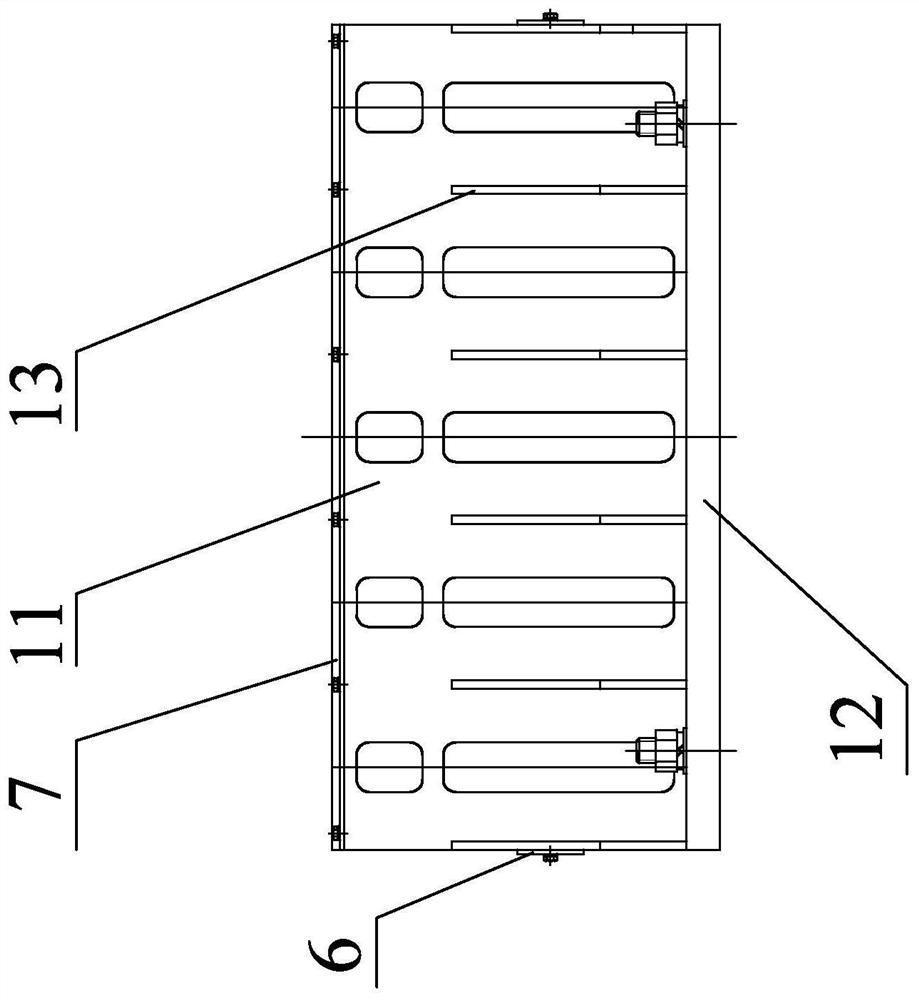

[0026] Specific implementation method three: combined Figure 3 to Figure 5 Explain that this implementation method, this implementation method is further limited to the fixture bracket 1 described in the specific implementation method. In this implementation method, the fixture bracket 1 includes the standing board 11 and the bottom panel 12, and the bottom surface of the vertical board 11 is fixed on the bottom surface. On the surface of the bottom panel 12, the top of the bottom panel 12 is far from the end of the stand 11 with n tolerance 121, each connector is set in a pore 121, and the top surface of the standing board 11 is provided with the length of the length direction. M thread blind hole, M is the positive integer, the stand 11 is far from the side 12 of the bottom panel 12, there is a connection square bar 111, the connected square bar 111 has a connecting slot 112, and another substrate 51 in the super material board 5 is set on the connection In the slot 112. Other c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com