Precise boring cutter for machining inner contour of deep hole of bottle cavity

A technology of inner contour and cavity depth, applied in the direction of boring bars, etc., can solve the problems of reduced rigidity, weak adaptability, difficulty in satisfying the rigidity of the mandrel and slider, etc., and achieve the effect of self-guided vibration and vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

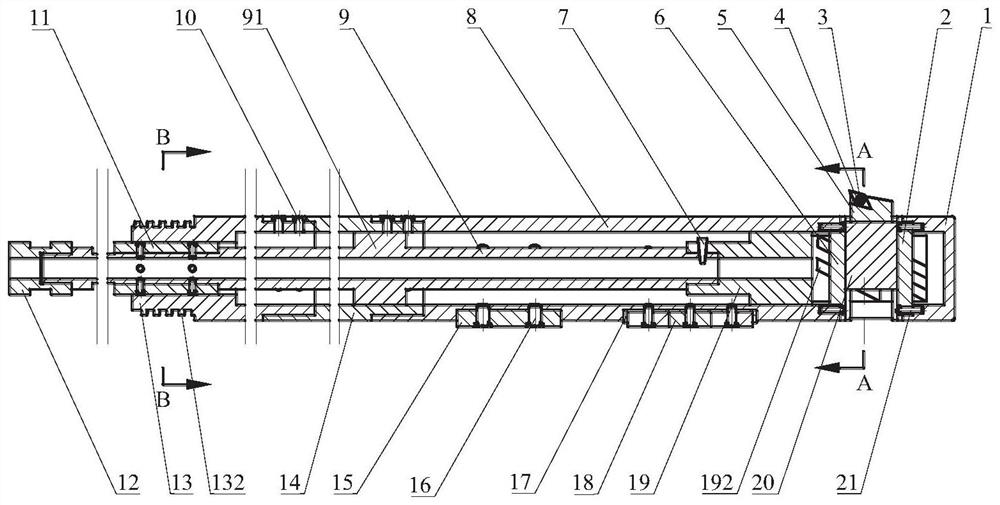

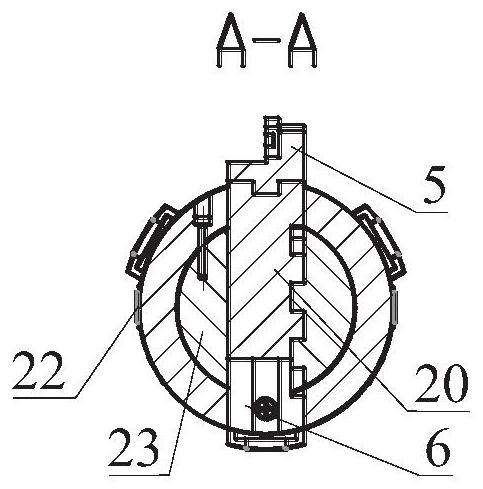

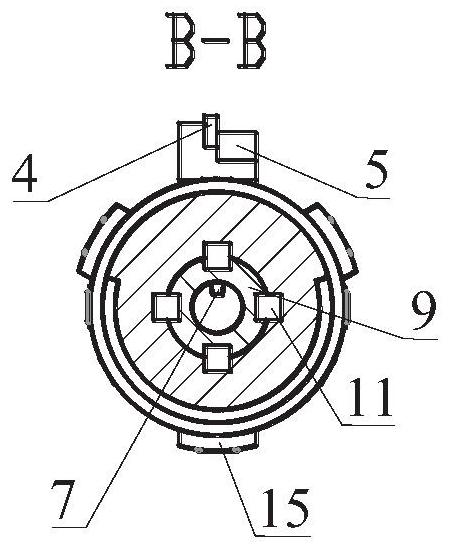

[0044] Embodiment 1: as Figure 1 to Figure 9 As shown, a precision boring tool for processing the inner contour of a deep hole in a bottle cavity includes a tool holder 5 and a front boring bar 8 coaxially arranged, a rear boring bar 13 and a pull bar 9, and an end cover 1 is mounted on the front boring bar with a cylindrical surface. The end of the rod 8, the front boring bar 8 and the rear boring bar 13 are all hollow cylinders, the pull rod 9 is arranged in the cavity of the hollow cylinder, and one end of the pull rod 9 extends out of the cylinder of the rear boring rod 13 and the transmission positioning block 12, the transmission positioning block 12 is used to drive the pull rod 9 to move in the axial direction, and the other end of the pull rod 9 is fixedly connected with the mandrel 19 for driving the tool holder 5 to move radially through the pin 7;

[0045] The tail of the rear boring bar 13 is connected to the main shaft of the machine tool through a rectangular t...

Embodiment 2

[0061] Embodiment 2: the same as Embodiment 1, the difference is that the inclined guide block 192 is three oblique rectangular projections extending and inclined relative to the axial direction, and the angle between the oblique rectangular projections and the axis is 26.565° , so that the driving ratio between the pull rod 9 and the slider 20 is 2:1, that is, the pull rod 9 expands and contracts 2 mm in a straight line in each axial direction, and the blade 4 provided on the tool holder 5 follows the radial and straight line of the slide block 20 by 1 mm.

[0062]Since the slope structure has a pressure angle during transmission, in order for the slider 20 to expand and contract freely on the slope, the slope angle must be greater than the pressure angle. At the same time, when the slope angle is too large, the pressure angle increases accordingly, so that the power consumed by the radial expansion and contraction of the slider 20 increases; when the slope angle is too small,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com