Patents

Literature

112results about How to "Short process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling method for composite strip of stainless steel and straight carbon steel

InactiveCN102553918AShort process stepsImprove rolling efficiencyMetal rolling arrangementsSS - Stainless steelComposite plate

A rolling method for a composite strip of stainless steel and straight carbon steel belongs to the technical field of rolling of composite strips and comprises the steps of preparing materials; pretreatment; blank overlaying; heating and heat rolling; unreeling; cold rolling and heat treatment; and finishing. Leading an initial rolling plate into a cold-rolling mill for cold rolling to obtain a cold-rolling composite rolling plate, then conveying the cold-rolling composite rolling plate into a heat treatment furnace for heat treatment, and controlling the temperature for heat treatment to obtain a cold composite rolling plate; and performing finishing on the cold composite rolling plate and obtaining the composite strip of the stainless steel and the straight carbon steel. The rolling method for the composite strip of the stainless steel and the straight carbon steel has the advantages that the rolling method is short in process procedure and high in rolling efficiency so as to save energy; enables the integral combination effect of base plate blank made of the straight carbon steel and composite plate blank made of the stainless steel to be fully ensured; is high in finished product rate; and can meet the requirements of industrialized amplification production.

Owner:江苏天成特种金属复合材料科技有限公司

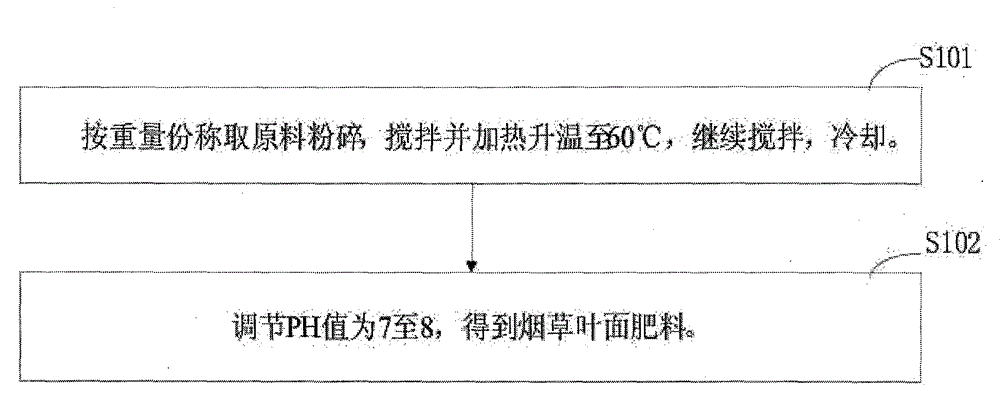

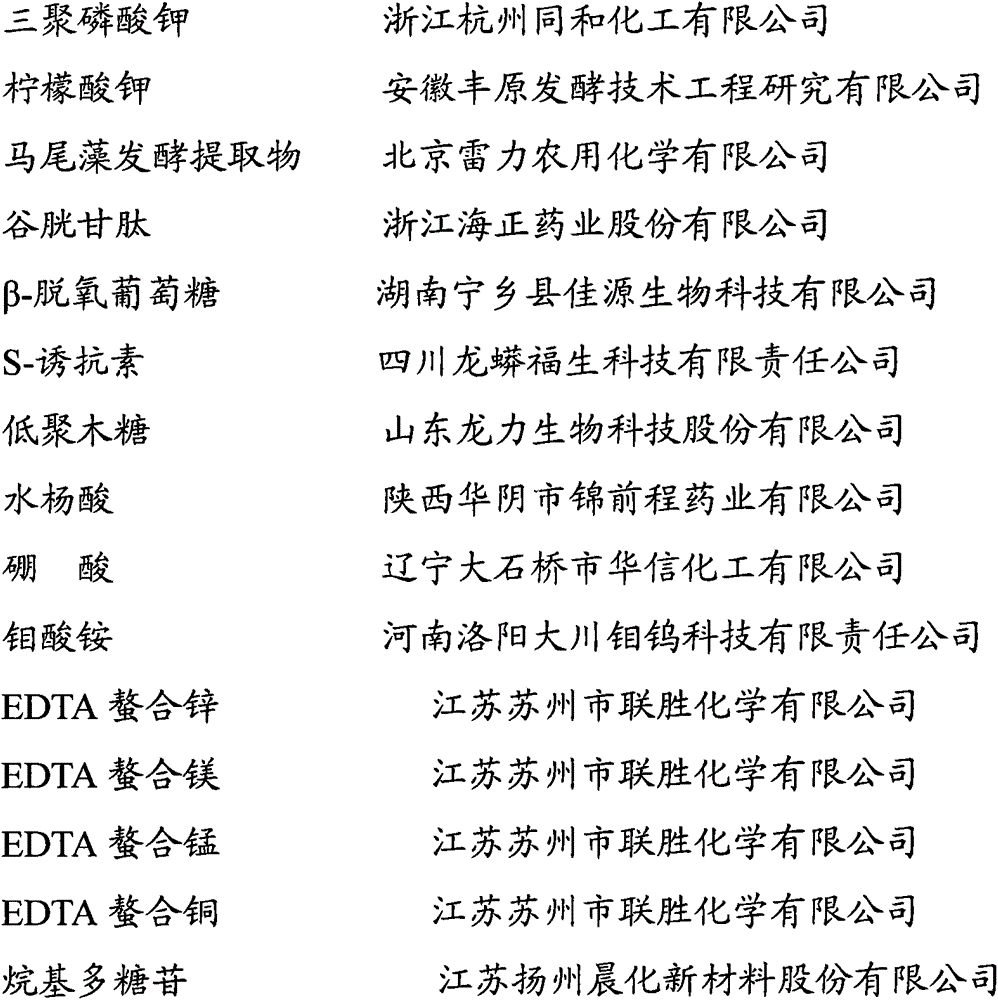

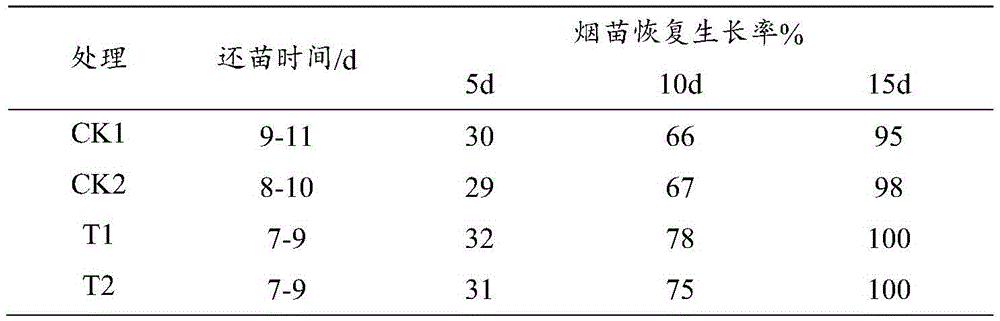

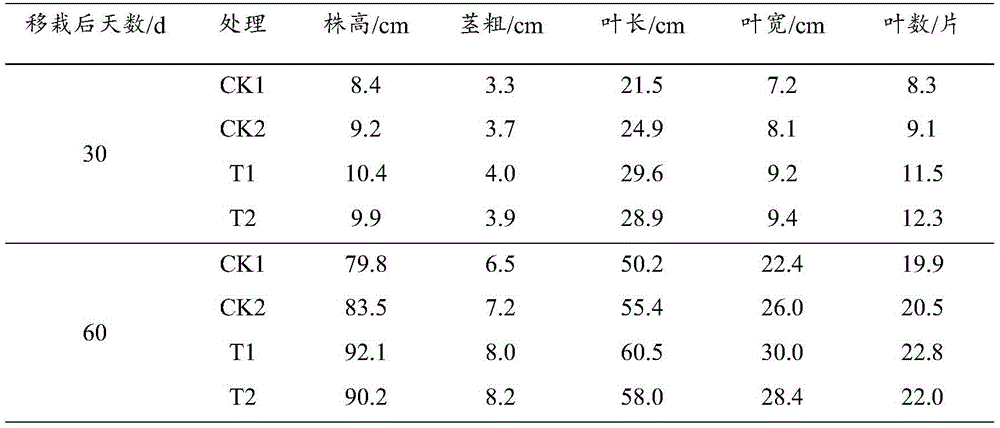

Tobacco foliar fertilizer and preparation method thereof

A tobacco foliar fertilizer and a preparation method thereof. The tobacco foliar fertilizer includes following components, by weight: 20-25 parts of potassium tripolyphosphate, 15-20 parts of potassium citrate, 3-6 parts of sargassum fermentation extract, 0.5-2 parts of glutathione, 0.5-2 parts of [beta]-deoxyglucose, 0.1-1 part of trans-abscisic acid, 0.5-1 part of xylooligosaccharide, 0.2-0.5 parts of salicylic acid, 1-3 parts of boric acid, 0.1-0.5 parts of ammonium molybdenate, 0.5-2 parts of EDTA-chelating zinc, 0.5-2 parts of EDTA-chelating magnesium, 0.3-2 parts of EDTA-chelating manganese, 0.3-1 part of EDTA-chelating copper, 0.5-1 part of alkyl polysaccharide glycoside and 31-56.2 parts of water. The tobacco foliar fertilizer is reasonable in combination and proportion, can promote growth of tobacco, can enhance the resistance capability on viruses, cold and dryness of tobacco, can increase yield, is green and environmental-friendly and can greatly improve quality of tobacco.

Owner:HUNAN AGRICULTURAL UNIV +5

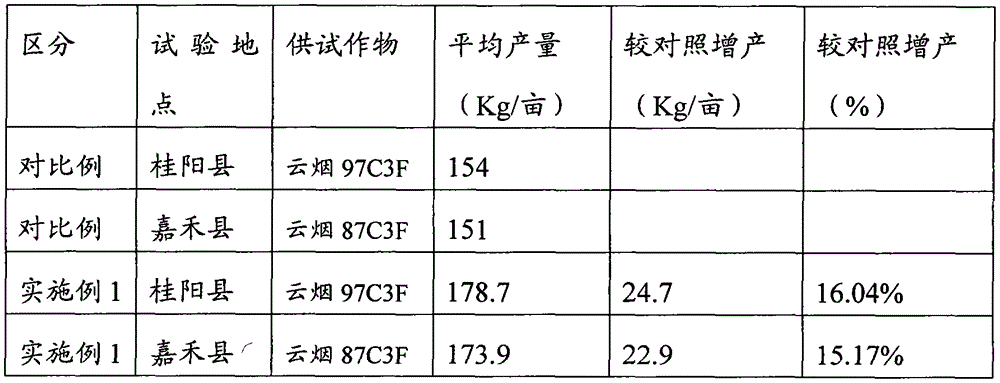

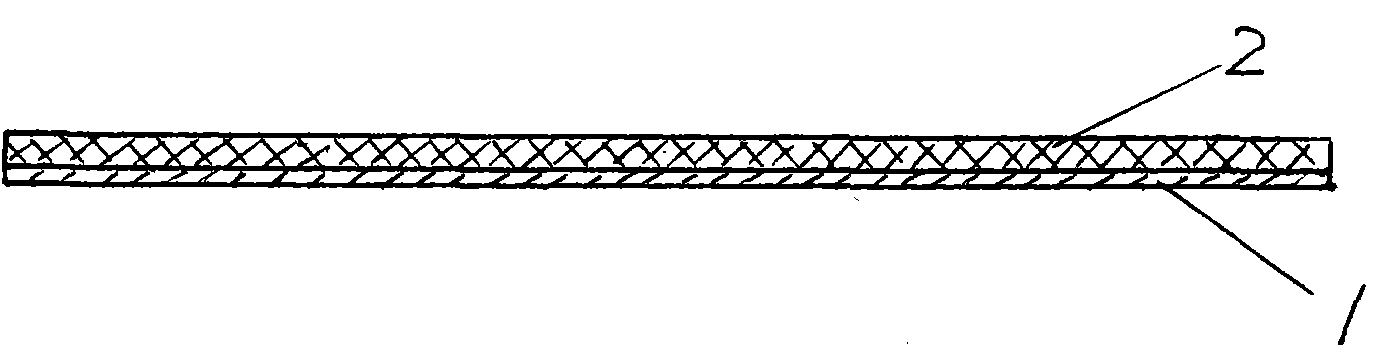

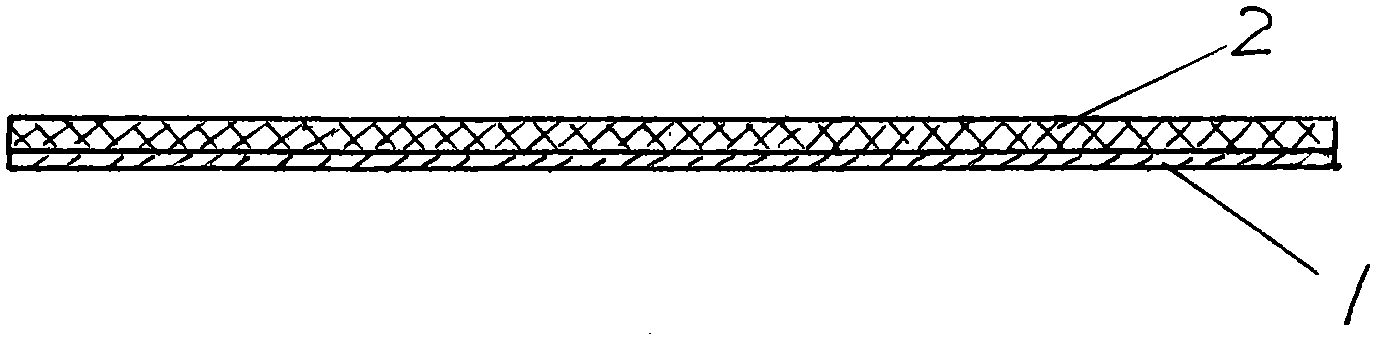

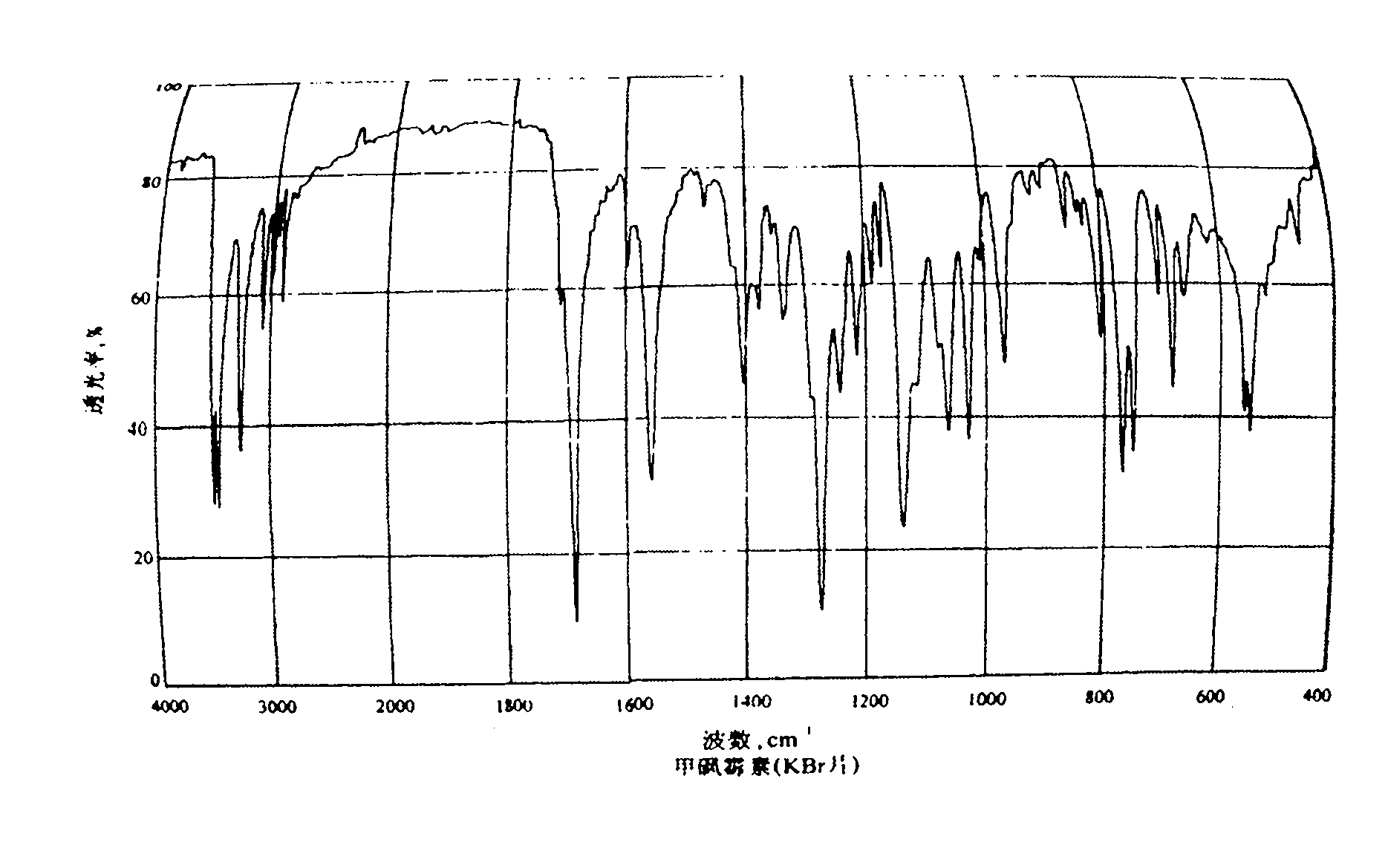

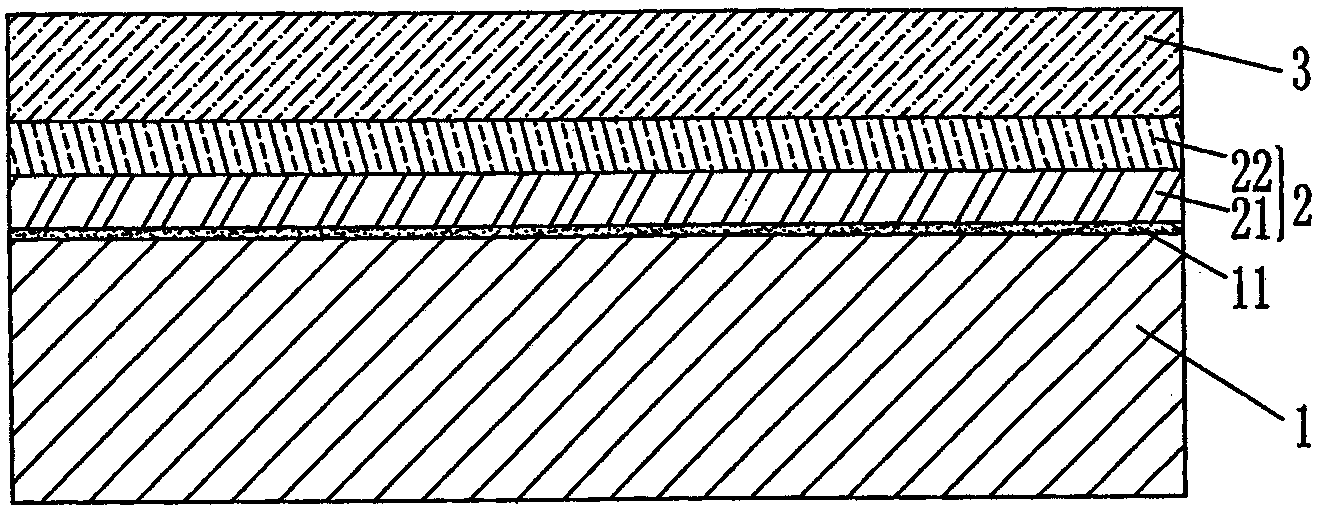

Glass fiber flame retardant silica gel cloth and preparation method thereof

The invention relates to glass fiber flame retardant silica gel cloth and a preparation method thereof, belonging to the technical field of gluing glass fiber products. The glass fiber flame retardant silica gel cloth comprises glass fiber cloth and a corrosion resistant flame retardant layer, wherein the corrosion resistant flame retardant layer is combined to at least one side surface of the glass fiber cloth and comprises the following raw materials in parts by weight: 60-70 parts of mixing silicon rubber, 25-30 parts of flame retardant agent, 2-5 parts of pigment and 0.1-0.5 part of vulcanizing agent. In the technical scheme, because the glass fiber cloth is used as a base material, and the corrosion resistant flame retardant layer formed by the mixing silicon rubber, the flame retardant agent, the pigment and the vulcanizing agent is combined to one side or both sides of the glass longitudinal fiber cloth, the glass fiber flame retardant silica gel cloth can be suitable for being used as a flexible connecting element, can achieve the ideal effects of high-temperature resistance, corrosion resistance and flame retardancy and also has excellent longitudinal and transverse tearing resistant strength; and the provided preparation method has simple and short process step and undemanding process and equipment requirement, not only can guarantee the comprehensive embodiment of the technical effect of the glass fiber flame retardant silica gel cloth but also can meet the industrialized amplification production requirement.

Owner:常熟市嘉诚织造有限公司

Preparation method of 20CrMo steel pipe

InactiveCN102699103AReduce consumptionShort process stepsMetal rolling arrangementsHeating furnacePipe

The invention relates to a preparation method of a 20CrMo steel pipe and belongs to the technical field of steel pipe preparation. The preparation method comprises the following steps that 20CrMo round steel is subjected to perforation under the condition of being heated to 1200 to 1250 DEG C to obtain a pipe blank, the perforation eccentricity is controlled, and the surface quality of the pipe blank is controlled; the pipe blank is introduced into an annealing furnace to be subjected to annealing, the annealing temperature and the annealing time are controlled, and an annealing pipe blank is obtained; the annealing pipe blank is introduced into a pipe rolling machine to be subjected to cold rolling, the number of reciprocating times of a machine head frame of the pipe rolling machine is controlled, the feeding length of the pipe blank in each time is controlled, and a rolled pipe is obtained; the rolled pipe is introduced into a heating furnace to be subjected to heating and heat insulation, the furnace discharge is carried out after the rolled pipe is cooled along with the furnace, and an annealing pipe blank is obtained; the annealing pipe blank is subjected to acid washing, phosphorization and saponification lubrication to obtain a pipe blank to be subjected to cold pulling; the pipe blank to be subjected to cold pulling is subjected to the cold pulling processing to obtain a cold pulling pipe; the cold pulling pipe is introduced into the annealing furnace to be subjected to finished product heat treatment, the finished product heat treatment temperature and the time are controlled, and the 20CrMo steel pipe is obtained. The preparation method has the advantages that the process steps are short, the hardness is high, and the energy source consumption is saved.

Owner:常熟市旋力轴承钢管有限公司

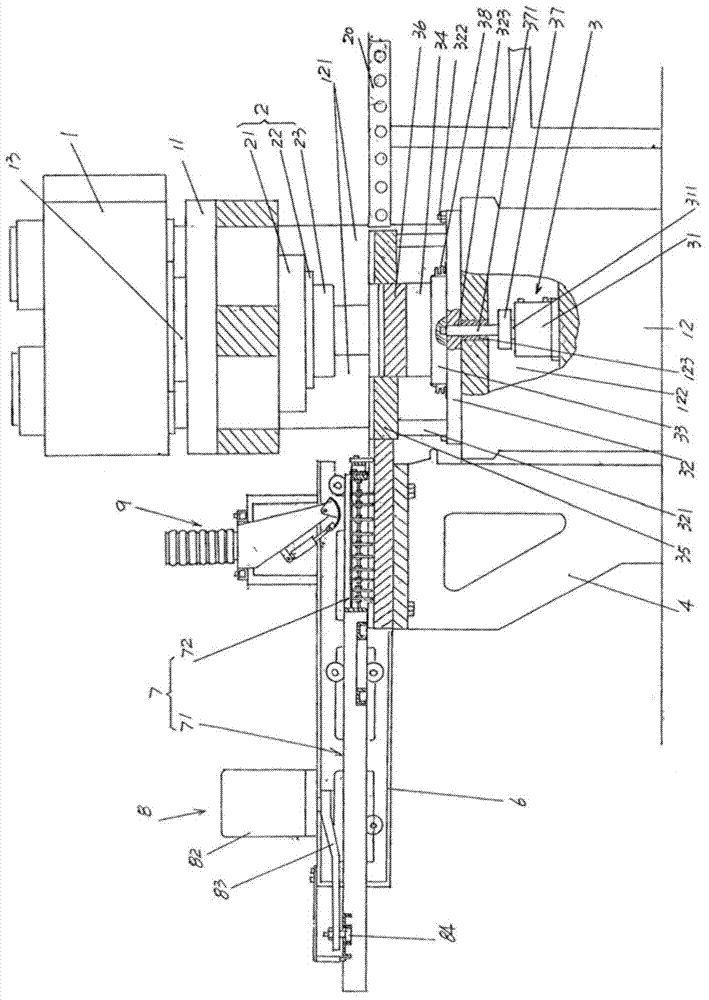

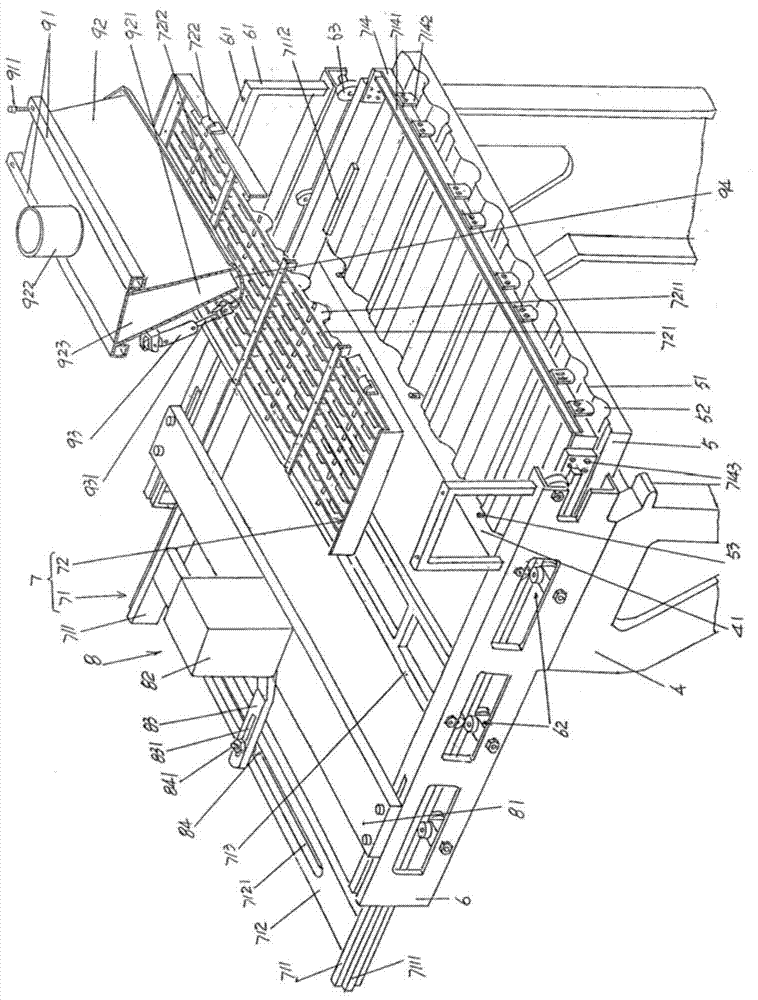

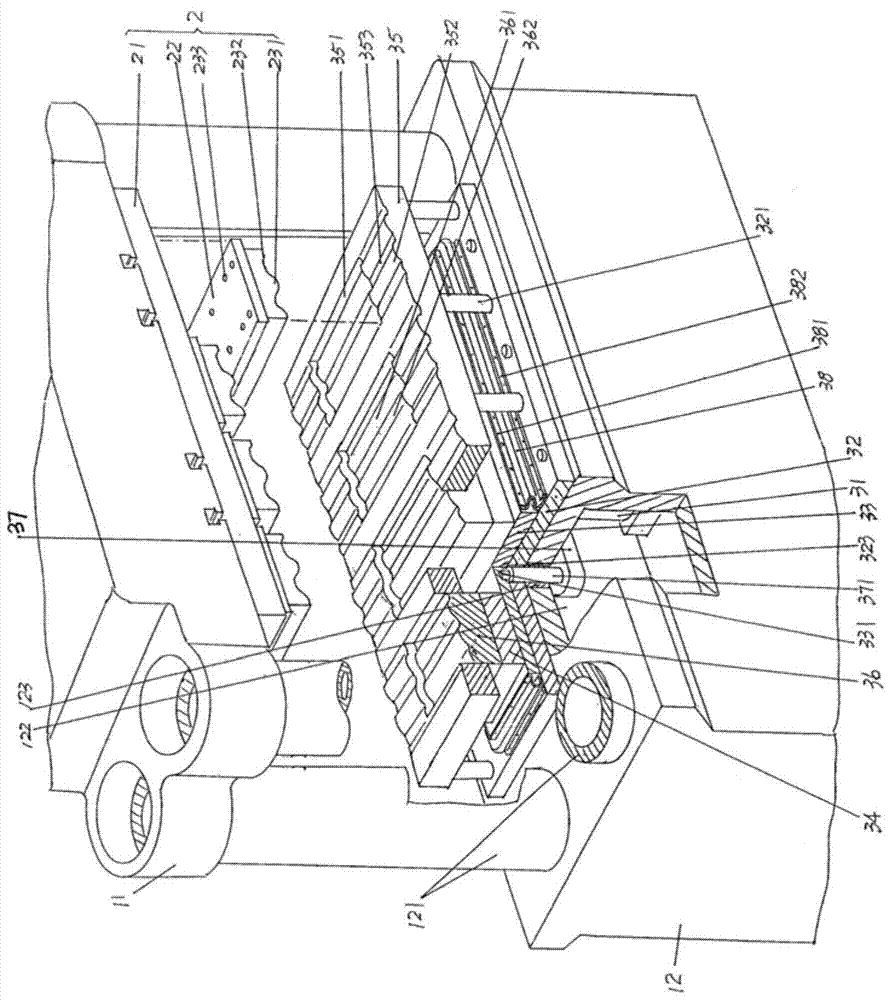

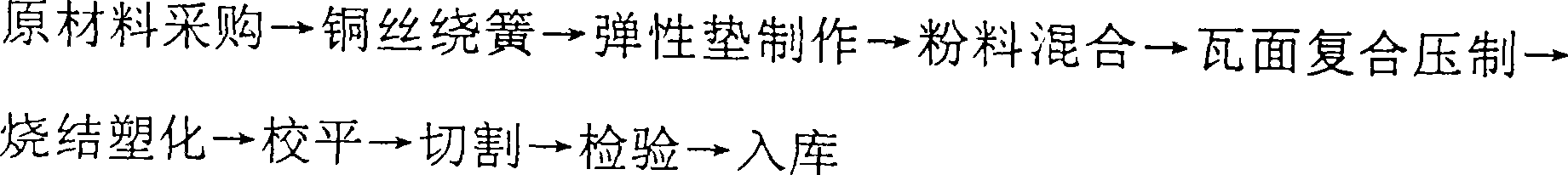

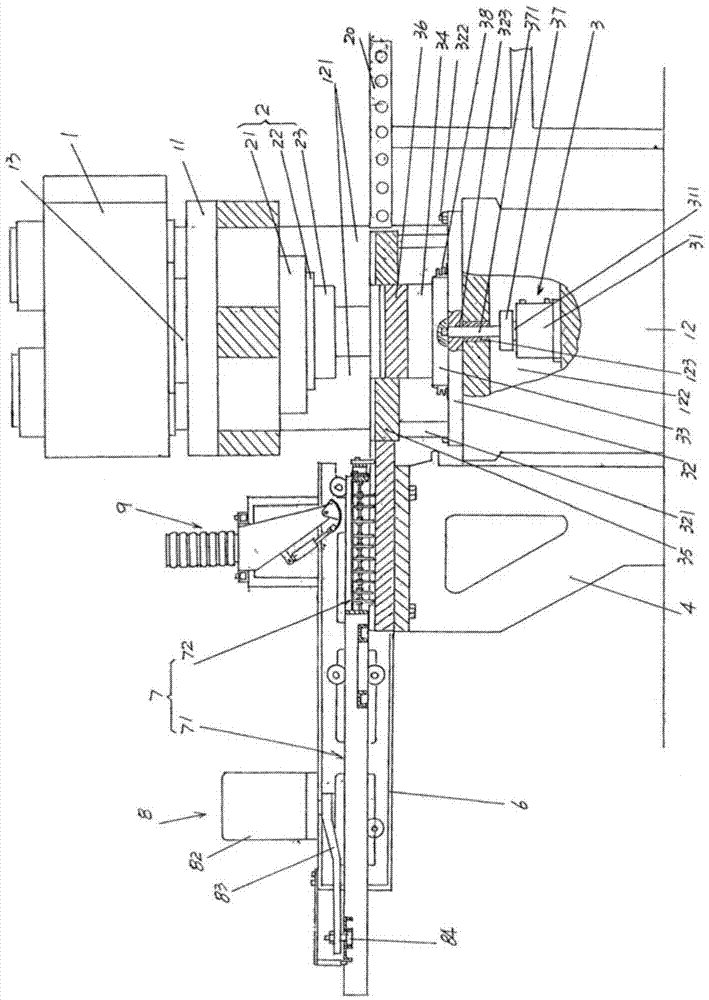

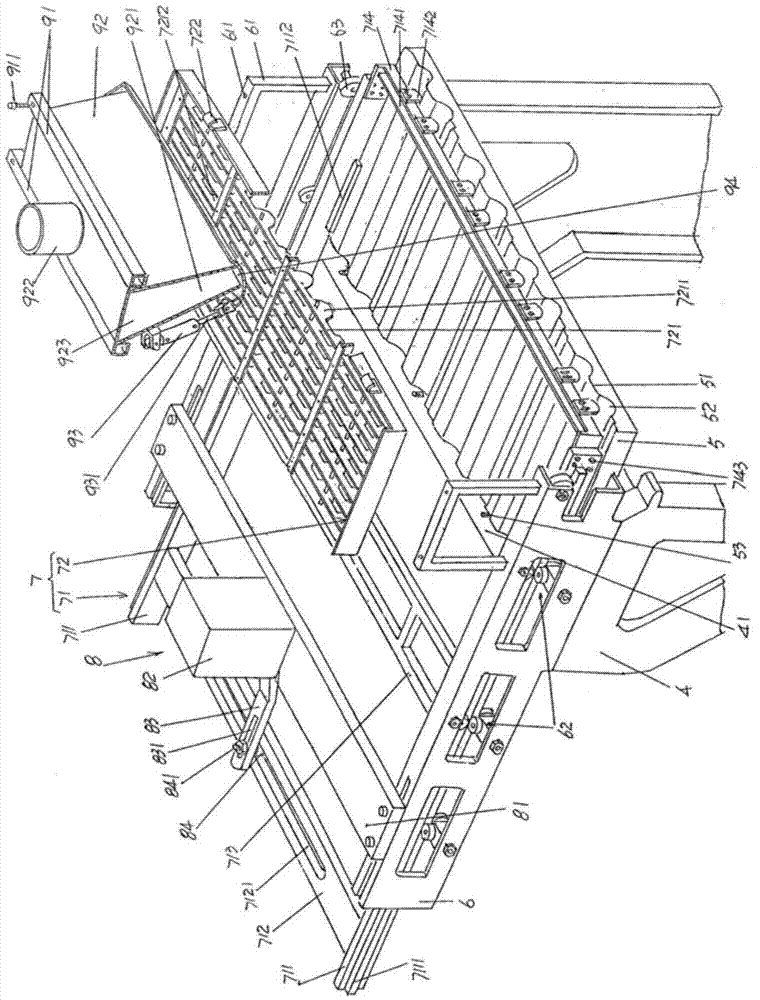

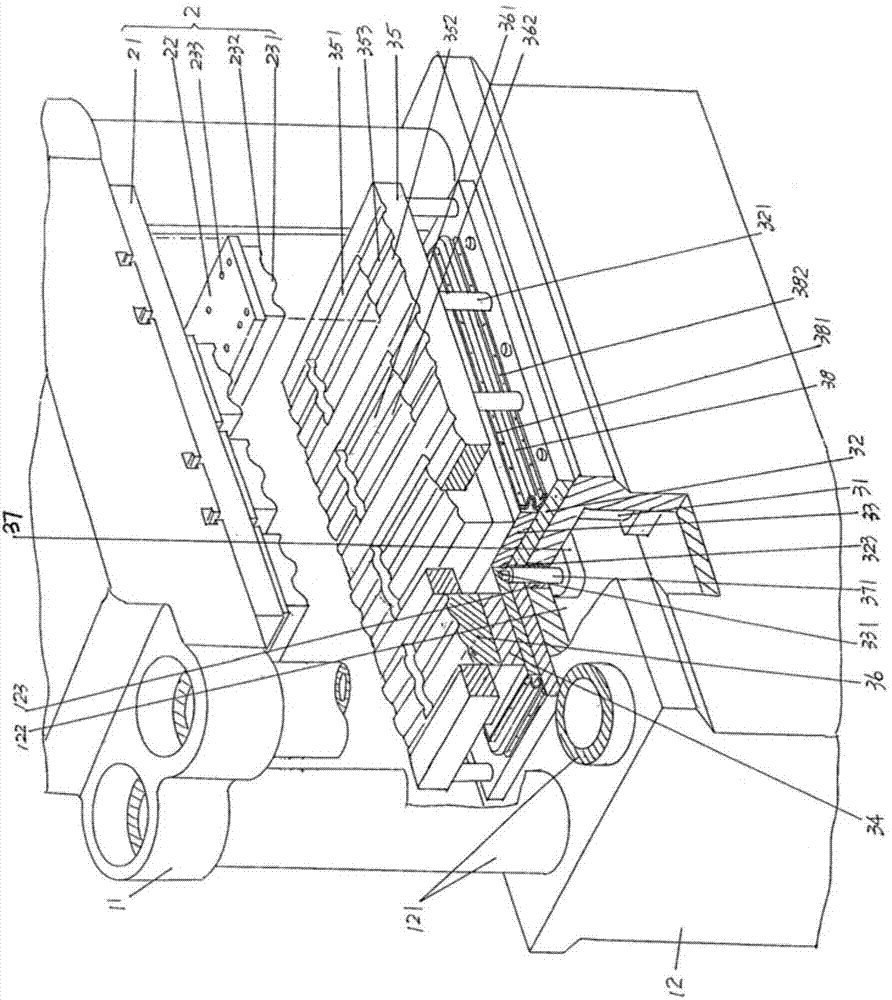

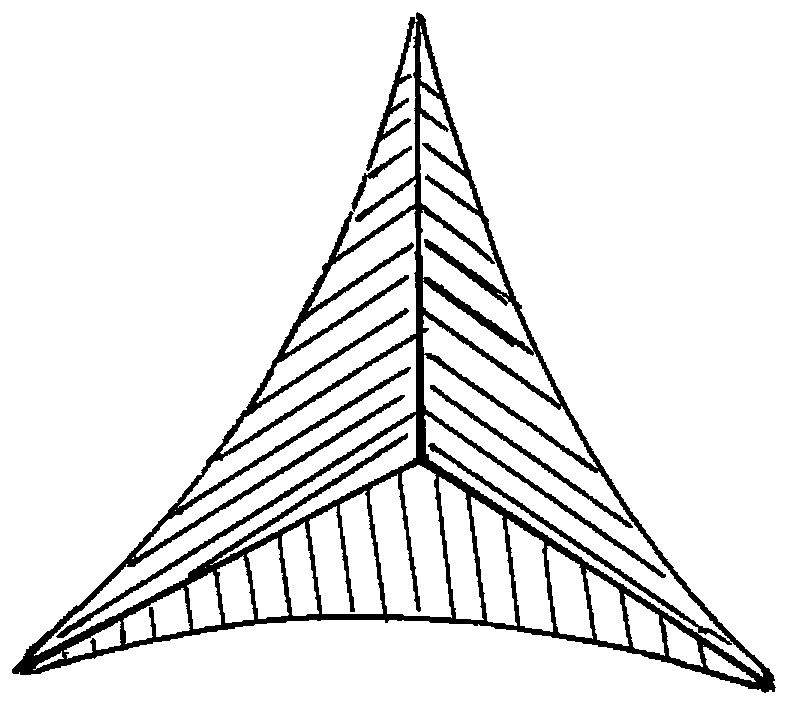

Colored glaze ceramic tile, production method of colored glaze ceramic tile, and forming device using production method

ActiveCN103538141AReduce weightImprove viewing effectRoof covering using tiles/slatesFeeding arrangmentsWeather resistanceCeramic tiles

The invention relates to a colored glaze ceramic tile, a production method of the colored glaze ceramic tile, and a forming device using the production method and belongs to the field of building roof materials. The colored glaze ceramic tile comprises a tile body and a surface colored glaze layer. The surface colored glaze layer is attached to the tile body and faces out when in use. The tile body is made with, by weight, 25-40% of clay, 10-20% of quartz sand, 5-15% of auxiliary material, 30-45% of flux, and 0.15-0.5% of additive. The colored glaze ceramic tile, the production method and the forming device have the advantages that materials are selected and matched reasonably, the weight of the obtained colored glaze ceramic tile is evidently lower than that of clay or cement tiles, storage and transportation cost can be saved, and the tile is good in strength and weather resistance and water resistance; energy can be saved, and the requirements for industrial enlarged production are met; the surface colored glaze layer can be reliably attached to the tile body, and the appearance of the colored glaze tile can be improved; the finally obtained colored glaze ceramic tile can be even in thickness and density.

Owner:常熟大象建陶有限公司

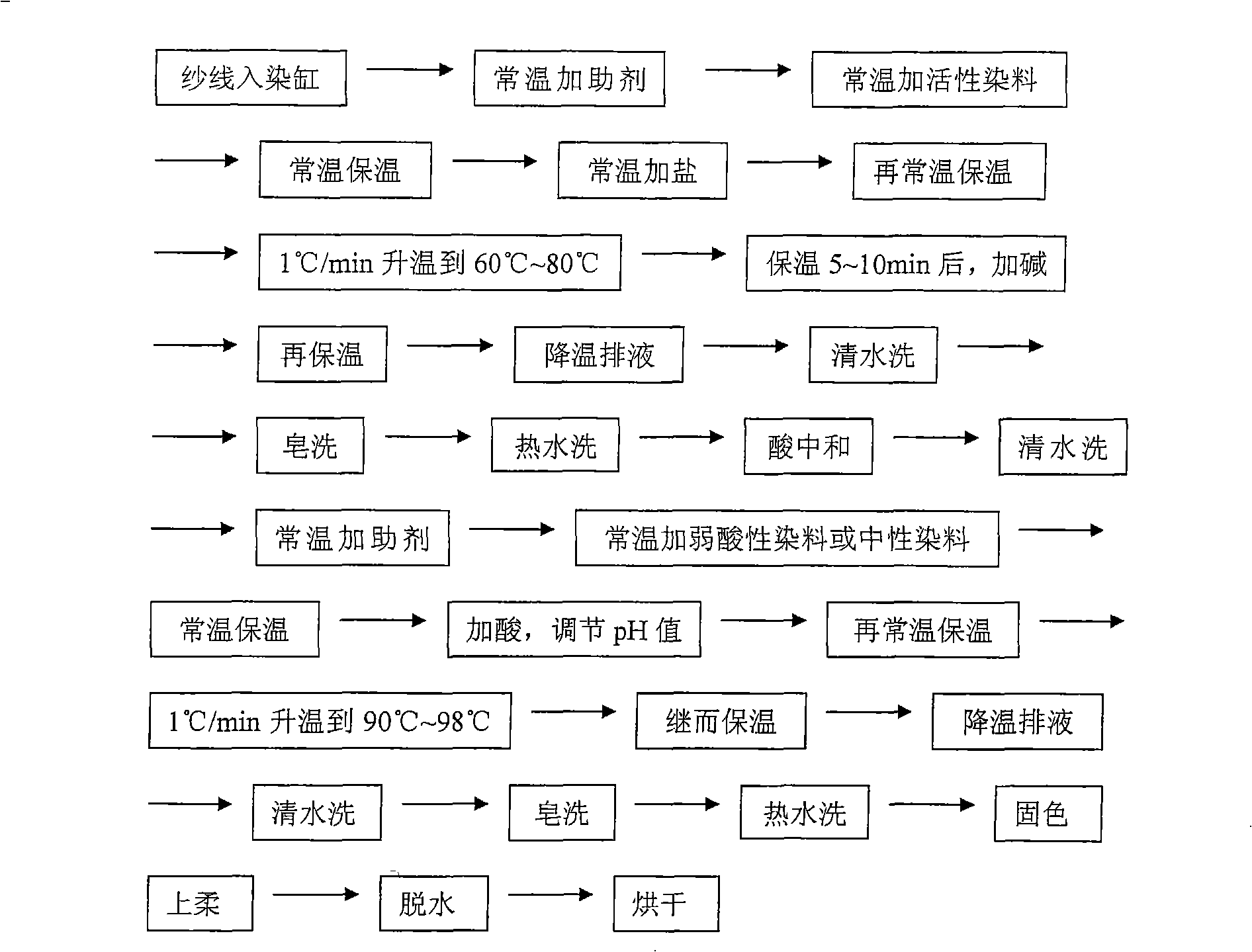

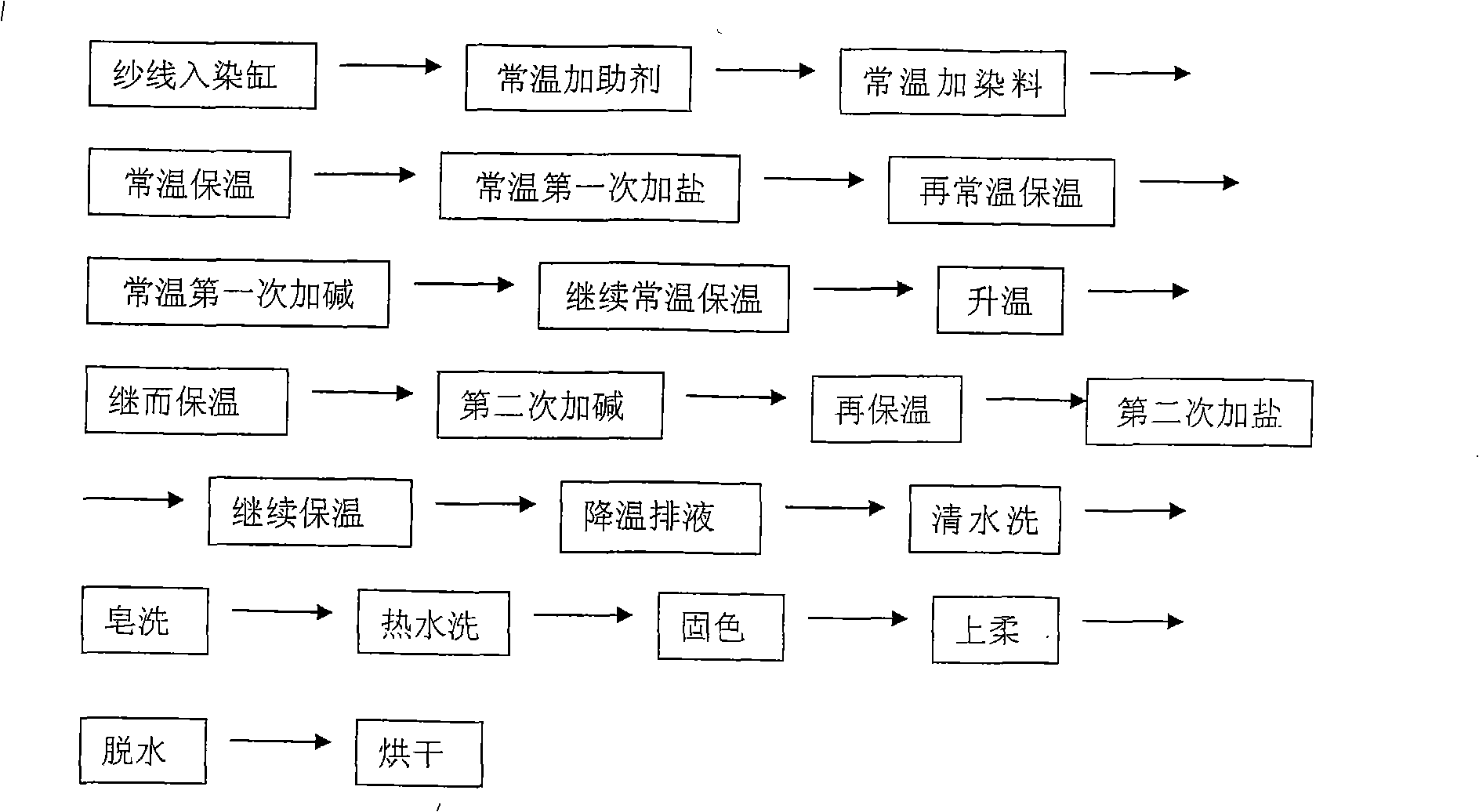

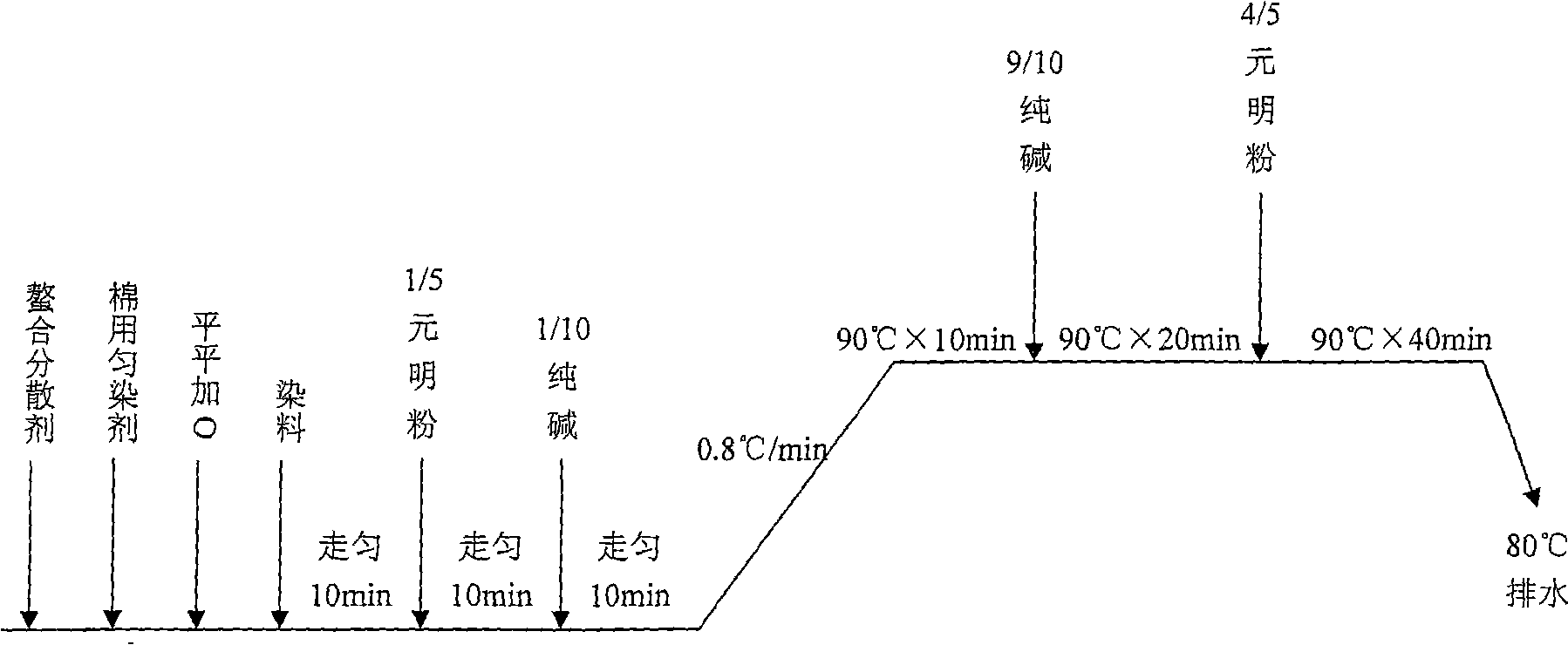

Dyeing process for silk and pashm blended yarn

InactiveCN101289812ALow costEmission reductionBeaming machinesDyeing processColour fastnessBreaking strength

The invention provides a process for dyeing silk-cashmere blended yarns, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: silk-cashmere blended yarns ready to be dyed are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; alkali is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; alkali is added in the dye vat for the second time; the dye vat is kept warmth again; salt is added in the dye vat for the second time; the dye vat is kept warmth again; finally after sequent steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed silk-cashmere blended yarns are obtained. The process has the advantages of high color fastness, good level-dyeing property, good homochromaatism, high breaking strength, bright color, filled yarns, uneasy teasing, time conservation, low dye cost, simple processing step, energy consumption reduction, low sewage discharge and environment protection.

Owner:常熟市亨时特染织有限公司

Preparation method of calcium sulfate whisker filled halogen-free flame retardant nylon alloy material

Belonging to the technical field of high polymer material preparation, the invention provides a preparation method of a calcium sulfate whisker filled halogen-free flame retardant nylon alloy material. The method comprises the steps of: first putting 210-250 parts of nylon 66 resin, 70-79 parts of a compatilizer, 3-5 parts of a coupling agent, 60-80 parts of calcium sulfate whiskers, and 30-50 parts of a phosphate that are weighed by weight into a mixer for mixing, then putting 0.9-1.8 parts of an antioxidant, 130-170 parts of a chopped glass fiber, and 0.5-1.2 parts of a surface modifier that are weighed by weight into the mixer for further mixing for 6-12min, thus obtaining the granulation material; and putting the granulation material into a twin-screw extruder for melt extrusion, and setting the temperature of each zone of the screws, thus obtaining the calcium sulfate whisker filled halogen-free flame retardant nylon alloy material. The method provided in the invention has the advantages of: brief technological steps, and undemanding equipment and operation requirements. The nylon alloy material prepared by the method of the invention has excellent heat resistance, and is halogen free, thus reflecting green and environmental protection.

Owner:苏州宇度医疗器械有限责任公司

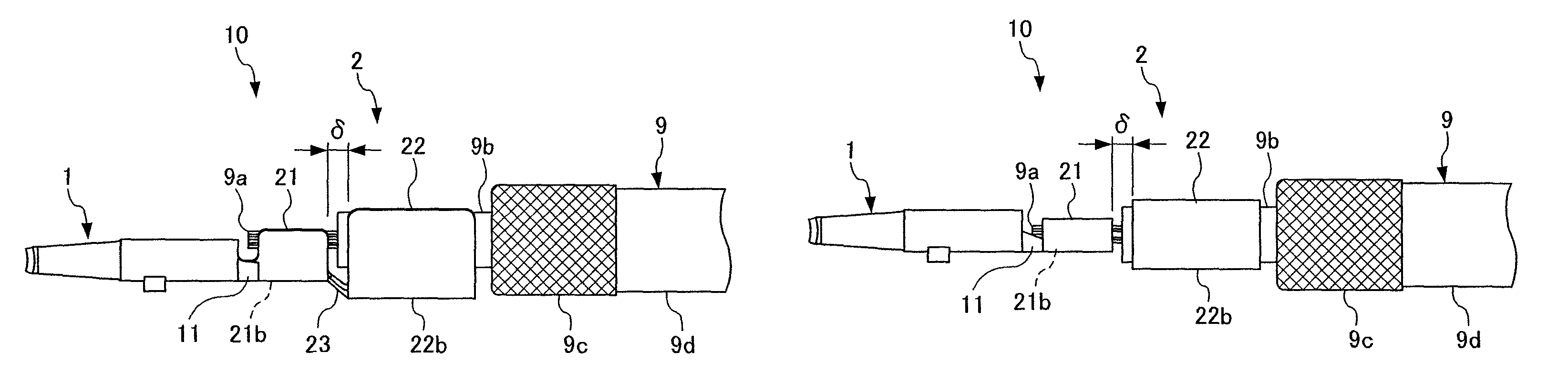

Contact for coaxiable cable having a tearable band between a conductor barrel and a crimp barrel

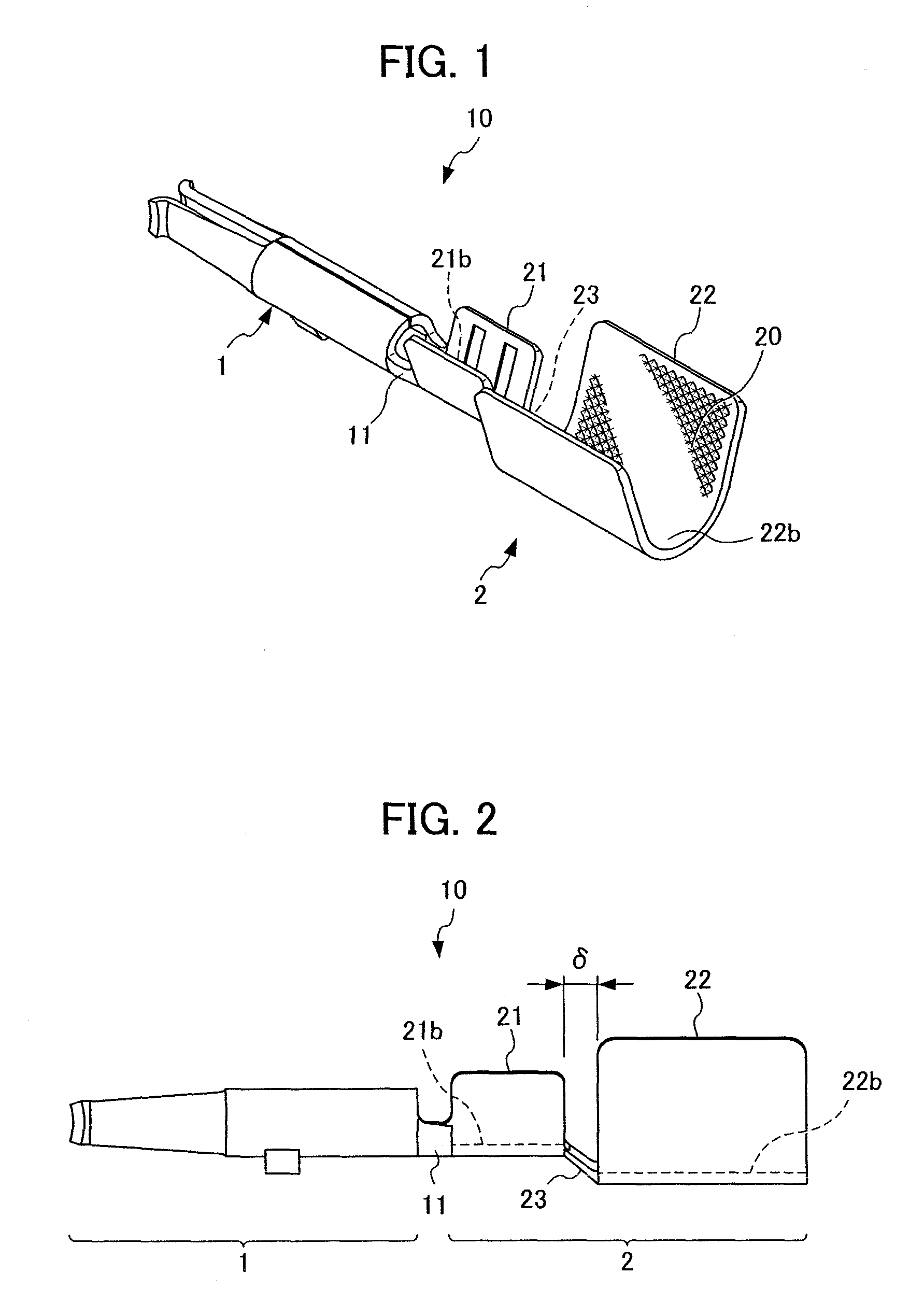

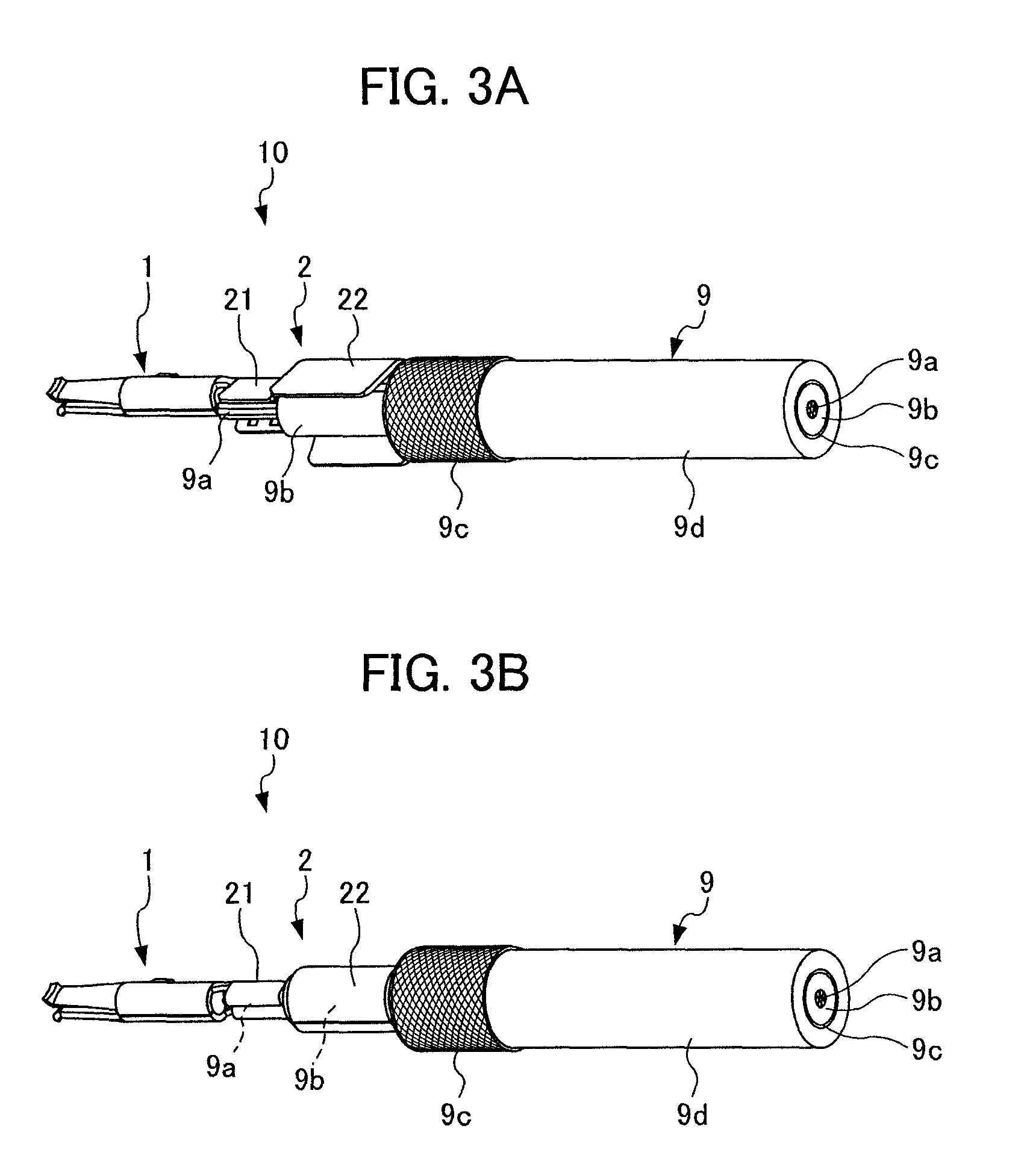

InactiveUS8277249B2Reduce processing stepsSuppress mutationElectrically conductive connectionsConnection formation by deformationCoaxial cableElectrical conductor

A contact for coaxial cable attached to an end of a coaxial cable includes a contact part and a connection part. The connection part includes a conductor barrel, an open crimp barrel, and a junction band narrow in width. The conductor barrel is disposed on a side to a base end portion of the contact part and can crimp the inner conductor. The open crimp barrel is adjacent to the conductor barrel and can crimp an exposed portion of the dielectric body so as to surround the exposed portion of the dielectric body in a cylindrical shape. The junction band joins the conductor barrel with the open crimp barrel so as to bridge the two. The both end portions of the junction band are torn during or after crimping of the conductor barrel and the open crimp barrel.

Owner:JST MFG CO LTD

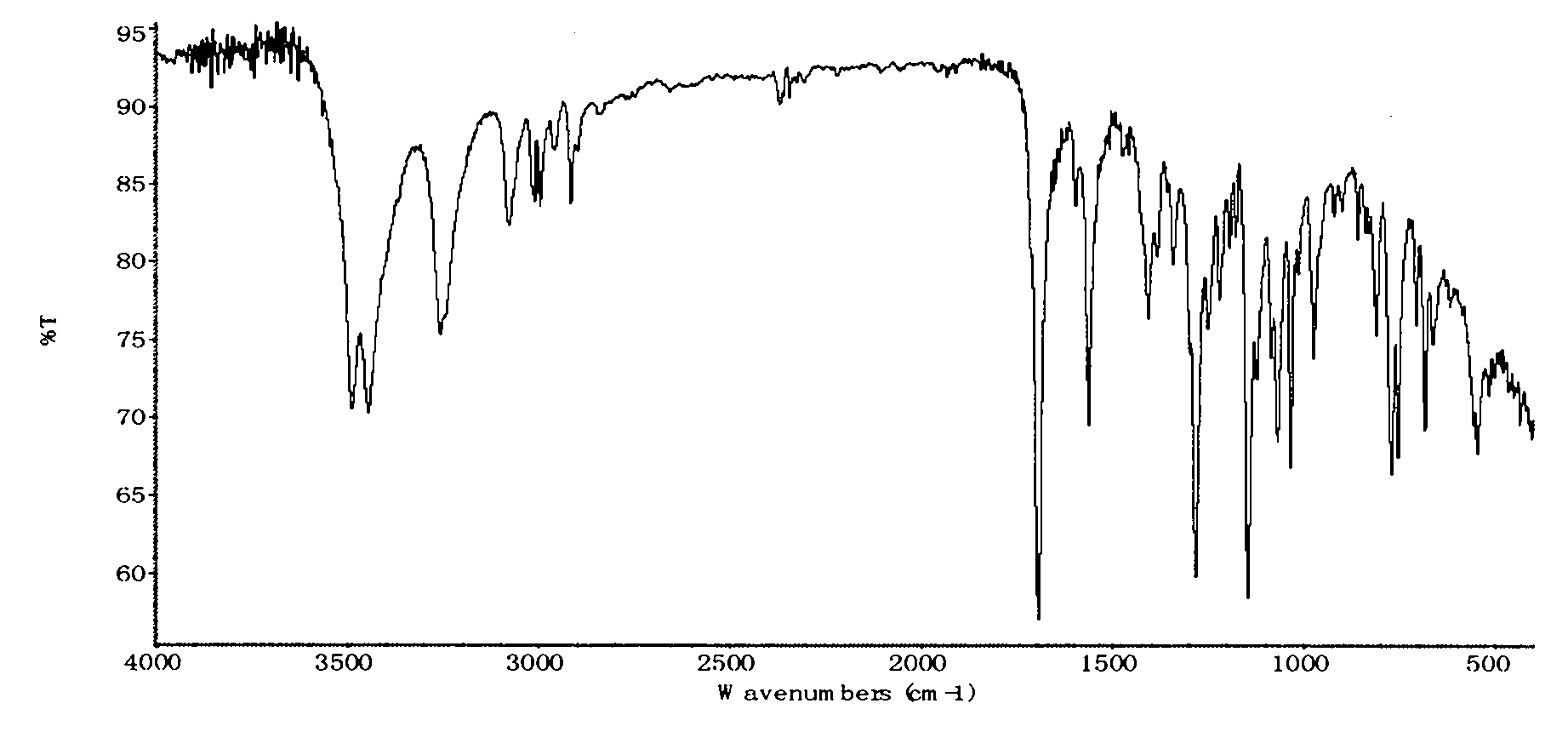

Natural L-alpha-glycero-phosphatidylcholine preparation method

InactiveCN102875592AShort process stepsSave resourcesPhosphatide foodstuff compositionsChemistryCationic exchange

The invention belongs to the technical field of natural drug isolation and purification and relates to a natural L-alpha-glycero-phosphatidylcholine preparation method. The method includes: using acid liquor for soaking macroporous cation exchange resin, draining the acid liquor, washing with water, soaking with alkali liquor, washing with water, soaking with acid liquor again, washing with deionized water and using low-carbon alcohol for replacement; adding powder phospholipid into the low-carbon alcohol, alkalifying for reaction, leaching, washing with the low-carbon alcohol, adjusting pH to be alkalescent, decomposing, condensing, cooling, transferring into a separating funnel, standing, and separating out a lower-layer low-carbon alcohol phase; packing the powder phospholipid and the alcohol-phase resin, adsorbing alcoholysis mixed solution, washing the resin with low-carbon alcohol to remove impurities; and eluting the resin with pure water; and decolorizing with decolorizing agent, decomposing and condensing to obtain a finished product. The natural L-alpha-glycero-phosphatidylcholine preparation method has the advantages that process steps are simple, and industrial production requirements are met; resources are saved and cost is reduced; and the total yield of the finished product reaches 65.47-86.08%, the external standard content is more than 99%, and the optical purity is up to 99%.

Owner:SUZHOU FUSHILAI PHARMA CO LTD

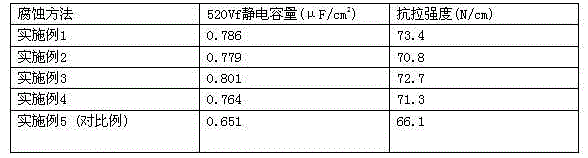

Corrosion process for anode aluminum foil with tunnel branched holes for aluminum electrolytic capacitor

InactiveCN104878441APrevent thinningDistinctive featuresElectrolytic capacitorsBenzoic acidOXALIC ACID DIHYDRATE

Owner:LIAOCHENG UNIV

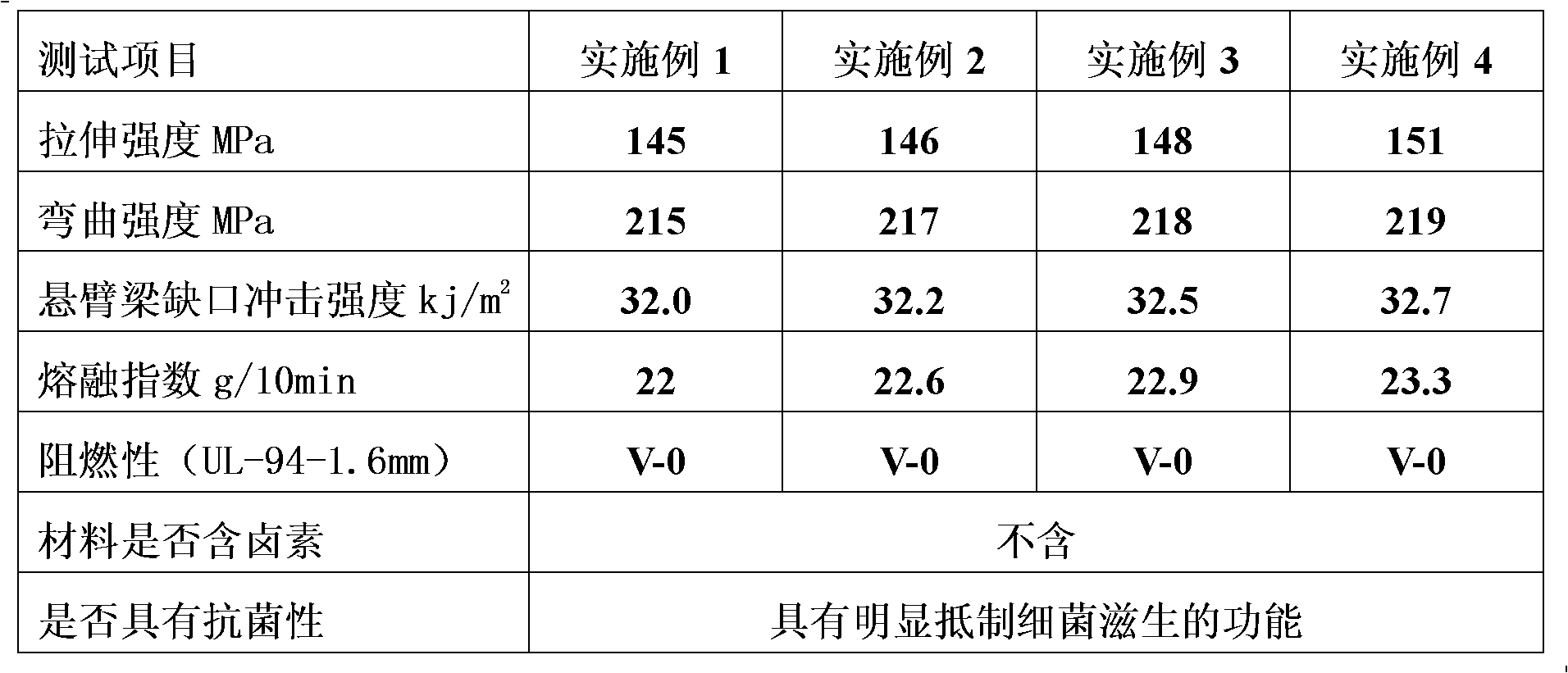

Preparation method of antibacterial halogen-free flame-retardant nylon alloy material

The invention provides a preparation method of an antibacterial halogen-free flame-retardant nylon alloy material, belonging to the technical field of high polymer material preparation. The method comprises the following steps of: weighing 60-65 parts of nylon 66 resin, 30-35 parts of nylon 1010 resin, 20-30 parts of rubber, 0.8-1.6 parts of coupling agent and 28-35 parts of flame retardant in parts by weight and putting into a high-speed mixer for mixing, then putting 1.2-2 parts of antibacterial agent, 0.4-0.9 parts of oxidation inhibitor, 45-50 parts of chopped glass fiber and 0.3-0.8 parts of surface modifier weighed in parts by weight for continued mixing so as to obtain a granulation material; putting the obtained granulation material into a paralleled twin-screw extruder for melt extrusion, and controlling the extrusion temperature of the paralleled twin-screw extruder to obtain the antibacterial halogen-free flame-retardant nylon alloy material. The antibacterial halogen-free flame-retardant nylon alloy material has the following advantages that: the processing steps are short, the tensile strength is greater than 145 MPa, the flexural strength is greater than 215 MPa, thenotch impact strength of a cantilever beam is greater than 32 kj / m<2>, the melt index is greater than 22 g / 10min, the flame resistance reaches to V-0 (UL-94-1.6mm), and the prepared material can resist the bacteria erosion.

Owner:CHANGSHU YAMEI MODEL CLOTHES RACK

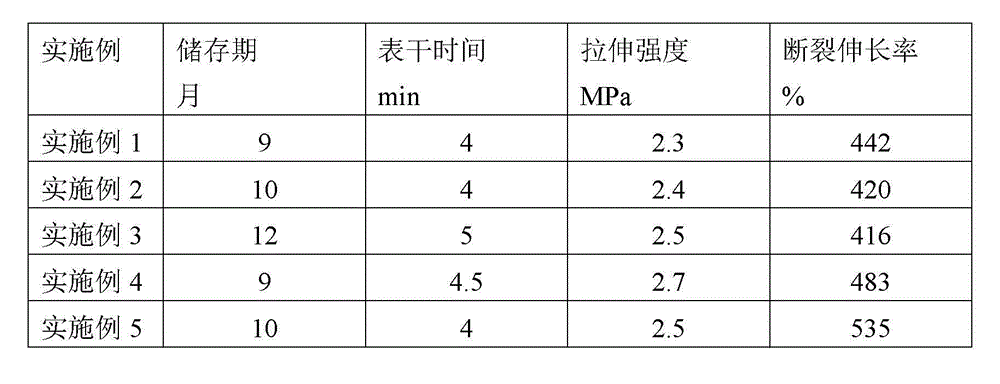

Dealcoholization type cured organosilicone sealant and preparation method thereof

InactiveCN103146339AImprove adaptabilityImprove curing speedAdhesivesAging resistanceUltimate tensile strength

The invention discloses a dealcoholization type cured organosilicone sealant and a preparation method thereof and belongs to the technical field of high polymer materials. The dealcoholization type cured organosilicone sealant consists of the following raw materials in parts by weight: 100 parts of 107 silicon oil, 10-200 parts of reinforcement filler, 0.1-1 part of silane coupling agent, 0.01-0.5 part of catalyst and 5-7 parts of cross-linking agent. The dealcoholization type cured organosilicone sealant has the advantages that sizing depth is 5mm, and the sealant can be cured within 24 hours, so that the sealant has excellent curing speed; because the tensile strength and the elongation at break can respectively reach 2MPa and 200-500 percent, the sealant has excellent mechanical properties; because the sealant is not yellowed within 1000 hours at the temperature of 150 DEG C and is not cracked, the sealant has outstanding ageing resistance; because the storage time can be 9-12 months long, the sealant has ideal stability; the sealant can be suitable for sealing a solar module frame; and because the provided preparation method is simple in process steps and the process requirements are not strict, the industrial large-scale production requirements can be met.

Owner:西卡(江苏)工业材料有限公司

Method for extracting oligomeric proanthocyanidins from grape seeds

InactiveCN102161651AReduce extraction costsEnsure safetyOrganic chemistryUltrafiltrationGrape seedProanthocyanidin

The invention discloses a method for extracting oligomeric proanthocyanidins from grape seeds, and belongs to the field of the separation and purification of the oligomeric proanthocyanidins. The method comprises the following steps of: preparing extracting solution, namely crushing dried grape seeds into small particles, loading the small particles into an extraction kettle, adding hot water into the kettle for circular extraction, controlling the size of the small particles and the weight ratio of the small particles to the water, controlling the extraction pressure, temperature and time of the extraction kettle, and controlling the times of circular extraction to obtain the extracting solution; preparing pure filtrate, namely filtering the extracting solution through a filter screen to obtain crude filtrate, filtering the crude filtrate through an ultrafiltration membrane, controlling the inlet pressure and outlet pressure, temperature and flow velocity of the ultrafiltration membrane to obtain fine filtrate, performing reverse osmosis filtration on the fine filtrate, and collecting generated filtrate for recycling; and concentrating and drying, namely adding the pure filtrate into a concentration drying tank for concentration and drying, and controlling the temperature, pressure and time of concentration and drying of the concentration drying tank to obtain an oligomeric proanthocyanidins product. The method has the advantages that: extraction cost is reduced, and the safety of the product is guaranteed; energy sources are saved, and the purity and yield of the product are guaranteed; and pollution-free production and environmental protection are embodied.

Owner:JIANGSU XINGCHI BIOTECH

Hole applied fertilizer special for tobacco and preparation method thereof

InactiveCN105601439AAids in growth and developmentEasy to operateMagnesium fertilisersAlkali orthophosphate fertiliserPhosphatePotassium

The invention belongs to the technical field of fertilizer, and provides a hole applied fertilizer for tobacco and a preparation method thereof. The hole applied fertilizer for the tobacco is prepared from, by weight, 5-30 parts of potassium fulvic acid, 1-25 parts of amino acid, 0.01-2 parts of azadirachtin, 20-70 parts of ammonium nitrate, 10-40 parts of monoammonium phosphate, 0.05-2 parts of compound sodium nitrophenolate, 0.05-2 parts of rooting powder, 1-10 parts of EDTA chelated magnesium and 1-10 parts of boric acid. According to the hole applied fertilizer for the tobacco, growth and development of root systems of tobacco plants are promoted by fully utilizing a plant growth regulator, chelated trace elements and multiple functional elements such as amino acid according to the physiological habits of the tobacco, the effect is better, the functions are comprehensive, and the hole applied fertilizer is suitable for the tobacco crops in the early transplanting stage.

Owner:HUNAN TAIGU BIOTECH

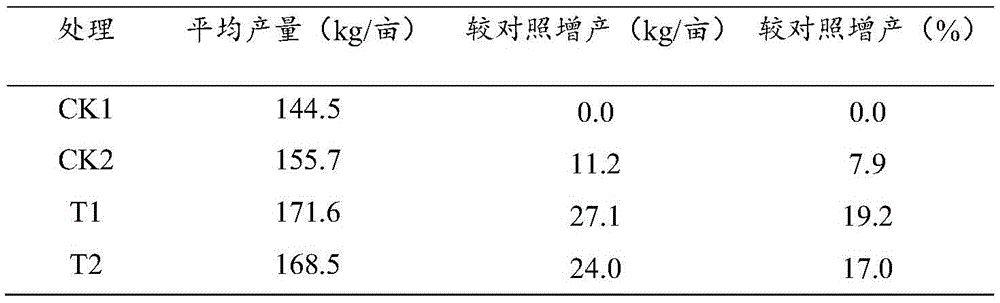

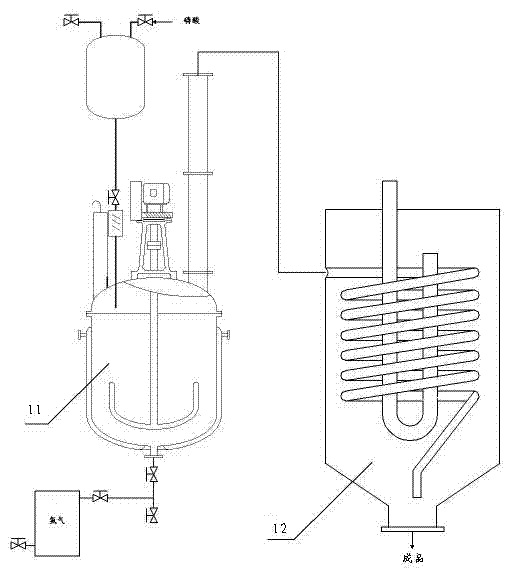

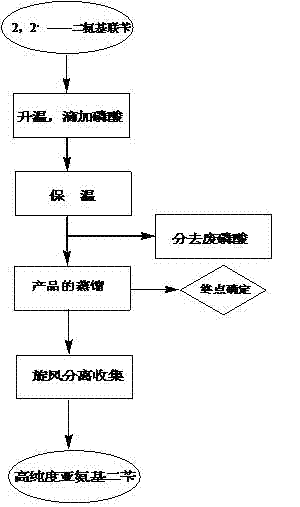

Method for preparing iminodibenzyl

The invention discloses a method for preparing iminodibenzyl. In the method, phosphoric acid is added into 2,2,-diamido-bibenzyl to form salt, and the salt is subjected to cyclization reaction to prepare the iminodibenzyl. The method is characterized in that after the phosphoric acid is separated from a product formed by the cyclization reaction of the 2,2,-diamido-bibenzyl, nitrogen is introduced to perform reduced pressure distillation, and the distilled iminodibenzyl is collected by a cyclone separator. The method for preparing the iminodibenzyl comprises the following steps of: adding the phosphoric acid into the 2,2,-diamido-bibenzyl to form the salt, performing the cyclization reaction to obtain iminodibenzyl, introducing the nitrogen directly, distilling under reduced pressure, and collecting the iminodibenzyl by the cyclone separator, wherein the product formed by the cyclization reaction is subjected to the steps of elutriation, recrystallization and the like. The method has a simple process, the yield of the product is improved, and the purity of the iminodibenzyl is over 99.0 percent.

Owner:JIANGSU TOHOPE PHARMA

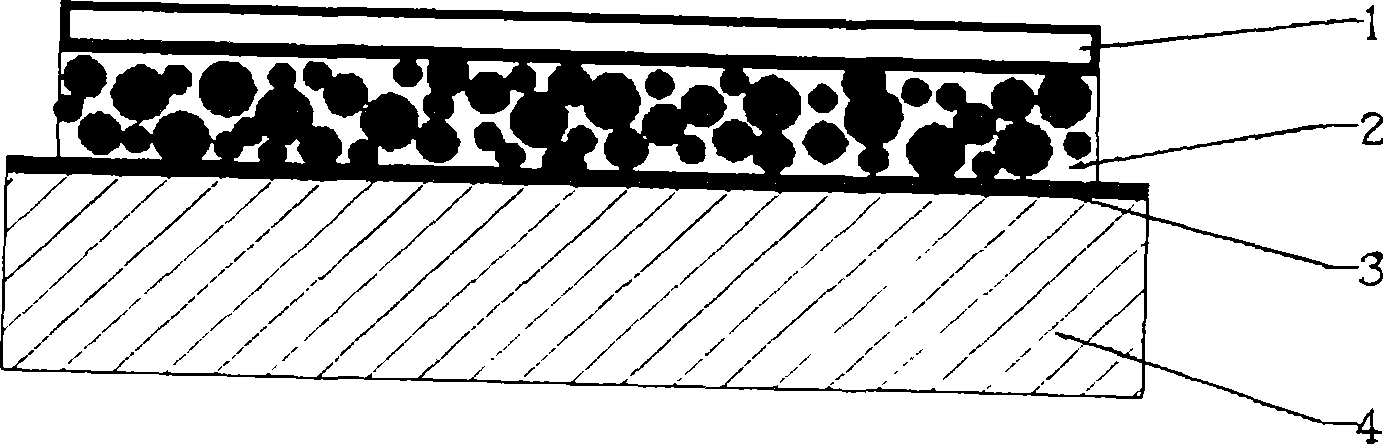

Elastic thrust block and production method thereof

InactiveCN101509518AImprove wear resistanceImprove thermal conductivityShaftsBearing componentsPorosityWater turbine

The invention relates to an anti-thrust-used thrust pad of a water-turbine generator set. The elastic thrust pad takes a metal multiaperture elastic cushion as a substrate, the holes of which is internally filled with modified polyfluortetraethylene plastics and the surface is formed with a wearing layer. The modified polyfluortetraethylene plastics are prepared by the following raw materials according to the percentage by weight: 18-22% of copper powder, 2-3% of supramoly and 75-80% of polyfluortetraethylene. The lead powder is not added in the filling material polyfluortetraethylene of the elastic thrust pad and the added copper powder effectively increases the wearing resistance and thermal conduction of composite plastics spindle bushing. The supramoly is added for generating self-lubricating effect, thus reducing the coefficient of friction of composite plastics tiling and further increasing the wearing resistance. The elastic cushion is formed by pressing three standard copper springs, which greatly improves the uneven phenomenon of the porosity factor of the elastic cushion and causes the uniformity of the elasticity modulus of the product to be increased and the service performance to be stable.

Owner:DALIAN HONGRUN COMPOSITE BEARING

Preparation method of glazed ceramic tile and molding device used in the method

ActiveCN103538141BReduce weightImprove viewing effectRoof covering using tiles/slatesFeeding arrangmentsWeather resistanceGlaze

Owner:常熟大象建陶有限公司

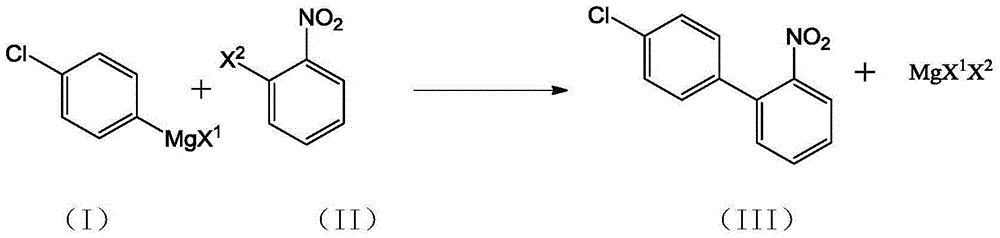

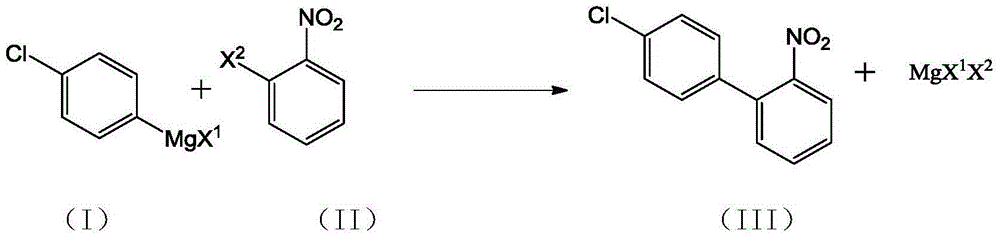

Preparation method of 4'-chloro-2-nitrobiphenyl

ActiveCN105017025AReduce usageReduce manufacturing costOrganic chemistryOrganic compound preparationNickel catalystPalladium catalyst

The invention discloses a preparation method of 4'-chloro-2-nitrobiphenyl. 4'-chloro-2-nitrobiphenyl is obtained by reaction of p-chlorophenyl magnesium halide and 2-nitro-halogenobenzene in a solvent in the presence of a nickel catalyst. The preparation method provided by the invention has the advantages of no need of using an expensive palladium catalyst, low cost, few reaction steps, high reaction selectivity and high yield.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

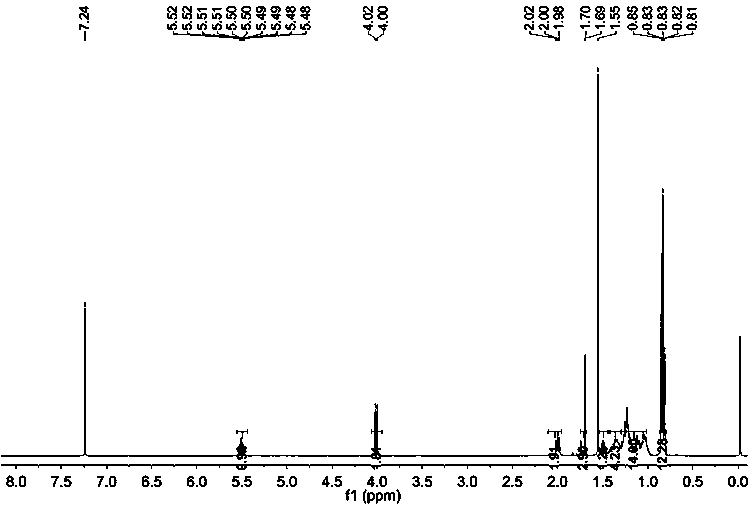

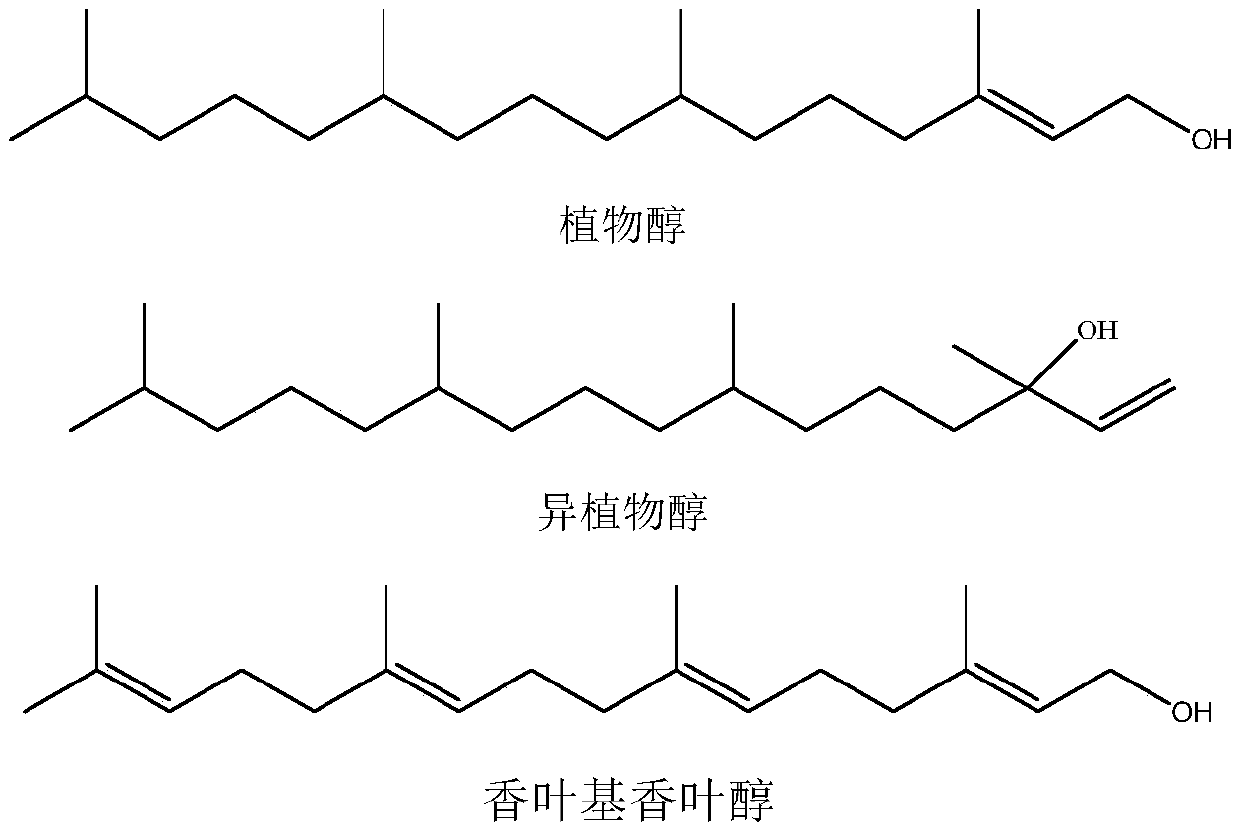

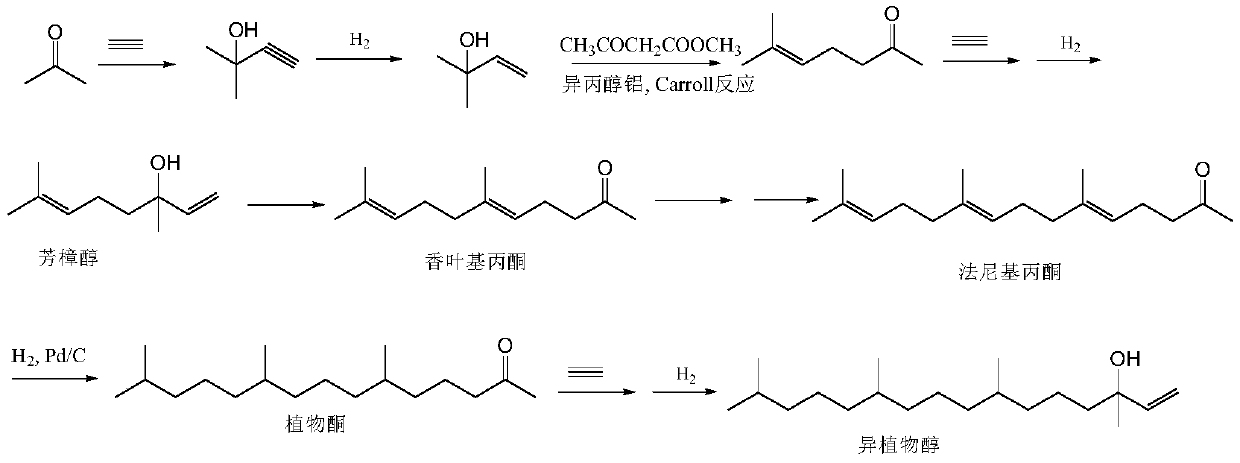

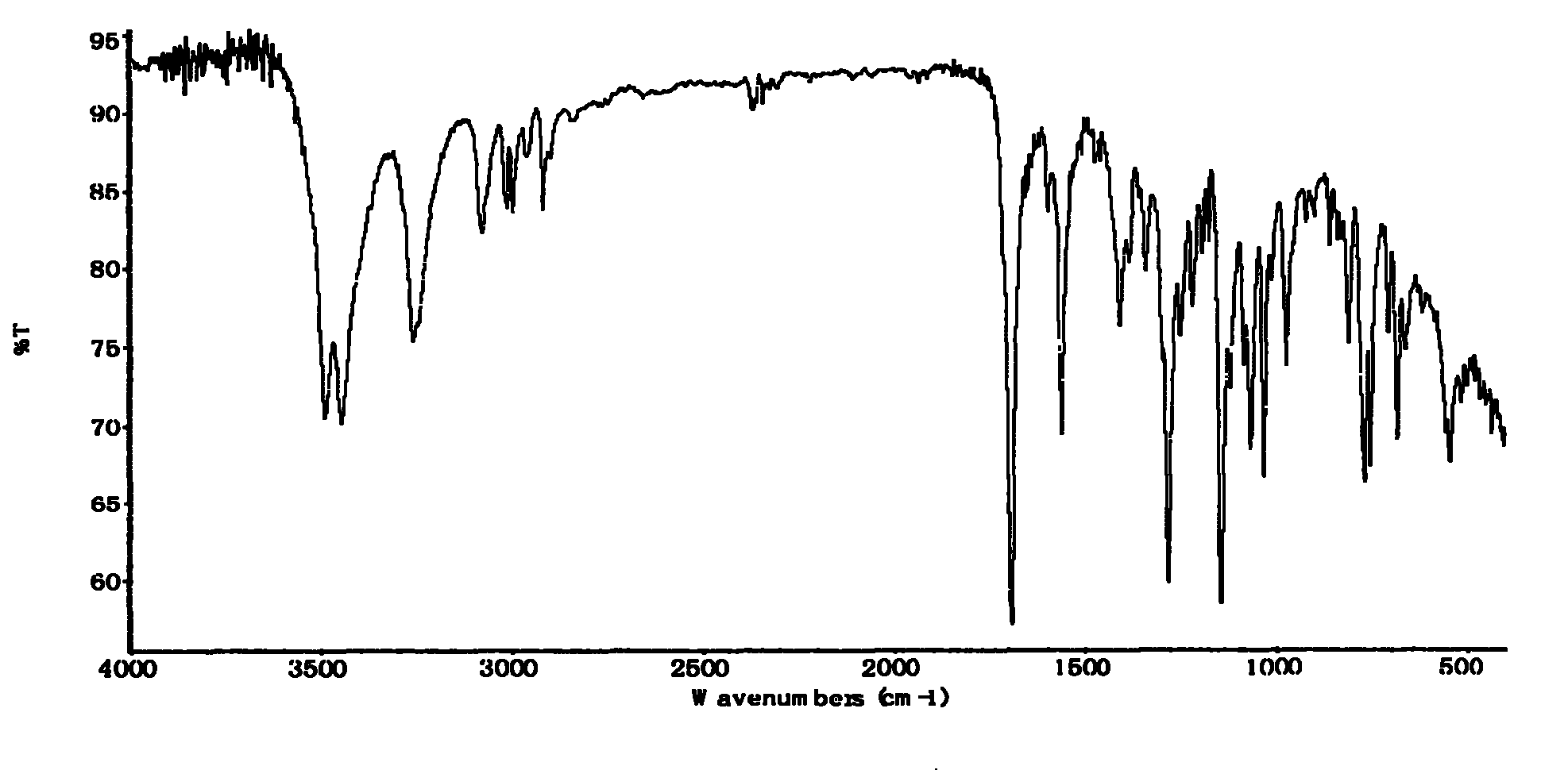

Synthesis method of intermediate farnesyl acetone and method for synthesizing phytol, isophytol and geranyl geraniol by using intermediate farnesyl acetone

ActiveCN111393275AShort synthetic routeReduce dosagePreparation by isomerisationOrganic compound preparationVitamin K2Side chain

The invention relates to a synthesis method of an intermediate farnesyl acetone, and a method for synthesizing vitamin E, vitamin K1, vitamin K2 side chain isophytol, phytol and geranyl geraniol by utilizing farnesyl acetone. Specifically, the method includes: taking acetone and 5-chloro-2-pentanone as the raw materials, carrying out three Grignard reactions to obtain a key intermediate farnesyl acetone, and hydrogenating the farnesyl acetone to obtain phytol ketone; reacting farnesyl acetone with a vinyl chloride Grignard agent to obtain geranyl linalool, and conducting rearrangement under acid catalysis to obtain geranyl geraniol; or reacting the farnesyl acetone directly with a hydroxyl-protected 2-chloroethanol Grignard agent to obtain geranyl geraniol; reacting phytol ketone with a vinyl chloride Grignard agent to obtain isophytol, and rearranging the isophytol under acid catalysis to obtain phytol; or directly reacting the phytol with a hydroxyl-protected 2-chloroethanol Grignardagent to obtain the phytol. The method has the advantages of cheap and easily available initial raw materials, short synthesis process steps, low product cost and the like.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA +1

Preparation method of thiamphenicol

ActiveCN101812000AReduce process stepsShort process stepsOrganic chemistryOrganic compound preparationThiamphenicolPotassium

The invention relates to a preparation method of antibiotic, in particular to a preparation method of thiamphenicol. The preparation method comprises the following steps: by weight, dissolving 100 parts of D-4-Methylsulfonylphenyl serine ethyl ester in 500-700 parts of methanol solvent, adding 24-27 parts of KBH4 to react at 30-60 DEG C for 4-8 hours, recycling 300-400 parts of methanol, neutralizing reaction solution with acid to adjust the pH value of the solution to 6-10, adding 42-45 parts of dichloroacetonitrile, performing a cyclization reaction for 4-6 hours, reducing pressure to recycle all of the solution, adding water to perform solid-liquid separation and obtain a solid mixture, adding 600-800 parts of water in the solid mixture, heating to 85-90 DEG C, keeping temperature at 85-90 DEG C for 30 minutes, and discoloring to obtain thiamphenicol. The invention is characterized by fewer steps, simple operation, short reaction time, low cost and the like.

Owner:JIANGSU HANSYN PHARMA

Thickened hot-dipping aluminum-zinc-plated steel plate and preparation method thereof

The invention discloses a thickened hot-dipping aluminum-zinc-plated steel plate and a preparation method of the thickened hot-dipping aluminum-zinc-plated steel plate and belongs to the technical field of coating steel plates. The thickened hot-dipping aluminum-zinc-plated steel plate comprises a substrate, wherein the surface of the outward side of the substrate in a used state is combined with a first plating-assistant layer, and the surface of the inward side of the substrate in the used state is combined with a second plating-assistant layer; the surface of the first plating-assistant layer is combined with a first structure layer; the surface of the second plating-assistant layer is combined with a second structure layer. Therefore, the thickness of a plated layer on the outward side of the substrate in the used state and the thickness of a plated layer on the inward side of the substrate in the used state are increased, and the sum of the thicknesses of the plated layers on the two sides is up to 270g / m<2>, so that the stability of the plated layers can be guaranteed, the good attachment effect between the plated layers and the substrate is achieved, the corrosion resistance performance, the processed shaping performance and the blackening resistance performance can be obviously improved, and the defects of falling off, cracking and the like of the plated layers during use can be avoided; the technical steps are simple and short; the technical requirement is low; the conventional aluminum-zinc-plated steel plate production line can be used for continuous and high-efficiency production.

Owner:江苏克罗德科技有限公司

Method for preparing acrylonitrile-butadiene-styrene copolymer toughened rigid polyvinyl chloride composite material

The invention provides a method for preparing an acrylonitrile-butadiene-styrene copolymer toughened rigid polyvinyl chloride composite material and belongs to the technical field of high molecular material preparation. The method comprises the steps of: firstly, feeding 61-67 parts of polyvinyl chloride resin, 4-7 parts of plasticizer, 8-13 parts of flexibilizer, 12-18 parts of filler, 0.9-1.5 parts of stabilizer, 4-7 parts of cellulose, 0.4-1 part of lubricant and 0.7-1.5 parts of carbon black into a high-speed mixer to obtain a mixture; and then feeding the mixture into a parallel twin-screw extruder for melt extrusion, and finally, subjecting the extruded material to water cooling, sized dicing and drying, thereby obtaining the finished product, wherein the temperatures of the screws of the parallel twin-screw extruder are controlled to 130 DEG C, 135 DEG C, 140 DEG C, 145 DEG C, 155 DEG C, 165 DEG C, 165 DEG C, 165 DEG C, 170 DEG C and 165 DEG C from the first zone to the tenth zone. The method provided by the invention is simple and short in process steps and rational in raw material selection.

Owner:CHANGSHU JIATAI METAL MATERIAL

Preparation method of trilobal polylactic acid pattern fiber

InactiveCN110067032AShort process stepsMeet the requirements of industrial scale-up productionSpinning head liquid feederConjugated synthetic polymer artificial filamentsChemistryPolylactic acid

The invention relates to a preparation method of a trilobal polylactic acid pattern fiber, which comprises the steps of preparing and drying a polylactic acid slice I, a polylactic acid slice II and apolylactic acid slice III, performing extrusion and metering through a extruder after adding the dry polylactic acid slice I into a first masterbatch to form first spinning melt, performing extrusionand metering through the extruder after adding the dry polylactic acid slice II into a second masterbatch to form second spinning melt, performing extrusion and metering through the extruder after adding the dry polylactic acid slice III into a third masterbatch to form third spinning melt, introducing the first spinning melt, the second spinning melt and the third spinning melt into a spinning trunk, allowing the first spinning melt, the second spinning melt and the third spinning melt to flow to a spinneret plate through respective melt flow channels, converge at a spinneret orifice and beextruded, performing air blast cooling and oiling to form a nascent fiber, and sequentially performing preliminary drafting, main drafting networking, hot plate forming and winding to a cylinder on the nascent fiber after balancing to form a finished product. The method is short in procedure; technical elements are not rigorous; and the fiber has a rich color effect and excellent fluffiness and air permeability.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

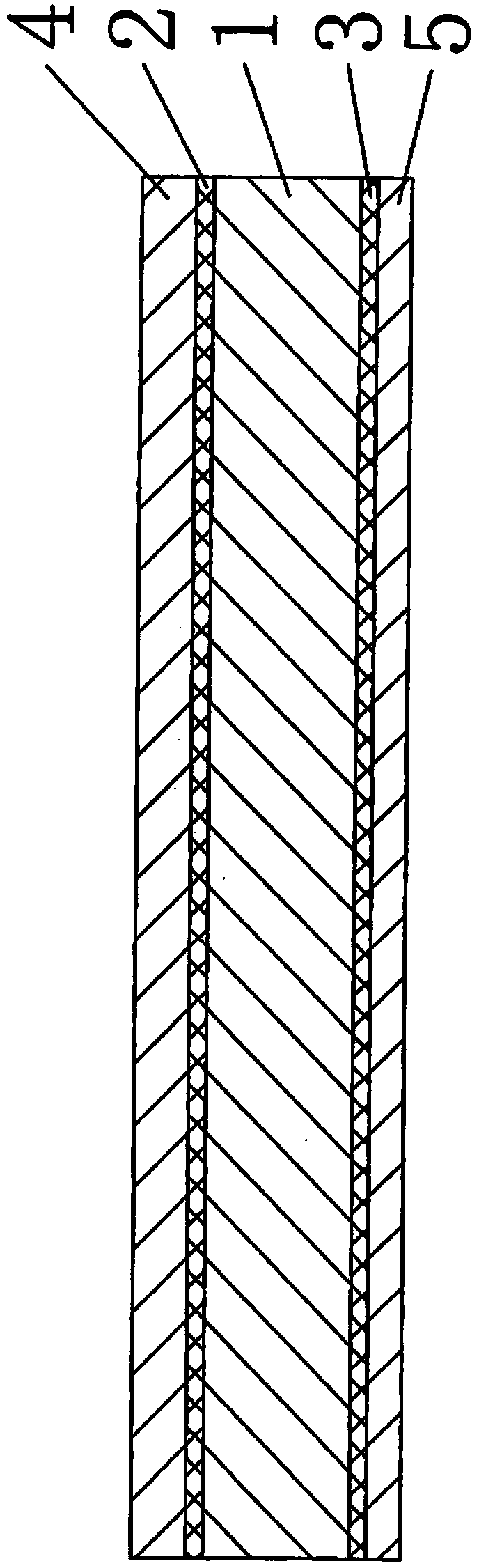

Waterproof corrosion-resistant color coating steel plate and preparation method thereof

InactiveCN104108209AHigh strengthStrong adhesionLaminationLamination apparatusSheet steelWeather resistance

The invention discloses a waterproof corrosion-resistant color coating steel plate and a preparation method thereof, belonging to the technical field of a color coating steel plate and preparation thereof. The method comprises the following steps: selecting and cleaning materials to obtain a steel plate matrix; chemically coating one side surface of the steel plate matrix and drying to obtain a plate blank; coating the surface of the chemical coating of the plate blank with a primer coating, and drying and curing; after cooling, coating the surface of the primer coating with a finish paint layer, and drying and curing to obtain a base plate; and coating the surface of the finish paint coating of the base plate with waterproof corrosion-resistant paint, and drying and curing to obtain the waterproof corrosion-resistant color coating steel plate. The waterproof corrosion-resistant color coating steel plate is excellent in waterproof anti-leakage property, weather resistance, chemical corrosion resistance and low-temperature flexibility; the process is simple and short, the adhesion between the waterproof corrosion-resistant layer and the steel plate surface is strong while the strength is excellent, the steel plate is free of peeling and bubbling after being soaked in water for 400h, and after 720h of neutral salt spray test, a transition layer is free of cracking or peeling.

Owner:CHANGSHU HUAYE STEEL STRIP

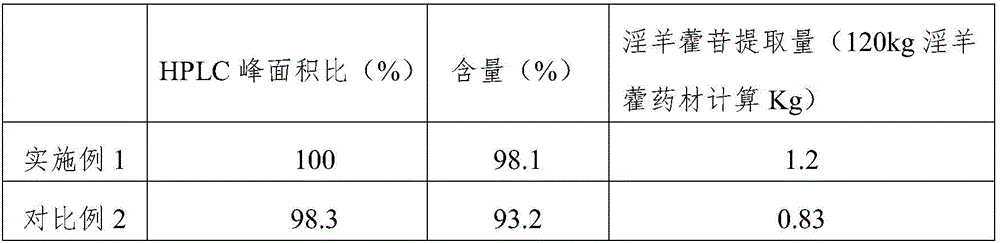

Method for extracting icariin from epimedium

ActiveCN106589020AIncrease contentLow extraction temperatureSugar derivativesSugar derivatives preparationAcetic acidEpimedium

The invention belongs to the technical field of traditional Chinese medicine extraction and in particular relates to a method for extracting icariin from epimedium. The method comprises the following steps: extracting an epimedium medicinal material by adopting a continuous countercurrent ultrasonic method, concentrating the obtained extracting solution, dissolving in water, extracting with ethyl acetate and n-butanol successively, taking an n-butanol extraction portion, concentrating, then passing through a macroporous adsorption column, and finally recrystallizing, so that the icariin product is obtained, and detection shows that the purity of the icariin product obtained by adopting the method provided by the invention is more than 98%. The method provided by the invention can be used for extracting the icariin from the epimedium rapidly and efficiently in a large scale; and the production cycle for producing the product is short, the energy consumption is low, and the environmental pollution is less.

Owner:北京颐方生物科技有限公司

Method for preparing 3, 4'-diaminodiphenyl ether

PendingCN111072503ALess Process WastewaterShort process stepsOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolDiaminodiphenyl ether

The invention discloses a method for preparing 3, 4'-diaminodiphenyl ether, which mainly comprises the following steps: adding m-aminophenol, an acid-binding agent and a solvent into a condensation reaction kettle, stirring, heating under the protection of inert gas, keeping the temperature at 100-120 DEG C, dropwisely adding p-nitrochlorobenzene, keeping the temperature for 2-4 hours after 5-7 hours, and continuing the reaction; after the reaction is finished, filtering to remove inorganic salt, transferring a filtrate into a hydrogenation kettle, adding a noble metal catalyst and a cocatalyst, performing nitrogen replacement, maintaining the temperature at 60-80 DEG C, and introducing hydrogen for catalytic hydrogenation under the hydrogen pressure of not more than 0.5 MPa; after the reaction is finished, filtering out the catalyst, distilling the filtrate, removing the solvent, rectifying, collecting 206-210 DEG C (2-3 mmHg) fraction which is white 3, 4'-diaminodiphenyl ether, and packaging under the protection of nitrogen. The method is short in process step, low in energy consumption and low in production cost, the content of the obtained 3, 4'-diaminodiphenyl ether is largerthan 99.5%, and the total molar yield is larger than 93%.

Owner:南通汇顺化工有限公司

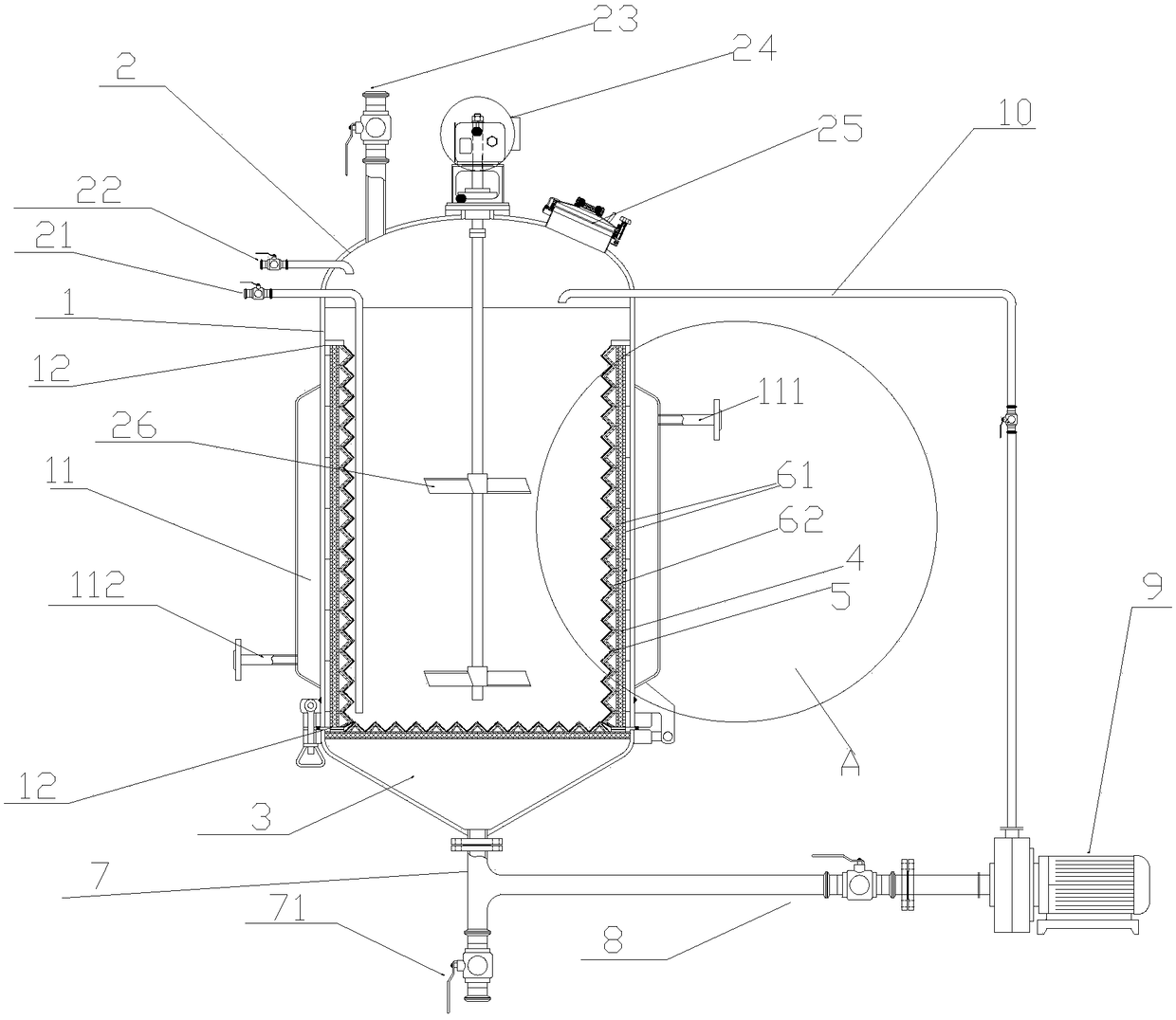

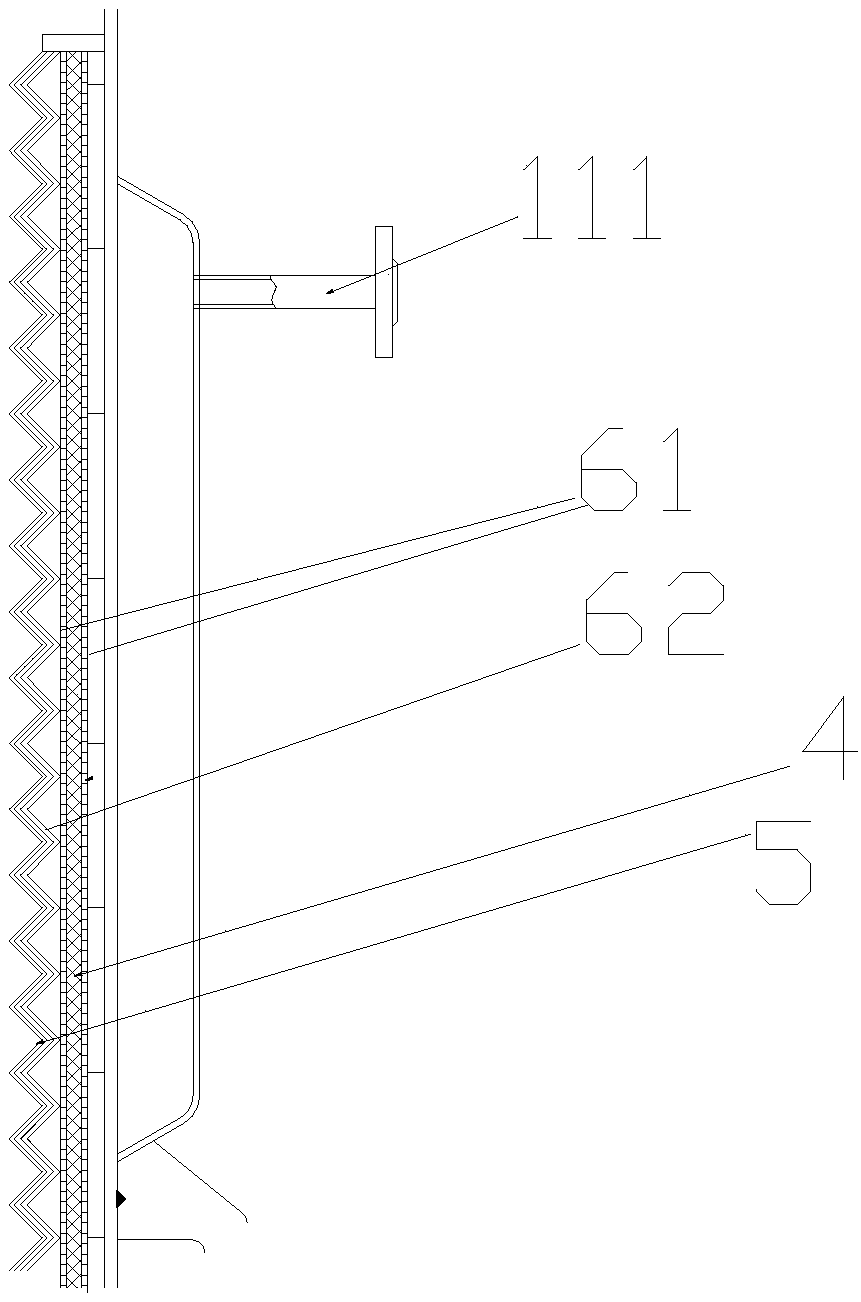

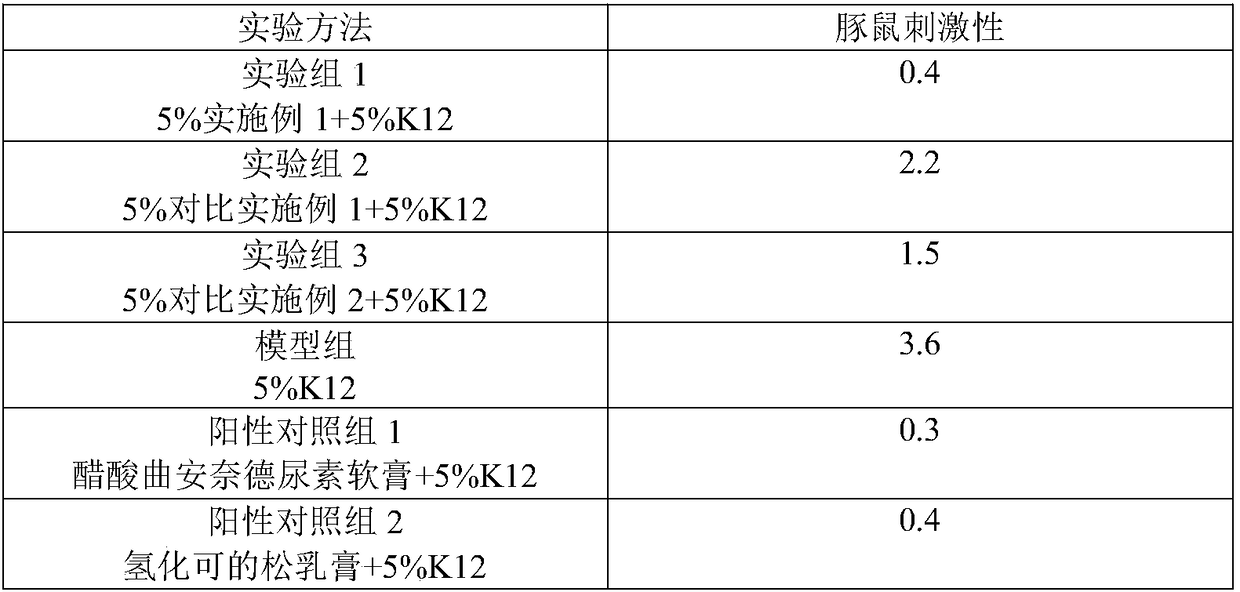

Preparation method, application and plant extraction device of gentian anti-irritant factor

ActiveCN107137261BReduce usageHigh extraction rateIon-exchange process apparatusCosmetic preparationsHigh concentrationActivated carbon

The invention provides a preparation method of geutianae anti-irritation factor and a plant extraction device. The preparation method comprises the following steps: smashing the medicinal material, namely, herba geutianae, feeding the smashed medicinal material into the plant extraction device, carrying out aqueous extraction, discharging the aqueous extracted solution and medicinal dregs; and adding a solvent, and carrying out thermal desorption under the condition that inert gas exists, thus obtaining the geutianae anti-irritation factor. The plant extraction device comprises a tank, a top cover and a lower opening cover, wherein the top cover and the lower opening cover are arranged on the top and bottom of the tank, and a ceramic film layer and a carbon fiber layer are arranged in the sequence from outside to inside on each of the inner side wall of the tank and the inner side of the lower opening cover. The preparation method and the plant extraction device have the advantages that extraction and adsorption are carried out at the same time, during the extraction process, the active ingredients are timely transferred into the activated carbon fibers, so that a relatively high concentration gradient is always kept between the extracted liquid and medicinal materials, the extracting ratio is high, and meanwhile, the use amount of the solvent is reduced.

Owner:SHANGHAI JIAYU BIOLOGICAL TECH CO LTD

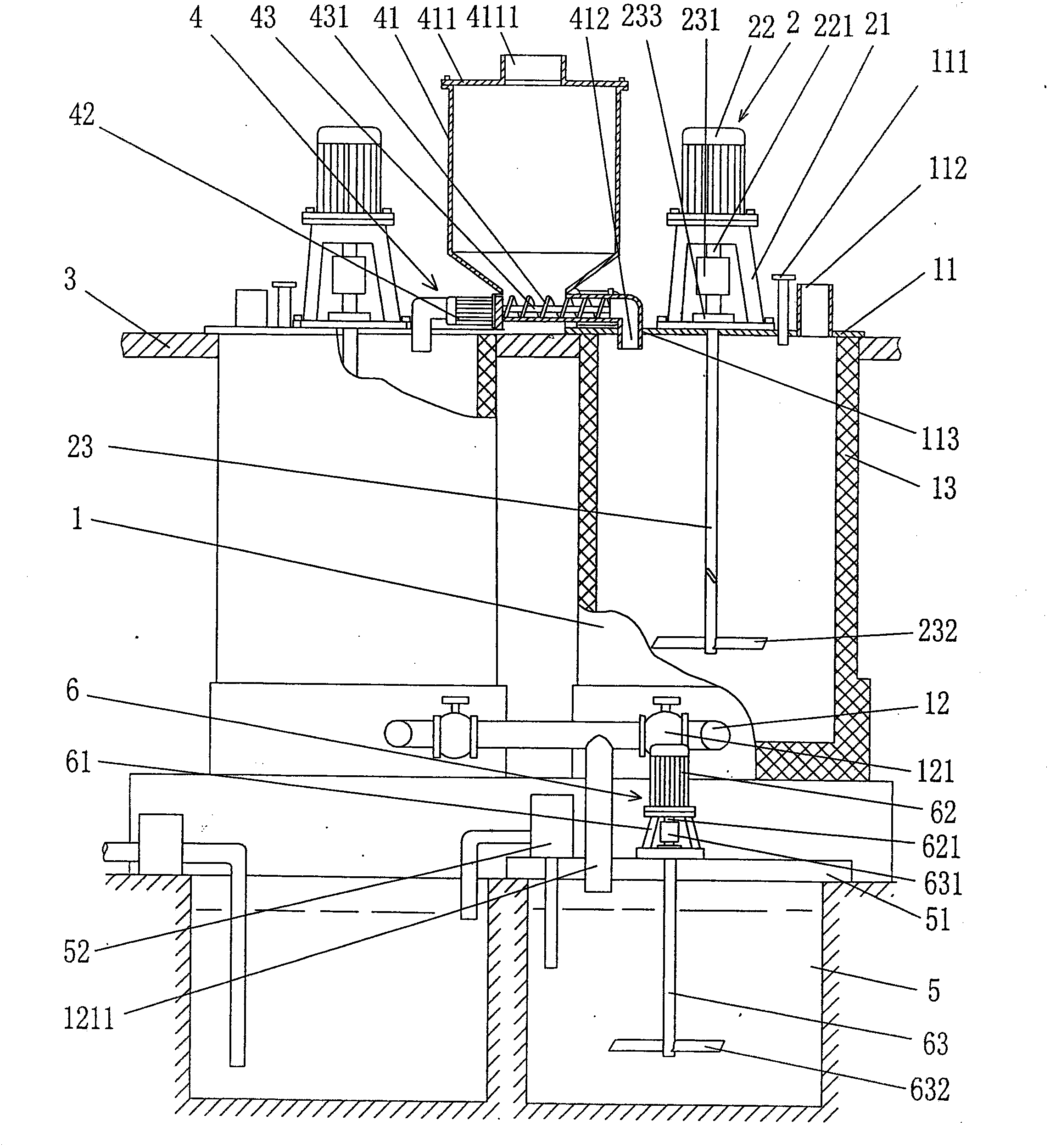

Method for preparing polyaluminum ferric chloride by using iron-containing acid pickle and aluminum ash

ActiveCN104229903AImprove protectionShort process stepsIron halidesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateChloride

The invention discloses a method for preparing polyaluminum ferric chloride by using iron-containing acid pickle and aluminum ash and belongs to the technical field of preparation of inorganic polymer coagulants. The method comprises the following steps: preparing a reaction device, wherein the reaction device comprises a reaction container, a stirring mechanism, a working platform, an aluminum ash spiral conveying mechanism, a settling pond and a settling pond stirring mechanism; an iron-containing acid pickle introduction joint and a waste gas outlet joint are formed in a top cover, and a reactant outlet joint is formed in the lower side part of the reaction container; the stirring mechanism is arranged on the top cover of the reaction container and extends into the reaction container; the working platform is connected with the upper side part of the reaction container; the aluminum ash spiral conveying mechanism is arranged on the working platform and is communicated with the reaction container; a supporting crossbeam is arranged on the upper part of the settling pond; the settling pond stirring mechanism is arranged at a central position of the supporting crossbeam and stretches into the settling pond; equipping a discharge valve on the reactant outlet joint; preparing an iron-containing waste acid stock solution; preparing a crude product of polyaluminum ferric chloride; and settling. The resources are saved, and the environmental protection is promoted; the requirement on large-scale industrialized production is met; and the method is good in energy-saving effect, simple in structure and convenient to operate.

Owner:CHANGSHU CITY FOR THE YU ENVIRONMENT TECH

Structural adhesive for dry hanging of wall decorative plates as well as preparation and usage method thereof

ActiveCN105542697AGuaranteed dry hanging effectLong-lasting dry-hanging effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerAdhesive

The invention provides a structural adhesive for dry hanging of wall decorative plates as well as a preparation and a usage method thereof, and belongs to the field of constructional adhesive technology. The adhesive comprises a component A and a component B, and the component A comprises the following raw materials: 40-70 parts of vinyl modified epoxy resin, 10-30 parts of modified polyester resin, 5-20 parts of a diluent, 5-15 parts of a flexibilizer, 0.05-0.5 parts of a polymerization inhibitor, 0.03-0.3 parts of a promoter, 1-3 parts of a thixotropic agent, and 10-40 parts of a reinforcing filler; the component B comprises the following raw materials: 30-60 parts of a curing agent, 20-50 parts of a plasticizer, 0.5-2.5 parts of an emulsifying agent, 1-3 parts of the thixotropic agent, and 10-30 parts of the reinforcing filler. The usage method comprises the following steps: the component A and the component B are uniformly mixed according to a mass ratio 100:5-20 for usage. The construction efficiency is improved; lasting dry hanging effect of stones is guaranteed; the adhesive is environmentally friendly. The method has a short process step, the usage equipment is simple and process requirement is not tough. Convenience during usage is shown.

Owner:江苏中来能源科技开发集团有限公司

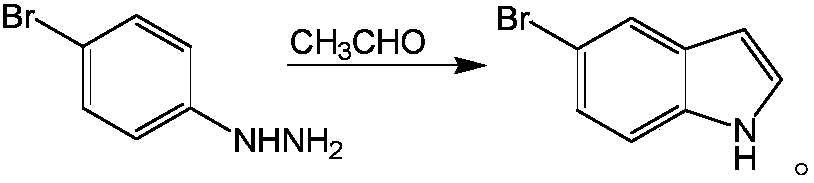

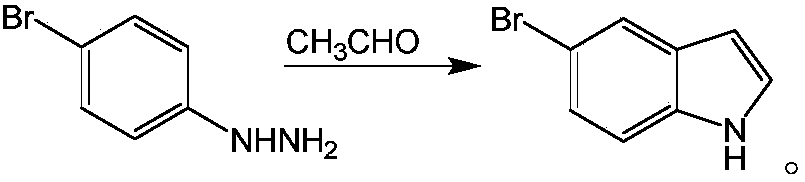

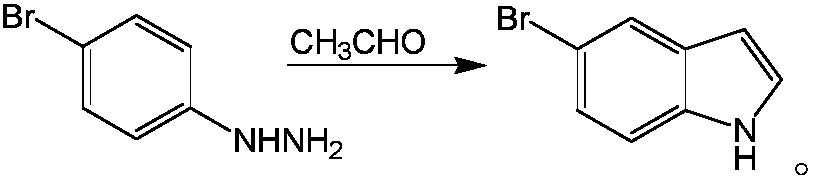

Method for synthesizing 5-bromo-7-azaindole

The invention discloses a method for synthesizing 5-bromo-7-azaindole. The method comprises dissolving 2-hydrazino-5-bromopyridine in a solvent, adding concentrated sulfuric acid into the solution, carrying out uniform mixing, heating the mixture to 70-90 DEG C, adding a catalyst into the mixed solution, adding acetaldehyde into the solution along with stirring, carrying out a reflux reaction process for 3-4h, then cooling the product to the room temperature, carrying out filtration, carrying out reduced pressure distillation on the filtrate and carrying out recrystallization to obtain 5-bromo-7-azaindole. The method has the advantages of simple processes, mild conditions, few by-products, high product purity and high product yield.

Owner:ITIC MEDCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com