Thickened hot-dipping aluminum-zinc-plated steel plate and preparation method thereof

A hot-dip aluminum and steel plate technology, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of lack of inspiration, lack of coating thickness, etc., and achieve excellent adhesion effect and process requirements Not harsh, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

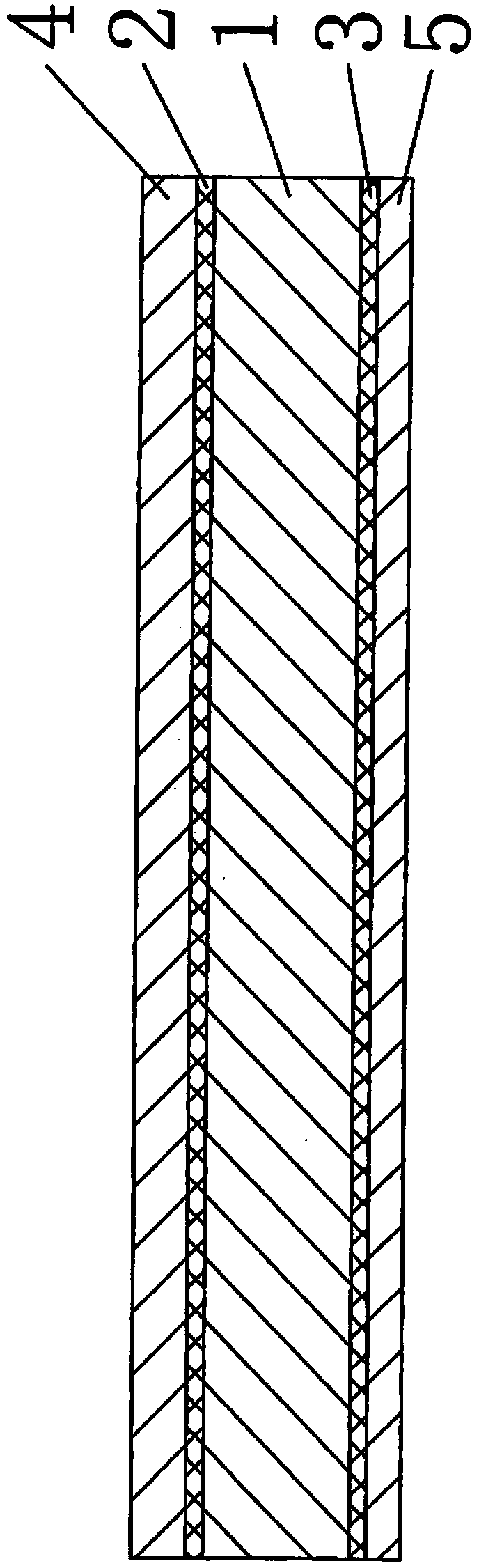

[0026] Prepared by figure 1 The steps of the thick hot-dip galvanized steel sheet of the structure shown are as follows:

[0027] A) Steel plate cleaning, select a 1.2mm thick cold-rolled steel plate with no scabs, pits and / or microcracks and other defects, and clean the two sides of the cold-rolled steel plate first, and then perform alkali Washing and electrolytic cleaning to remove surface oxide scale and / or oil stains, after cleaning, it is introduced into a drying tunnel for drying to obtain a substrate 1;

[0028] B) Coating the assisting layer, using the roller coating method to coat the first assisting layer 2 on the surface of the substrate 1 facing outward in the use state, and using the roller coating method to use the substrate 1 In the state, the surface of the inward-facing side is coated with the second assisted plating layer 3 to obtain the assisted plating steel sheet. The thickness of the first and second assisted plating layers 2 and 3 mentioned in this step are...

Embodiment 2

[0031] Change the thickness of the cold-rolled steel sheet in step A) to 5mm, and the cleaning is changed to first brush cleaning on both sides of the cold-rolled steel sheet, then pickling and electrolytic cleaning; change the first assist coating in step B) 2 and the thickness of the second plating assist layer 3 are changed to 2μm, and the weight parts of the raw materials constituting the plating assist layer are changed to: 50 parts of zinc chloride, 0.1 part of sodium fluoride, 10 parts of sodium chloride, 1 part of tin chloride, composite 1 part of surfactant and 37.9 parts of water, of which: the composite surfactant is N-hydroxyethyl perfluorooctyl sulfonamide; the thickness of the first structural layer in step C) is changed to 60 μm, and the thickness of the second structural layer is changed Change the chemical elements and their mass percentages in the aluminum-zinc-silicon rare earth alloy to: 60% aluminum, 2% silicon, 0.5% mixed rare earth, and 37.5% zinc. Among t...

Embodiment 3

[0033] Change the thickness of the cold-rolled steel sheet in step A) to 0.5 mm, and the cleaning is changed to alkaline washing and then pickling on both sides of the cold-rolled steel sheet; change the first auxiliary layer 2 and The thickness of the second plating assistance layer 3 is changed to 55nm, and the weight parts of the raw materials constituting the first and second plating assistance layers 2 and 3 are changed to: 15 parts of zinc chloride, 2 parts of sodium fluoride, 1 part of sodium chloride, and chlorine 0.5 parts of tin oxide, 3 parts of composite surfactant, 78.5 parts of water, among which: the composite surfactant is a mixture of 1.5 parts of alkylphenol polyoxyethylene ether and 1.5 parts of perfluorooctylsulfonyl quaternary iodide; Step C ) The thickness of the first structural layer 4 is changed to 25μm, the thickness of the second structural layer 5 is changed to 20μm, and the chemical elements and their mass percentages in the Al-Zn-Si rare earth alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com