Patents

Literature

46results about How to "Excellent resistance to blackening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

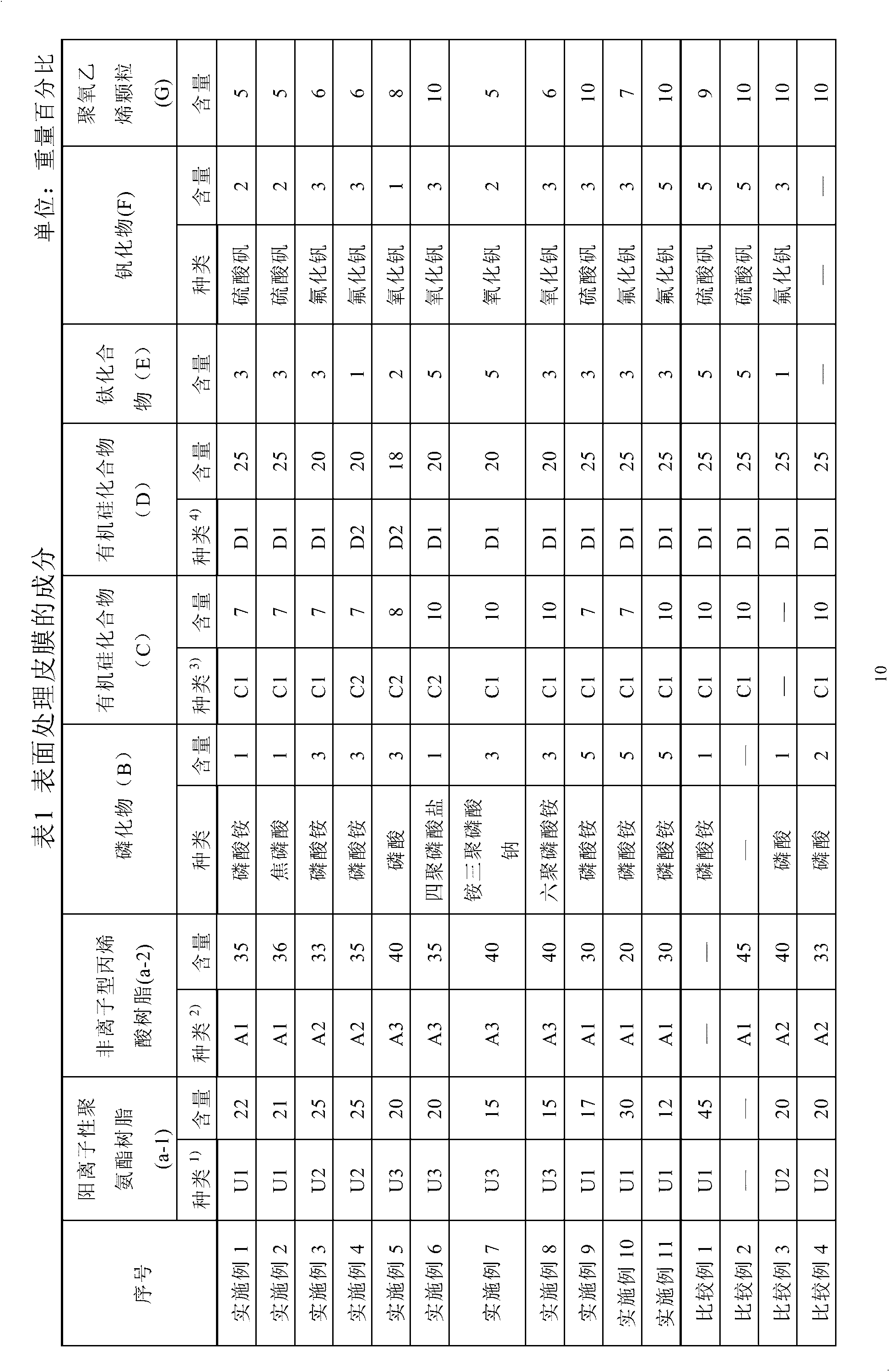

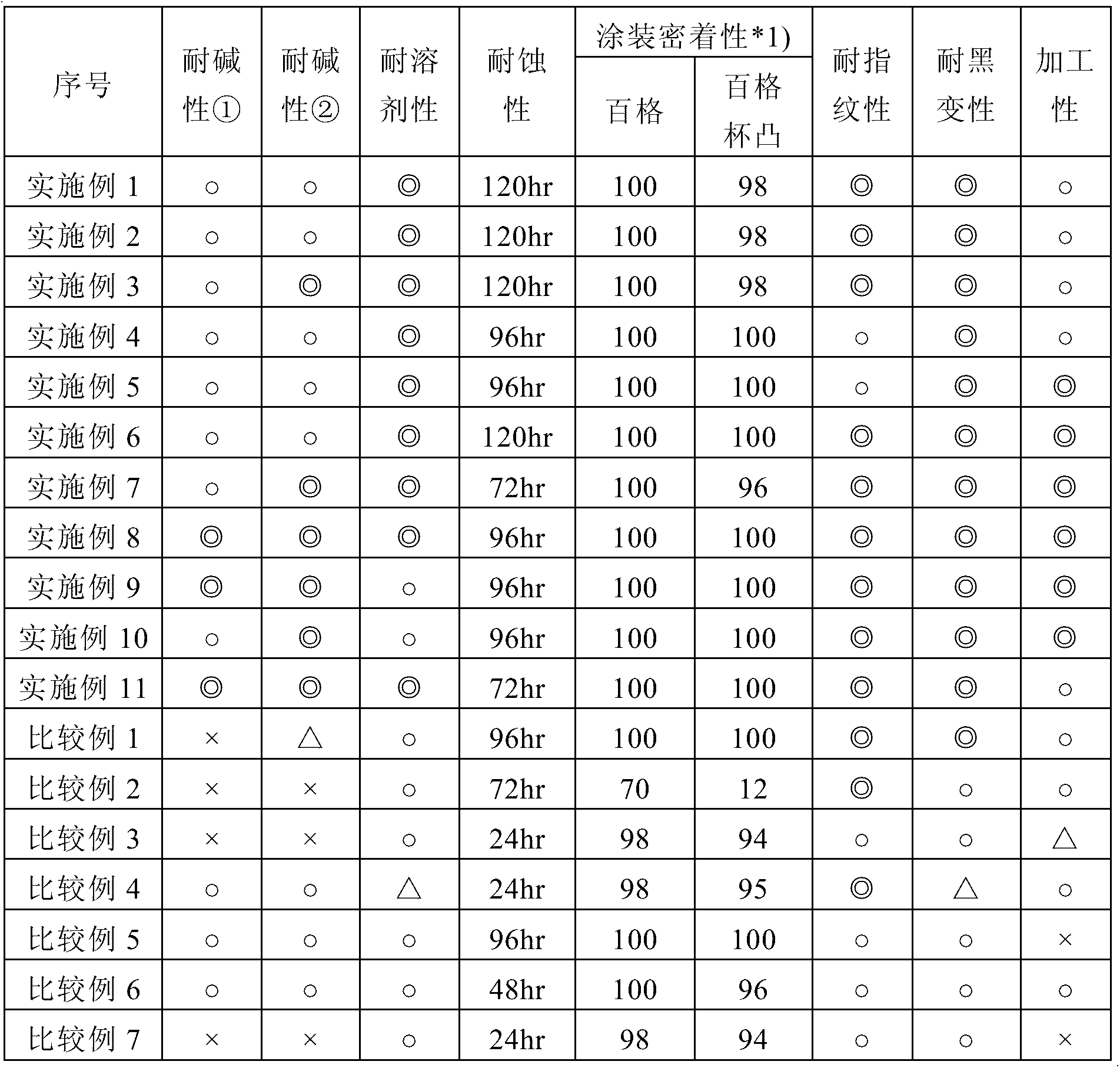

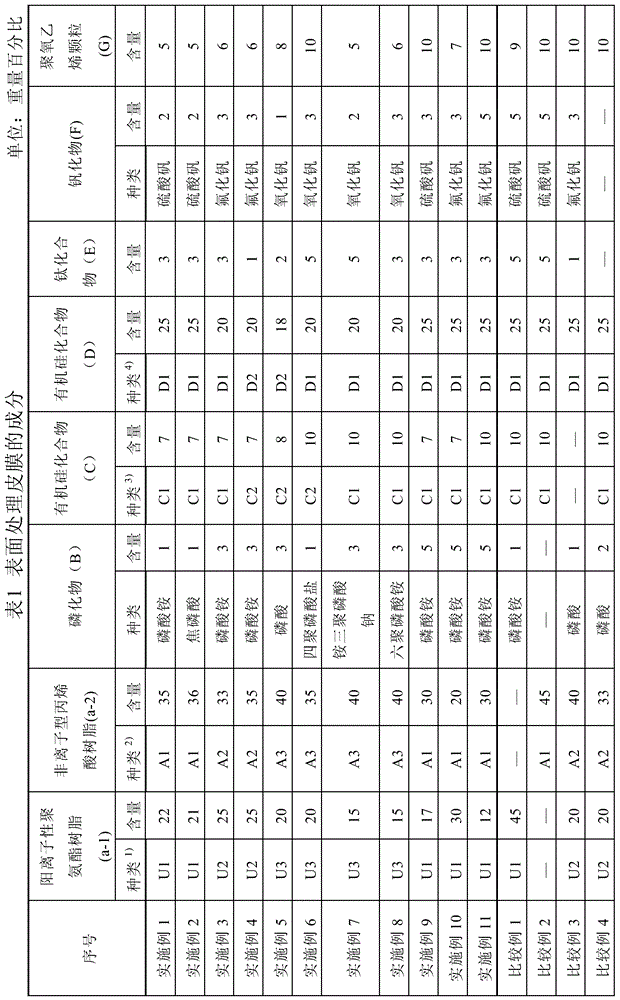

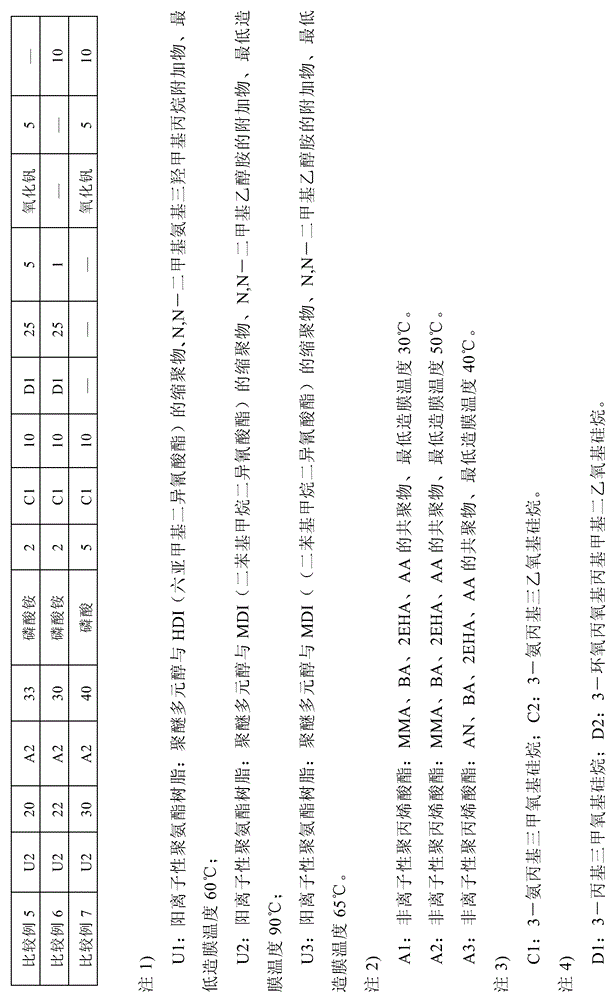

Surface treatment agent for metal, surface treatment method for metallic material, and surface-treated metallic material

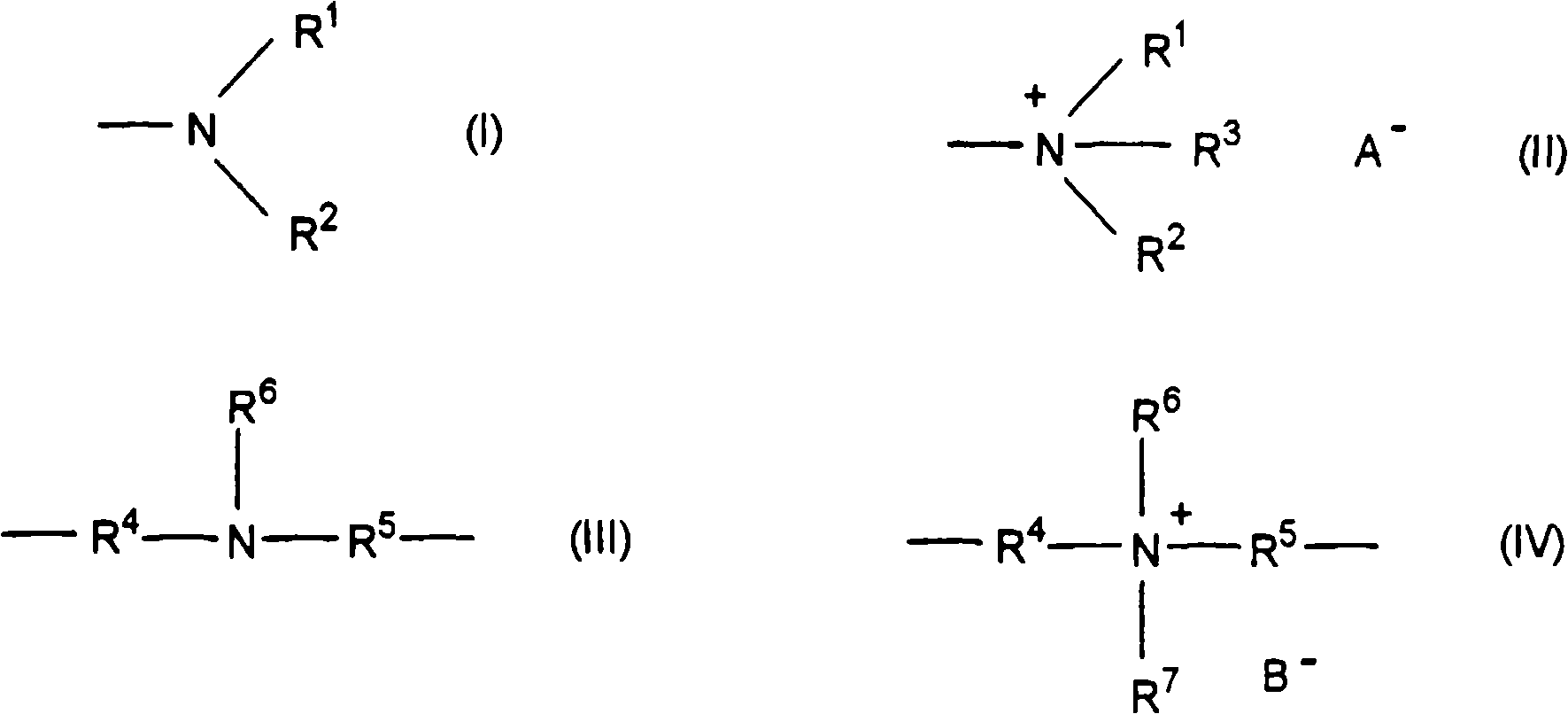

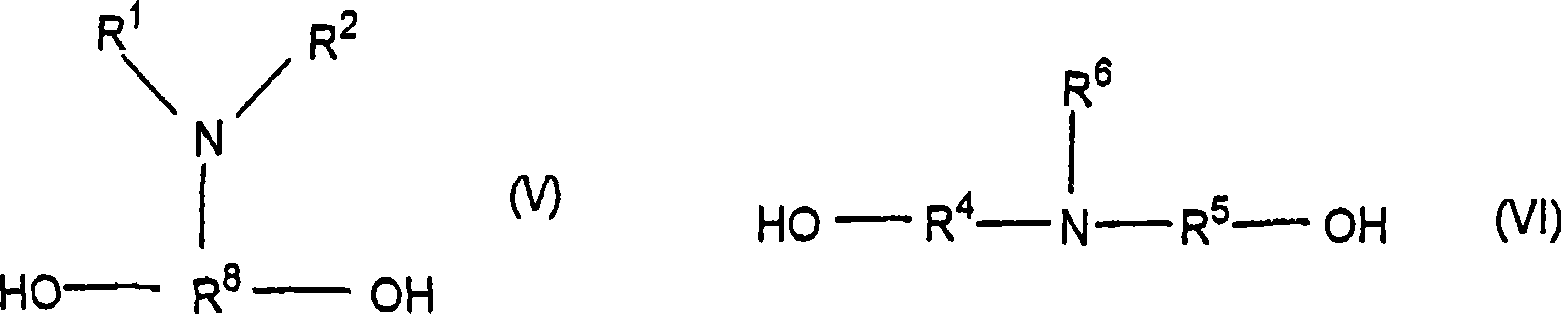

InactiveCN101048476AImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsMetallic material coating processesVanadium CompoundsEmulsion

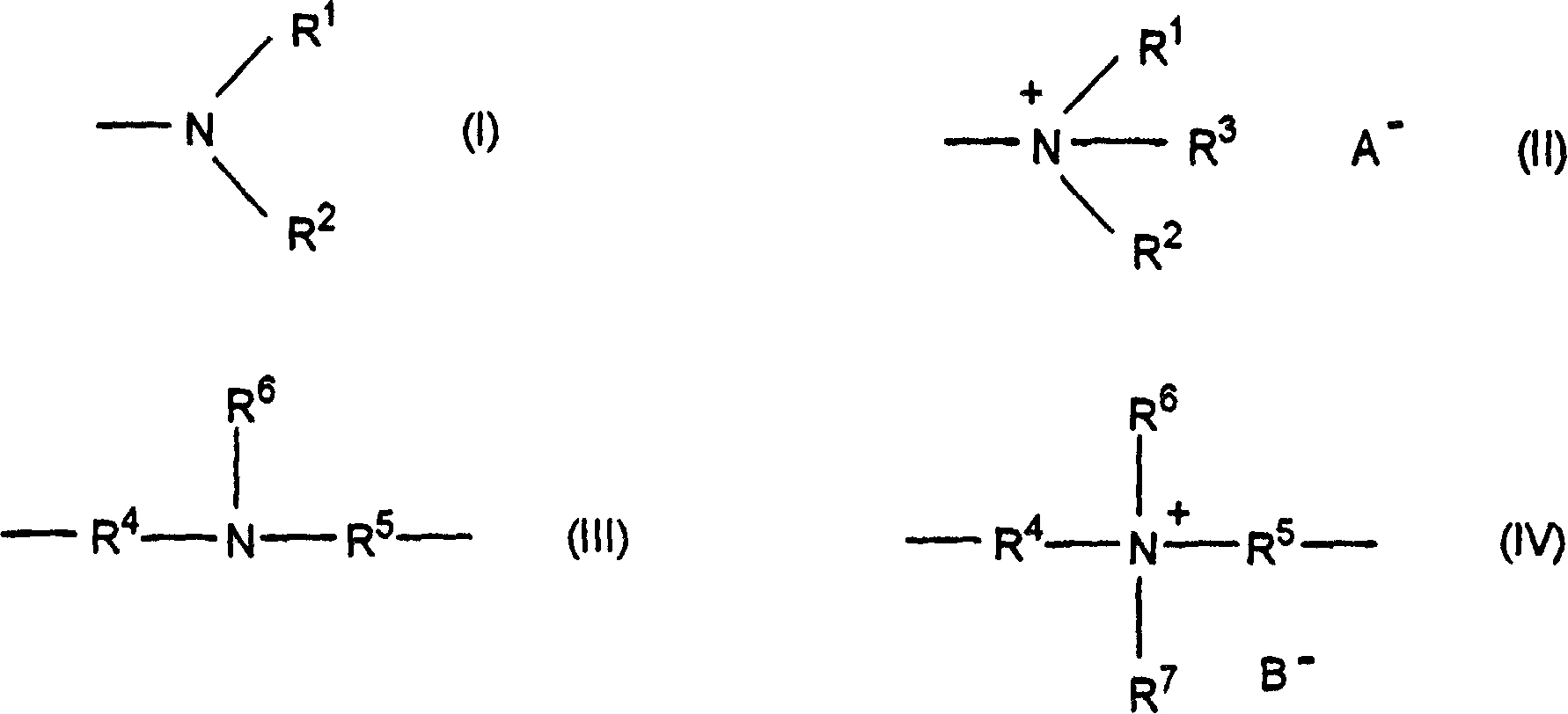

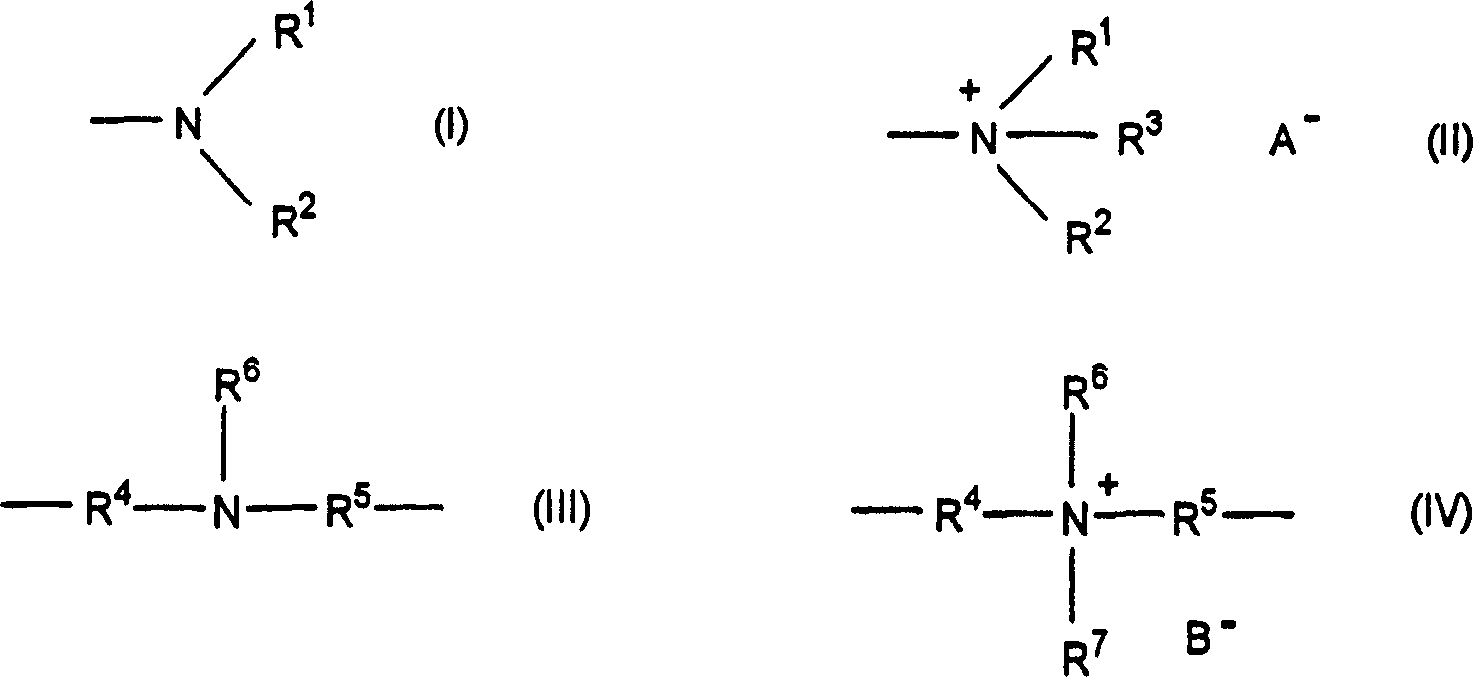

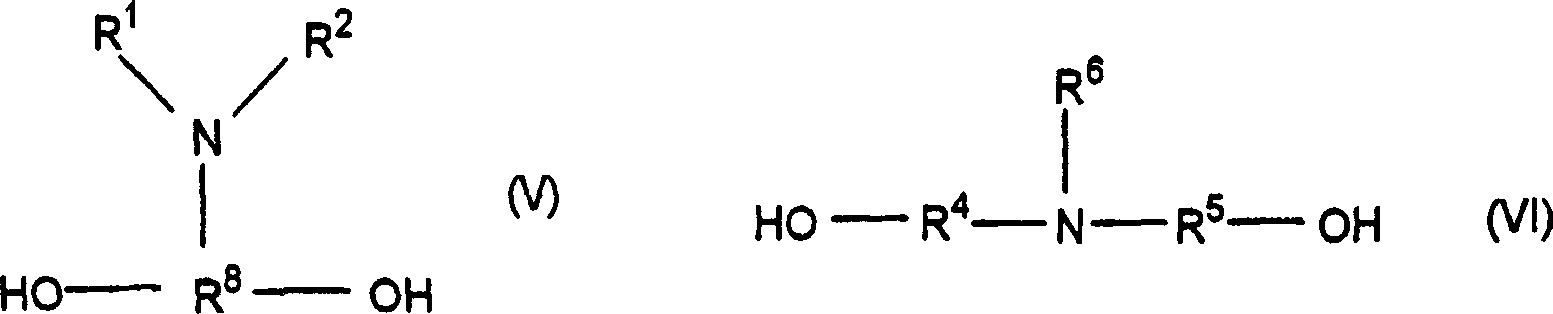

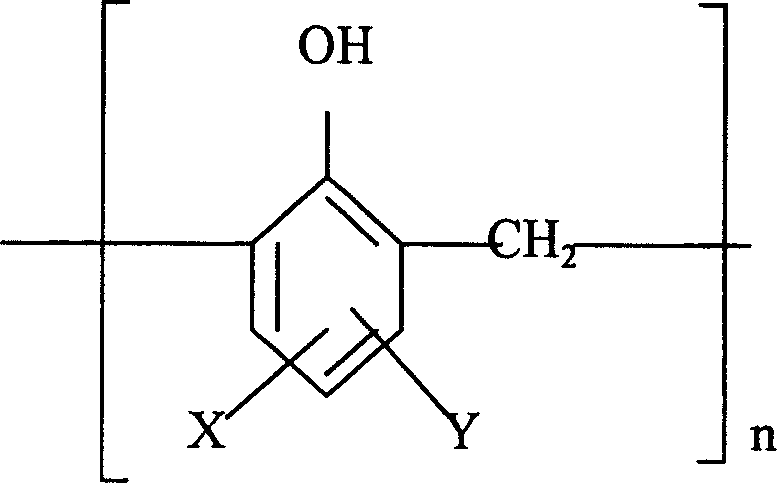

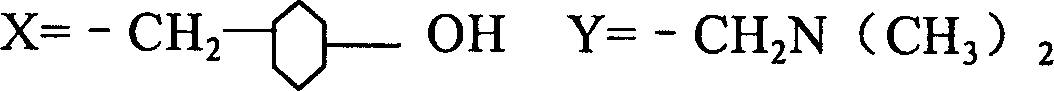

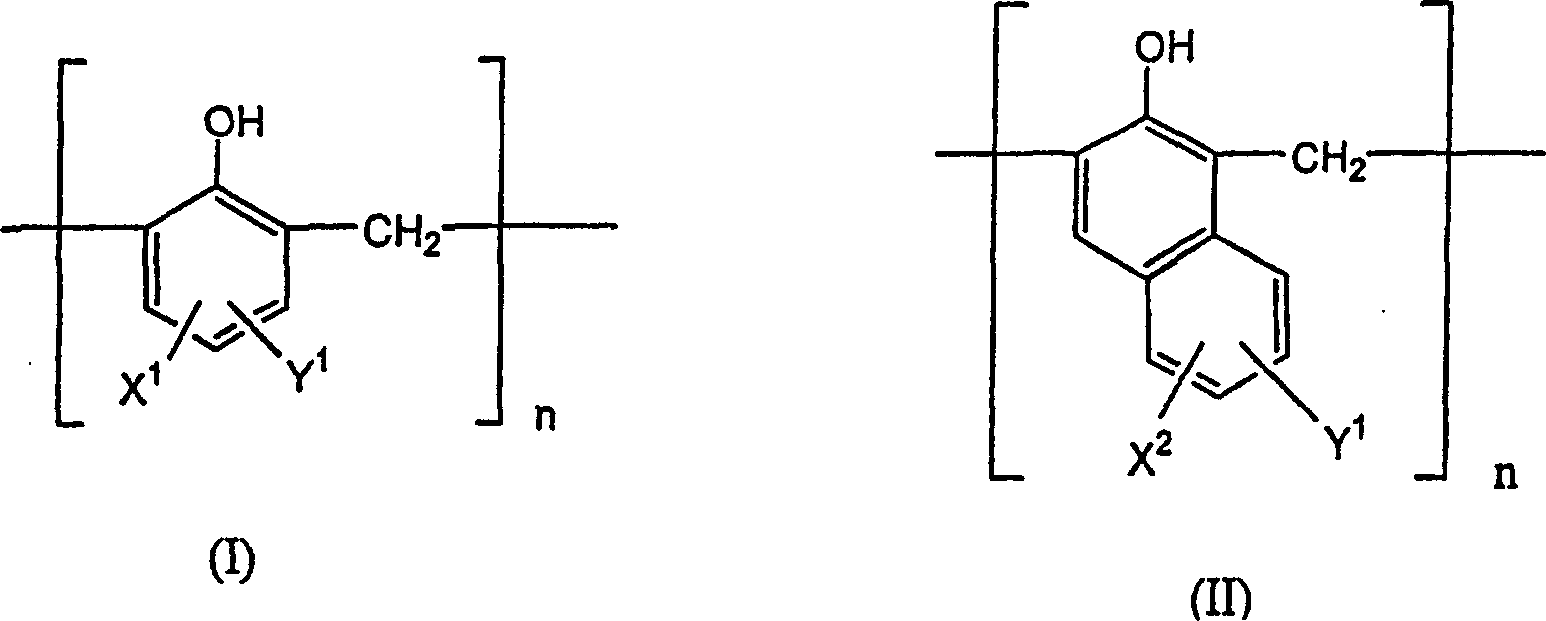

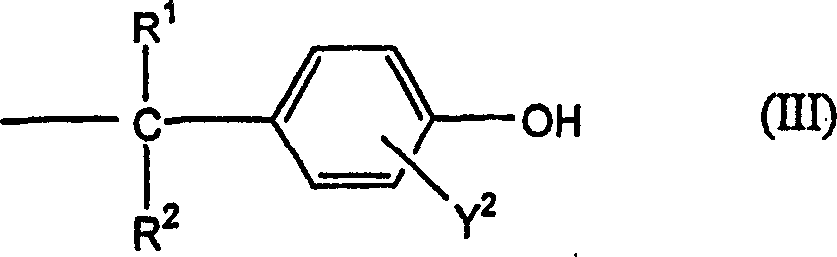

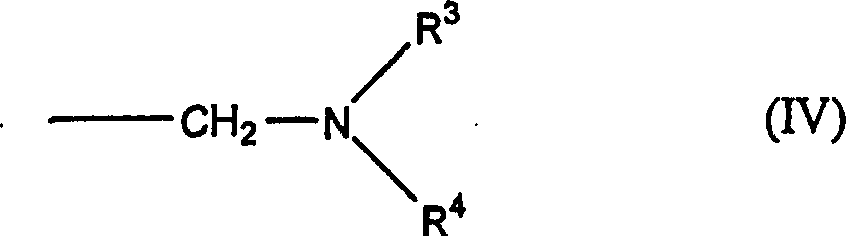

An agent for treating metal surfaces which comprises an aqueous medium and, incorporated therein, (A) a cationic urethane resin which is water-soluble or in an aqueous emulsion form, (B) a cationic polycondensation product obtained from a phenol compound and an aldehyde, and (C) a zirconium compound and / or titanium compound. A coating film formed from the treating agent imparts excellent corrosion resistance and alkali resistance to a metallic material. When the proportion of the urethane resin (A) is equal to or higher than that of the polycondensation product (B), yellowing resistance can be also imparted. By incorporating a metal compound (D) containing a specific metal, excellent blacking resistance also can be imparted. Furthermore, by incorporating an acid ingredient (E) and a vanadium compound (F), a further improvement in performances can be attained.

Owner:NIHON PARKERIZING

Composition and method for surface treatment of metal materials

ActiveCN1614089AExcellent fingerprint resistanceExcellent blackening resistanceMetallic material coating processesEpoxyAcrylic resin

The present invention provides a surface treatment composition and a surface treatment method capable of forming a film having excellent corrosion resistance, fingerprint resistance, blackening resistance, paint adhesion, etc. on the surface of a metal material. It contains an aqueous medium and the following components: (A) metal ions selected from Mn ions, Co ions, Zn ions, Mg ions, Ni ions, Ti ions, V ions and Zr ions, (B) having at least 4 fluorine atoms and elements selected from Ti, Zr, Si, Hf, Al and B, (C) has active hydrogen-containing amino, epoxy, vinyl, mercapto and methacryloxy Silane coupling agent with selected reactive functional groups, and (D) aqueous emulsification using resin selected from cationic or nonionic polyurethane resin, acrylic resin, epoxy resin, polyester resin and polyamide resin as the resin component Resin composition for surface treatment of metal materials and method for surface treatment of metal materials using the same.

Owner:NIHON PARKERIZING

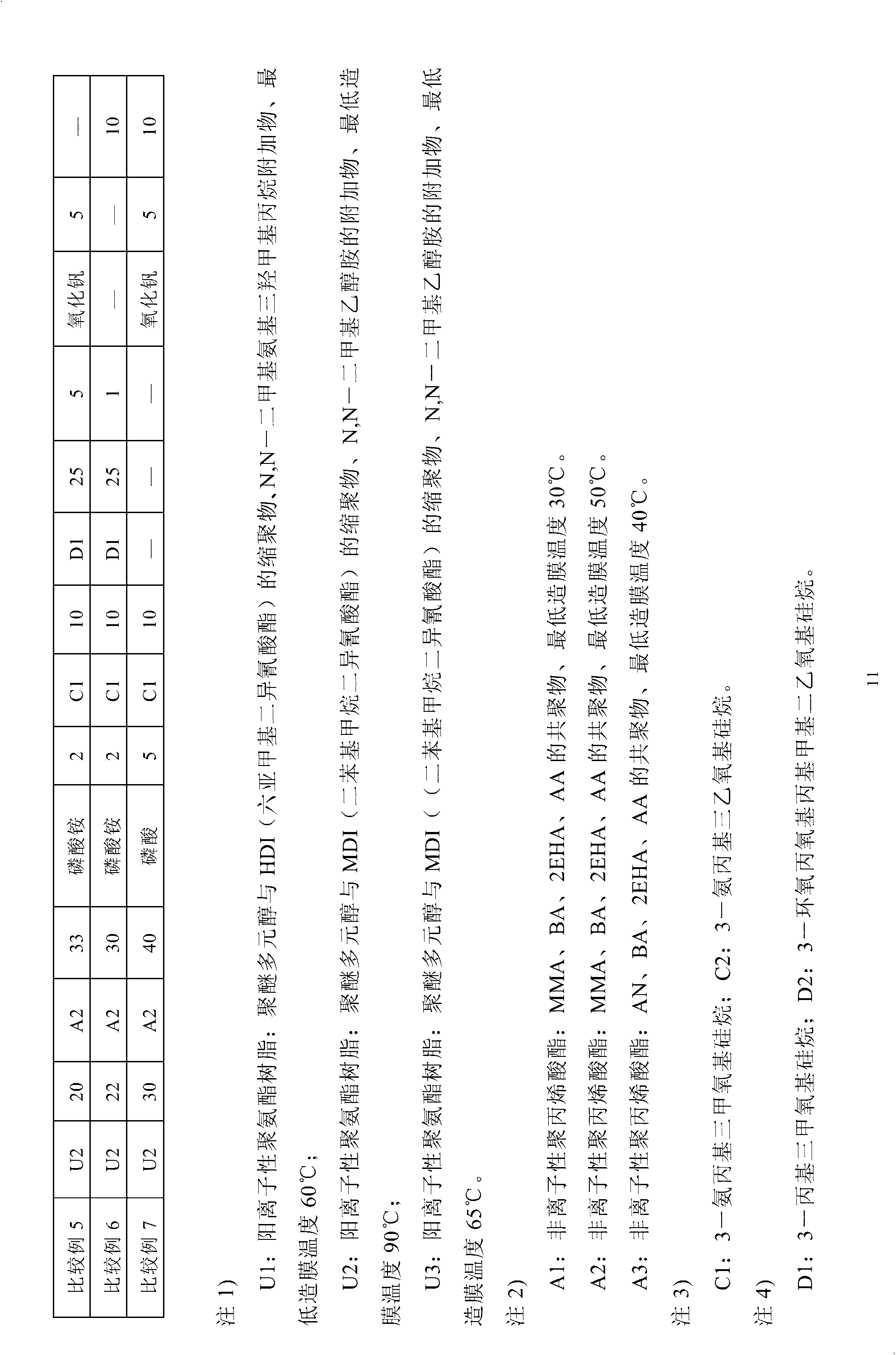

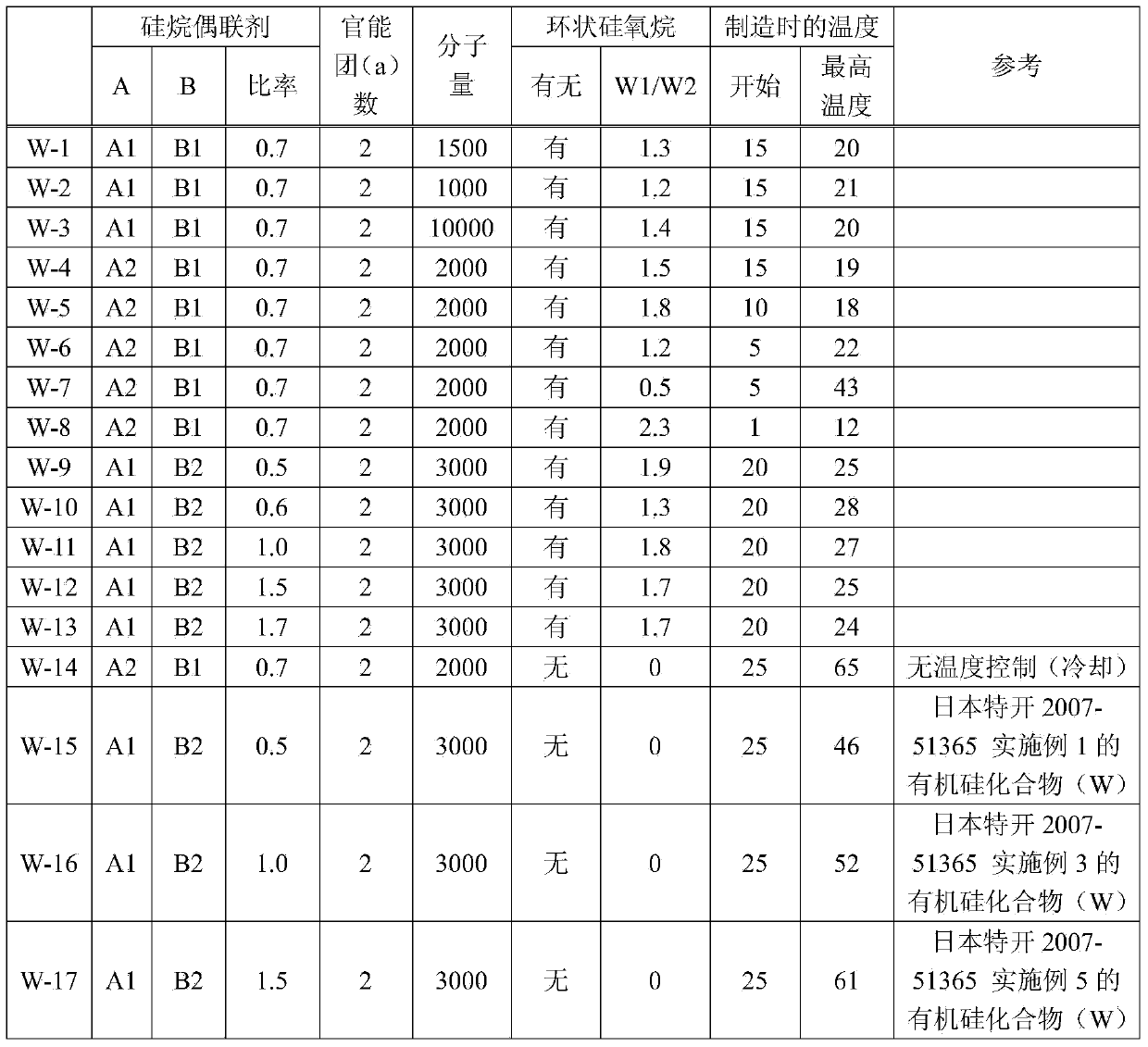

Compound composition and process for surface treating of metal material

ActiveCN1814860AAccelerated corrosionExcellent resistance to blackeningMetallic material coating processesPhosphoric acidMetallic materials

To provide a composition for surface treatment of a non-chromium metallic material capable of depositing a film having excellent corrosion resistance, black discoloration resistance and coating adhesivity on the surface of the metallic material, and to provide a surface treatment method using the composition. In the composition for surface treatment of the metallic material, (A) at least one kind of phosphoric compound to be selected from a group consisting of phosphoric acid, condensed phosphoric acid, organic phosphonic acid, and ammonium salt thereof, (B) fluoro acid having at least one element selected from a group consisting of at least four fluorine atoms, titanium, zirconium, silicon, hafnium, aluminum and boron, and (C) silane coupling agent (C1) having at least one active hydrogen containing amino radical, and silane coupling agent (C2) having at least one epoxy radical are dissolved in aqueous medium or blended in a dispersive state, and the ratio of the solid of the component (A) to the total solids of the components (A)-(C) is 0.1-80 mass%. The composition is used for the surface treatment method of the metallic material.

Owner:NIHON PARKERIZING

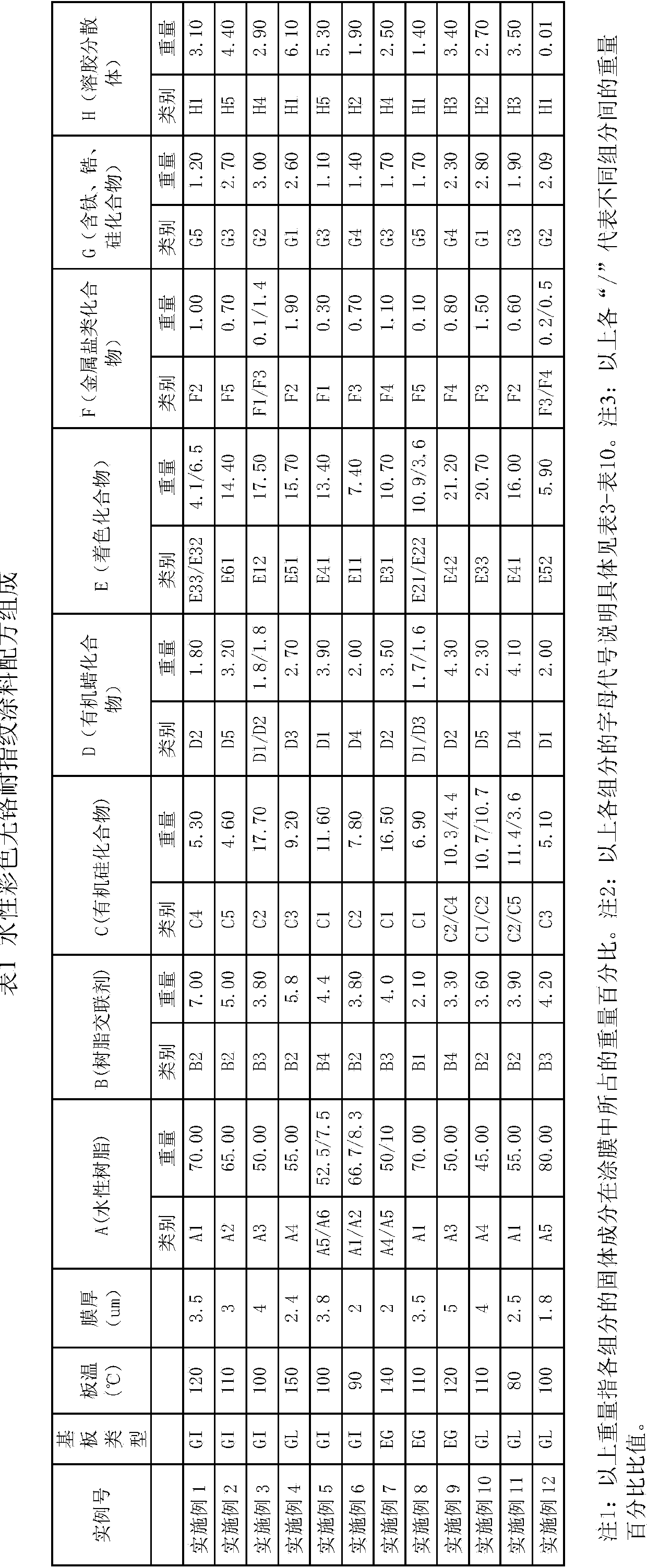

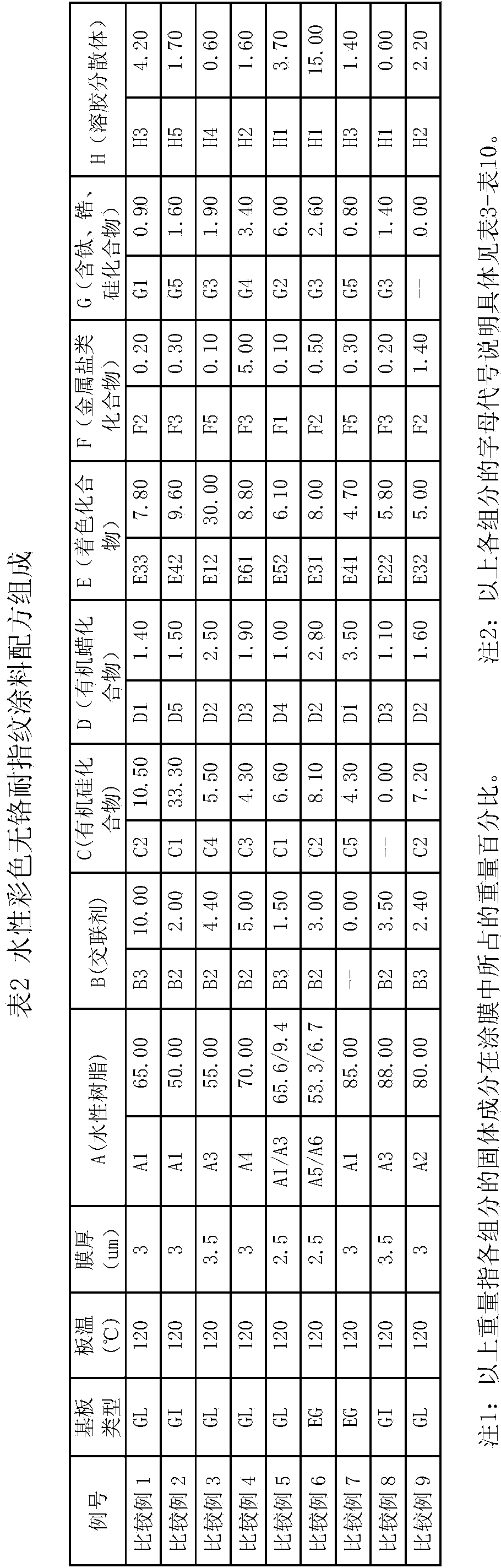

Aqueous colorful chromium-free anti-fingerprint coating for coating surface of metal material and construction method thereof

ActiveCN103740255AImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsEpoxy resin coatingsCorrosion resistantOrganosilicon

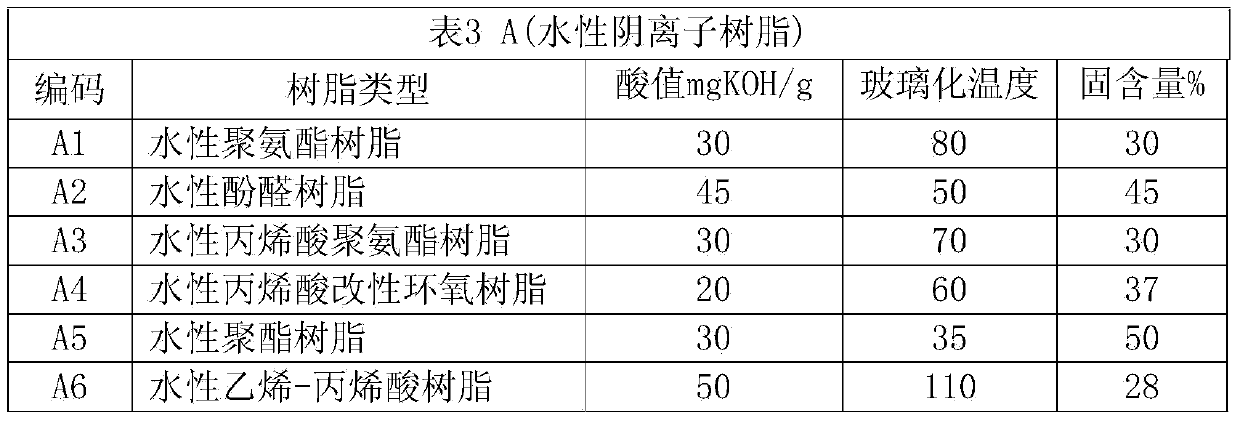

The invention relates to an aqueous colorful chromium-free anti-fingerprint coating for coating the surface of a metal material and a construction method thereof. A coated film formed by coating the coating on the surface of the metal material and drying is composed of following components in percentage by weight: 30%-90% of aqueous polymer resin (A), 1%-30% of a resin cross-linking agent (B), 1%-30% of an organic silicon compound (C), 0.5%-10% of an organic wax compound (D), 1%-30% of a coloring compound (E), 0.05%-3% of a metal salt type compound (F), a compound (G) which is selected from at least one one of titanium, zirconium and silicon and accounts for 0.1%-5% of the weight percent of the coated film by using the element to calculate, a sol dispersion body (H) of a monomer or a compound which is selected from at least one of Si, Zr, Ti, Al, Sn, Hf, Ce and Nb and accounts for 0.01%-10% of the weight percent of the coated film. The anti-fingerprint coating has excellent corrosion resistance, alkali resistance, water resistance, chemical resistance, striatonigral degeneration resistance and machinability.

Owner:上海华谊涂料有限公司

Low-temperature anti-fingerprint surface treating agent for galvanized steel sheet and environment-friendly surface treated galvanized steel sheet

ActiveCN104073100AHighlight corrosion resistanceHighlight drug resistancePolyurea/polyurethane coatingsWater basedSolvent

The invention relates to a low-temperature anti-fingerprint surface treating agent for a galvanized steel sheet and an environment-friendly surface treated galvanized steel sheet of which the surface is treated by use of the surface treating agent. The surface of the galvanized steel sheet does not contain chromium and does not need to be dried at a high temperature, and a surface treatment film can be formed on the surface under a low-temperature drying condition; the manufacturing process is environment-friendly and low in energy consumption; a composition (namely the surface treating agent) containing specific water-based resin and phosphide, specific organic silicon compound, titanium compound, vanadium compound and oxidic polyethylene particles is applied to the surface of the galvanized steel sheet and then dried at a low temperature ranging from 50 to 75 DEG C, and consequently, the obtained surface treated galvanized steel sheet has excellent properties such as excellent alkali resistance, solvent resistance, corrosion resistance, fingerprint resistance, coating adherence and the like.

Owner:BAOSHAN IRON & STEEL CO LTD +2

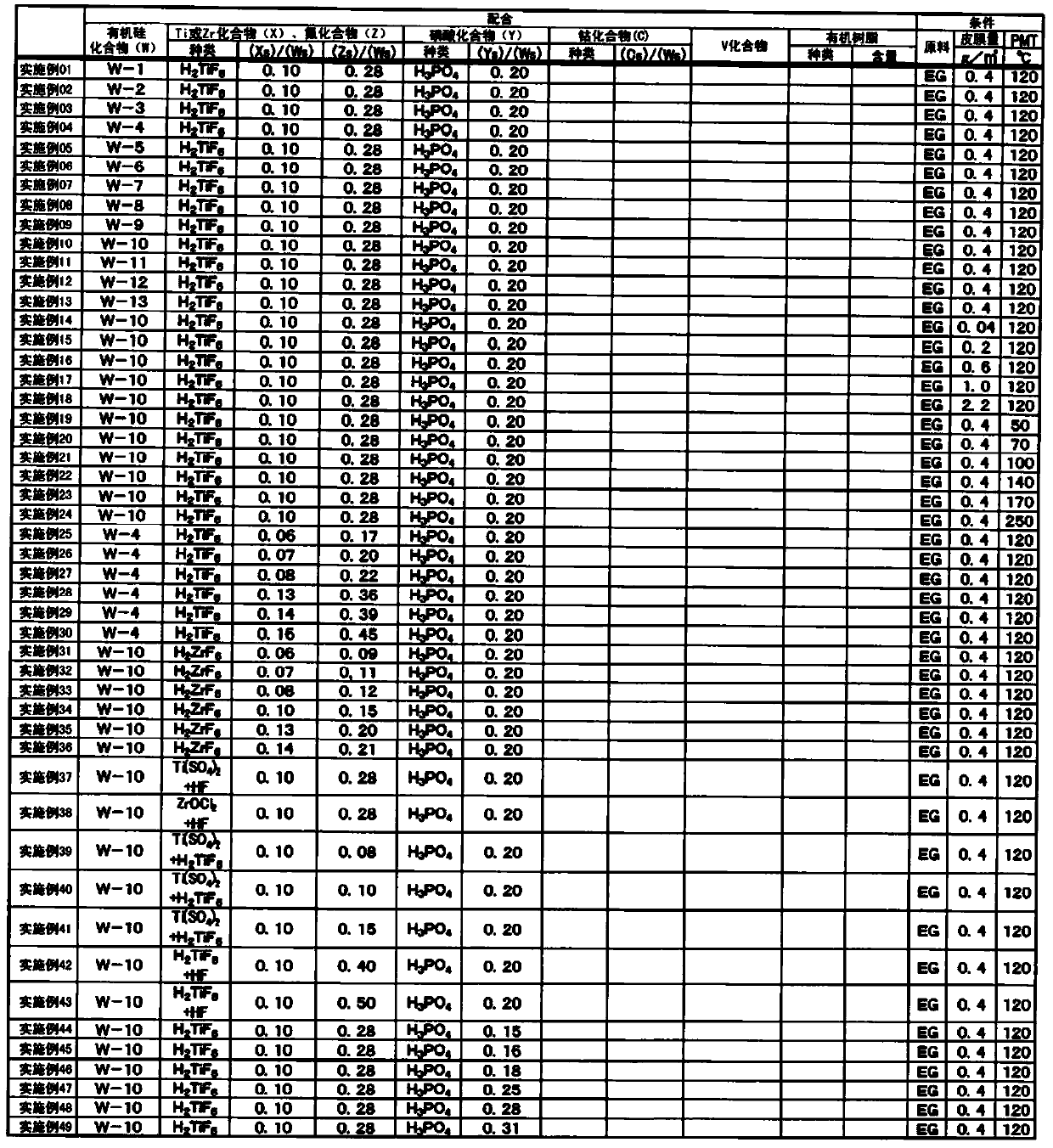

Surface-treated metal material and aqueous metal surface treatment agent

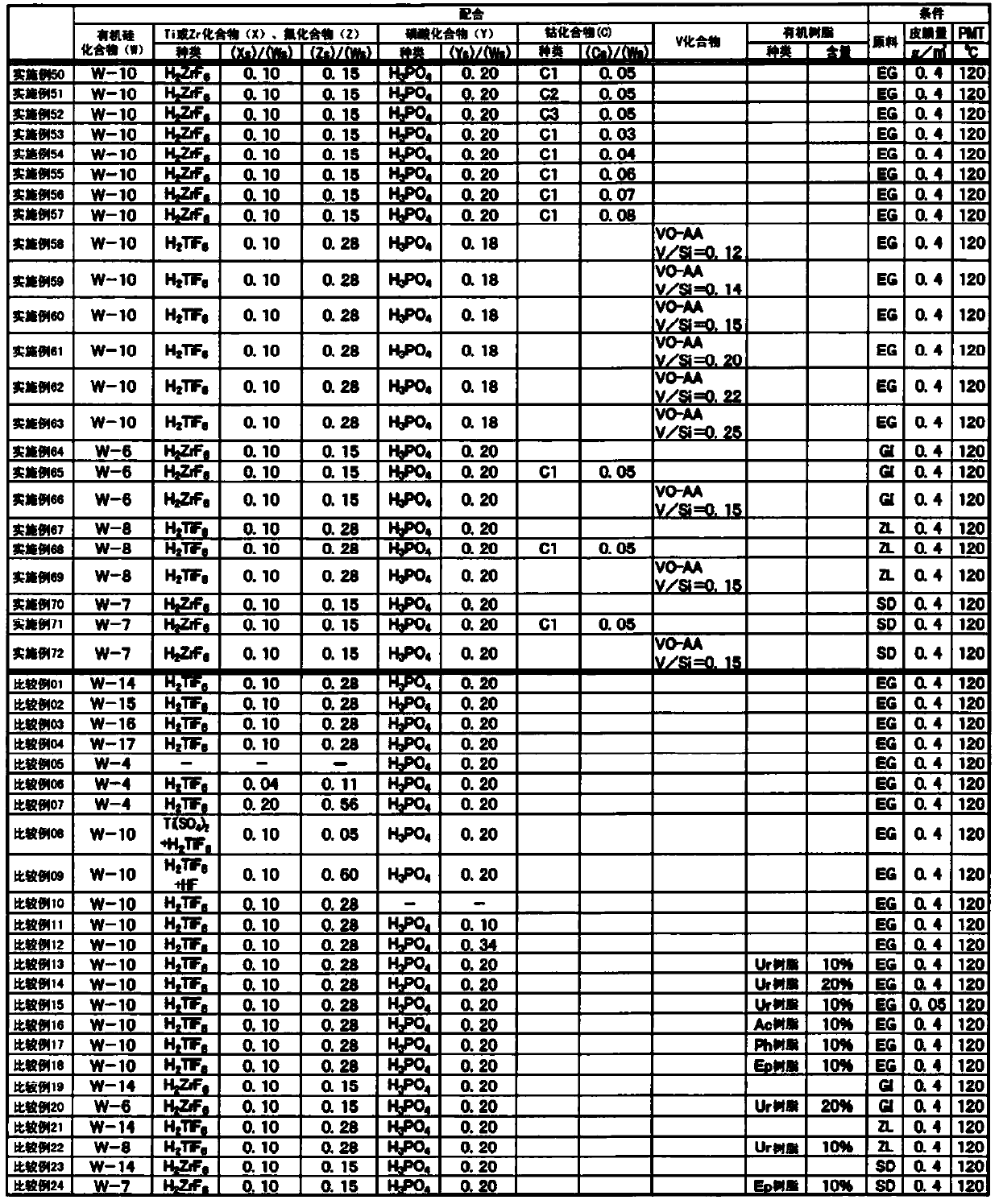

ActiveCN103635607AImprove corrosion resistanceImprove heat resistanceLiquid surface applicatorsLayered productsComposite filmZirconium compounds

A surface-treated metal material according to the present invention is a metal material the surface of which is coated with a composite film comprising an organic silicon compound (W) having cyclic siloxane bonds, at least one type of metal compound (X) selected from the group consisting of titanium compounds and zirconium compounds, a phosphoric acid compound (Y), and a fluorine compound (Z). In each component of the composite film, the ratio (XS / WS) of the solid content weight (WS) of Si derived from the organic silicon compound (W) and the solid content weight (XS) of the at least one metal component selected from the group consisting of Ti and Zr contained in the metal compound (X) is between 0.06 and 0.16, the ratio (YS / WS) of the solid content weight (WS) and the solid content weight (YS) of P derived from the fluorine compound (Z) is between 0.15 and 0.31, and the ratio (ZS / WS) of the solid content weight (WS) and the solid content weight (ZS) of F derived from the fluorine compound (Z) is between 0.08 and 0.50.

Owner:NIPPON STEEL CORP +1

Method for producing alloyed hot-dipping galvanized steel sheet

InactiveCN101255540AGood welding performance and coating performanceGood corrosion resistanceHot-dipping/immersion processesSteel platesHot-dip galvanization

The present invention discloses a production method for an alloyed hot-dip galvanizing steel plate, comprising the processes of strip steel producing, strip steel galvanizing, alloying, leveling and passivating, wherein in the strip steel galvanizing process, the temperature of strip steel entering a galvanized pot is 450 to 470 DEG C, and the temperature of zinc liquid is 455 to 465 DEG C. Compared with current technology, the method can produce a steel plant which not only has good welding property and coating property of a traditional alloyed hot-dip galvanizing steel plate, but also has superior corrosion-resistant property, black -patina-resistant property, conductivity and environment protecting property, and is particularly suitable for manufacturing kinescopes.

Owner:MAANSHAN IRON AND STEEL COMPANY

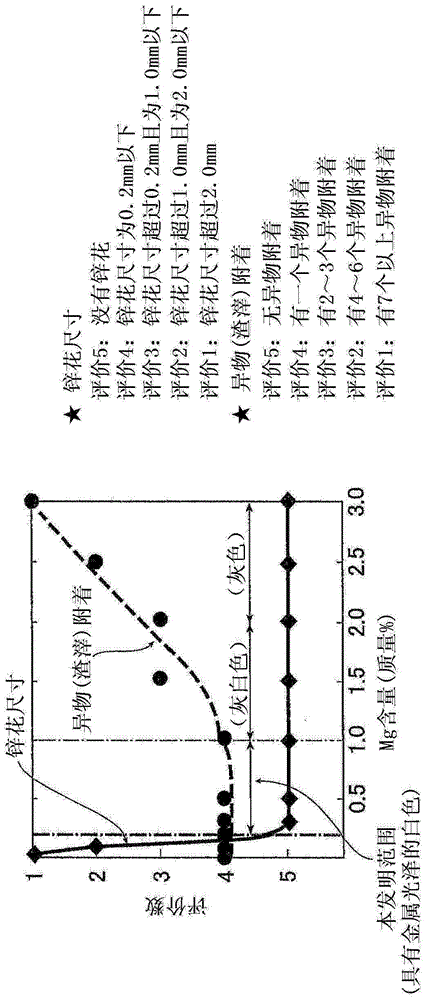

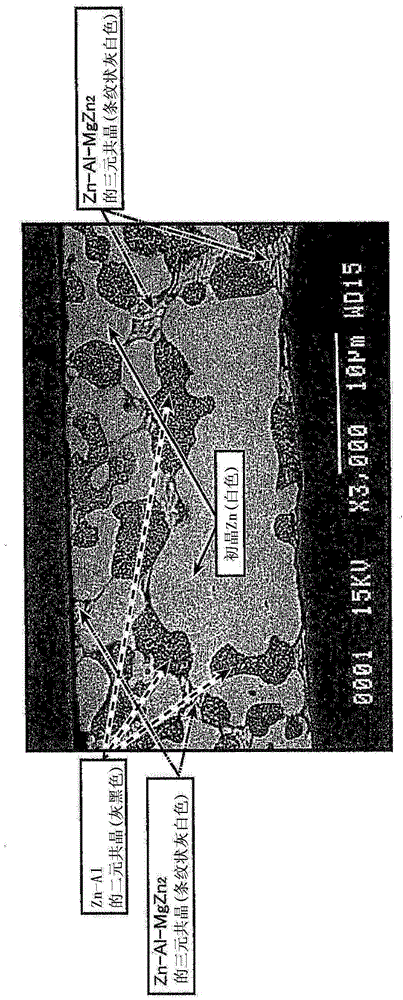

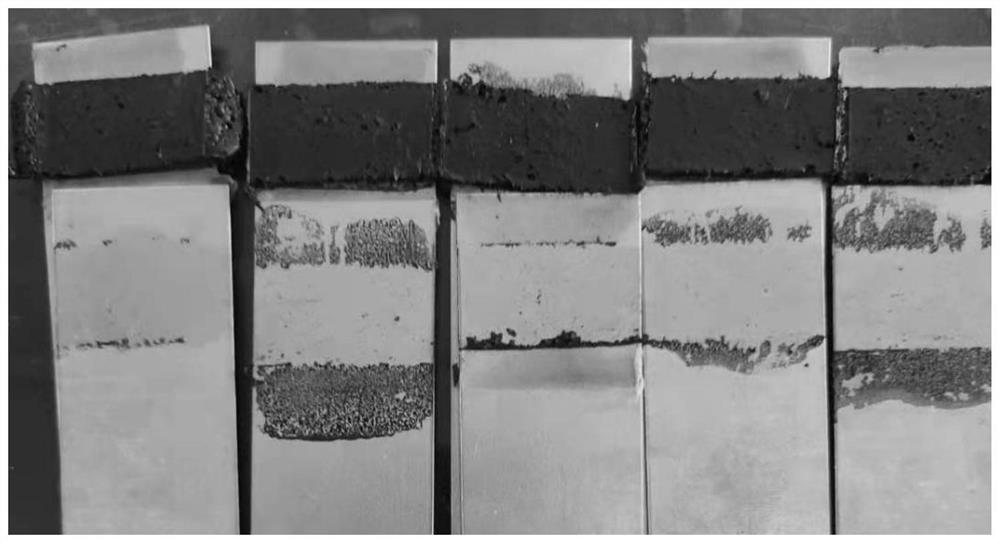

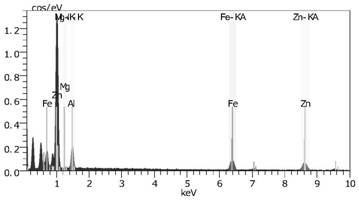

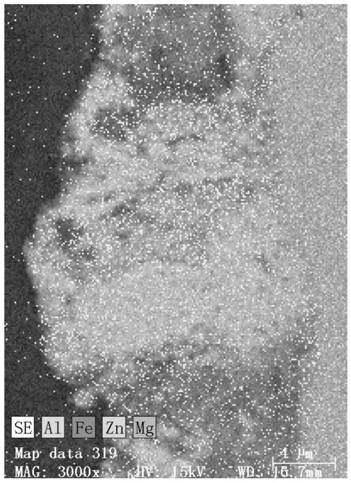

High-surface quality zinc-aluminum-magnesium steel plate with excellent blackening resistance and production method

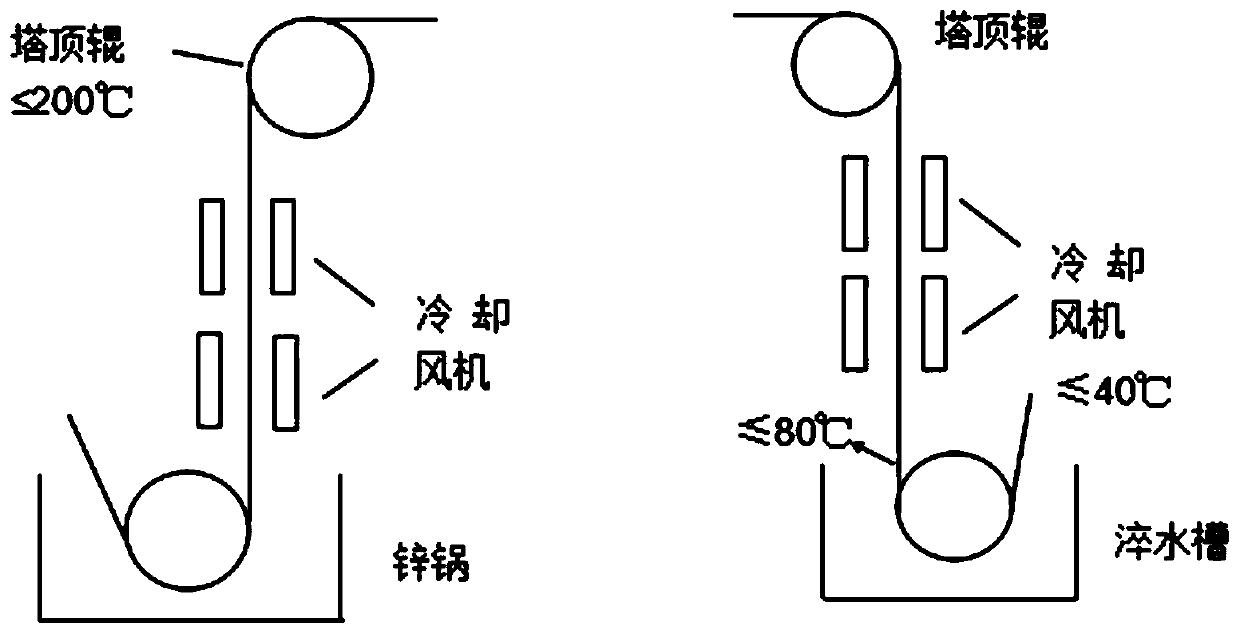

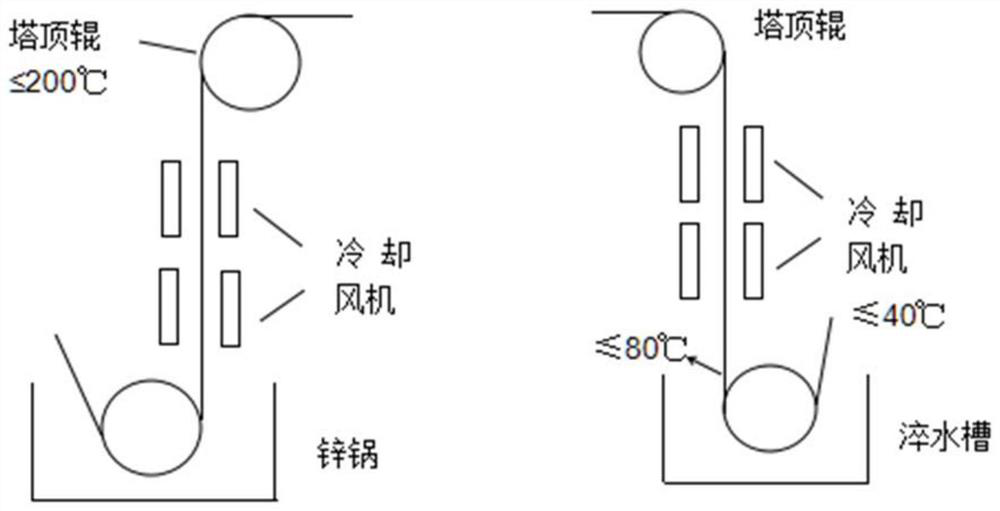

The invention provides a high-surface quality zinc-aluminum-magnesium steel plate with excellent blackening resistance and a production method. A plating solution is prepared from the following components: 1.0 to 3.0 percent of Al, 1.0 to 3.0 percent of Mg, 0.005 to 0.055 percent of Cu, 0.005 to 0.035 percent of Ti, 0.05 to 1.0 percent of Si, and the balance of Zn and unavoidable impurities. The temperature of the plating liquid is 410 to 460 DCG C; and the temperature of strip steel into a pot is 400 to 480 DEG C. The cooling speed after plating is 10 to 30 DEG C / s; the plate temperature is cooled to not higher than 200 DEG C; the temperature of a plate before entering a quenching tank is not higher than 80 DEG C; and the plate enters the quenching tank and is cooled to not higher than 40DEG C. Compared with the prior art, Si, Ti and Cu are added into the plating solution; a product has little zinc slag by matching the processes of immersion plating, cooling after plating, finishingand the like; the grain size of a plated layer is refined; and the high-surface quality zinc-aluminum-magnesium steel plate has excellent blackening resistance and corrosion resistance, and meanwhile,has excellent surface quality and processing and forming performance.

Owner:MAANSHAN IRON & STEEL CO LTD

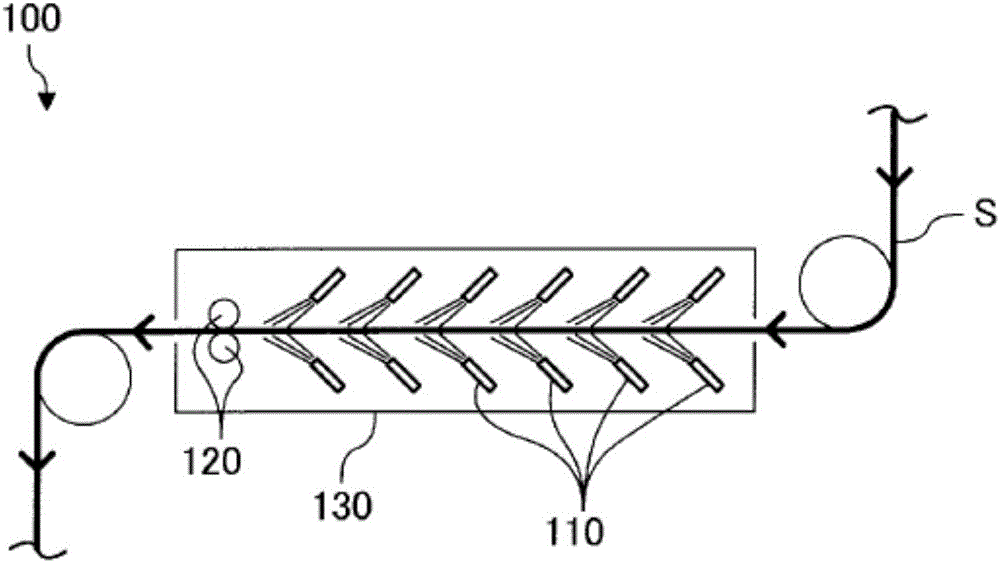

Manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance

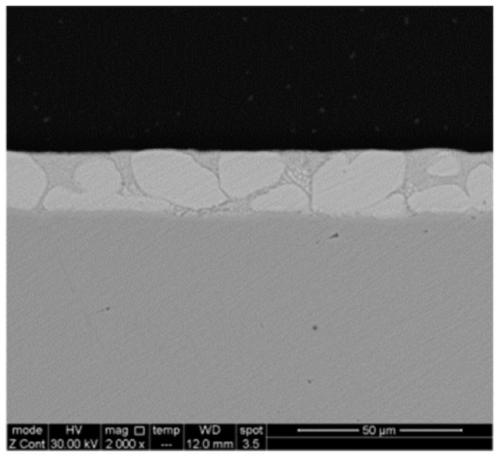

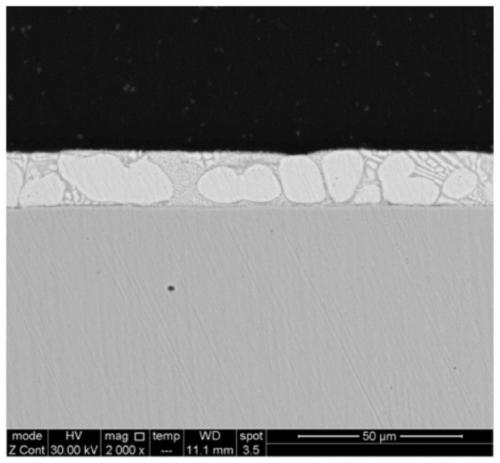

ActiveCN108690944AImprove corrosion resistanceImprove surface conditionHot-dipping/immersion processesFurnace typesCorrosionCoating

The invention discloses a manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance. The manufacturing method comprises the following steps: increasing the oxygen partial pressure in an annealing furnace to 30-80 ppm when basic strip steel enters a preheating section of the annealing furnace, wherein the dew point of the preheating furnace is 0-50DEG C, the furnace pressure of the annealing furnace is 300-500 Pa, and the preheating temperature is 500-700 DEG C; controlling the dew point of a soaking section at 30 DEG C below zero to 30 DEG Cafter the basic strip steel enters the soaking section, wherein the hydrogen content in percent by volume is 15-25%; and finally, controlling the cooling speed at 20-100 DEG C / s for cooling, wherein the basic strip steel enters a zinc pot to produce Mg-containing hot dipped steel plates. Mg-enriched ternary eutectic phase sheets in coatings of the steel plates are small in interlayer spacing, relatively short and uniform in distribution, Mg-containing oxides are unlikely produced, and the hot dipped steel plates have high corrosion resistance and good blacken resistance. In a severe environment, the corrosion resistance of the coatings is 2-3 times of that of conventional hot dipped steel plates, or the corrosion resistance is even higher, and the quality of the surface tissues of the coatings is good.

Owner:武汉钢铁有限公司

Hot-dip Zn-Al alloy coated steel sheet and process for the production thereof

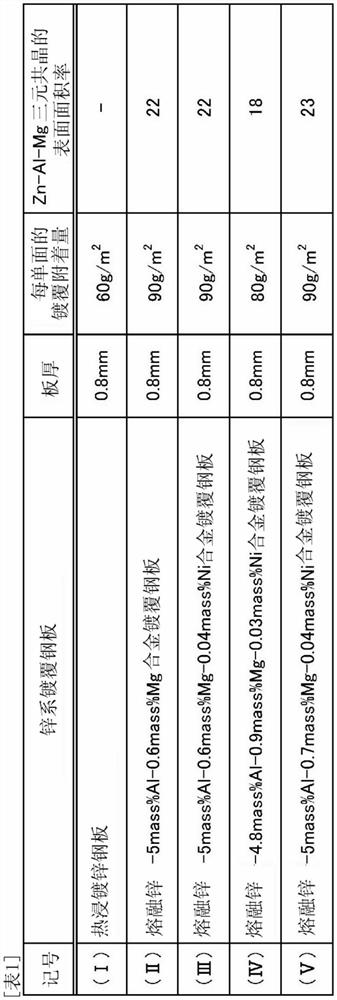

ActiveCN104561874AEasy to processExcellent resistance to blackeningHot-dipping/immersion processesThin material handlingSheet steelAlloy

A hot-dip Zn-Al alloy coated steel sheet exhibiting a beautiful coating appearance with metallic luster, in which no spangle or very fine spangles are formed, and having excellent blackening resistance and a method for manufacturing the hot-dip Zn-Al alloy coated steel sheet are provided. The hot-dip Zn-Al alloy coated steel sheet includes a hot-dip Zn-Al alloy coating layer containing 1.0 to 10 percent by mass of Al, 0.2 to 1.0 percent by mass of Mg, 0.005 to 0.1 percent by mass of Ni, and the balance being Zn and incidental impurities on at least one surface of a steel sheet. The manufacturing method includes the steps of dipping the steel sheet into a hot-dip Zn-Al alloy coating bath and pulling up and cooling the steel sheet, wherein the steel sheet pulled up from the coating bath is cooled to 250°C at a cooling rate of 1°C to 15°C / sec.

Owner:JFE GALVANIZING & COATING CO LTD +1

A low-temperature anti-fingerprint surface treatment agent for galvanized steel sheets and an environment-friendly surface treatment galvanized steel sheet

ActiveCN104073100BImprove gelationGood alkali resistanceMetallic material coating processesVanadium CompoundsCoating adhesion

Owner:BAOSHAN IRON & STEEL CO LTD +2

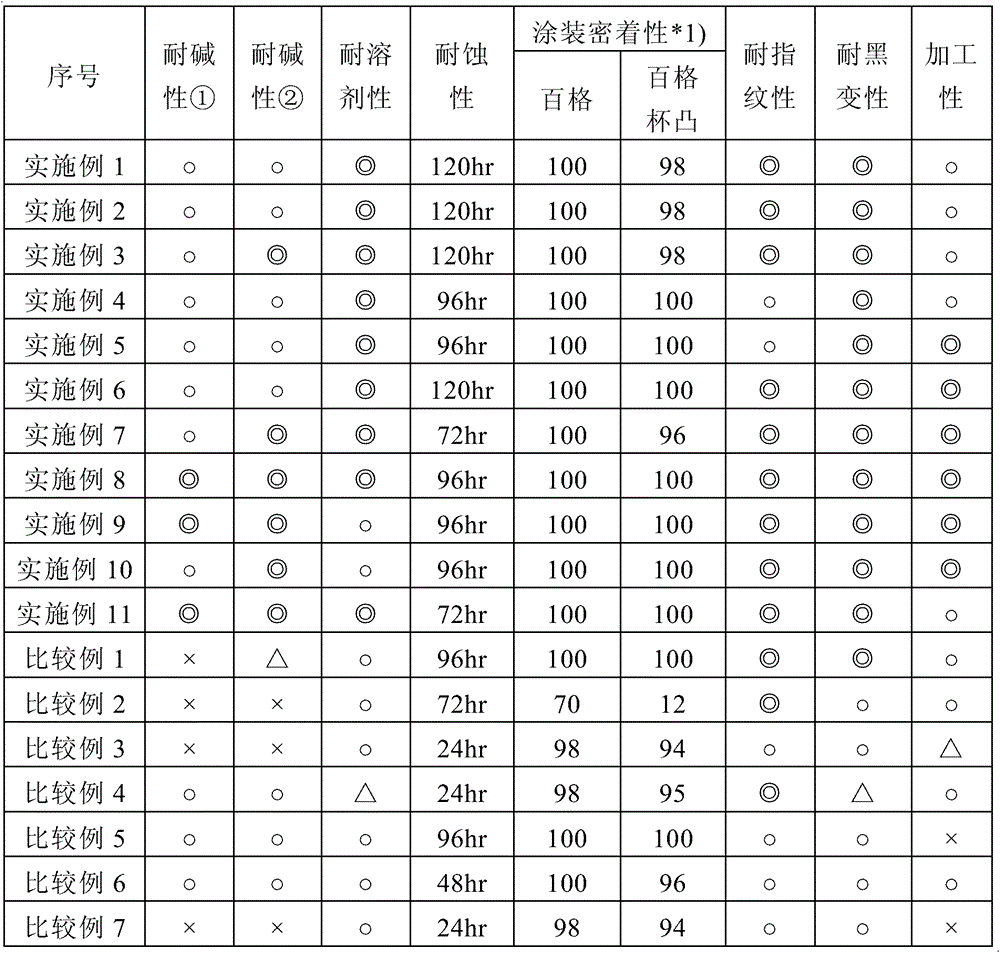

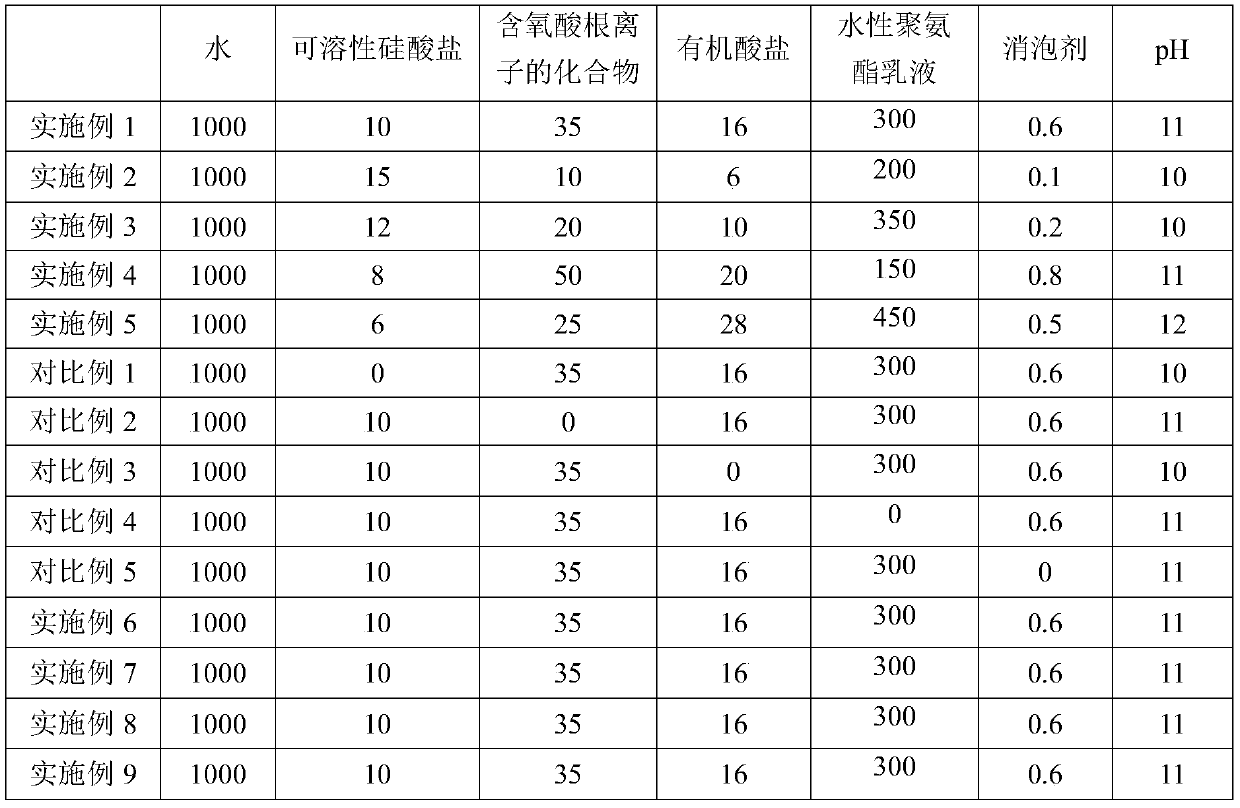

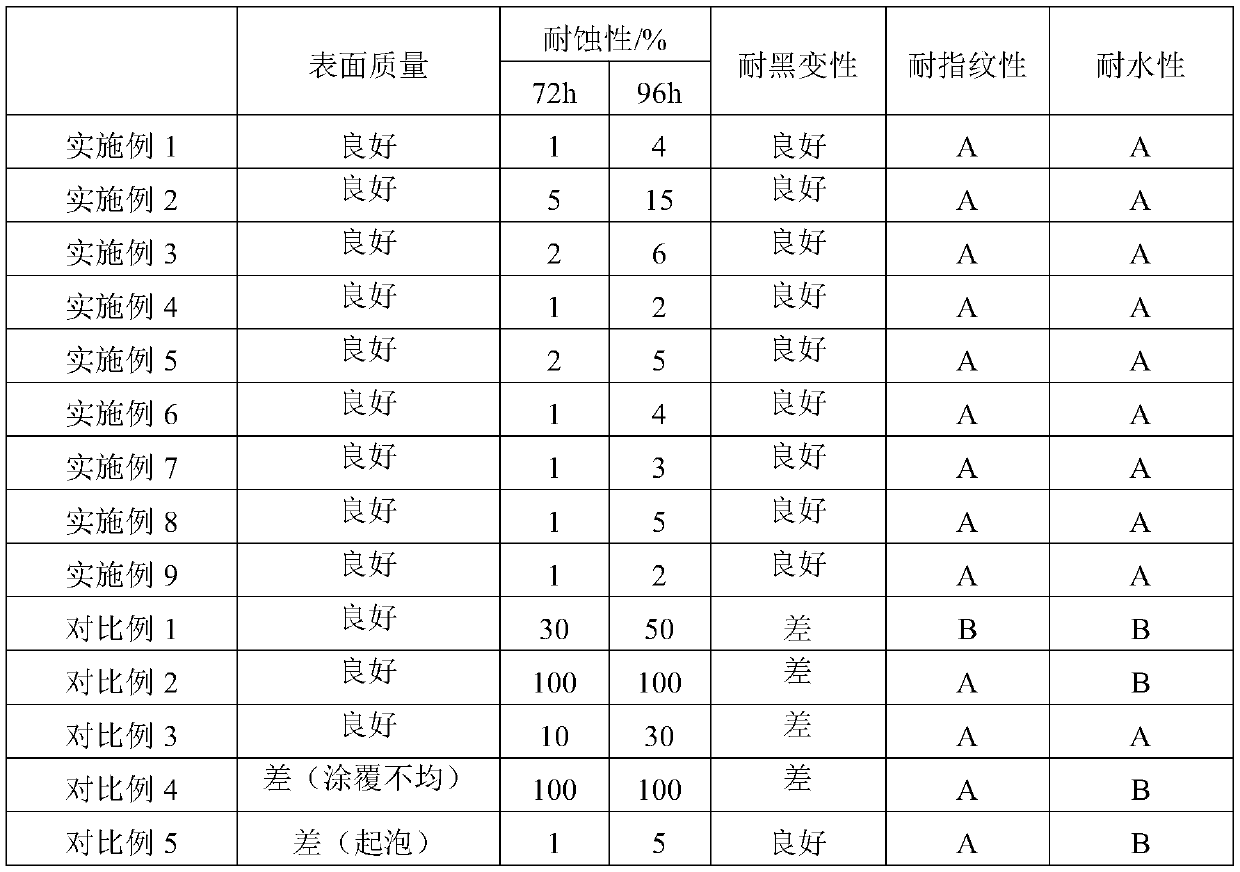

Chromium-free passivation solution for surface of hot-dip zinc-aluminum-magnesium steel plate and preparation method of hot-dip zinc-aluminum-magnesium chromium-free passivation plate

InactiveCN111575690AImprove stabilityGood coating performanceMetallic material coating processesOxidizing acidDefoaming Agents

The invention discloses a chromium-free passivation solution for the surface of a hot-dip zinc-aluminum-magnesium steel plate and a preparation method of a hot-dip zinc-aluminum-magnesium chromium-free passivation plate, and belongs to the technical field of hot-hip zinc-aluminum-magnesium steel plates. The passivation solution is prepared from, by weight, 5-15 parts of silicate, 10-50 parts of strong oxidizing acid group ion containing compound, 5-30 parts of organic acid salt, 150-450 parts of waterborne polyurethane emulsion and 0.1-10 parts of a defoaming agent. The coating of the hot-dipzinc-aluminum-magnesium steel plate is prepared from, by weight, 1%-5% of Al, 0.2%-3% of Mg, 0%-0.3% Si and the balance Zn. After the passivation solution is used for hot-dip zinc-aluminum-magnesium steel plates, the steel plate has excellent environmental protection performance, coating property, corrosion resistance, blackness resistance, fingerprint resistance and water resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

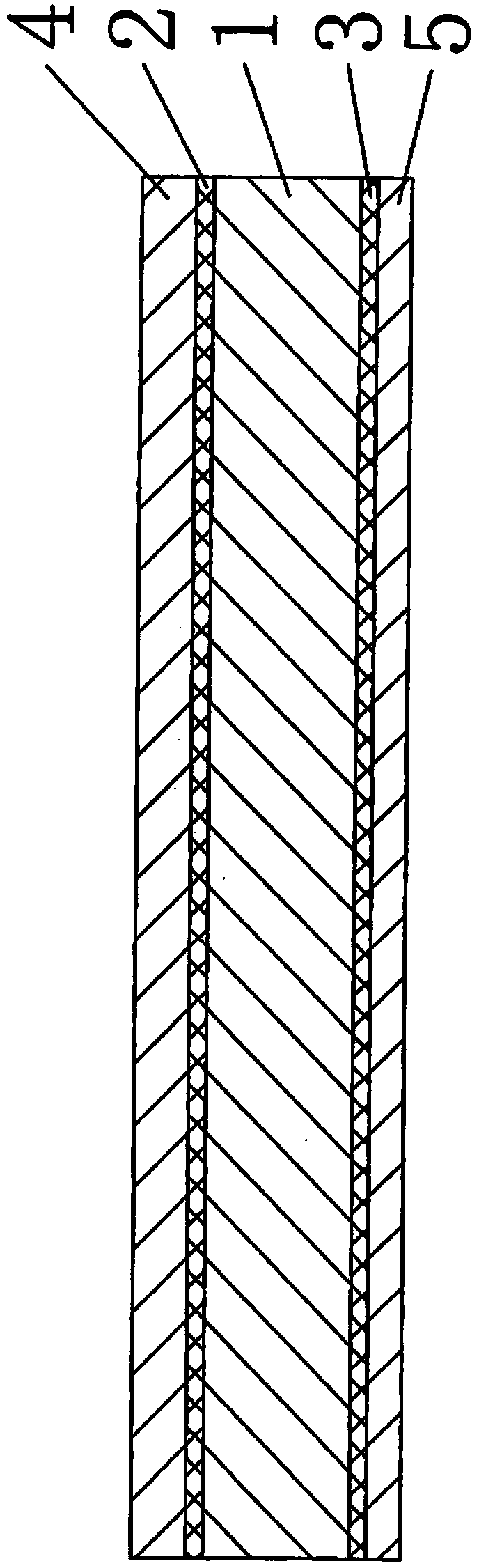

Thickened hot-dipping aluminum-zinc-plated steel plate and preparation method thereof

The invention discloses a thickened hot-dipping aluminum-zinc-plated steel plate and a preparation method of the thickened hot-dipping aluminum-zinc-plated steel plate and belongs to the technical field of coating steel plates. The thickened hot-dipping aluminum-zinc-plated steel plate comprises a substrate, wherein the surface of the outward side of the substrate in a used state is combined with a first plating-assistant layer, and the surface of the inward side of the substrate in the used state is combined with a second plating-assistant layer; the surface of the first plating-assistant layer is combined with a first structure layer; the surface of the second plating-assistant layer is combined with a second structure layer. Therefore, the thickness of a plated layer on the outward side of the substrate in the used state and the thickness of a plated layer on the inward side of the substrate in the used state are increased, and the sum of the thicknesses of the plated layers on the two sides is up to 270g / m<2>, so that the stability of the plated layers can be guaranteed, the good attachment effect between the plated layers and the substrate is achieved, the corrosion resistance performance, the processed shaping performance and the blackening resistance performance can be obviously improved, and the defects of falling off, cracking and the like of the plated layers during use can be avoided; the technical steps are simple and short; the technical requirement is low; the conventional aluminum-zinc-plated steel plate production line can be used for continuous and high-efficiency production.

Owner:江苏克罗德科技有限公司

Zinc-aluminum-magnesium plating layer surface treating agent as well as preparation method and use method thereof

ActiveCN112538306AImprove densification performanceHinder contactHot-dipping/immersion processesAnti-corrosive paintsFluorideSILICONE DIOXIDE

The invention discloses a zinc-aluminum-magnesium plating layer surface treating agent as well as a preparation method and a use method thereof, and belongs to the technical field of zinc-aluminum-magnesium alloy plating layer steel plate surface treatment. In order to meet the requirements of household appliances and automobile users on blackening resistance and environmental friendliness of hot-dip galvanized aluminum-magnesium alloy coated steel plates, the invention provides a zinc-aluminum-magnesium plating layer surface treating agent which comprises 1-5 parts of fluoride, 3-10 parts ofperiodate, 0.5-5 parts of weakly alkaline medium, 20-50 parts of water-based organic resin, 5-15 parts of colloidal silicon dioxide and 100 parts of water. Fluoride and periodate react with Mg on thesurface of a plating layer under the weak alkaline condition to generate a compact film layer, water-based organic resin adheres to the surface of the plating layer, gaps are filled with colloidal silicon dioxide, contact between the plating layer and water vapor and oxygen in the environment is effectively hindered, and the corrosion resistance, blackening resistance, water resistance and fingerprint resistance of the surface coating are remarkably improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Zinc-magnesium-aluminum coated steel plate with excellent blackening resistance and adhesive performance and preparation method of zinc-magnesium-aluminum coated steel plate

ActiveCN113832425AExcellent resistance to blackeningGood adhesivenessHot-dipping/immersion processesLiquid surface applicatorsCarboxylic acidZinc salts

The invention provides a zinc-magnesium-aluminum coated steel plate with excellent blackening resistance and adhesive performance and a preparation method of the zinc-magnesium-aluminum coated steel plate. A zinc coating comprises the following components in percentage by mass: 0.1-6.0% of Al, 0.1-4.0% of Mg and the balance of Zn and inevitable impurities. A chemical conversion layer comprises zinc salt of organic carboxylic acid with 6 or less carbon atoms; and compared with the prior art, the zinc-magnesium-aluminum coated steel plate provided by the invention has excellent blackening resistance and adhesive performance.

Owner:MAANSHAN IRON & STEEL CO LTD

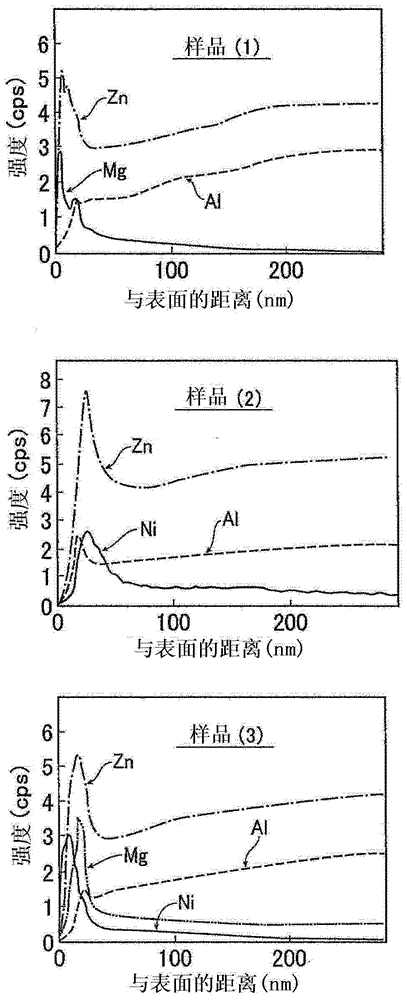

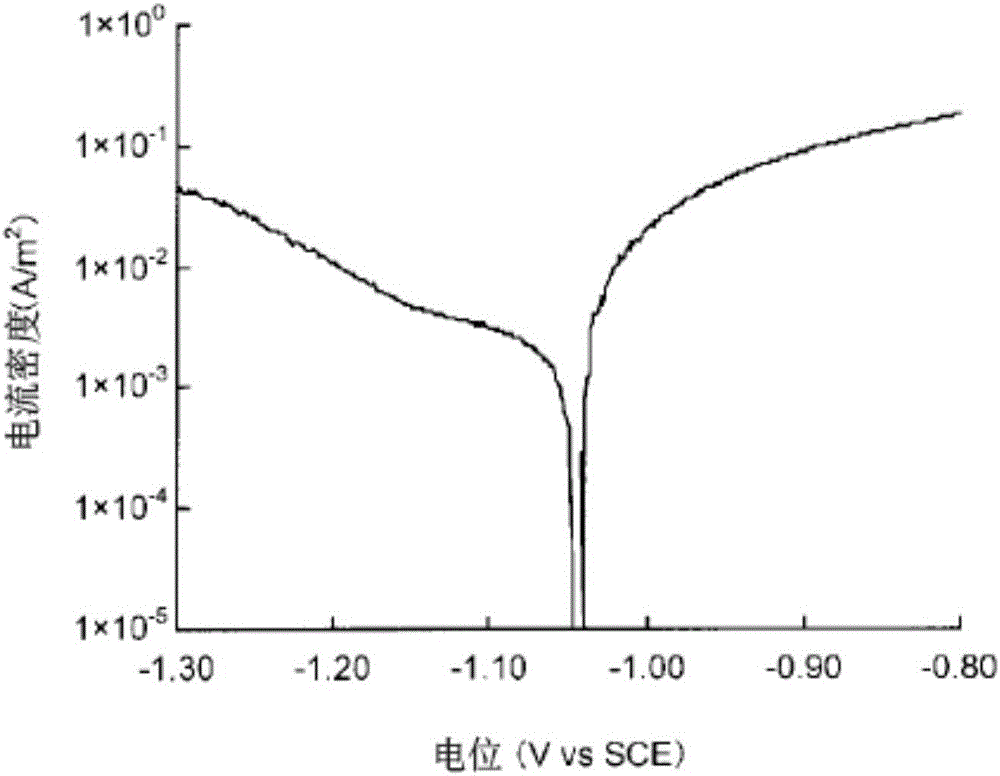

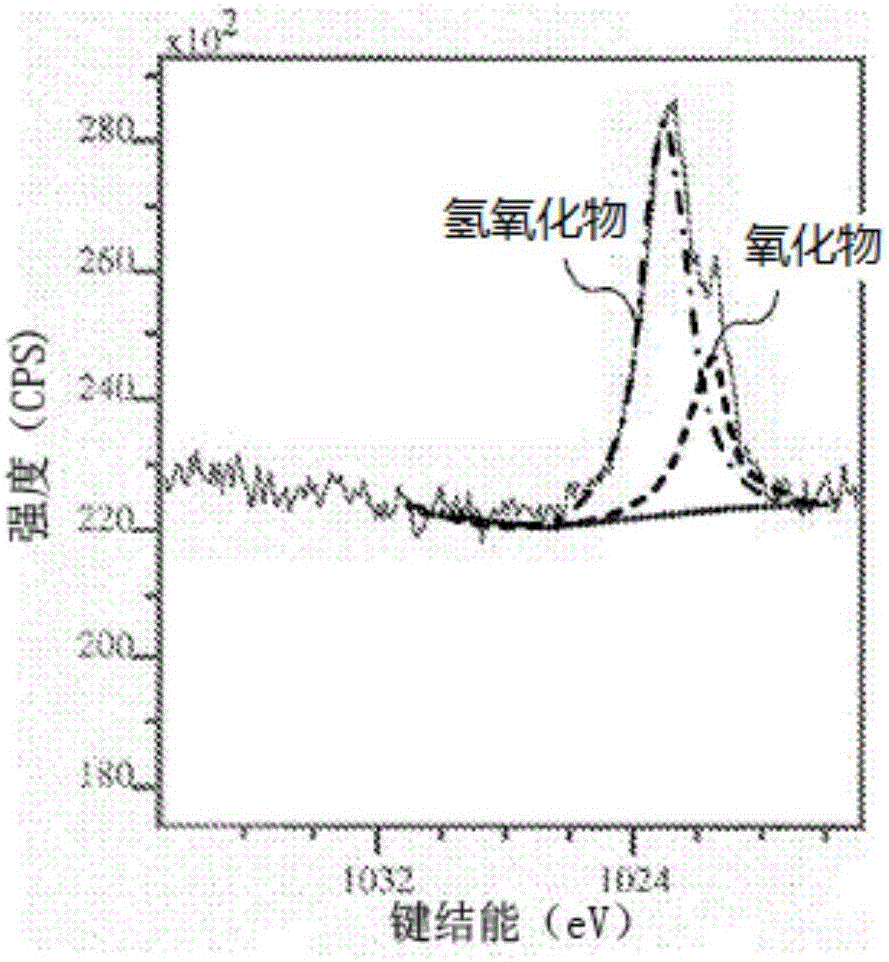

Hot-dip zn-alloy-plated steel sheet and method for producing same

ActiveCN105992834AExcellent resistance to blackeningHot-dipping/immersion processesLiquid/solution decomposition chemical coatingAlloyUltimate tensile strength

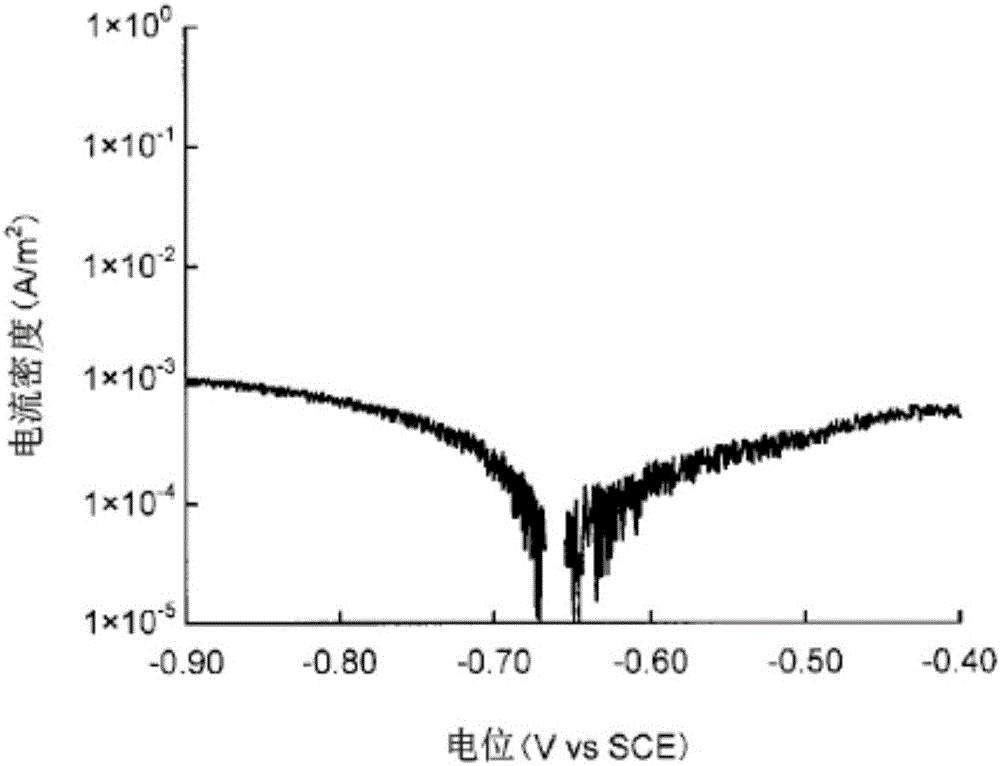

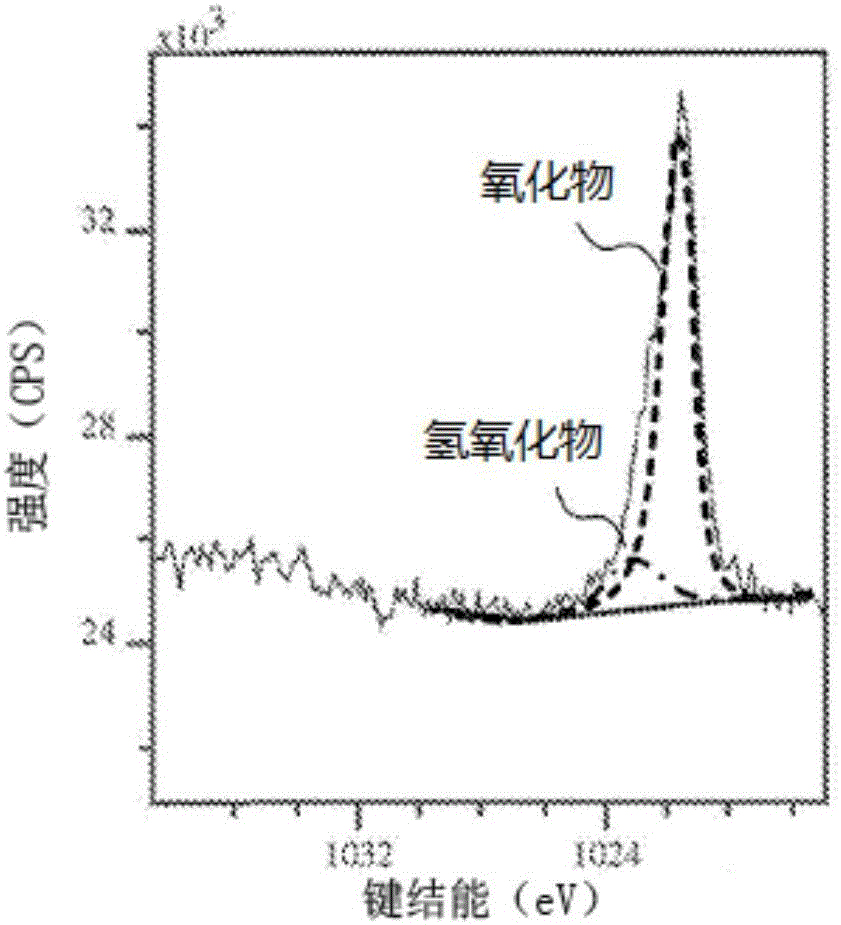

This hot-dip Zn-alloy-plated steel sheet comprises: a steel sheet; and a hot-dip Zn-alloy-plated layer arranged on a surface of the steel sheet. The entire surface of the hot-dip Zn-alloy-plated layer satisfies the following formula (1): S[Zn(OH)2] / (S[Zn(OH)2]+S[Zn]) * 100 <= 40. In formula (1): S[Zn] is the area exhibited by a peak having a center at approximately 1022 eV ascribable to metallic Zn in an intensity profile in XPS analysis of the surface of the hot-dip Zn-alloy-plated layer; and S[Zn(OH)2] is the area exhibited by a peak having a center at approximately 1023 eV ascribable to Zn(OH)2 in an intensity profile in XPS analysis of the surface of the hot-dip Zn-alloy-plated layer.

Owner:NISSHIN STEEL CO LTD

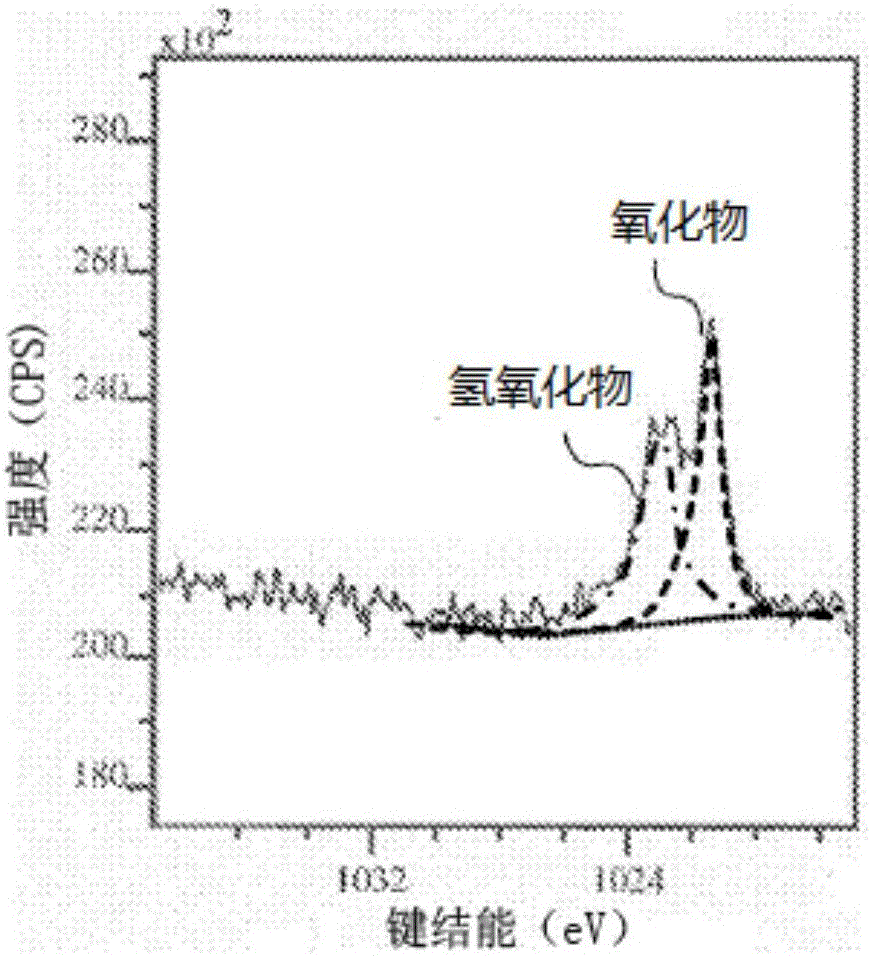

Hot-dip zn-alloy-plated steel sheet

ActiveCN105793469AEasy to manufactureEasy to resist melanosisHot-dipping/immersion processesSuperimposed coating processAlloyUltimate tensile strength

This hot-dip Zn-alloy-plated steel sheet comprises: a steel sheet; a hot-dip Zn-alloy-plated layer arranged on a surface of the steel sheet; and a complex oxide coating film arranged on a surface of the hot-dip Zn-alloy-plated layer. The complex oxide coating film includes vanadium and a constituent component of the hot-dip Zn-alloy-plated layer, and the entire surface of the coating film satisfies the following formula (1): S[Hydroxide] / (S[Hydroxide]+S[Oxide]) 100 <= 40. In formula (1): S[Oxide] is the area exhibited by a peak having a center at approximately 1022 eV ascribable to a Zn oxide in an intensity profile in XPS analysis of the surface of the complex oxide coating film; and S[Hydroxide] is the area exhibited by a peak having a center at approximately 1023 eV ascribable to a Zn hydroxide in an intensity profile in XPS analysis of the surface of the complex oxide coating film.

Owner:NISSHIN STEEL CO LTD

Surface treatment agent for metal, surface treatment method for metallic material, and surface-treated metallic material

InactiveCN101048476BImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsMetallic material coating processesVanadium CompoundsEmulsion

An agent for treating metal surfaces which comprises an aqueous medium and, incorporated therein, (A) a cationic urethane resin which is water-soluble or in an aqueous emulsion form, (B) a cationic polycondensation product obtained from a phenol compound and an aldehyde, and (C) a zirconium compound and / or titanium compound. A coating film formed from the treating agent imparts excellent corrosion resistance and alkali resistance to a metallic material. When the proportion of the urethane resin (A) is equal to or higher than that of the polycondensation product (B), yellowing resistance can be also imparted. By incorporating a metal compound (D) containing a specific metal, excellent blacking resistance also can be imparted. Furthermore, by incorporating an acid ingredient (E) and a vanadium compound (F), a further improvement in performances can be attained.

Owner:NIHON PARKERIZING

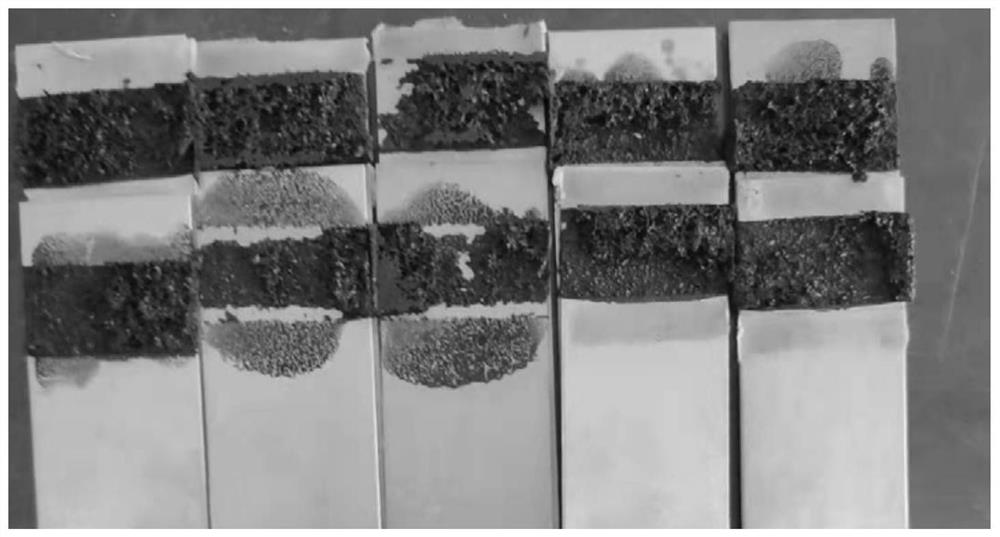

Phosphate-treated galvanized steel sheet having excellent resistance to corrosion and blackening

ActiveCN101068951ASame corrosion resistanceExcellent resistance to blackeningHot-dipping/immersion processesSuperimposed coating processSheet steelZinc

Disclosed is a phosphate-treated galvanized steel sheet wherein a zinc plating layer is formed on a steel sheet surface, a phosphate treatment layer is formed on the zinc plating layer, and an Ni adhesion portion is interposed between the zinc plating layer and the phosphate treatment layer in an amount of 0.1-500 mg / m<2>. This phosphate-treated galvanized steel sheet is excellent in corrosion resistance and blackening resistance. The phosphate treatment layer may preferably contain not less than 0.1% by mass but less than 2.0% by mass of Mg.

Owner:JFE STEEL CORP

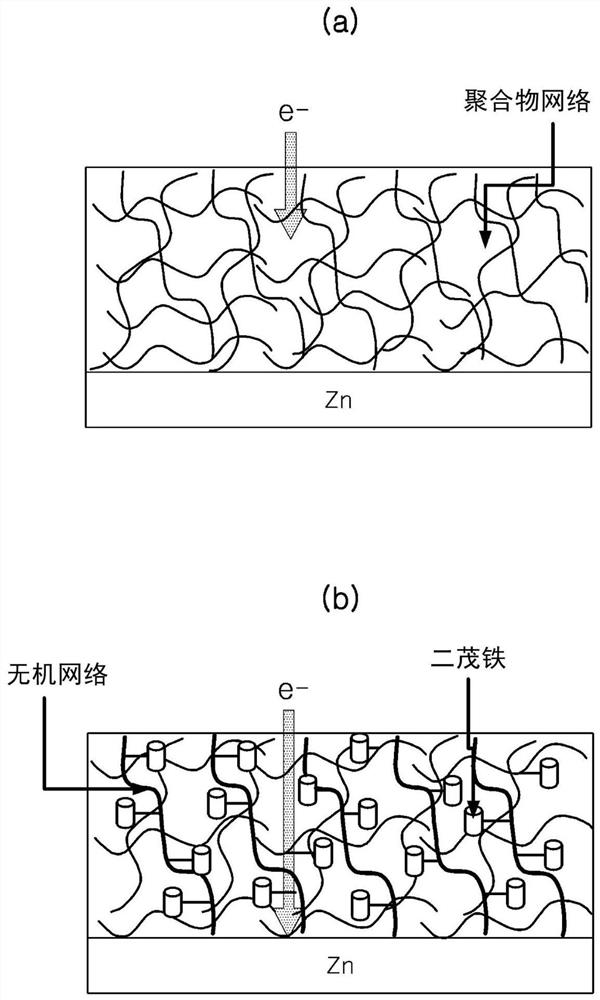

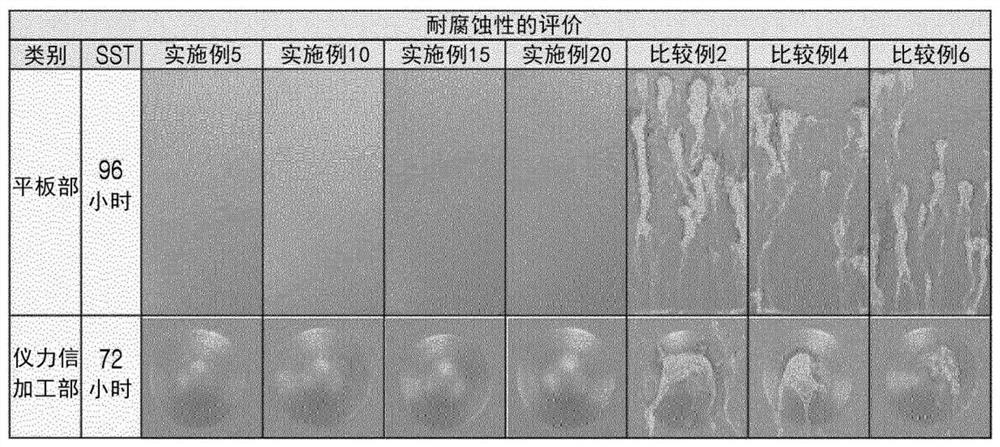

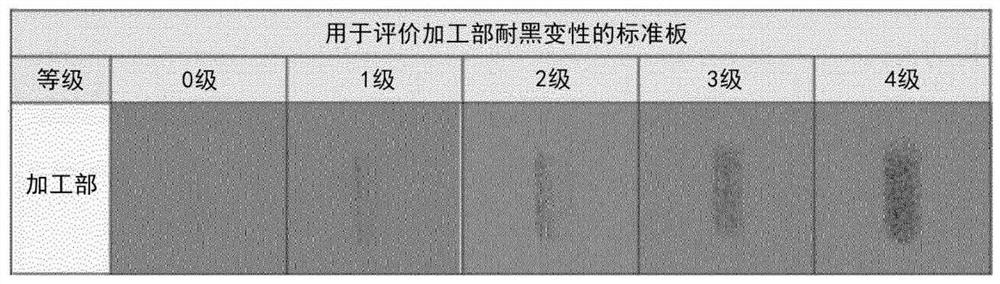

Organic-inorganic composite coating composition, and zinc-plated steel sheet surface-treated using same

InactiveCN113015770AImprove corrosion resistanceImprove antioxidant capacityLiquid surface applicatorsPolyurea/polyurethane coatingsSilane compoundsPolymer science

The present invention provides an organic-inorganic composite resin composition for coating the surface of a zinc-plated steel sheet, comprising 5-25 wt% of a polymer resin, 4-20 wt% of a silane compound, 3-10 wt% of a curing agent and 0.1-2 wt% of ferrocene compound on the basis of the total weight of the composition.

Owner:浦项股份有限公司

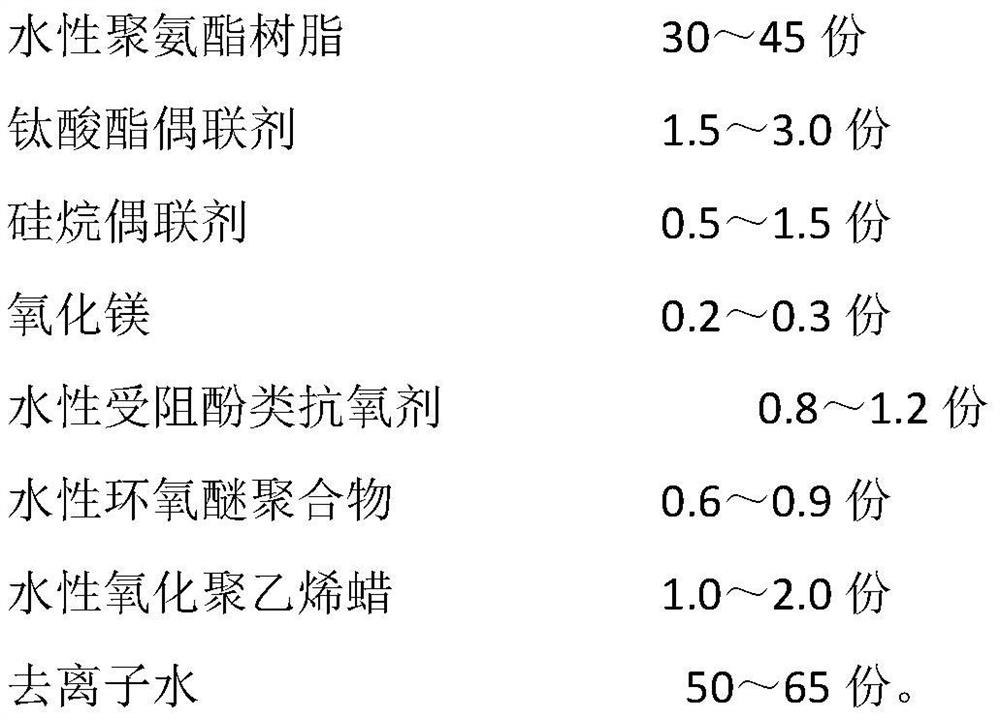

Surface treating agent for medium-aluminum zinc-aluminum-magnesium coated steel plate and manufacturing method thereof

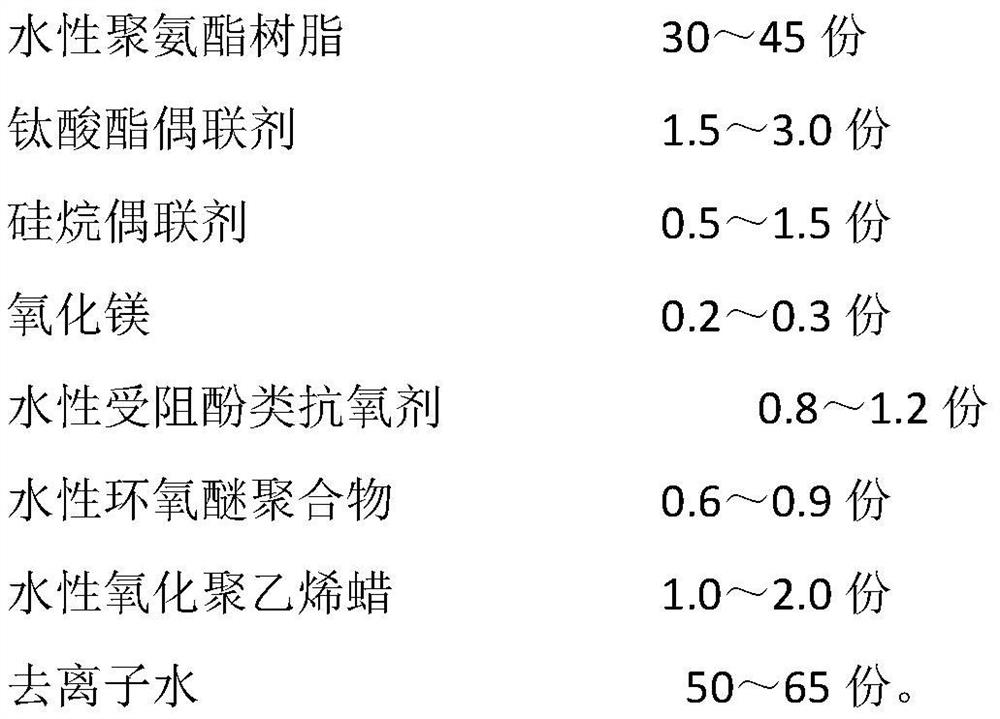

ActiveCN112391621AExcellent resistance to salt spray and corrosion resistanceGood alkali resistanceMetallic material coating processesEpoxyEther

The invention discloses a surface treating agent for a medium-aluminum zinc-aluminum-magnesium coated steel plate and a manufacturing method thereof. The surface treating agent for the medium-aluminumzinc-aluminum-magnesium coated steel plate comprises the following components in parts by weight of 30-45 parts of waterborne polyurethane resin, 1.5-3.0 parts of a coupling agent of organic titanate, 0.5-1.5 parts of a silane coupling agent, 0.2-0.3 part of magnesium oxide, 0.8-1.2 parts of a water-based hindered phenol antioxidant, 0.6-0.9 part of water-based epoxy ether polymer, 1.0-2.0 partsof water-based oxidized polyethlene wax and 50-65 parts of deionized water.

Owner:立邦(上海)化工有限公司

Chemical conversion treatment solution and chemically converted steel sheet

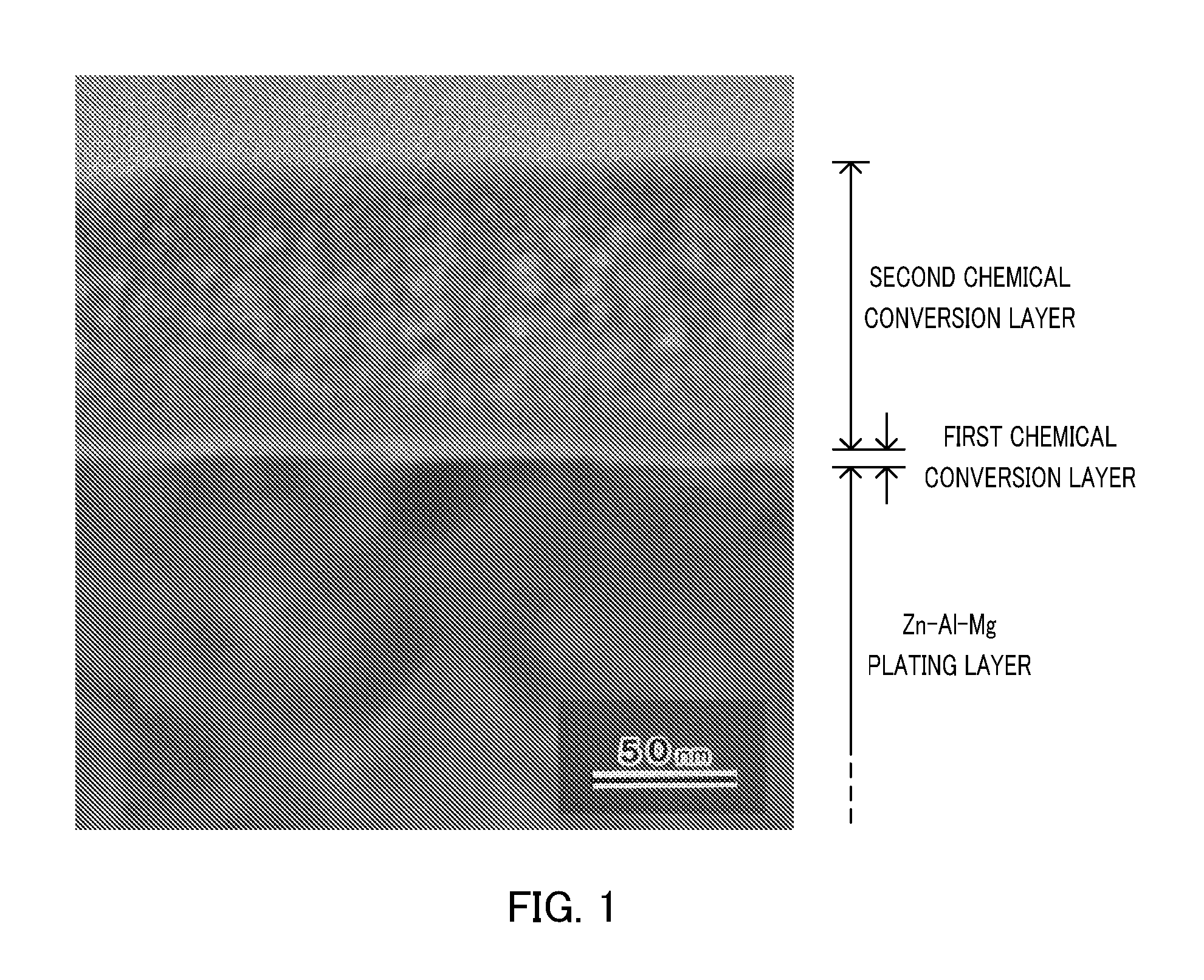

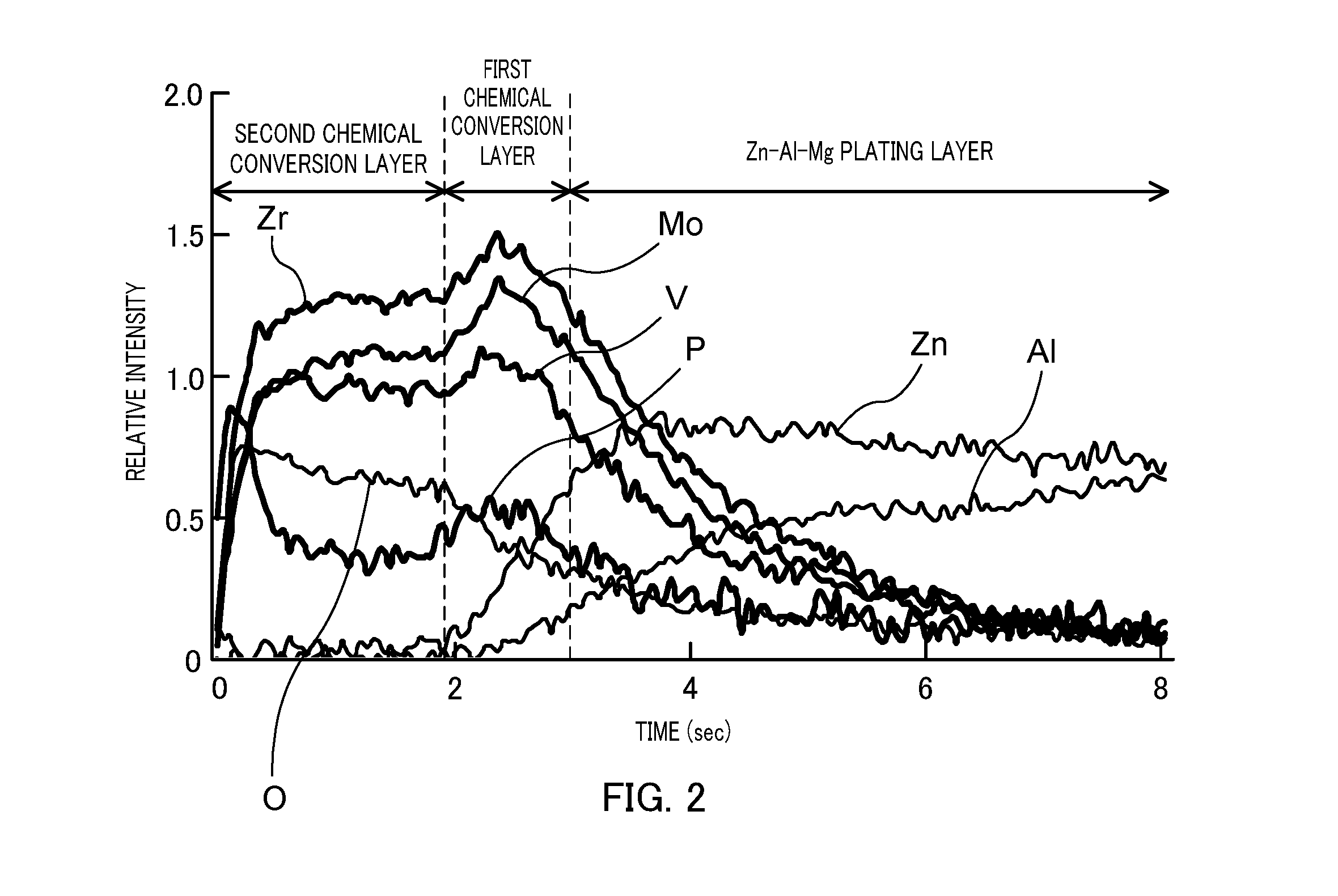

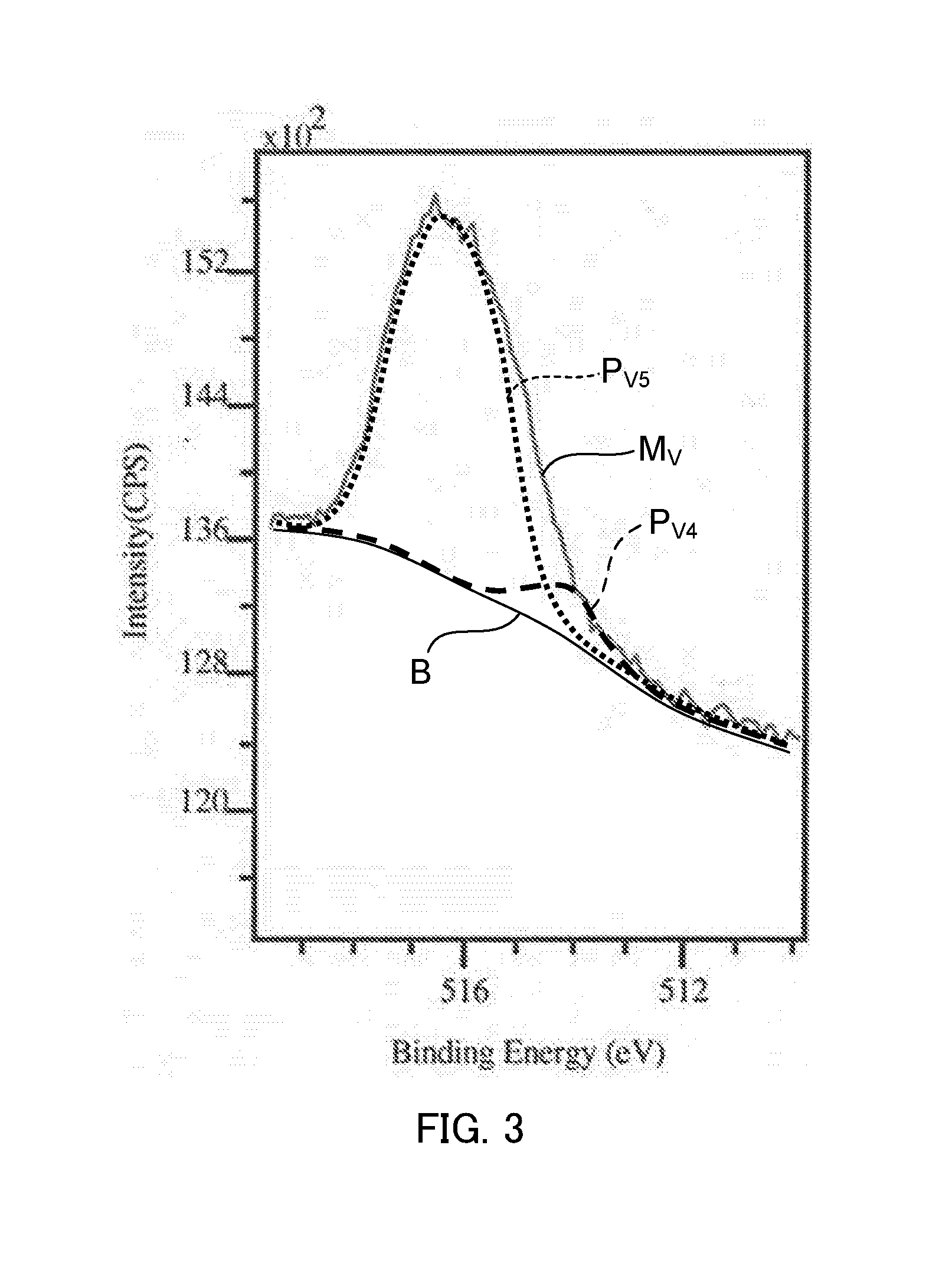

InactiveUS20160237572A1Improve corrosion resistanceExcellent resistance to blackeningHot-dipping/immersion processesSheet steelOxygen

A chemically converted steel sheet having a chemically converted coating film is made by coating a Zn-based plated steel sheet with a chemical conversion treatment solution and drying the same. The chemically converted coating film is constituted by a first chemically converted layer including V, Mo, and P, and a second chemically converted layer provided on said layer and including a group 4A metal oxygen acid salt, and the ratio of pentavalent V to all the Vs in the chemically converted coating film is 0.7 or greater. The chemical conversion treatment solution includes specific proportions of V, Mo, an amine, the group 4A metal oxygen acid salt, and P, and substantially does not include hydrophilic resins, fluorine, or silicon.

Owner:NISSHIN STEEL CO LTD

Hot-dip galvanized aluminum-magnesium alloy coated steel plate and preparation method

PendingCN113737117AImprove corrosion resistanceExcellent resistance to blackeningHot-dipping/immersion processesFurnace typesMetallurgyAnimal husbandry

The invention relates to a hot-dip galvanized aluminum-magnesium alloy coated steel plate and a preparation method. The hot-dip galvanized aluminum-magnesium alloy coated steel plate prepared by the method not only has excellent corrosion resistance, blackening resistance and notch protectiveness, but also has good surface quality and mechanical properties, and can completely meet application in the fields of household appliances, machinery, agriculture, animal husbandry and the like.

Owner:TIANJIN ROLLING ONE STEEL

Environment friendly chromate-free passivation solution based on silicate, and passivation technology thereof

InactiveCN111455364AImprove stabilityImprove corrosion resistanceMetallic material coating processesDiethylene glycol monobutyl etherSodium metasilicate

The invention belongs to the technical field of electroplating processing, and particularly relates to an environment friendly chromate-free passivation solution based on silicate, and a passivation technology thereof. The environment friendly chromate-free passivation solution based on the silicate provided by the invention comprises water, low mass molecule alcohol, sodium silicate, potassium silicate, sodium metasilicate, silane hydrolysate, diphenol propane, diethylene glycol monobutyl ether, sorbitol, phytic acid, glacial acetic acid, tannin, boric acid, sodium metasulfite, sodium nitrate, sodium hydrogen sulfite and other components, has excellent stability and can be stably stored for more than three months; and in the aspect of a passivation performance, a passivated coating has excellent corrosion resistance, blackening resistance and high temperature baking resistance. A passivation technology of the environment friendly chromate-free passivation solution based on the silicate provided by the invention comprises the steps of steeping, airing, ageing and the like. The environment friendly chromate-free passivation solution based on the silicate and the passivation technology thereof are simple and convenient to operate, economical in cost and stable and reliable in quality, and have higher popularization and application values.

Owner:太仓市金鹿电镀有限公司

Chromium-free aluminum coating agent and preparation method thereof

The invention belongs to the technical field of surface treatment, and discloses a chromium-free aluminum coating agent and a preparation method thereof. Based on the total weight of the non-chromium aluminum coating agent, the non-chromium aluminum coating agent comprises the following components in percentage by weight: 20-40% of phytic acid, 1-20% of a surfactant, 1-20% of sodium tripolyphosphate, 1-20% of a metal ion chelating agent, 1-20% of a silicon-aluminum compound and 10-40% of water. The non-chromium aluminum coating agent does not contain phosphorus, is environment-friendly, is convenient to use, and is beneficial to reducing the cost.

Owner:马鞍山中顺佰斯予菲环保科技有限公司

Method for hot-dip galvanizing strip steels

ActiveCN102312183BGood welding performanceGood coating performanceHot-dipping/immersion processesStrip steelWear resistance

The invention discloses a method for hot-dip galvanizing strip steels, the method of the invention optimizes the traditional hot-dip galvanizing liquid, optimizes the orientation of coating crystal grains and obviously raises the scratch resistance, wear resistance and adhesiveness of a coating layer. The method employs a non-chrome environmentally-friendly passivating solution formula for satisfying the requirement of environmental protection. Compared with the prior art, the hot-dip galvanized strip steels have good welding performance and coating performance of the traditional alloying hot-dip galvanizing strip steels, and have excellent corrosion resistant performance, black resistance performance, conductivity and environmental protection performance.

Owner:WUXI GUANGRUN METAL PROD CO LTD

Method for producing hot-dipped steel sheet excellent in blackening resistance and corrosion resistance

ActiveCN108690944BImprove corrosion resistanceImprove surface conditionHot-dipping/immersion processesFurnace typesHydrogen contentStrip steel

The invention discloses a manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance. The manufacturing method comprises the following steps: increasing the oxygen partial pressure in an annealing furnace to 30-80 ppm when basic strip steel enters a preheating section of the annealing furnace, wherein the dew point of the preheating furnace is 0-50DEG C, the furnace pressure of the annealing furnace is 300-500 Pa, and the preheating temperature is 500-700 DEG C; controlling the dew point of a soaking section at 30 DEG C below zero to 30 DEG Cafter the basic strip steel enters the soaking section, wherein the hydrogen content in percent by volume is 15-25%; and finally, controlling the cooling speed at 20-100 DEG C / s for cooling, wherein the basic strip steel enters a zinc pot to produce Mg-containing hot dipped steel plates. Mg-enriched ternary eutectic phase sheets in coatings of the steel plates are small in interlayer spacing, relatively short and uniform in distribution, Mg-containing oxides are unlikely produced, and the hot dipped steel plates have high corrosion resistance and good blacken resistance. In a severe environment, the corrosion resistance of the coatings is 2-3 times of that of conventional hot dipped steel plates, or the corrosion resistance is even higher, and the quality of the surface tissues of the coatings is good.

Owner:武汉钢铁有限公司

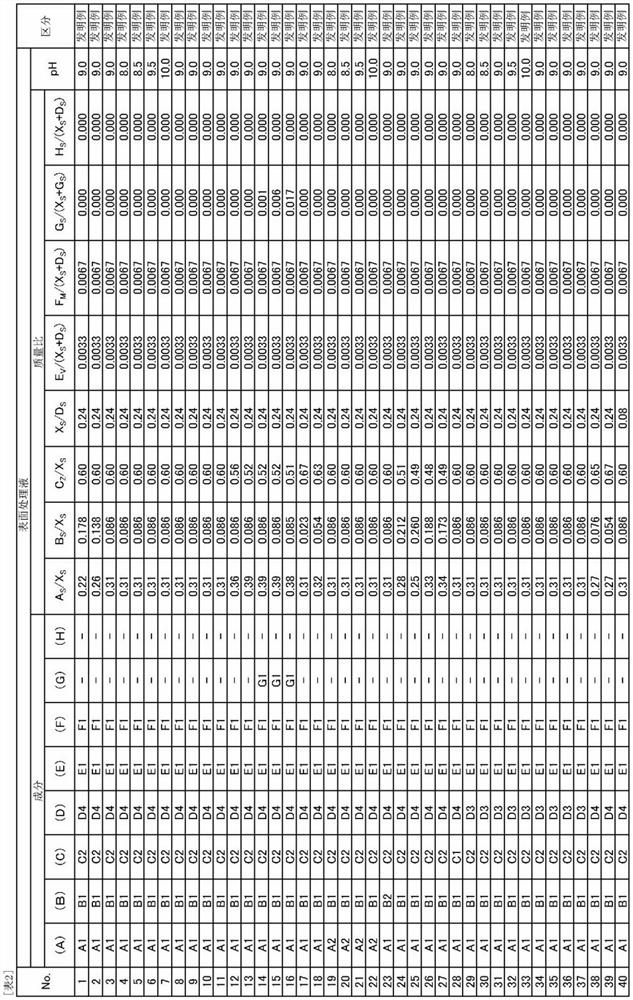

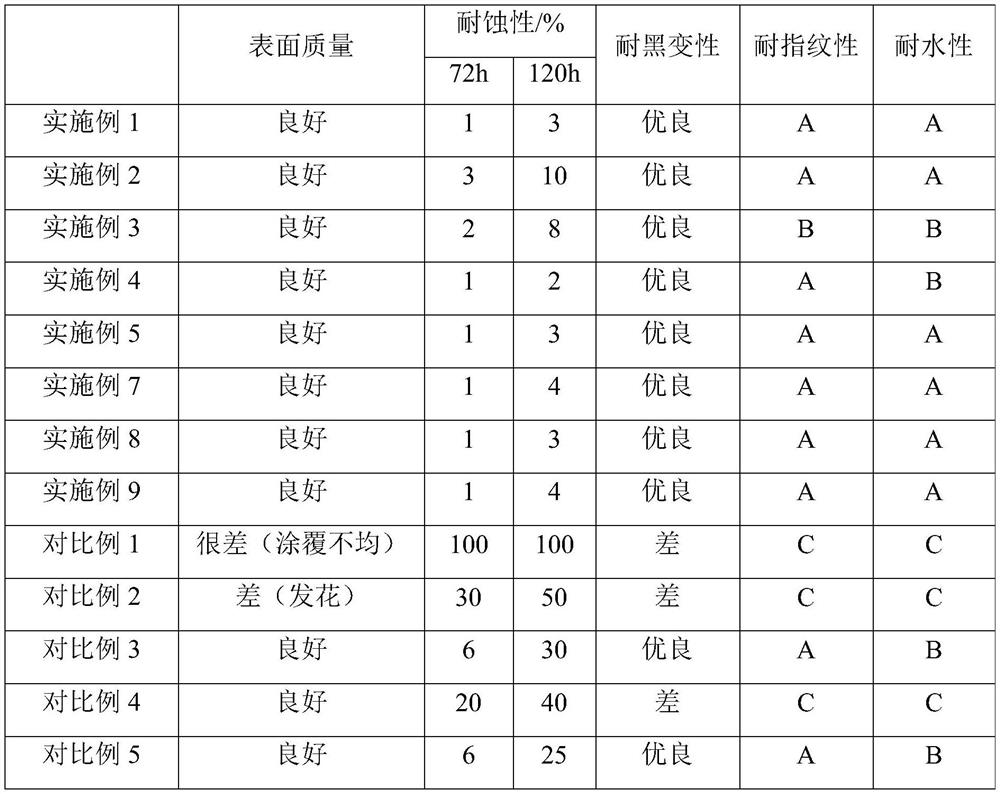

Surface treatment liquid for zinc-based coated steel sheet, zinc-based coated steel sheet with surface-treated film, and method for producing the same

ActiveCN109804103BGood storage stabilityImprove corrosion resistanceHot-dipping/immersion processesSuperimposed coating processChromium CompoundsCrack resistance

The present invention provides a surface treatment solution for producing a zinc-based plated steel sheet with a surface treatment film that does not contain a chromium compound in the surface treatment film and is resistant to discoloration by heat. , heat cracking resistance, corrosion resistance of the flat part, corrosion resistance after alkali degreasing, blackening resistance, stacking blackening resistance, water seepage resistance, solvent resistance, sweat resistance, coating adhesion and storage stability. excellent. The surface treatment liquid for zinc-based plated steel sheets of the present invention is characterized in that a silane coupling agent (A) having a glycidyl group, a tetraalkoxysilane (B), a zirconium carbonate compound (C), a glass transition Anionic polyurethane resin (D), vanadium compound (E), molybdic acid compound (F) and water at temperature (Tg) of 80°C to 130°C have pH of 8.0 to 10.0 and the addition amount of each component satisfies a predetermined relationship.

Owner:JFE STEEL CORP

Zinc-aluminum-magnesium coating surface treatment agent and preparation method and use method thereof

ActiveCN112538306BImprove densification performanceHinder contactHot-dipping/immersion processesAnti-corrosive paintsColloidal silicaMg alloys

The invention discloses a zinc-aluminum-magnesium coating surface treatment agent and a preparation method and a use method thereof, belonging to the technical field of zinc-aluminum-magnesium alloy coating steel plate surface treatment. The invention provides a surface treatment agent for zinc-aluminum-magnesium coating, which comprises 1-5 parts of fluoride, high iodine 3-10 parts of acid salt, 0.5-5 parts of weak alkaline medium, 20-50 parts of water-based organic resin, 5-15 parts of colloidal silica and 100 parts of water. In the invention, fluoride and periodate react with Mg on the surface of the coating layer under weak alkaline conditions to form a dense film layer, the water-based organic resin adheres to the surface of the coating layer, and the colloidal silica is filled in the gap, which effectively hinders the coating layer. The contact with water vapor and oxygen in the environment significantly improves the corrosion resistance, blackening resistance, water resistance and fingerprint resistance of the surface coating.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High surface quality zinc-aluminum-magnesium steel sheet with excellent blackening resistance and production method

The invention provides a high surface quality zinc-aluminum-magnesium steel sheet with excellent blackening resistance and a production method, and the composition of the plating solution: Al1.0-3.0%, Mg1.0-3.0%, Cu0.005-0.055%, Ti0. 005‑0.035%, Si 0.05%‑1.0%, and the balance is Zn and inevitable impurities. The temperature of the plating solution is 410°C-460°C, and the temperature of the strip steel into the pot is 400°C-480°C. The cooling rate after plating is 10-30℃ / s, and the plate temperature is cooled to not higher than 200℃; the plate temperature before entering the quenching water tank is not higher than 80℃, and the plate temperature is not higher than 40℃ before entering the quenching water tank. Compared with the prior art, the present invention adds Si, Ti and Cu to the plating solution, and cooperates with processes such as immersion plating, post-plating cooling, and smoothing. Blackening performance and corrosion resistance, as well as excellent surface quality and processability.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com