Zinc-aluminum-magnesium coating surface treatment agent and preparation method and use method thereof

A surface treatment agent, zinc-aluminum-magnesium technology, applied in coating, hot-dip plating process, metal material coating process, etc., can solve the problems of undetermined performance, unseen and other problems, and improve corrosion resistance. , The effect of improving compactness and excellent blackening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Further, the present invention also provides a preparation method of the above-mentioned zinc-aluminum-magnesium coating surface treatment agent, which comprises the following steps: taking each component by weight, dissolving a weakly alkaline medium in water, and then adding fluoride and periodic acid After dissolving the salt, add water-based organic resin, and finally add colloidal silica, and stir to obtain.

[0035] In a weakly alkaline environment, fluoride and periodate are more easily dissolved, complete and stable, so the present invention first dissolves the weakly alkaline medium in water to make the system in alkaline conditions; in addition, in order to make fluoride and periodate Salts are easier to dissolve, and one of them can be added first, and then the other component is added after dissolving; then adding water-based organic resin and colloidal silica, the stability of the surface treatment agent is better. By controlling the order of addition and a...

Embodiment 7

[0047] In Example 7, the difference from Example 1 is that the weakly alkaline medium is sodium oxalate.

Embodiment 8

[0048] In Example 8, the difference from Example 1 is that the water-based organic resin is a water-based silicone acrylic resin.

[0049] Preparation of Surface Treatment Agent

[0050] Take each component by weight, dissolve the weak alkaline medium in water, then add fluoride, add periodate after dissolving, add water-based organic resin after dissolving, finally add colloidal silica, and stir evenly.

[0051] Surface treatment of hot-dip galvanized aluminum-magnesium alloy coated steel plate

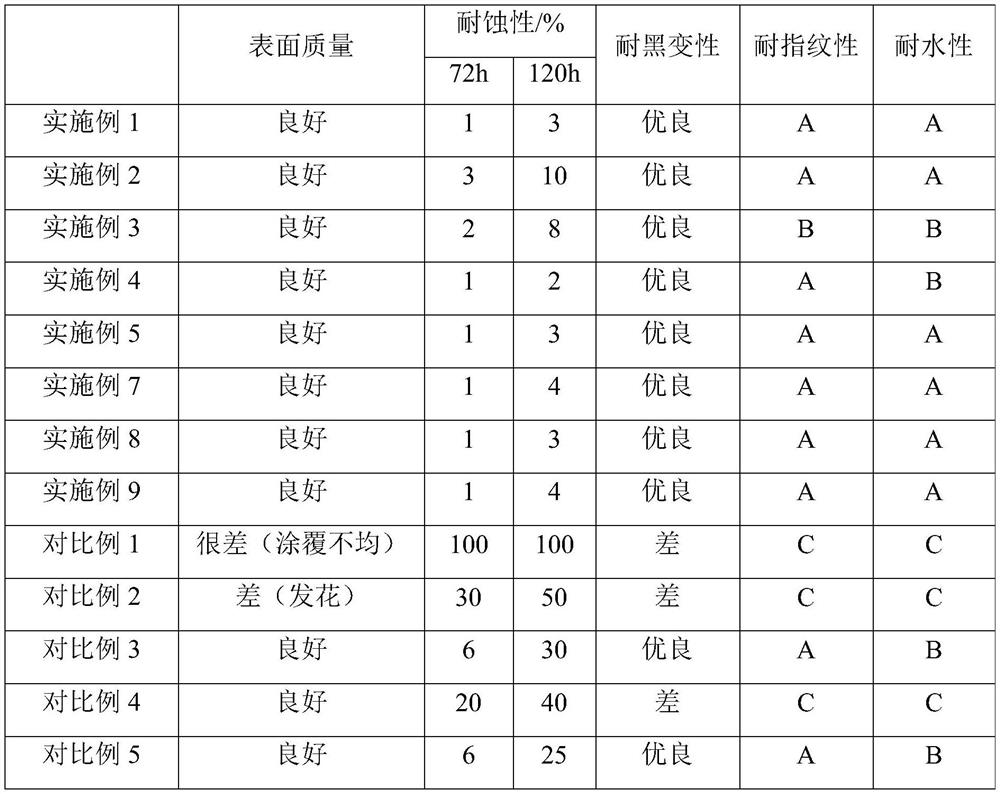

[0052] The surface treatment agents obtained in Examples 1 to 8 and Comparative Examples 1 to 5 were respectively roll-coated on hot-dip galvanized aluminum-magnesium alloy coated steel sheets of 2.5wt% Al-2.5wt% Mg-Zn, and the curing temperature was 95°C (The curing temperature was determined by using a temperature measuring paper) for 20 s to obtain hot-dip galvanized aluminum-magnesium coated plates 1-8 and comparative examples L1-L5, respectively.

[0053] Table 2 Coating thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com