Aqueous colorful chromium-free anti-fingerprint coating for coating surface of metal material and construction method thereof

A metal material and anti-fingerprint technology, which is applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem of uniform storage stability and effectiveness of coatings, and can not solve the problem of insufficient corrosion resistance of coating films. Meeting customer needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

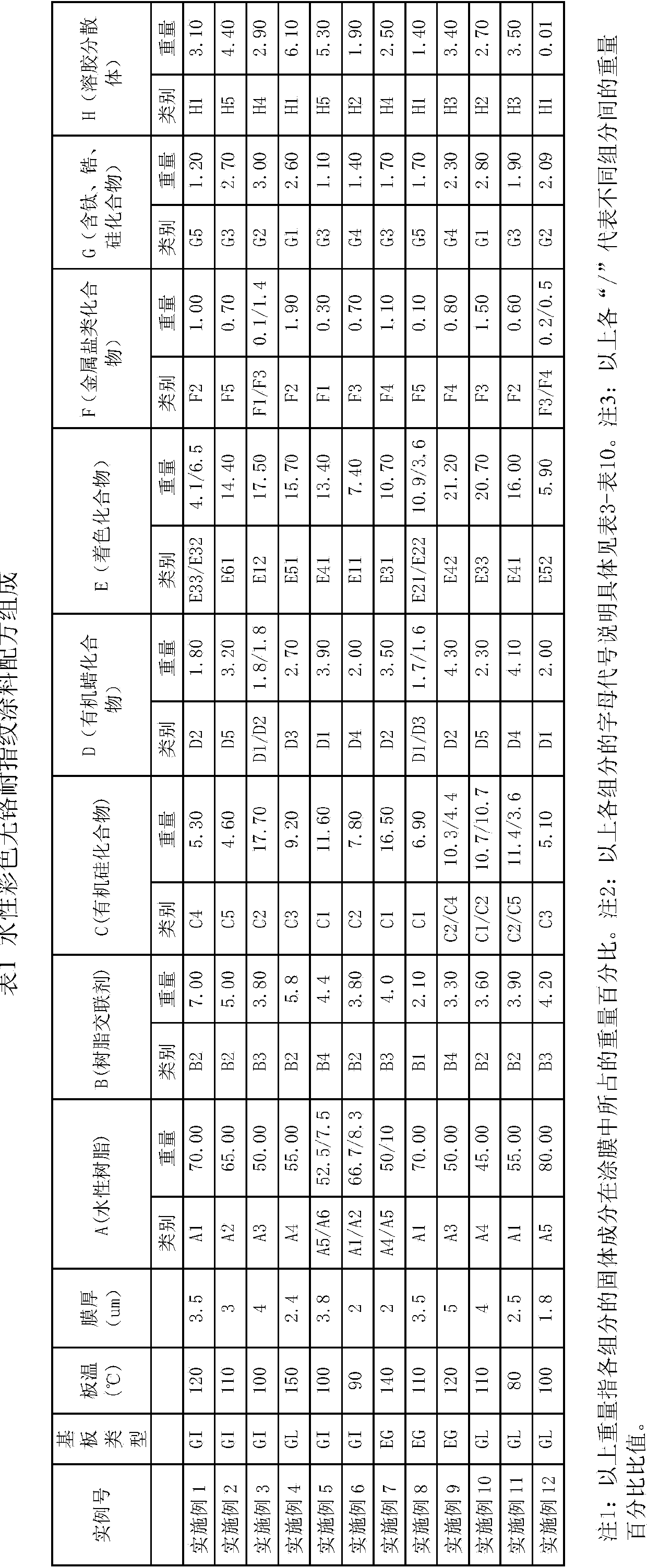

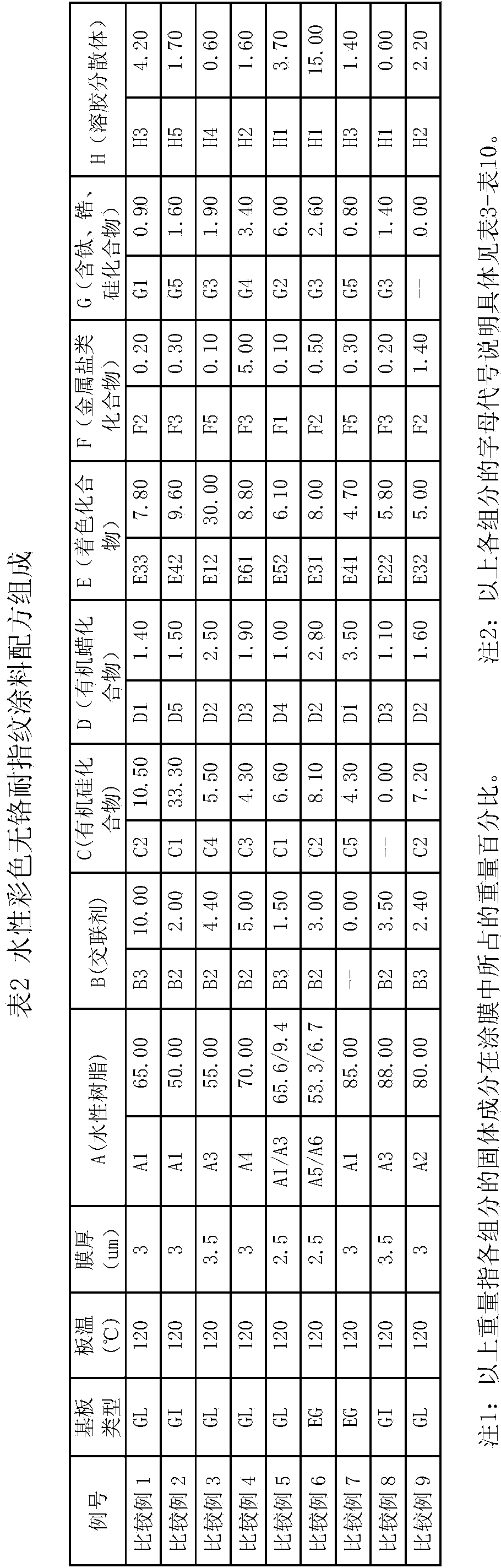

[0070] Examples and comparative examples of the present invention are given below to further describe the present invention in detail, but the present invention is not limited thereto.

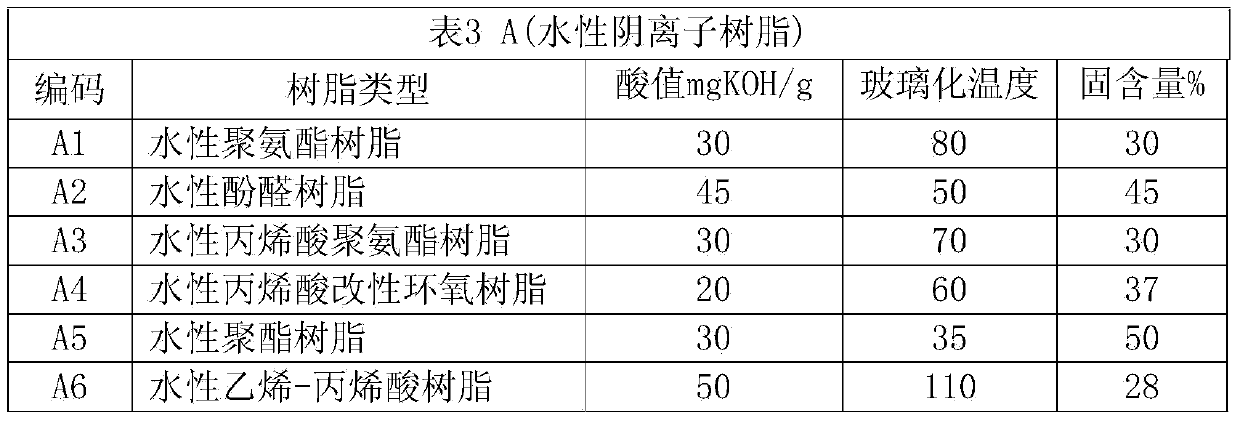

[0071] (1) Preparation of matrix resin A

[0072] 1. Preparation of Waterborne Polyurethane Resin (A1)

[0073] Add 80 parts of dehydrated polyester diol with an average molecular weight of 2000, 120 parts of bisphenol A epoxy adduct with an average molecular weight of 600, and 15 parts of bisphenol A in a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer Methylol propionic acid, then add 100 parts of N-methylpyrrolidone and heat to dissolve fully, then add 113 parts of dicyclohexylmethane diisocyanate, heat up to 110°C and react for 4 hours, measure its acid value to 30mgKOH / g, Cool to 70°C and add 10 parts of triethylamine, and add the reactant dropwise to deionized water mixed with 5 parts of triethylamine under high-speed stirring to obtain an anionic polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com