Organic-inorganic composite coating composition, and zinc-plated steel sheet surface-treated using same

A technology of galvanized steel sheet and composition, which is applied to devices, coatings, conductive coatings and other directions for coating liquid on the surface, can solve problems such as difficulty in ensuring surface conductivity, deterioration of equipment appearance, and degradation of coating film performance, etc. Excellent workability, improved electrical conductivity, and low curing temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 36

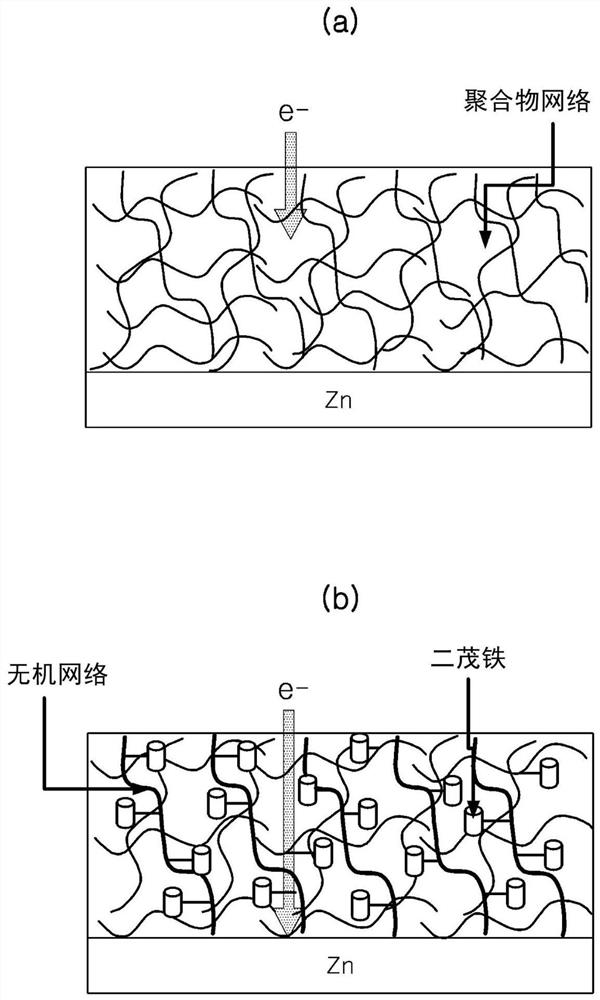

[0065] When preparing the composite coating composition, a polyurethane emulsion resin with a glass transition temperature of -28°C and a number-average molecular weight of 50,000 and hydrolyzed ureidopropyl triethylate were sequentially added as the main compounds with the composition shown in Table 1. Oxysilane (Ureidopropyltriethoxysilane), carbodiimide compound (Silia Carbodiimide (Silia Carbodiimide), SiliCycle Co., Ltd.), titanium fluoride compound and ferrocene compound (vinylferrocene, Aldrich Chemical Co.) as additives, polysiloxane-based dispersant and surface modification permanent polyethylene wax (PE WAX) and the rest of pure water, and aged for 24 hours to prepare an organic-inorganic composite coating composition with a pH of 5±0.5.

[0066] Afterwards, using a roll coater, the prepared composition is coated on the galvanized steel sheet and baked and dried so that the temperature of the steel sheet reaches 150° C., thereby preparing a coating with an adhesio...

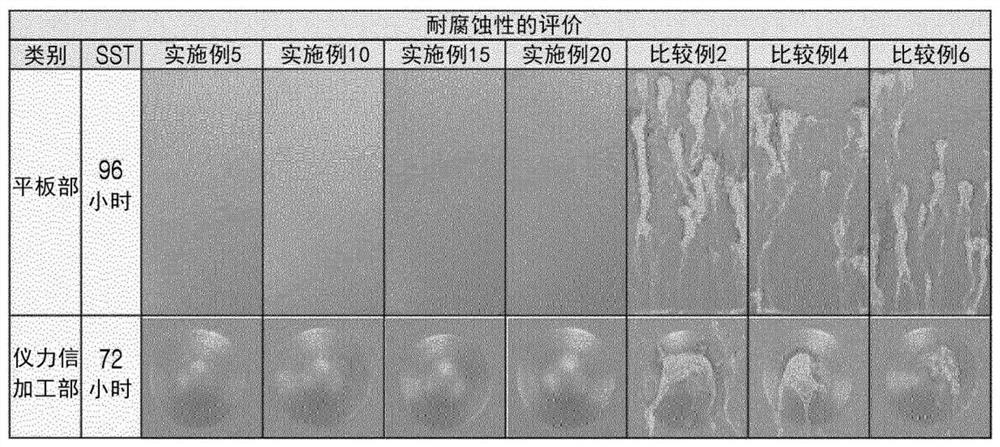

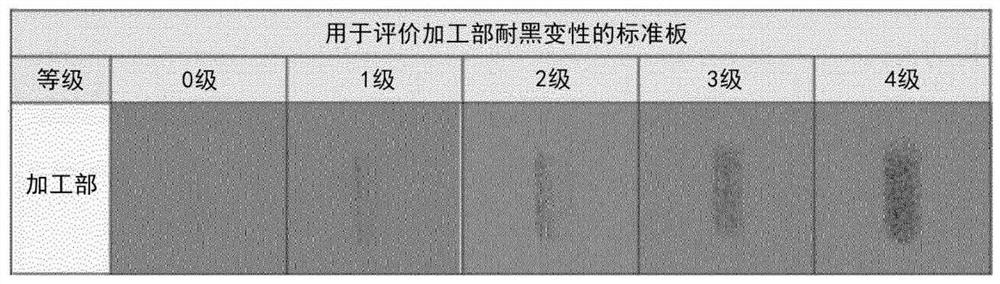

experiment example

[0075] As far as the quality evaluation of coated steel sheets is concerned, the physical properties required for chromium-free fingerprint-resistant steel sheets are evaluated, such as solution stability, corrosion resistance, processing blackening, chemical resistance, electrical conductivity, heat resistance, high temperature Humidity, etc., and each physical property was measured by the following method.

[0076] 1. Solution stability

[0077] In order to measure the solution stability of the composite coating composition solution, the initial viscosity (η i ). After being placed in an oven at 50°C for 5 days, it was cooled to normal temperature, and after stirring at normal temperature for 10 days, the final viscosity (η f ), calculate the change value of the viscosity, and evaluate according to the evaluation standard. The evaluation results of the solution stability are shown in Table 3 and Table 4.

[0078]Dη=(η f -η i ) / η i ×100(%)

[0079]

[0080] ◎: Dη is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com