Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Excellent film adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium- and fluorine-free chemical conversion treatment solution for metal surfaces, metal surface treatment method, and metal surface coating method

ActiveCN102575357AImprove corrosion resistanceExcellent film adhesionHot-dipping/immersion processesPretreated surfacesOrganic compoundIndustrial scale

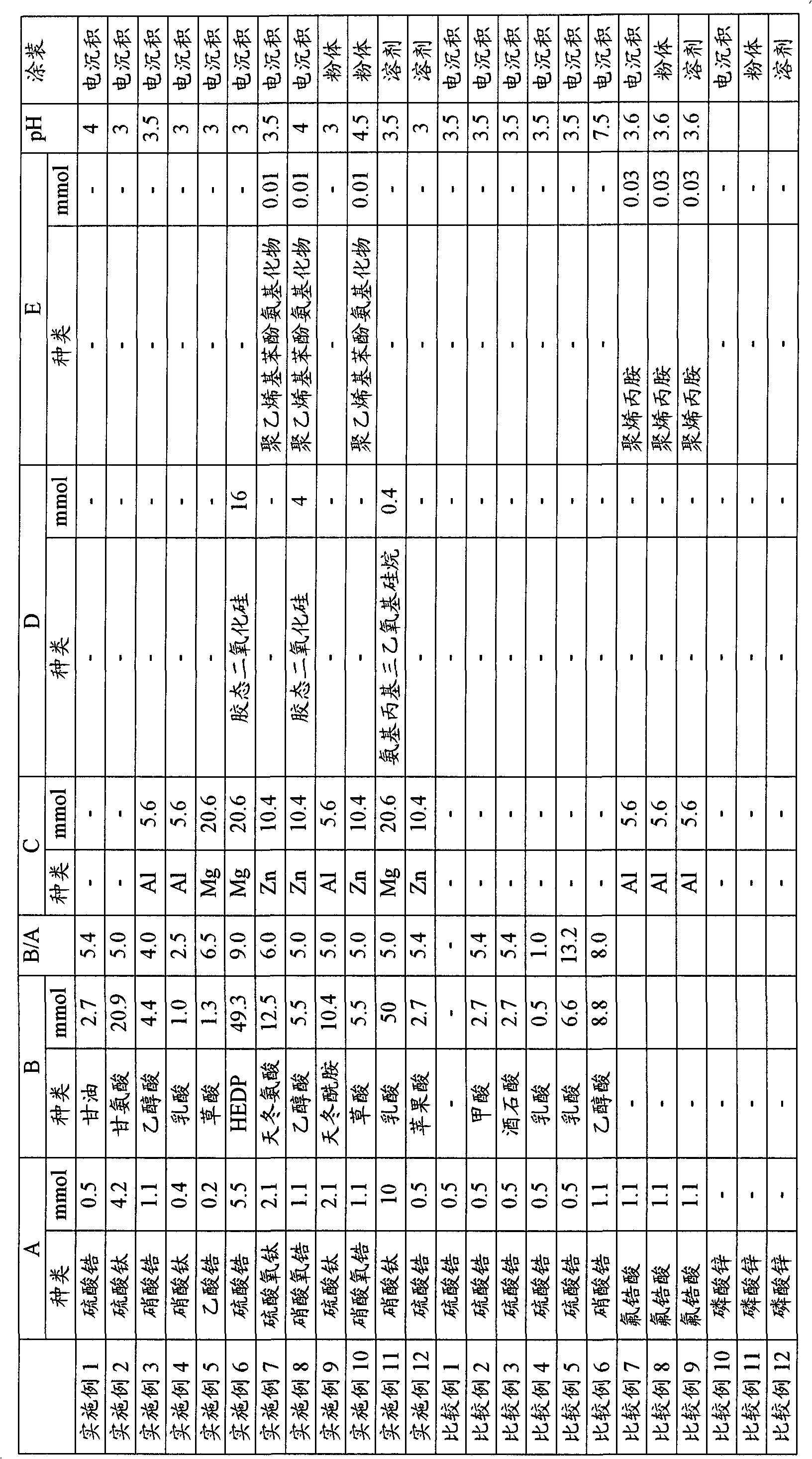

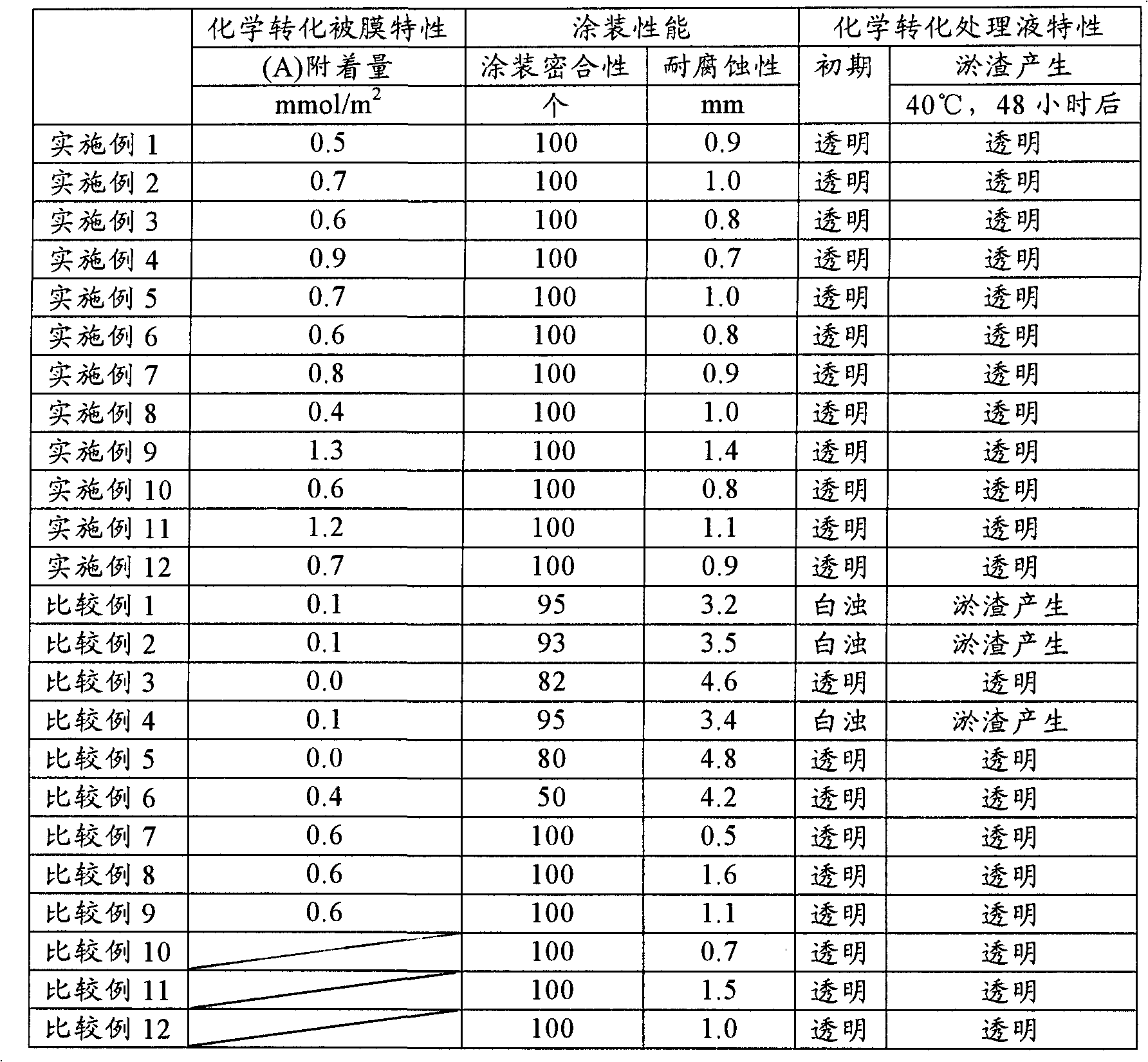

Disclosed are: a chemical conversion treatment solution for metal surfaces, which enables the formation of a chemical conversion coating film having excellent corrosion resistance and excellent adhesion properties on the surfaces of metal base materials in spite of a fact that the solution does not contain chromium and fluorine, and is suitable for treatments on industrial scales; and a metal surface treatment method. Specifically disclosed are: a chemical conversion treatment solution for metal surfaces, which comprises at least one compound (A) selected from a water-soluble titanium compound and a water-soluble zirconium compound and an organic compound (B) that has multiple functional groups and can serve as a stabilizing agent, and which has a pH value of 2.0 to 6.5, wherein the content of the compound (A) is 0.1 to 10 mmol / L, and the content of the organic compound (B) is 2.5- to 10-fold larger than the content of the metal in the compound (A) by mole; and a method for treating the surface of a metal base material or a structure body using the chemical conversion treatment solution for metal surfaces.

Owner:NIHON PARKERIZING

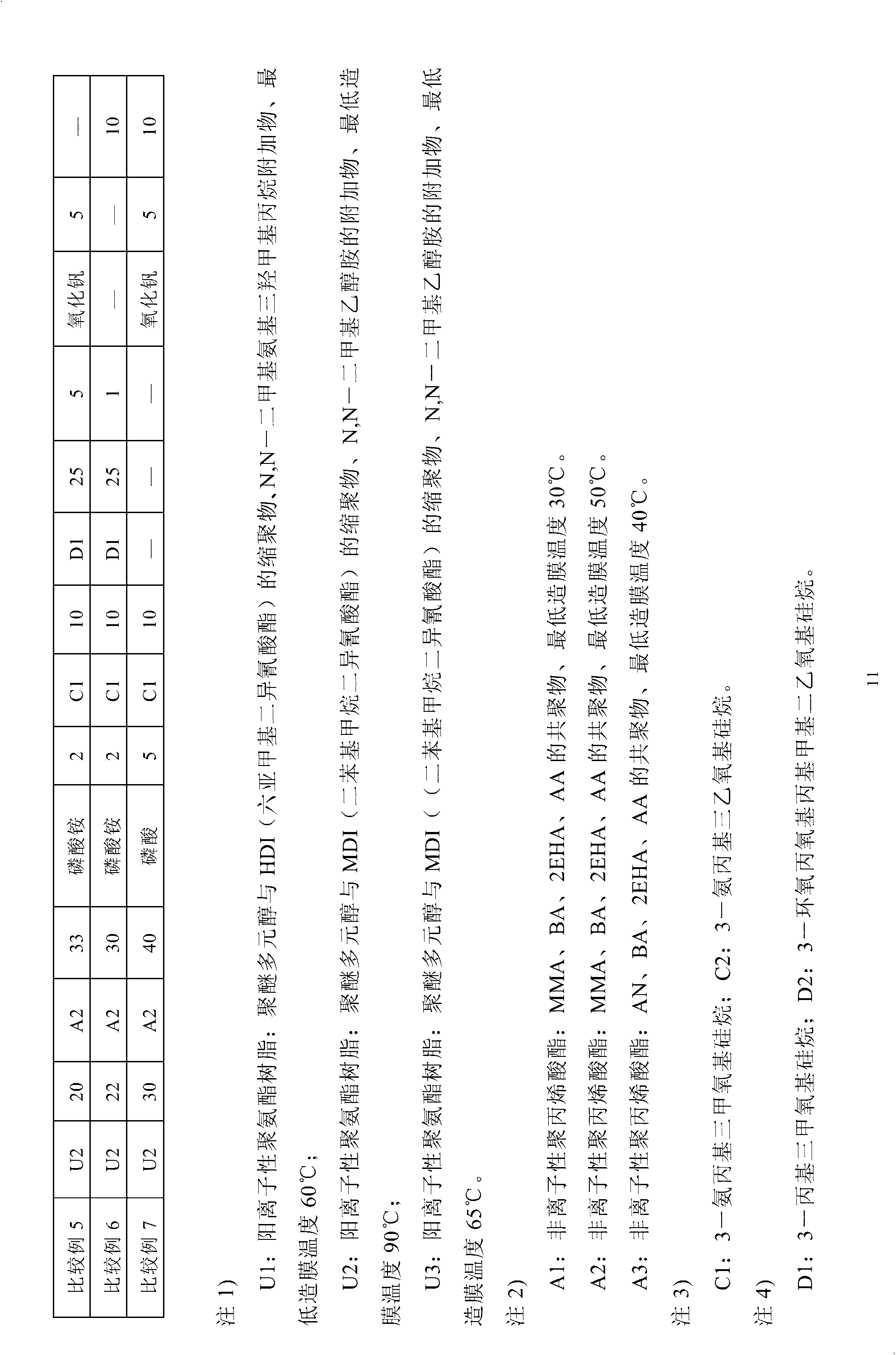

Low-temperature anti-fingerprint surface treating agent for galvanized steel sheet and environment-friendly surface treated galvanized steel sheet

ActiveCN104073100AHighlight corrosion resistanceHighlight drug resistancePolyurea/polyurethane coatingsWater basedSolvent

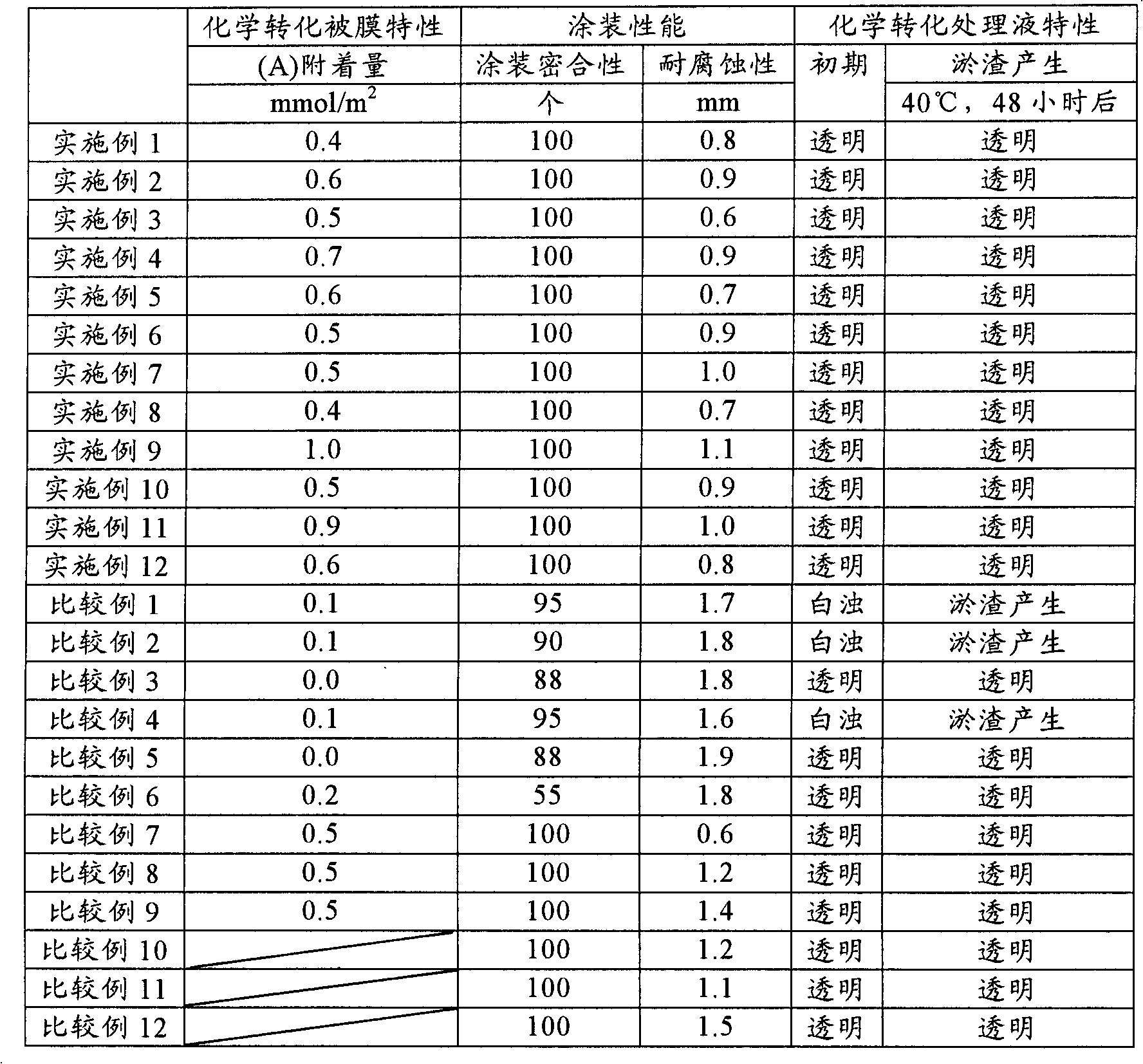

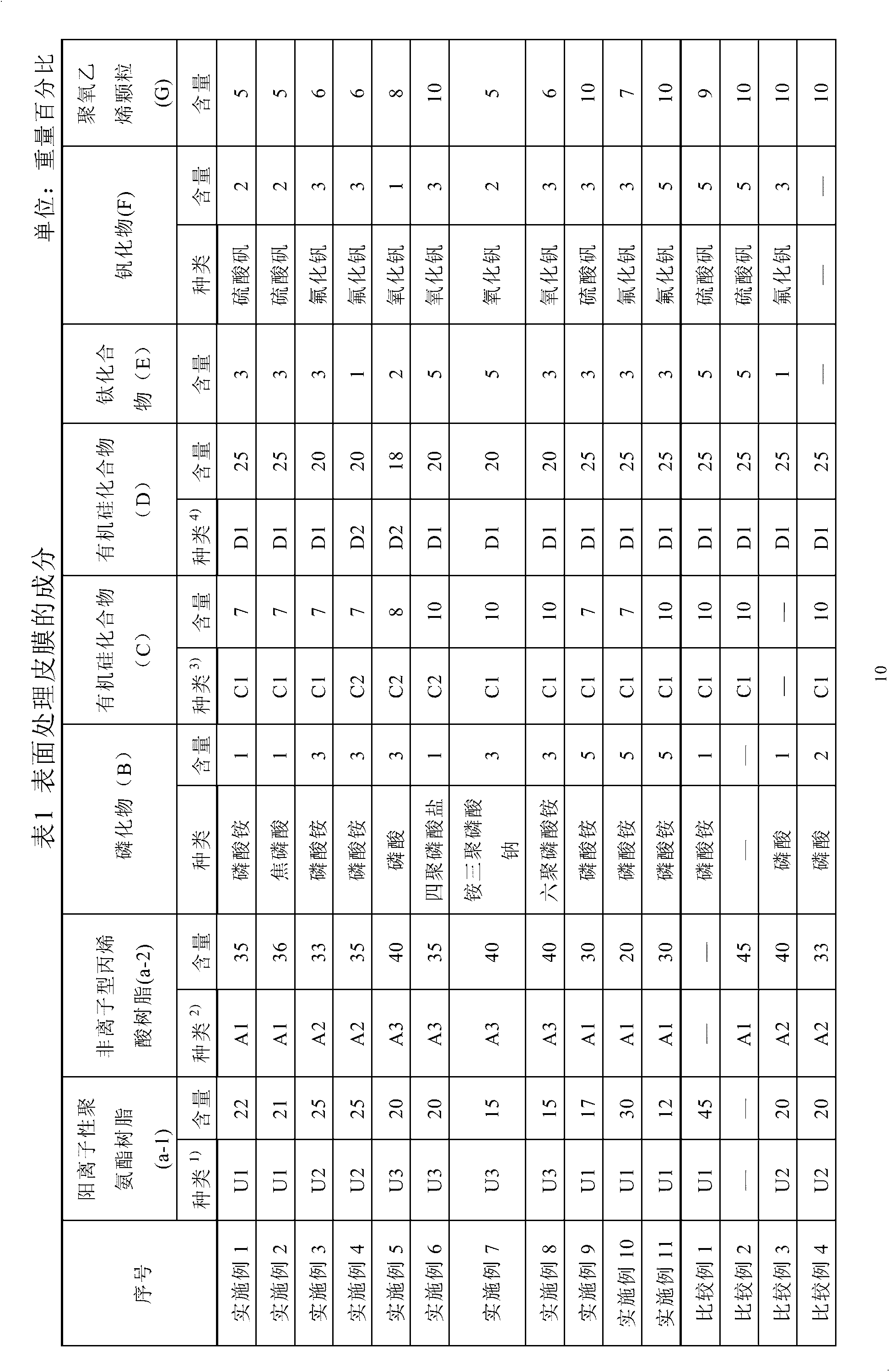

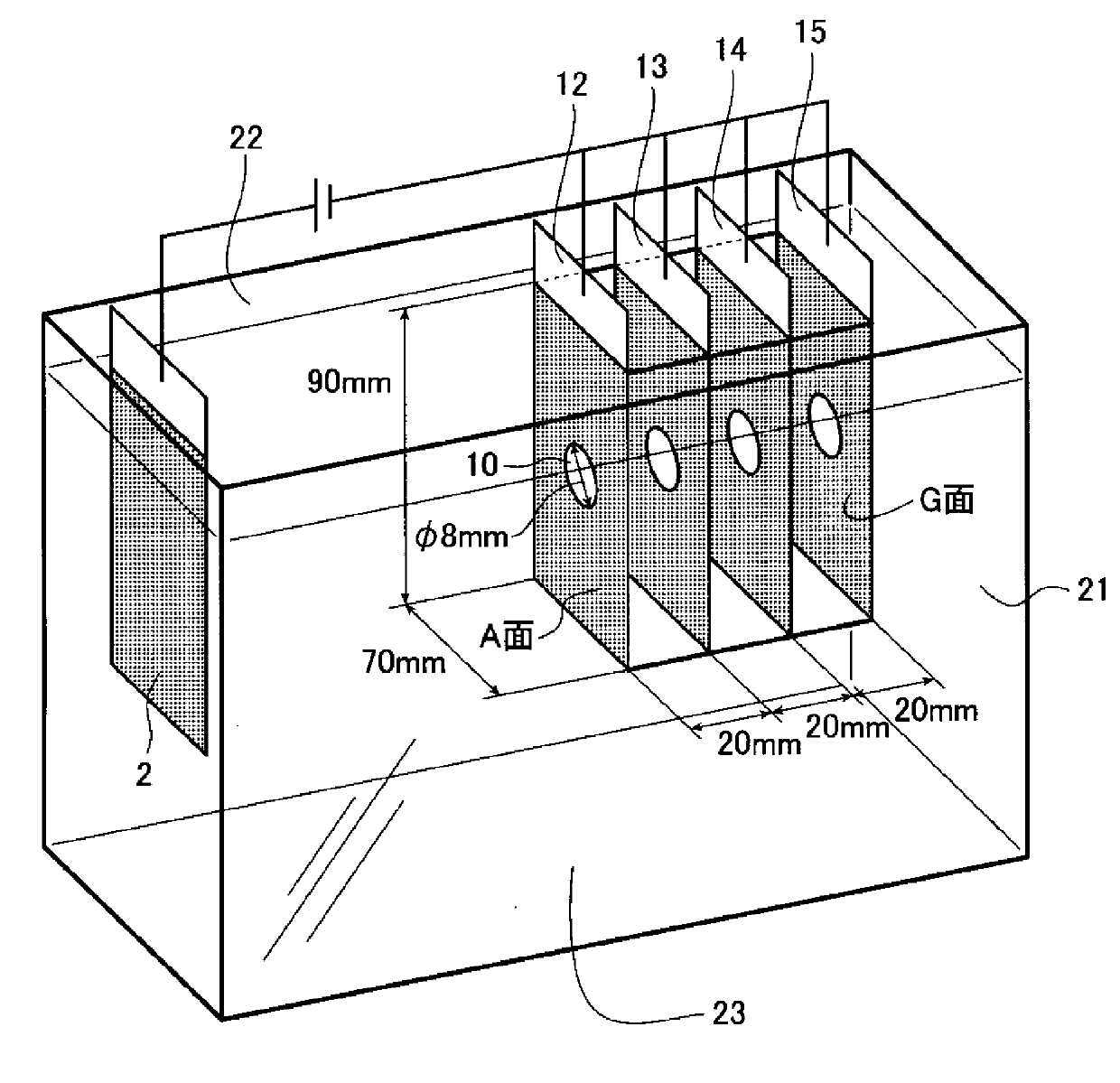

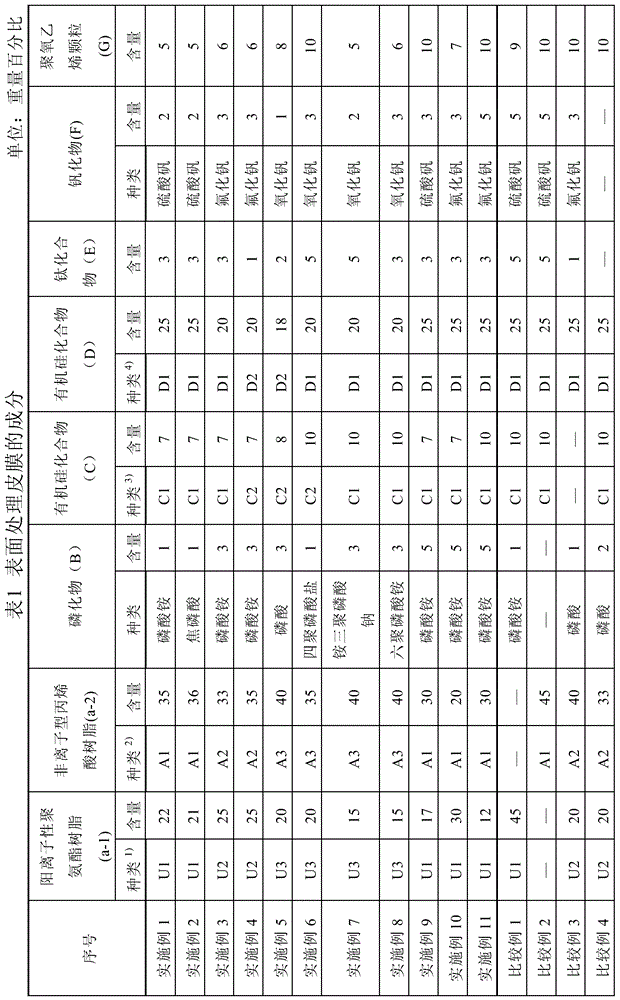

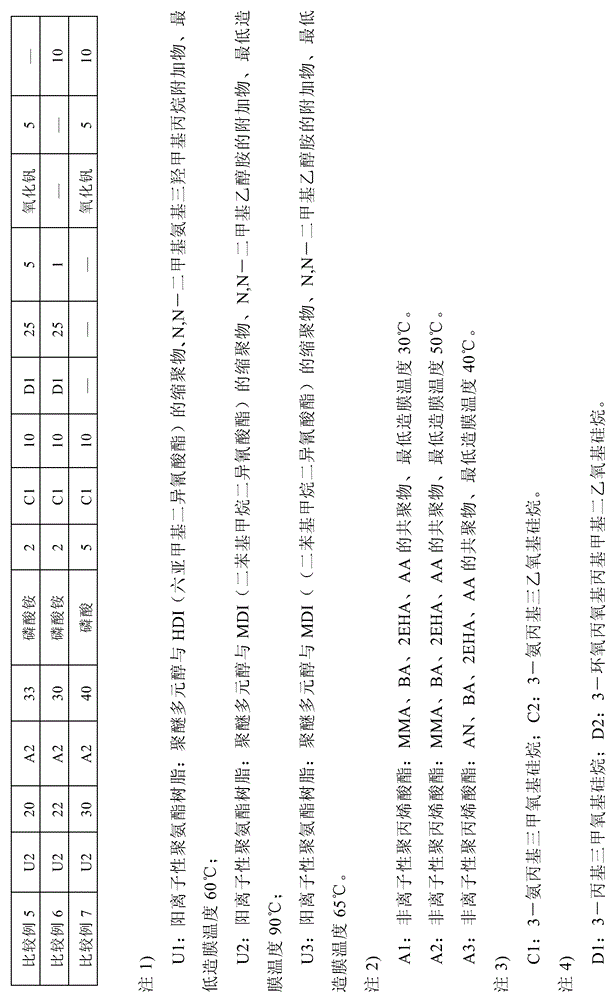

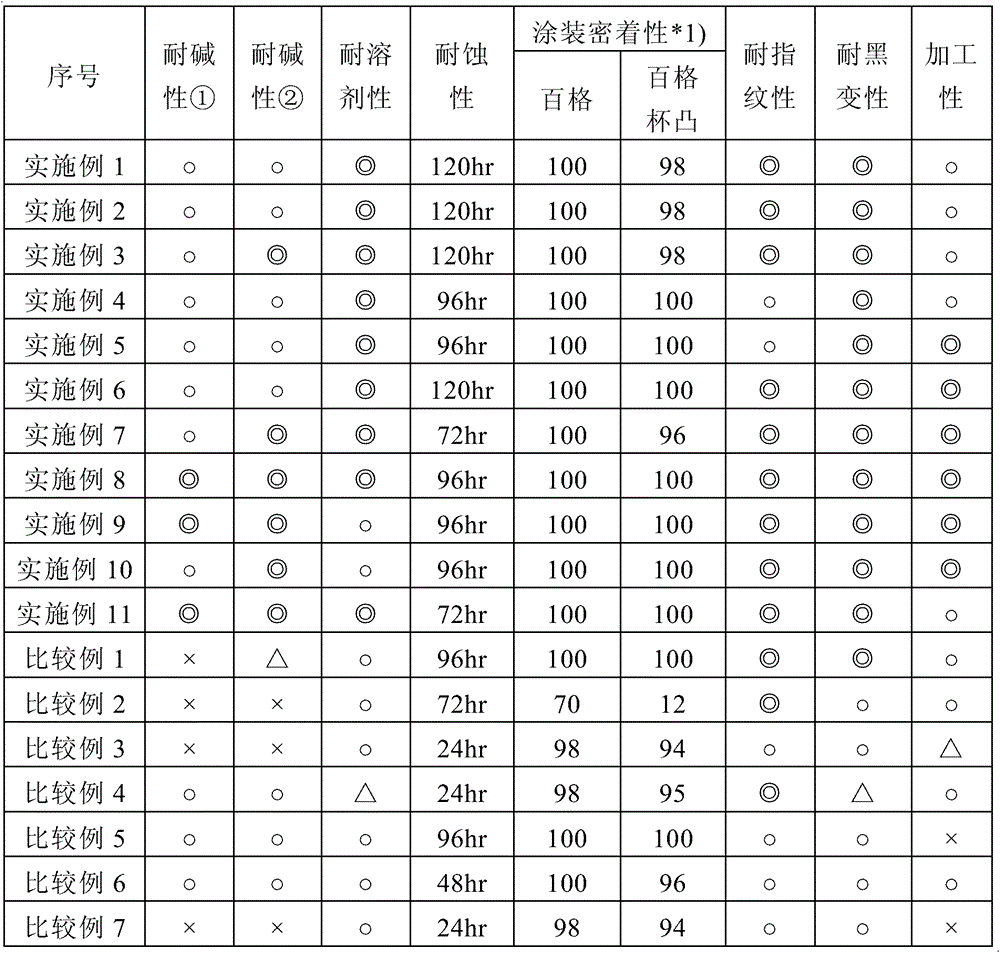

The invention relates to a low-temperature anti-fingerprint surface treating agent for a galvanized steel sheet and an environment-friendly surface treated galvanized steel sheet of which the surface is treated by use of the surface treating agent. The surface of the galvanized steel sheet does not contain chromium and does not need to be dried at a high temperature, and a surface treatment film can be formed on the surface under a low-temperature drying condition; the manufacturing process is environment-friendly and low in energy consumption; a composition (namely the surface treating agent) containing specific water-based resin and phosphide, specific organic silicon compound, titanium compound, vanadium compound and oxidic polyethylene particles is applied to the surface of the galvanized steel sheet and then dried at a low temperature ranging from 50 to 75 DEG C, and consequently, the obtained surface treated galvanized steel sheet has excellent properties such as excellent alkali resistance, solvent resistance, corrosion resistance, fingerprint resistance, coating adherence and the like.

Owner:BAOSHAN IRON & STEEL CO LTD +2

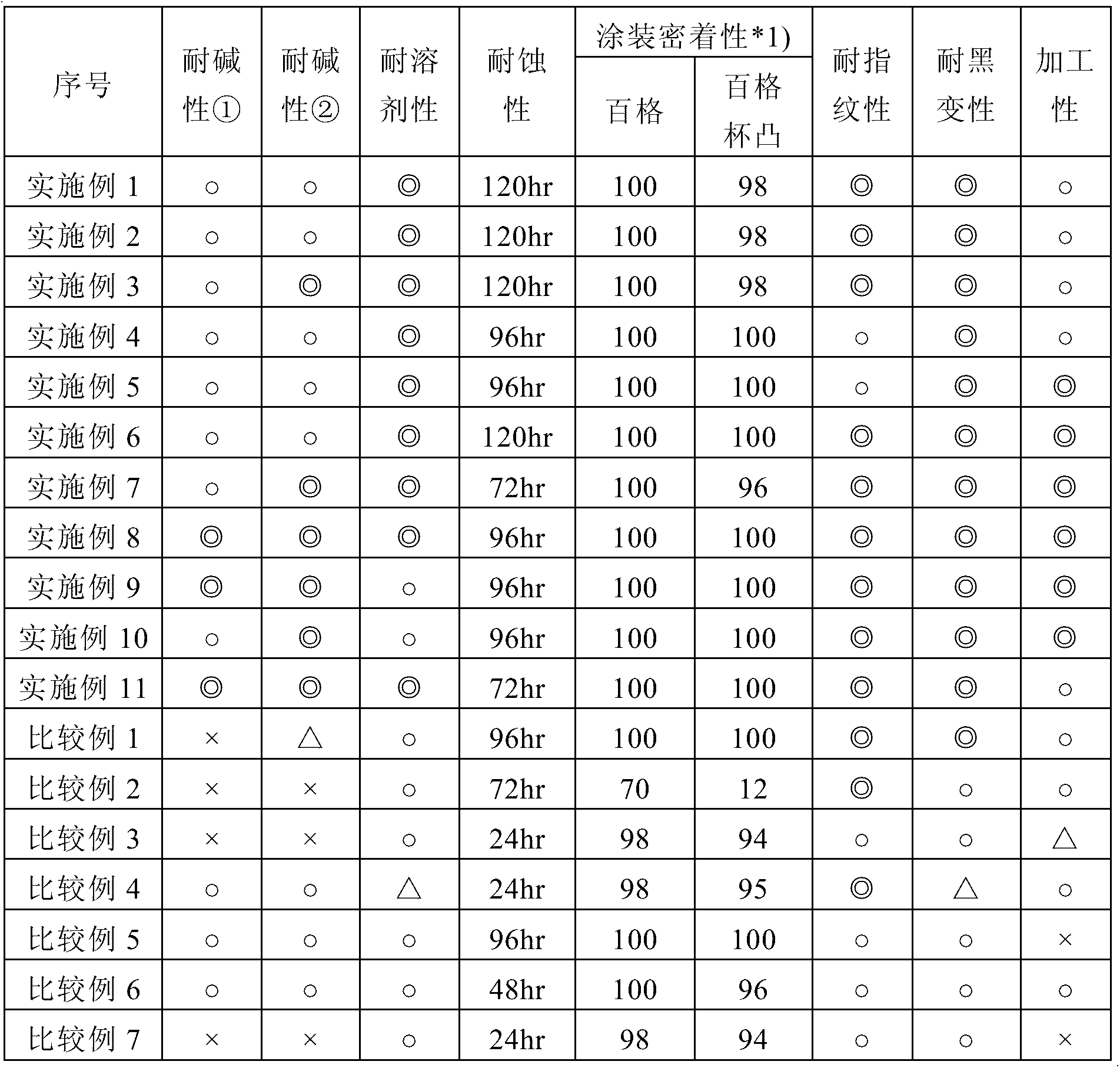

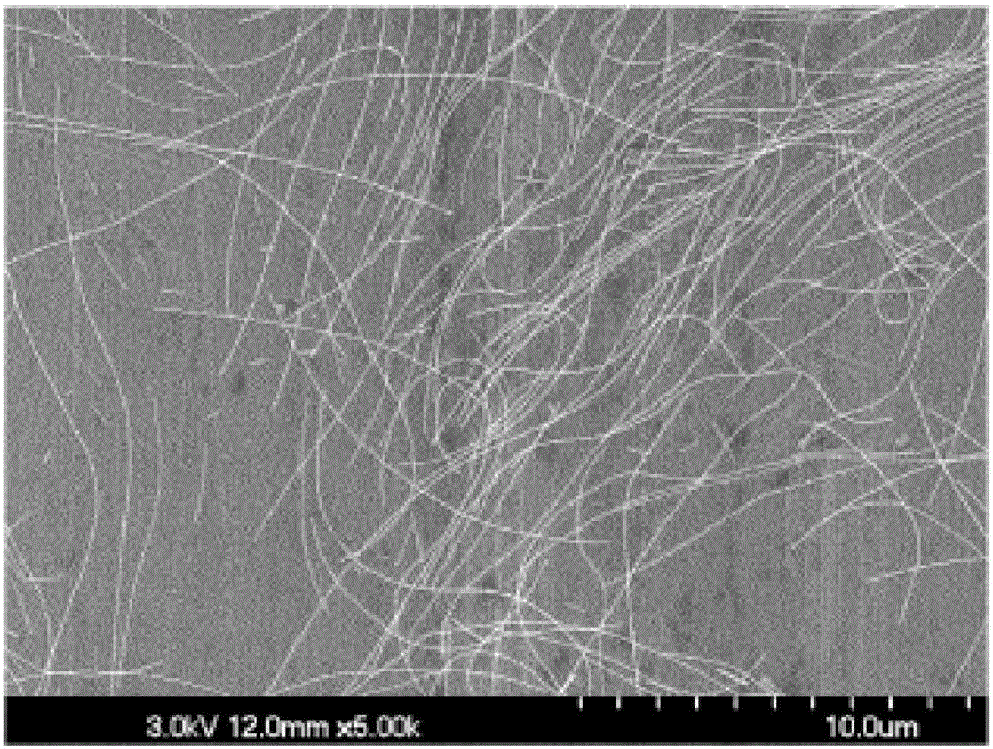

Method for producing silver nanowire ink, the silver nanowire ink, and transparent electroconductive coating film

InactiveCN106103610AImprove conductivityExcellent optical propertiesConductive layers on insulating-supportsConductive materialOptical transmittanceOrganic chemistry

Owner:DOWA ELECTRONICS MATERIALS CO LTD

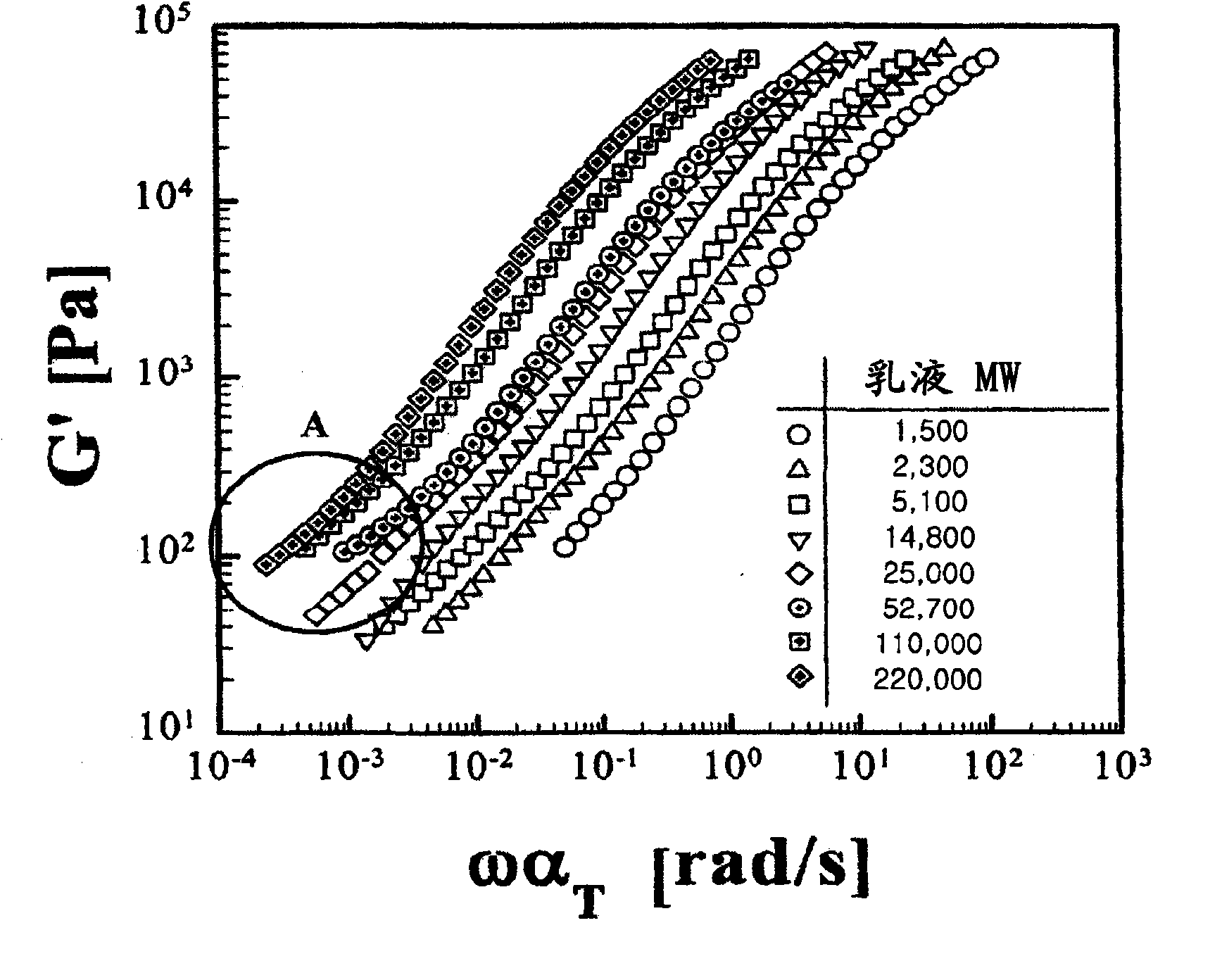

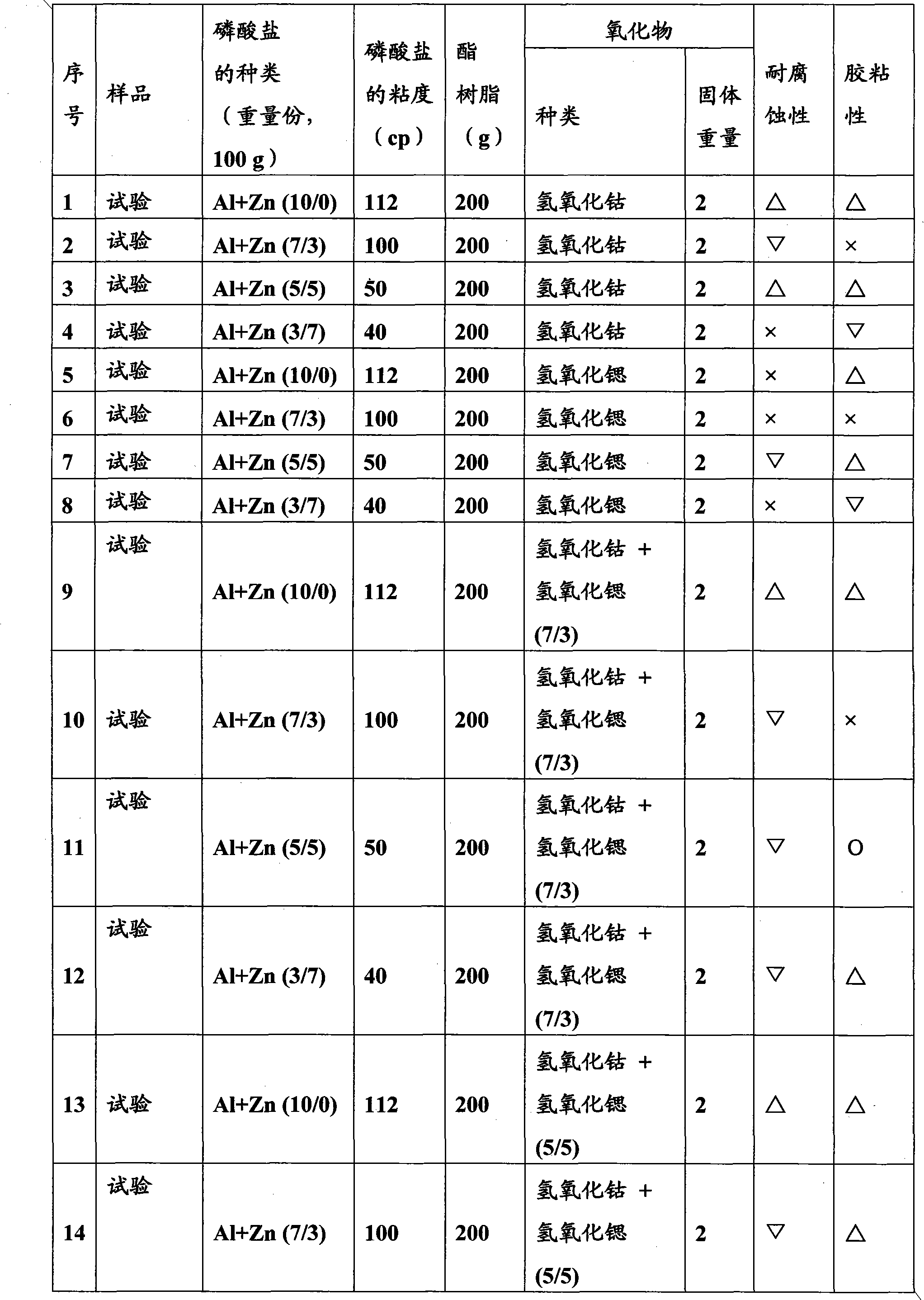

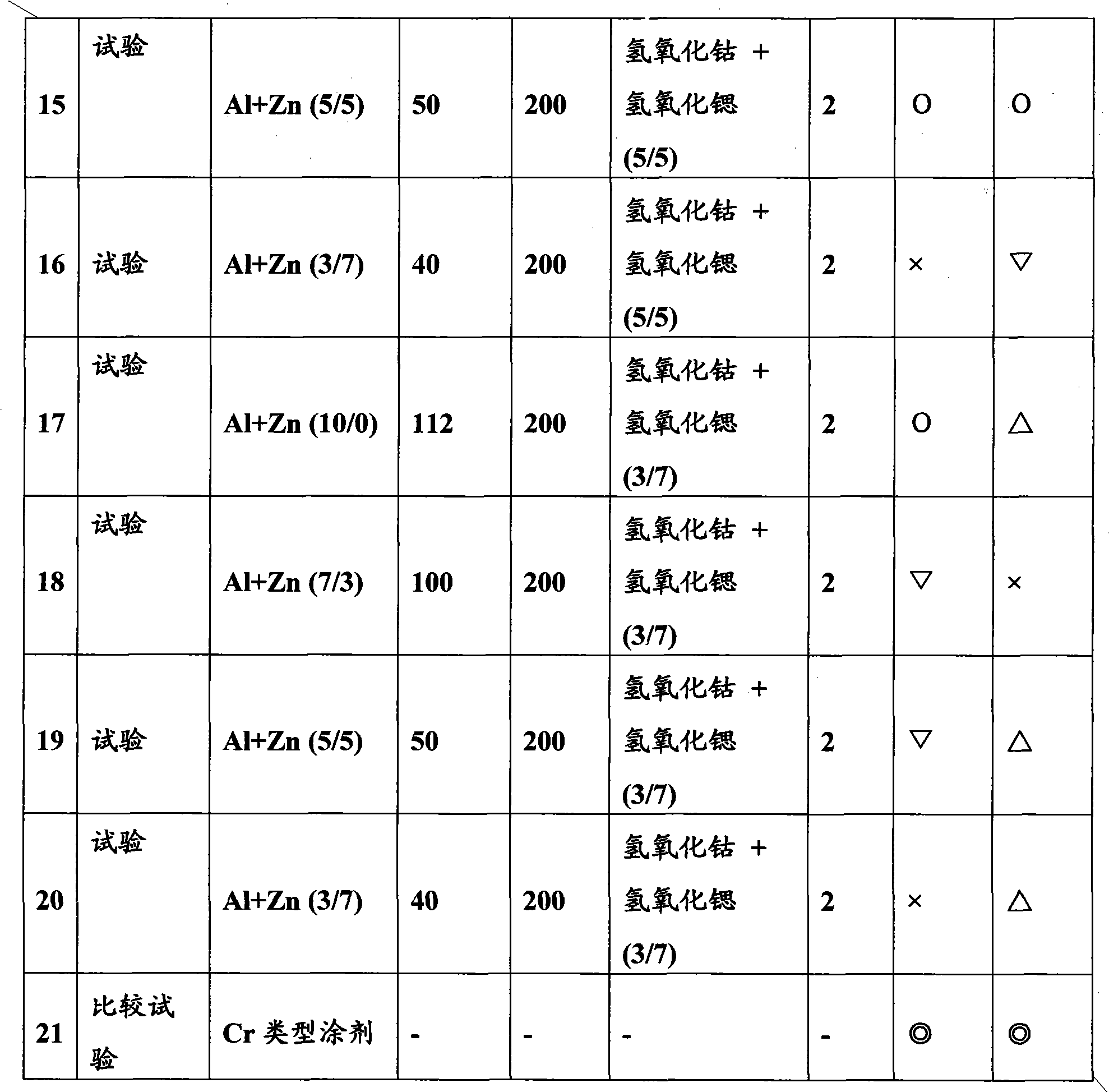

Coating solution for forming insulating film, method for forming insulating film of non-oriented electrical steel sheet and non-oriented electrical steel sheet by using it

ActiveCN101910464AGood compatibilityImprove corrosion resistanceMetallic material coating processesChromium freePolyester

Disclosed is a coating composition having superior compatibility and surface gloss for forming an insulating film and a method of forming the film. The coating composition includes, based on 100 g of a mixture solution of monoaluminum phosphate and monozinc phosphate, 0.5-5 g of a mixture solution of cobalt hydroxide and strontium hydroxide, 150-300 g of a polyester emulsion resin, 3-10 g of aluminum silicate, and 0.5-6.0 g of a chelating agent, in which the polyester emulsion resin has a weight average molecular weight of 2,000-15,000, a solid content of 15-25% and a viscosity of 100-500 cp. Even when the coating composition which is chromium-free is applied in the form of a thick film on a non-oriented electrical steel sheet, superior insulating properties, corrosion resistance, film adhesion, compatibility and surface gloss can be exhibited.

Owner:浦项股份有限公司

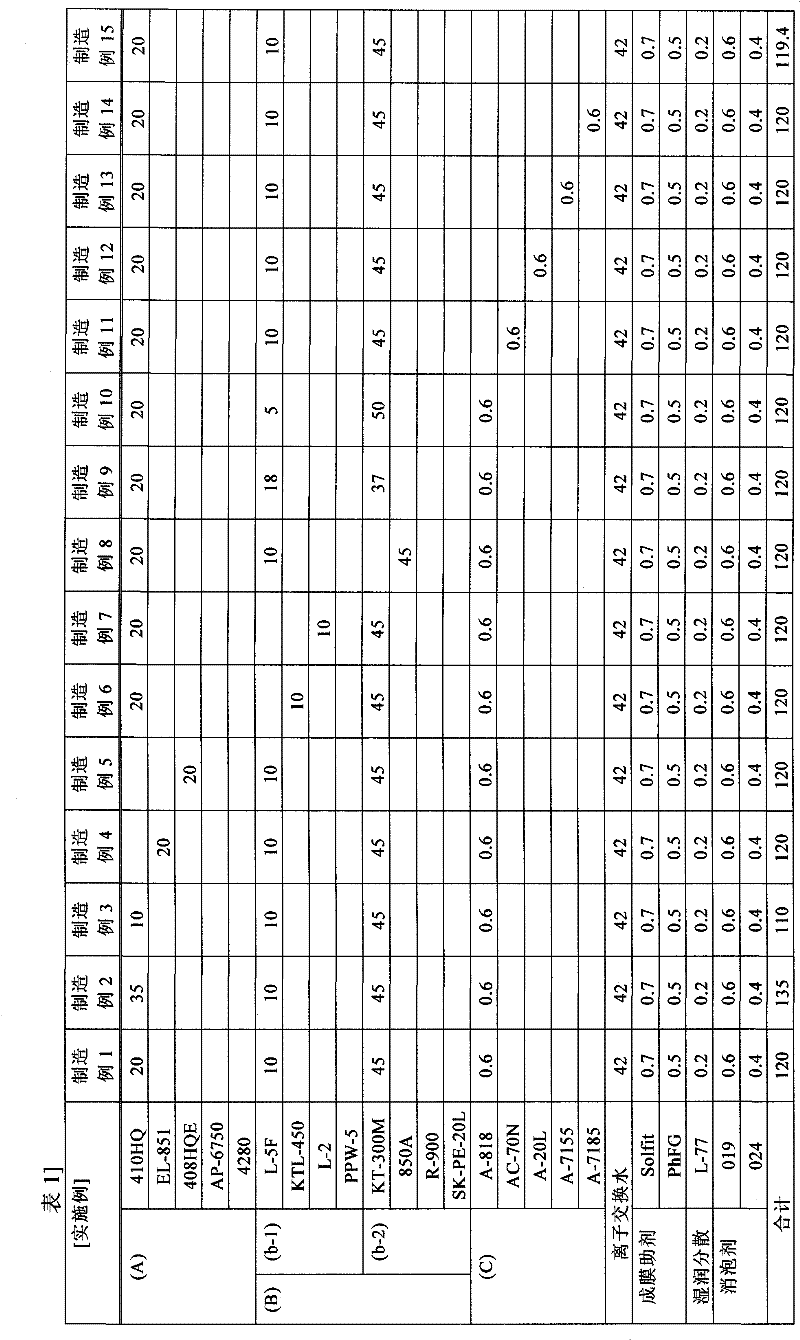

Aqueous coating composition

InactiveCN102203199AExcellent film adhesionImprove workabilityOther chemical processesNutsEmulsionHeat resistance

Disclosed is an aqueous coating composition having excellent coating adhesion, workability, heat resistance and chemical resistance. Particularly disclosed is an aqueous coating composition for sealing, which is suitable for members to be screwed in. The aqueous coating composition contains, as main components, (A) an ethylene-vinyl acetate copolymer resin emulsion and (B) two or more PTFE resin powders having different particle diameters. The aqueous coating composition is characterized by containing 35-80 parts by mass of water per 100 parts by mass of the total of the components (A) and (B).

Owner:THREEBOND FINE CHEM CO LTD

Chemical treatment liquid for steel material coating primer and method of treatment

ActiveCN102089459AExcellent coating adhesionAccelerated corrosionElectrophoretic coatingsSuperimposed coating processChemical treatmentPhysical chemistry

Owner:NIHON PARKERIZING

A low-temperature anti-fingerprint surface treatment agent for galvanized steel sheets and an environment-friendly surface treatment galvanized steel sheet

ActiveCN104073100BImprove gelationGood alkali resistanceMetallic material coating processesVanadium CompoundsCoating adhesion

Owner:BAOSHAN IRON & STEEL CO LTD +2

Hot stamp molded body

InactiveCN109072396AExcellent fatigue propertiesGood welding performanceHot-dipping/immersion processesSuperimposed coating processChemical compositionInter layer

The hot stamp molded body according to an embodiment of the present invention is provided with a base metal and a plated layer. The plated layer comprises, in order from the base metal to the surface,an interfacial layer, an intermediate layer, and an oxide layer. For the interfacial layer: the structure comprises at least a total of 99 area% of [alpha]Fe, Fe3Al and FeAl; the average Al content is in the range of 8.0 mass% to 32.5 mass%; the average Zn content is limited to being greater than the Zn content of the base metal and 5 mass% or less; the balance of the chemical components comprises Fe and impurities; and the average film thickness is at least 1.0 [mu]m. For the intermediate layer, the structure comprises at least a total of 99 area% Fe(Al, Zn)2 and Fe2(Al, Zn)5; the average Alcontent is 30-50 mass%; the average Zn content is 10-40 mass%; the balance of the chemical components comprises Fe and impurities; and the average film thickness is at least 5.0 [mu]m. For the oxidelayer, the average film thickness is 0.1-3.0 [mu]m.

Owner:NIPPON STEEL CORP

Novel polyimide precursor composition and use thereof

ActiveCN101657482AGood physical propertiesLow viscositySemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusHigh concentrationImide

Disclosed is a polyimide precursor composition solution which can be cured at a low temperature (at 250 DEG C or less) without using a siloxane diamine. This polyimide precursor composition solution has low viscosity even at high concentration. Also disclosed are a photosensitive resin composition obtained from such a polyimide precursor composition solution and having good physical properties, a photosensitive resin film, a thermosetting resin composition, a polyimide insulating film and a printed wiring board with insulating film. Specifically disclosed is a polyimide precursor composition solution containing at least (A) a urethane imide oligomer having a terminal carboxylic acid group and (B) a diamine compound and / or an isocyanate compound.

Owner:KANEKA CORP

Chromate-free precoated metal sheet with metallic appearance and water-based coating composition for use in manufacturing same

ActiveCN103906578AGood chemical resistanceIncrease added valueInorganic pigment treatmentAnti-corrosive paintsWater basedMetal sheet

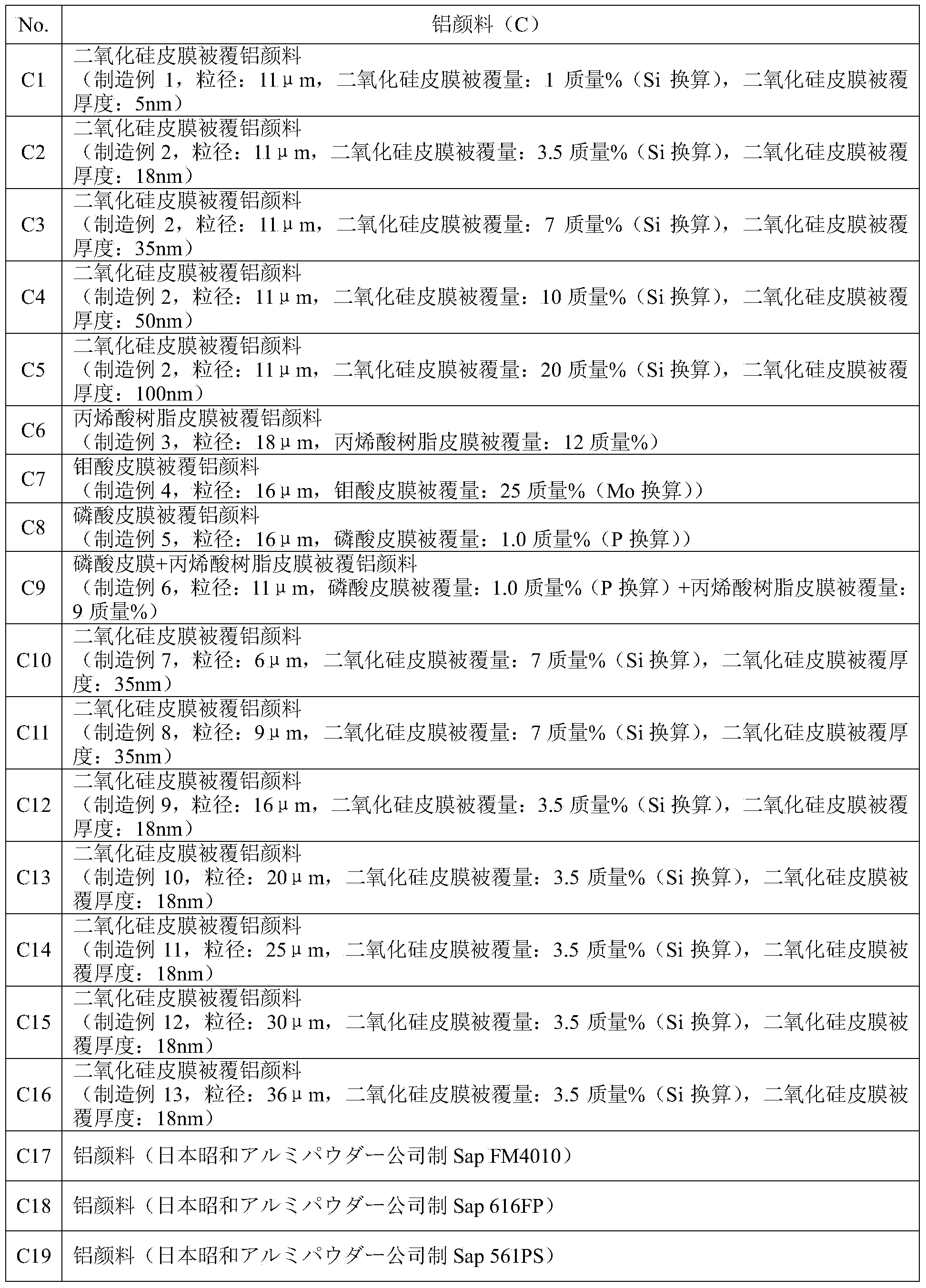

A chromate-free coated metal sheet according to the present invention includes: a metal sheet; and a coating film α which contains an organic resin A as a film formation component and a flaky aluminum pigment C having a deactivation-treated surface on at least one surface of the metal sheet; wherein the thickness of the coating film α is in a range of 2 to 10 μm.

Owner:NIPPON STEEL CORP +1

Surface-treated steel sheet

ActiveCN107636207AImprove barrier propertiesExcellent film adhesionElectrolytic coatingsSuperimposed coating processZinc metalVanadium oxide

This surface-treated steel sheet includes: a steel sheet; and a plating layer that is formed on one or both sides of the steel sheet and includes zinc, and vanadium or zirconium. The plating layer hasdendritic crystals which include zinc metal, and an inter-crystal fill region which fills a region between the dendritic crystals and shows an amorphous diffraction pattern in electron diffraction. For the plating layer including vanadium, the inter-crystal fill region includes hydrated vanadium oxide or vanadium hydroxide, and for the plating layer including zirconium, the inter-crystal fill region includes hydrated zirconium oxide or zirconium hydroxide.

Owner:NIPPON STEEL CORP

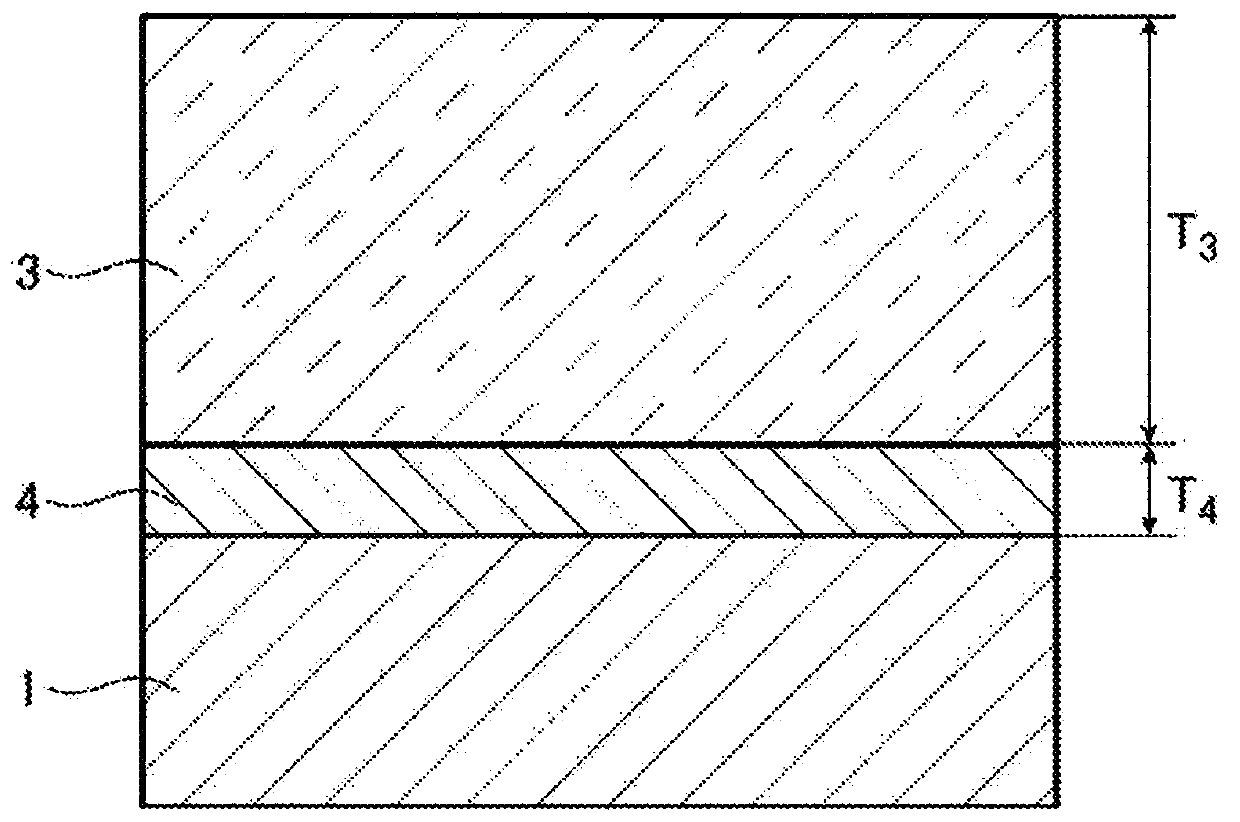

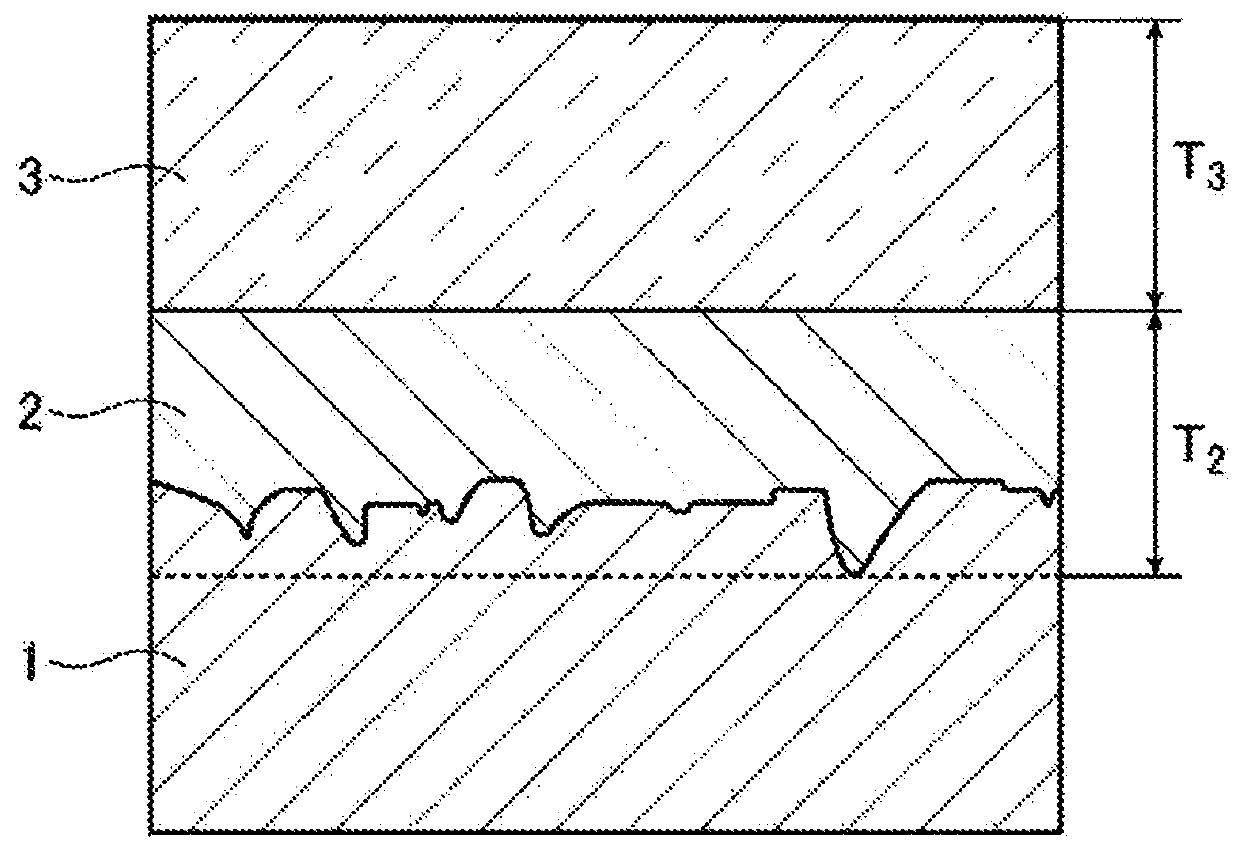

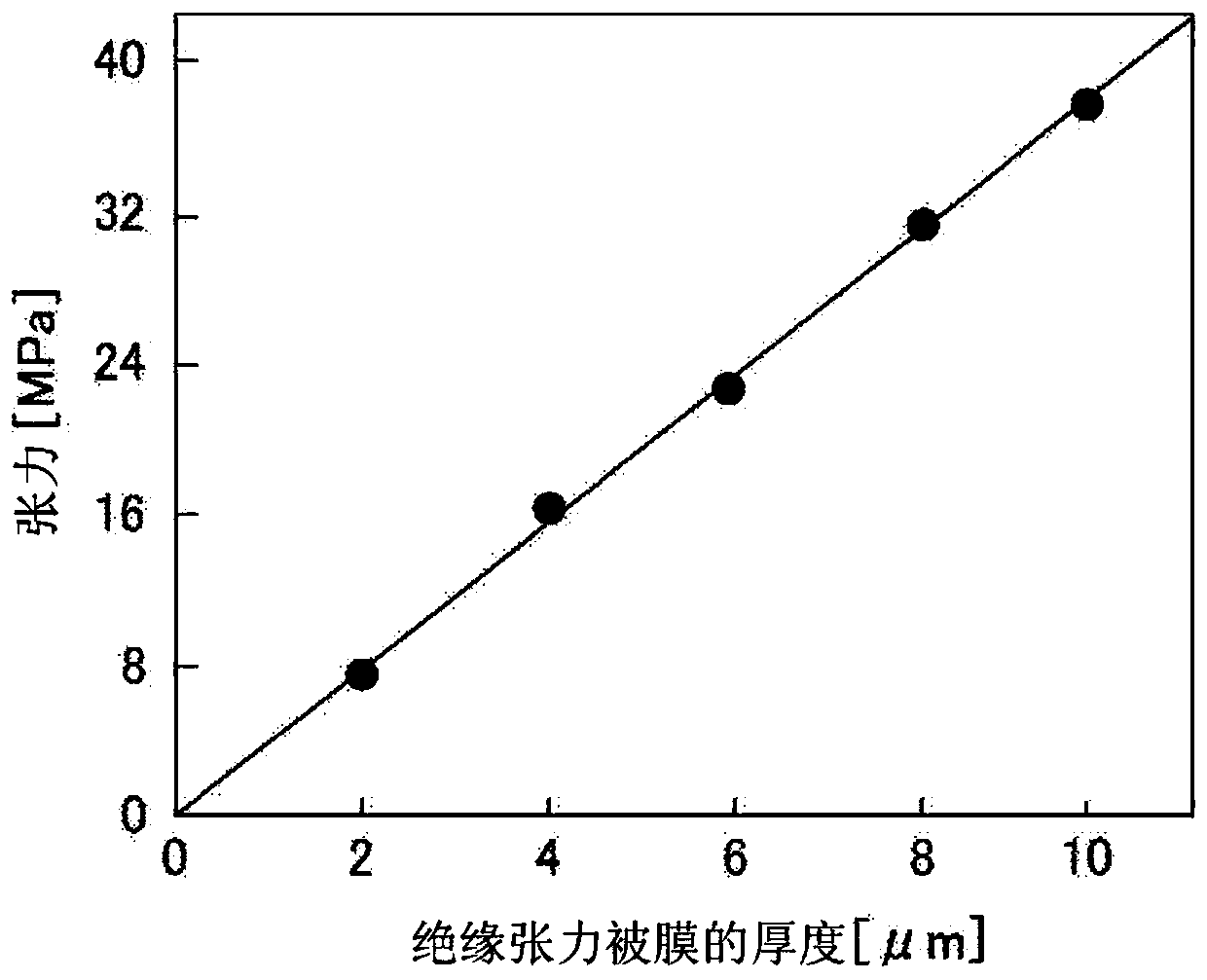

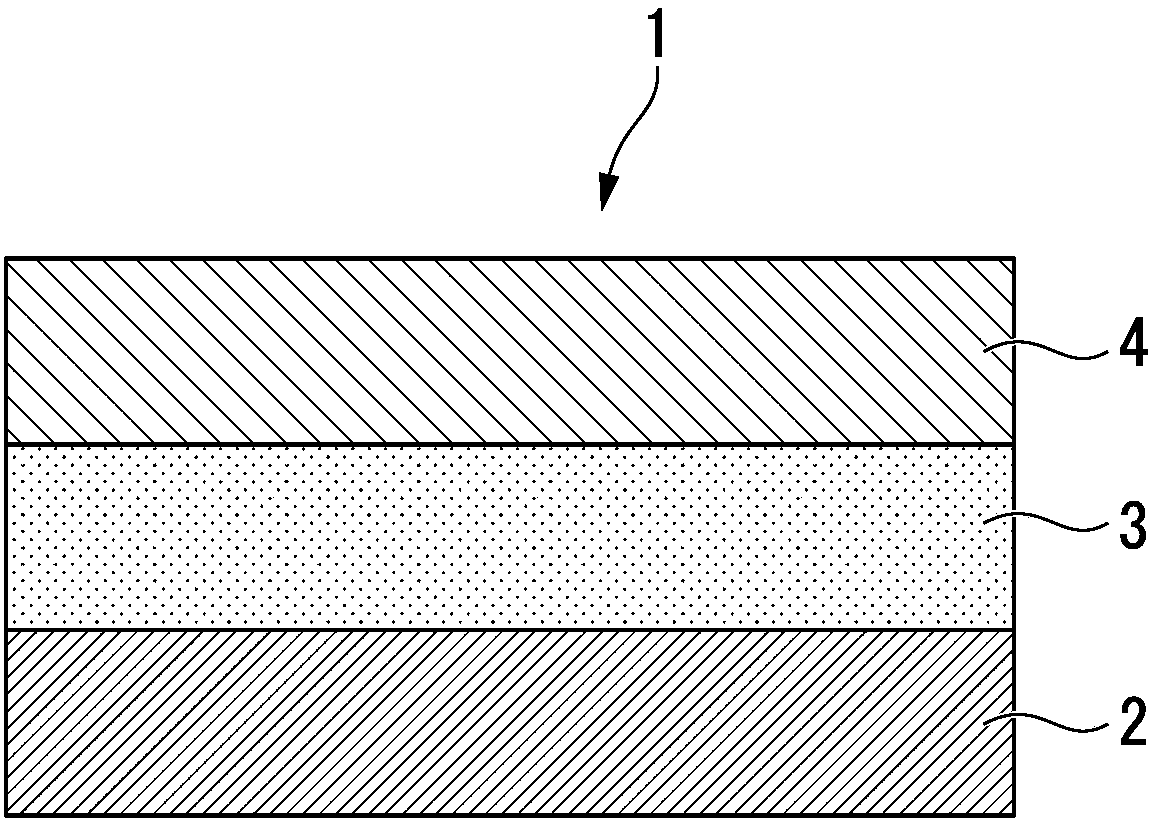

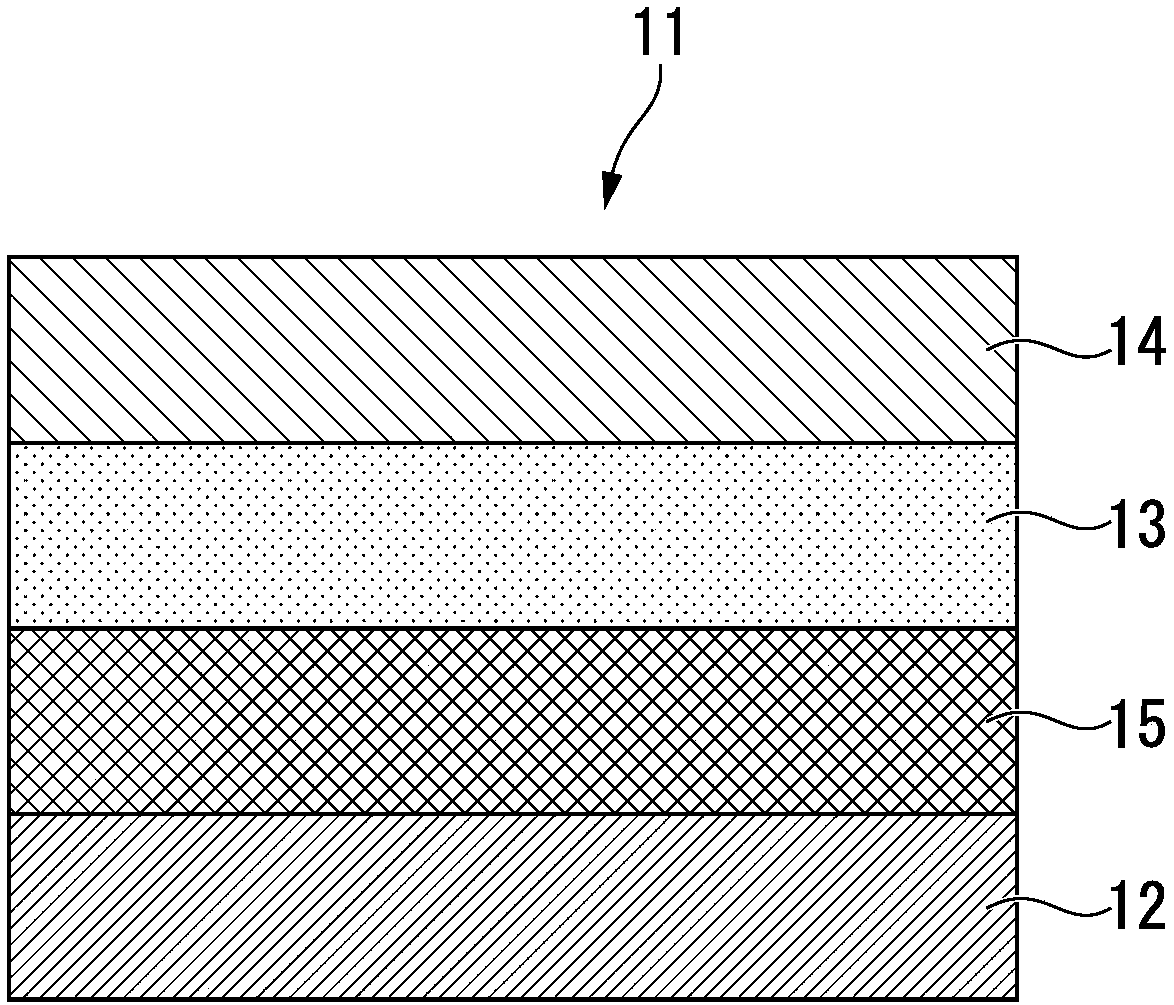

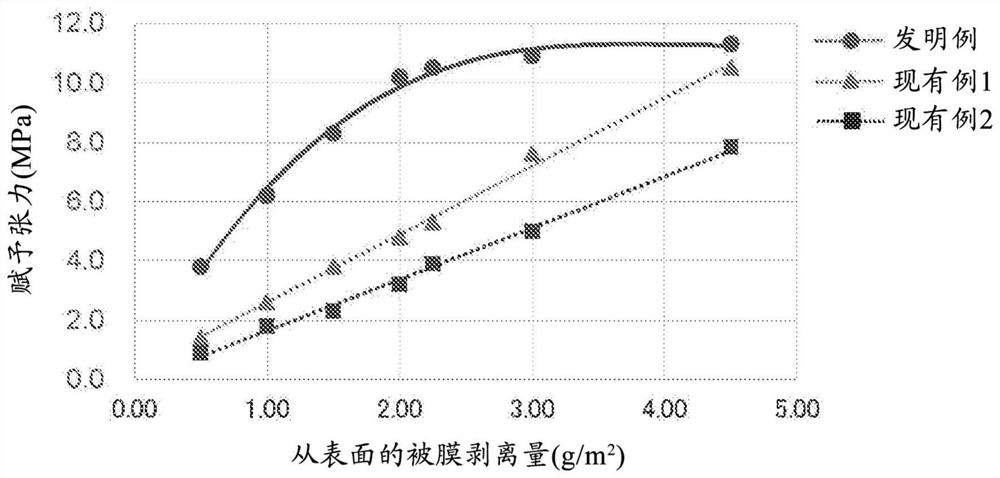

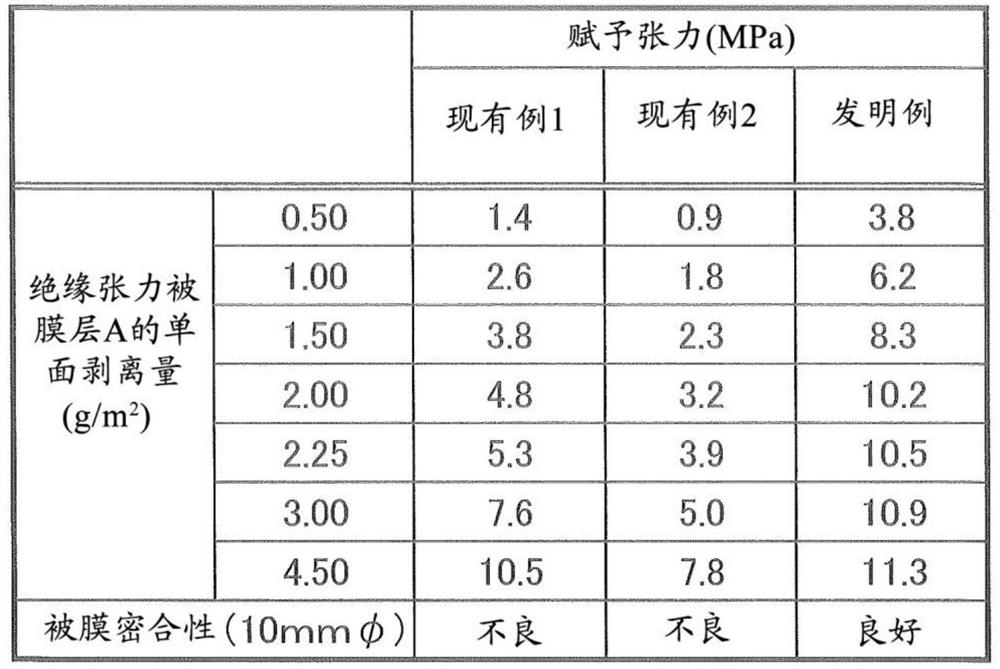

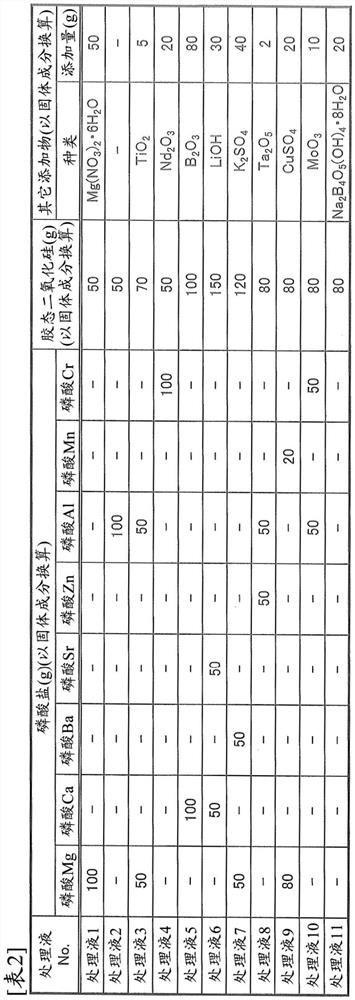

Grain-oriented electromagnetic steel sheet and method for producing grain-oriented electromagnetic steel sheet

PendingCN109983159AExcellent film adhesionExcellent magnetic propertiesVacuum evaporation coatingSputtering coatingCeramic coatingMagnetic characteristic

Provided are: a grain-oriented electromagnetic steel sheet which exhibits excellent magnetic characteristics and excellent coating film adhesion after strain relieving annealing; and a method for producing this grain-oriented electromagnetic steel sheet. This grain-oriented electromagnetic steel sheet comprises: a steel sheet; a coating film layer A that is a ceramic coating film which is formed on the steel sheet and has an oxide content of less than 30% by mass; and a coating film layer B that is an insulating tension coating film which is arranged on the coating film layer A and contains anoxide. The binding energy of the 1s orbital of oxygen in the coating film layer B is higher than 530 eV; and the tension applied to the steel sheet by the coating film layer B per a thickness of 1.0Mum of the coating film layer B is 4.0 MPa / Mum or more.

Owner:JFE STEEL CORP

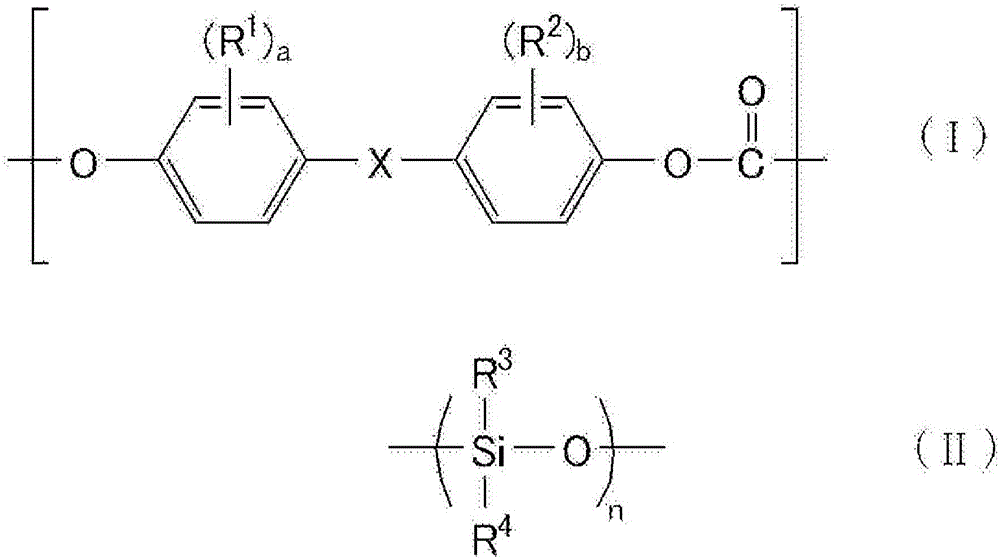

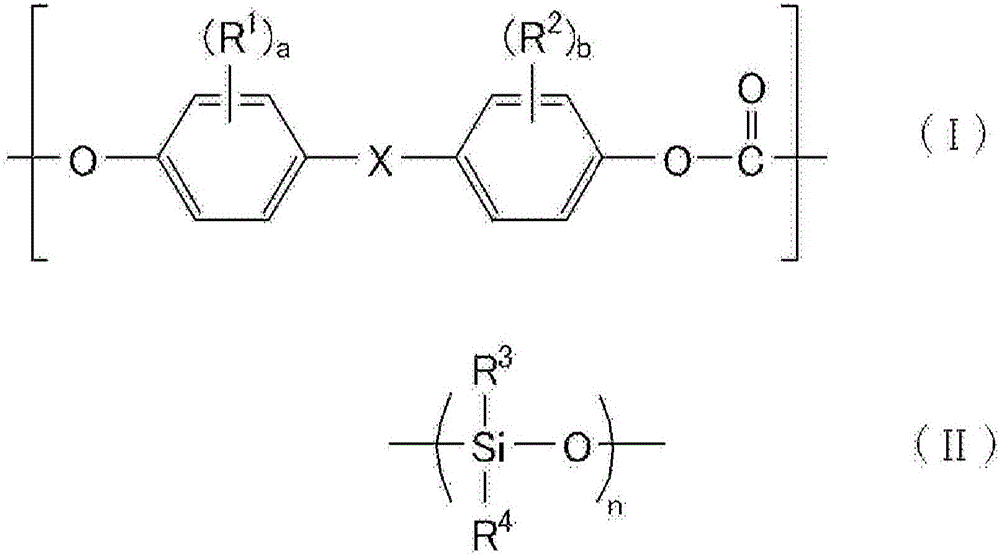

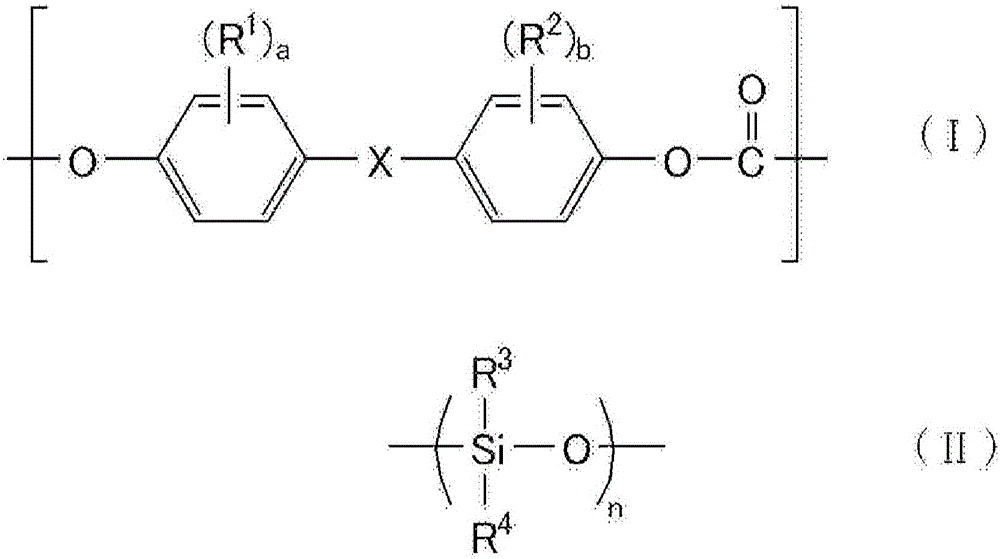

Polycarbonate resin molding material for articles to be coated, molded article and coated molded article

ActiveCN106103589AReduced impact resistanceExcellent film adhesionCoatingsPolymer chemistryCopolymer

A polycarbonate resin molding material for articles to be coated, which contains (A) a polycarbonate resin containing (A-1) a polycarbonate-polyorganosiloxane copolymer having a specific structure and (B) a copolymer having a constituent unit derived from butadiene, and wherein the content of the polyorganosiloxane block moiety in the whole molding material is 0.50-10% by mass and the content of the constituent unit derived from butadiene in the whole molding material is 1-10% by mass.

Owner:IDEMITSU KOSAN CO LTD

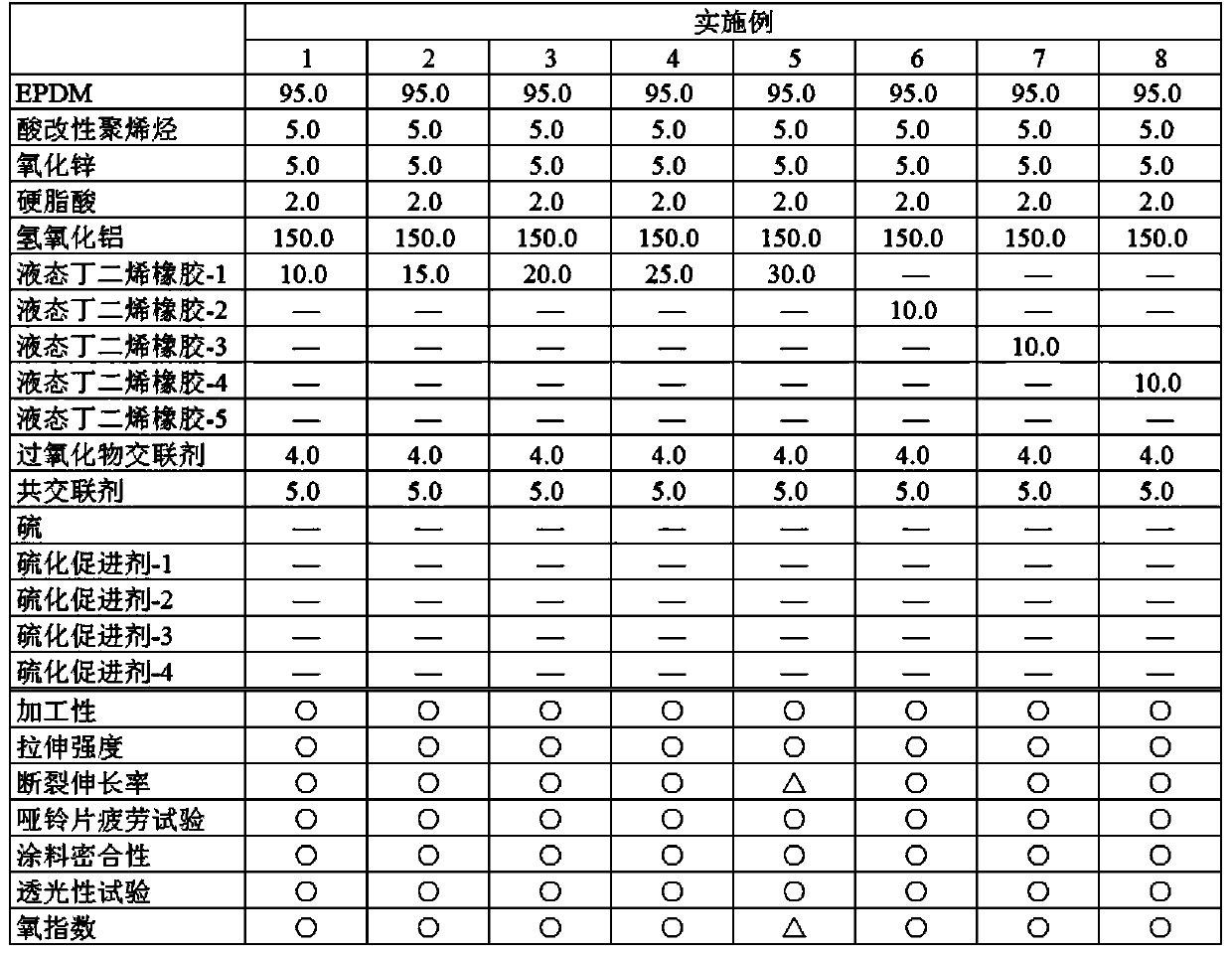

Rubber composition having coating affinity and bellows for rail cars

ActiveCN110225943AImprove performanceHigh affinityAxle-box lubricationCoatingsPolymer scienceCross linker

Provided is a rubber composition having coating affinity comprising mainly component (A), and components (B) and (C) below. Also provided are bellows for rail cars comprising a crosslinked body of therubber composition having coating affinity. The rubber composition having coating affinity is capable of exhibiting excellent performance as a material for forming rubber products (rubber products such as bellows for rail cars) that require rubber properties including tensile strength and breaking elongation, and durability as well as coating adhesion. (A) An ethylene-propylene-diene rubber (EPDM). (B) A non-hydrogenated liquid butadiene rubber having functional group reactable with an isocyanate group and / or a hydroxyl group. (C) An organic peroxide crosslinking agent.

Owner:SUMITOMO RIKO CO LTD

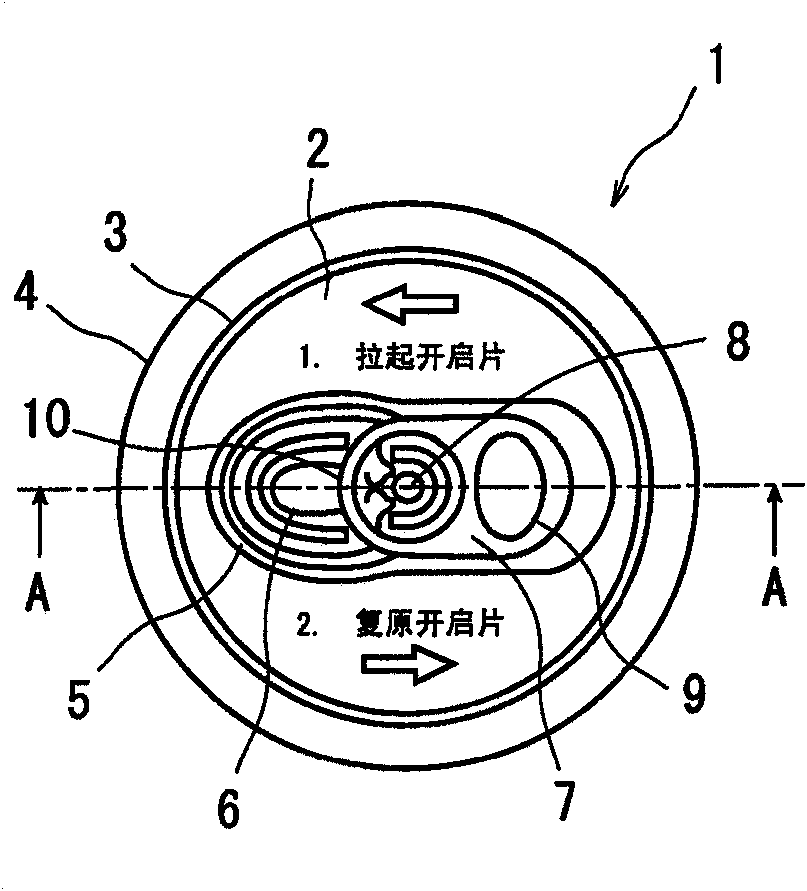

Aluminum lid provided with coating film composed of aqueous coating material

ActiveCN102089215BImprove corrosion resistanceExcellent film adhesionRigid containersAcrylic resinPolymer chemistry

Disclosed is an aluminum lid which is obtained by shaping a coated aluminum base, which has a coating film composed of an aqueous coating material, so that the coating film forms the inner surface of the lid. The important characteristic of the aluminum lid is in that the coating film has a sea-island phase-separated structure wherein dispersion phases composed of a carboxyl group-containing acrylic resin are dispersed in a continuous phase composed of a base resin. Consequently, the aluminum lid is free from the problems of conventional aluminum lids using conventional aqueous coating materials, and thus has excellent corrosion resistance, openability and formability.

Owner:TOYO SEIKAN KAISHA LTD

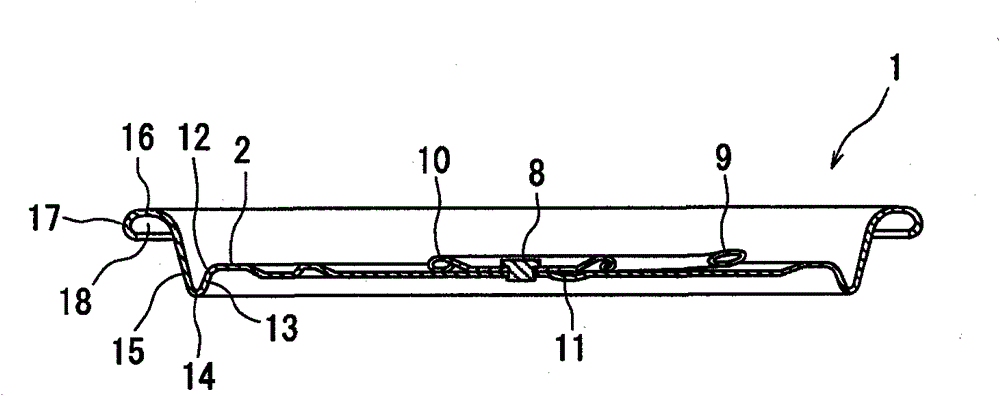

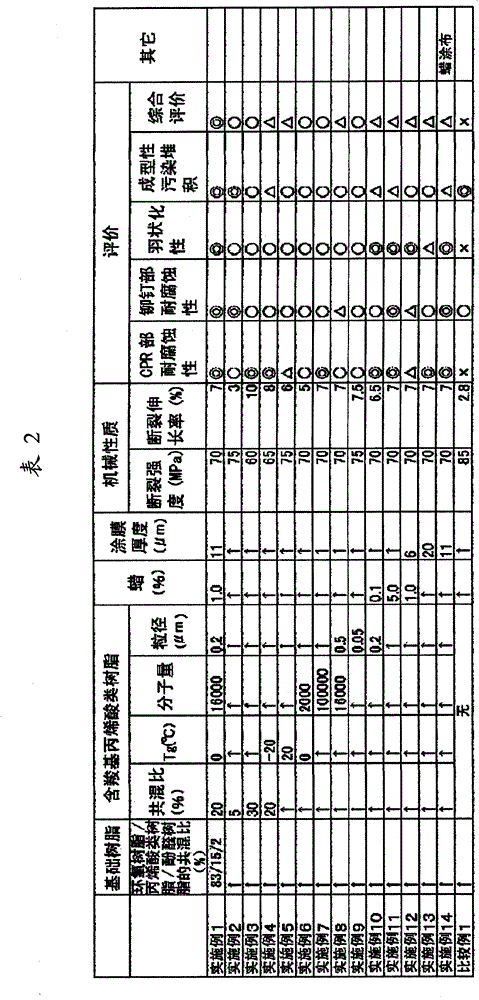

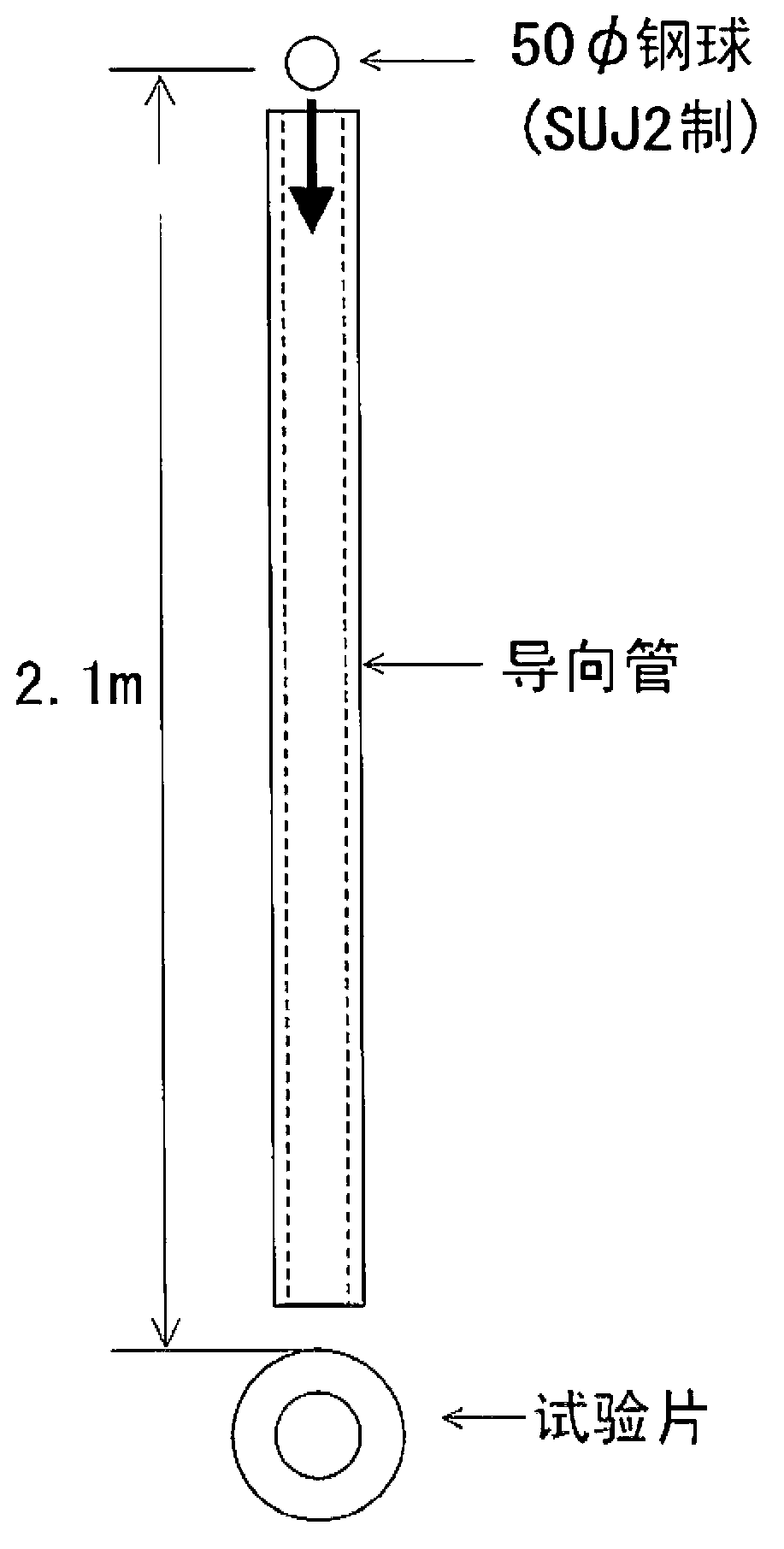

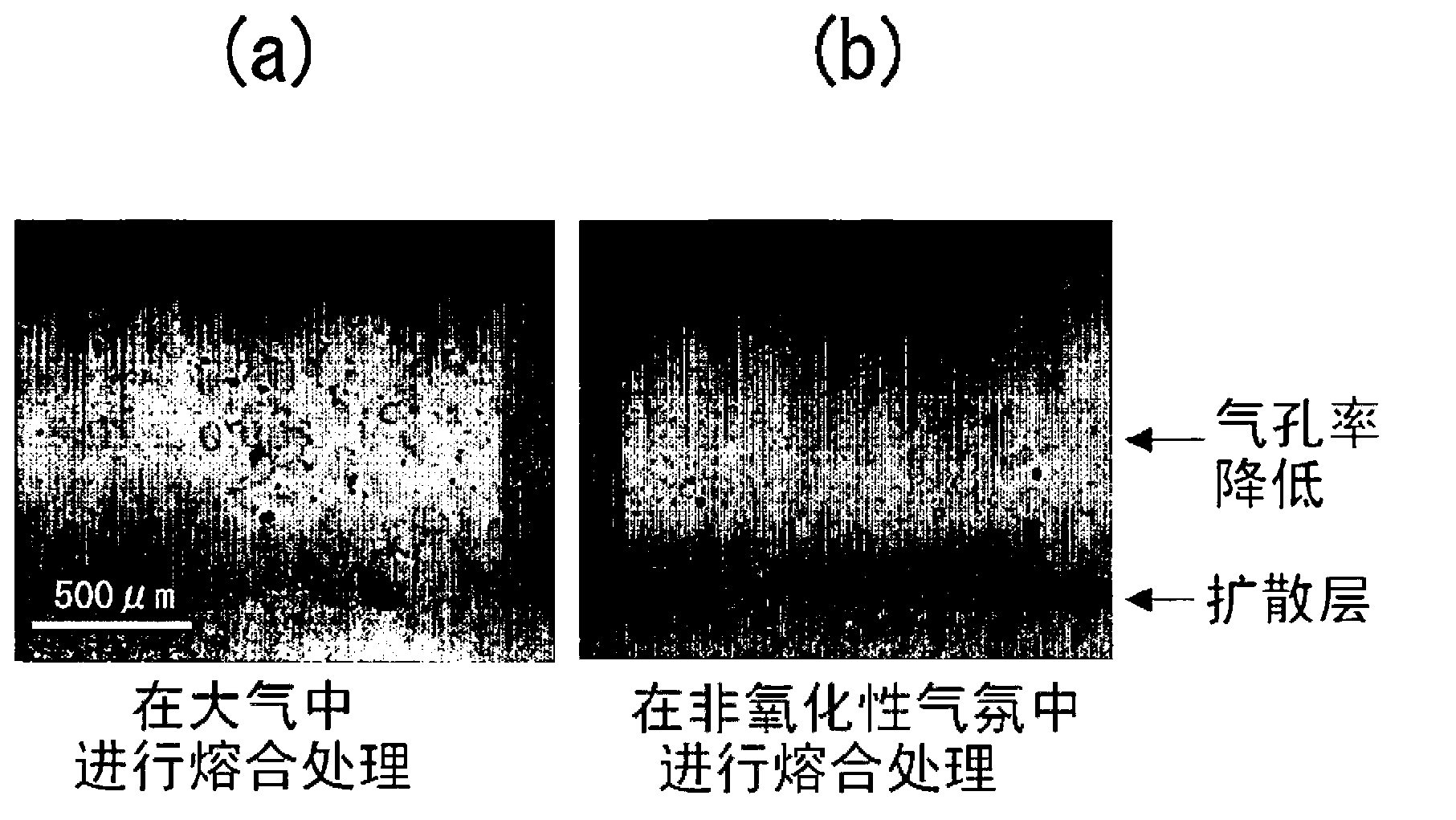

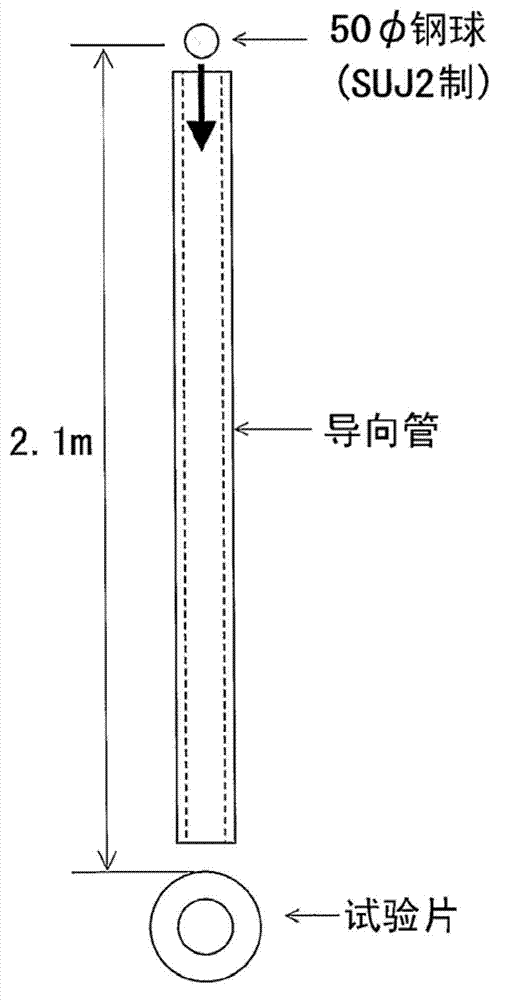

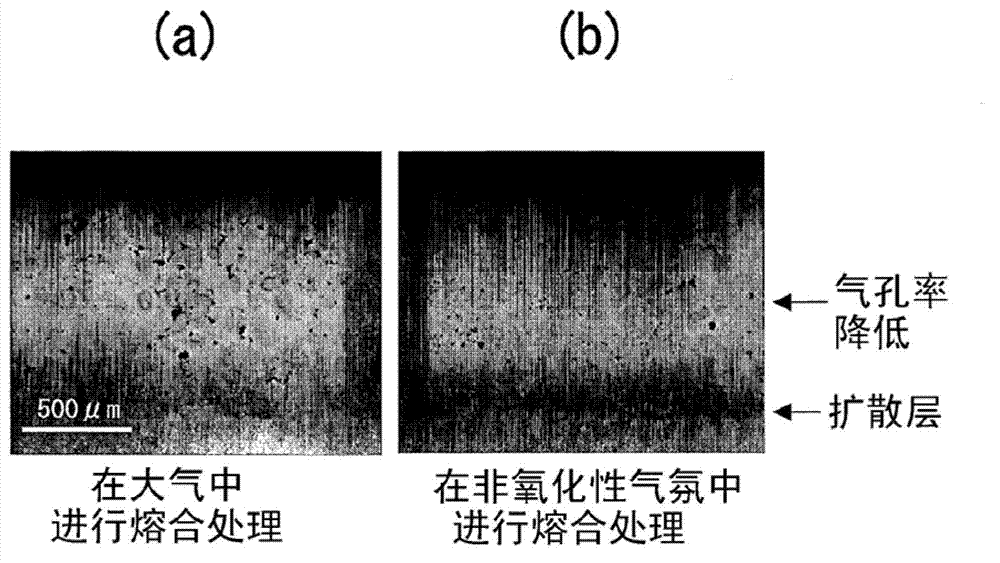

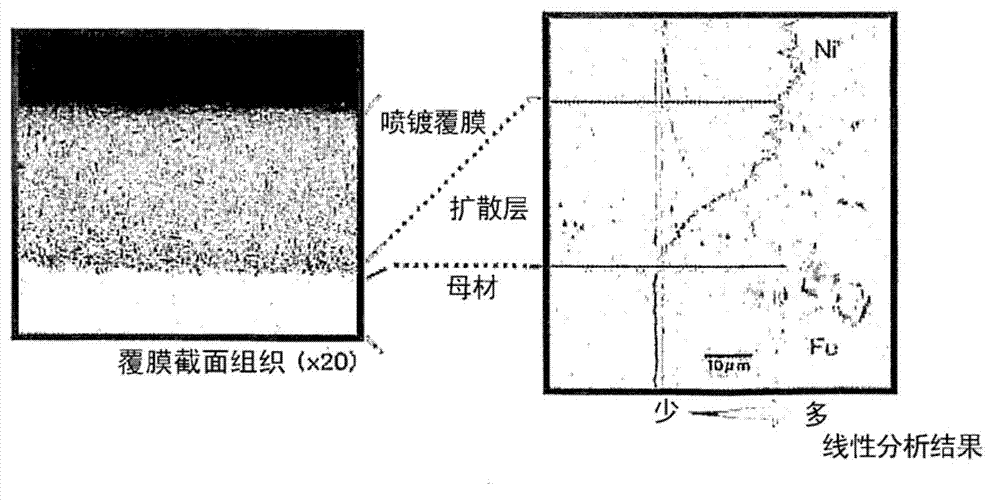

Roll for hot-rolling apparatus and process for producing same

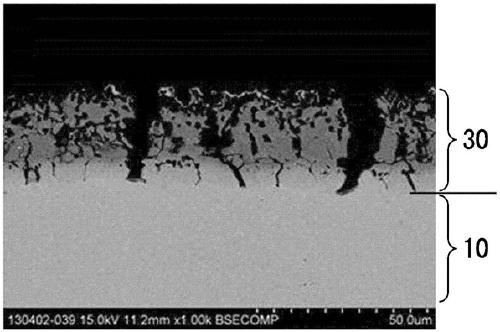

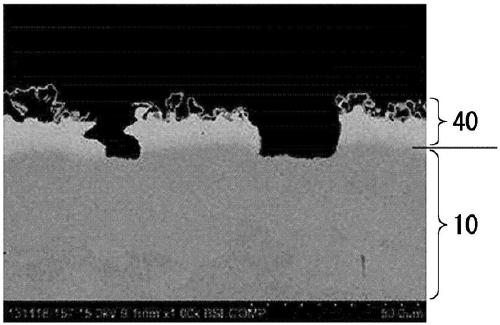

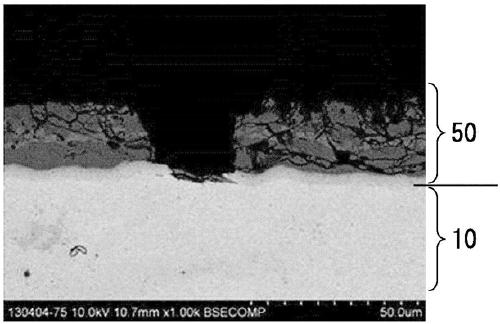

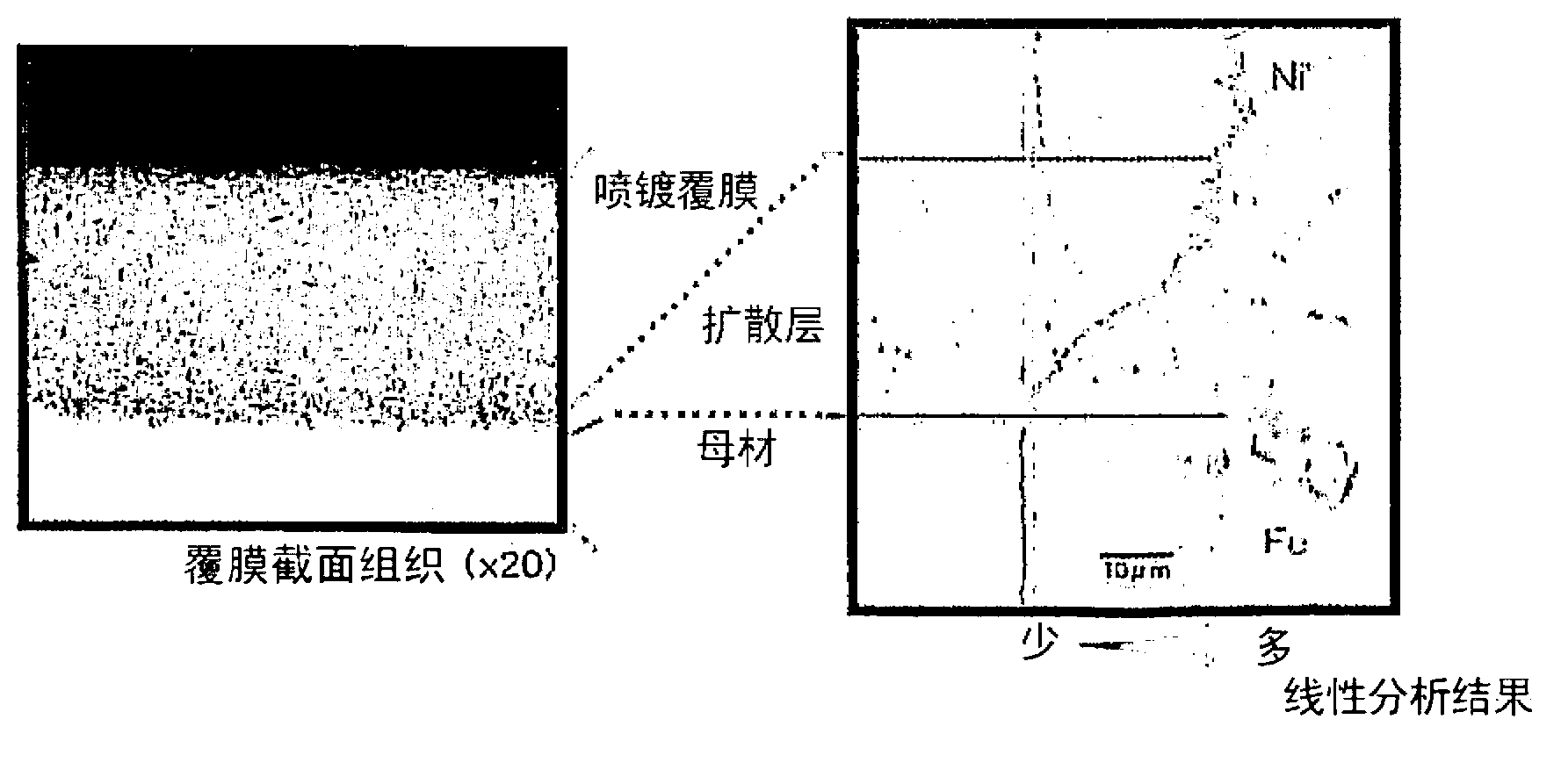

InactiveCN103025908AImproved film adhesionStrong corrosion resistanceMolten spray coatingSolid state diffusion coatingShoreCeramic particle

A roll suitable for use in hot-rolling apparatuses is provided at low cost, the roll comprising a roll base which has a high hardness and is less apt to suffer deformation damages such as dents and a coating film formed on the surface of the roll base by thermal spraying, the coating film having excellent adhesion, wear resistance, and steel-sheet-conveying properties. Also provided is a process for advantageously producing the roll. The surface of a roll base comprising a steel which contains 0.9-3.2 mass% Cr and has a carbon equivalent Ceq, defined by equation (1), of 0.45-1.65 mass% is coated by thermal spraying with a coating film constituted of a self-fluxing alloy containing hard ceramic particles. Thereafter, the coated roll base is subjected to fusing treatment in a non-oxidizing atmosphere to form a diffusion layer having a thickness of 30-200 [mu]m between the coating film formed by thermal spraying and the roll base, and is then cooled or heat-treated. Thus, the roll base is made to have a hardness of 35-60 in terms of Shore hardness HS.

Owner:TOCALO CO LTD +1

Grain-oriented electrical steel sheet

ActiveCN110832118BExcellent film adhesionInorganic material magnetismSolid state diffusion coatingElectrical steelChemical composition

Owner:NIPPON STEEL CORP

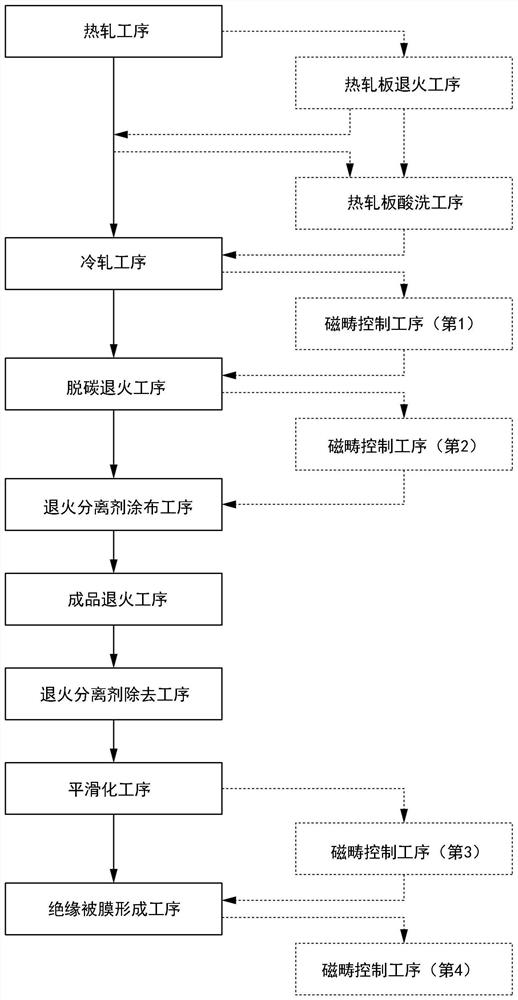

Method for manufacturing grain-oriented electrical steel sheet

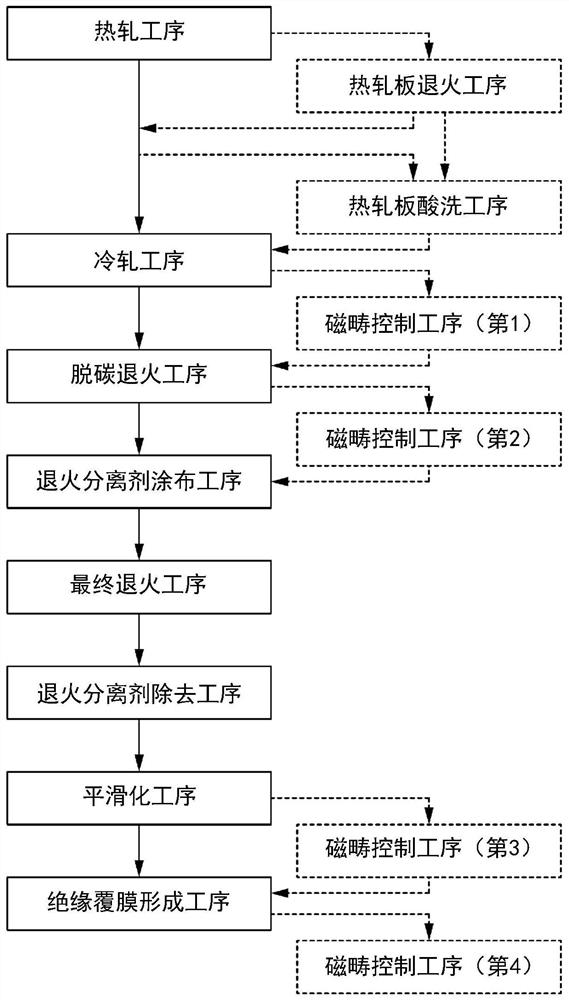

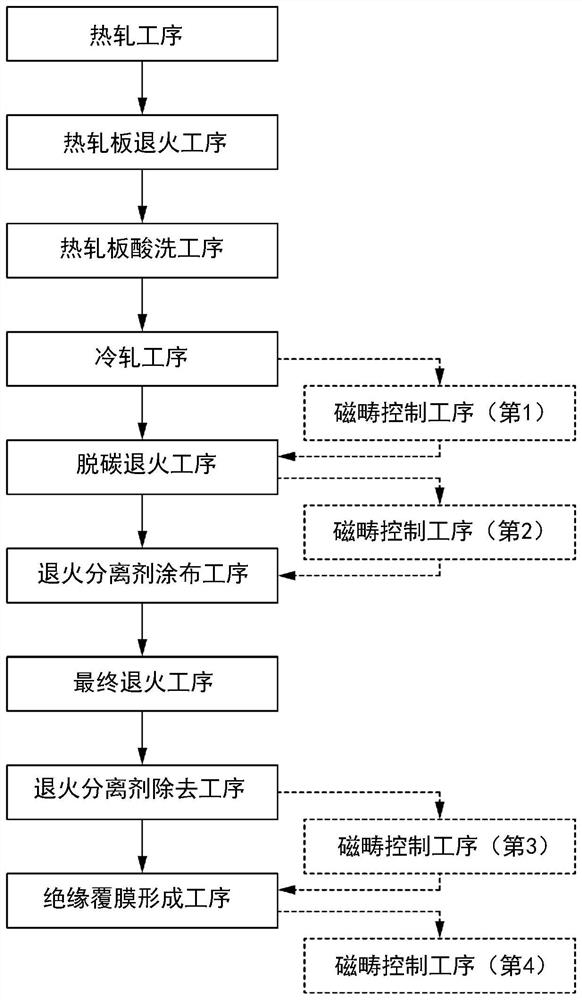

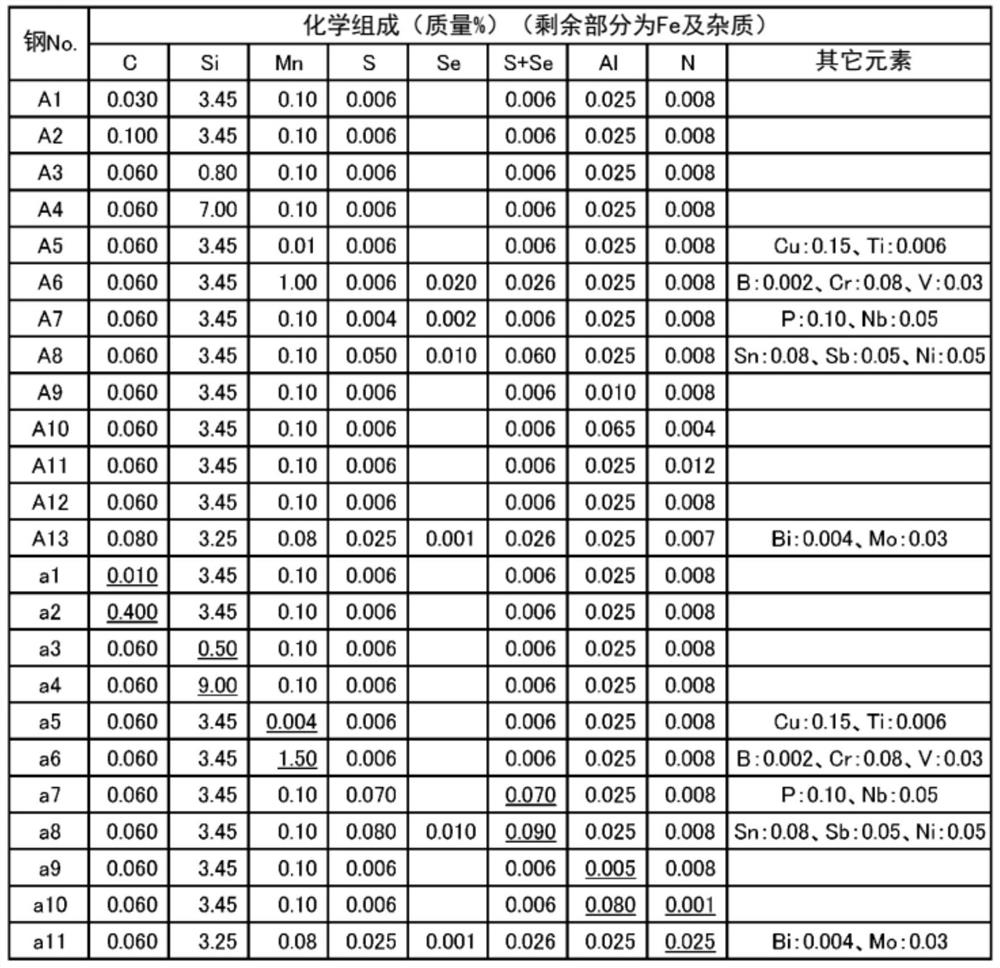

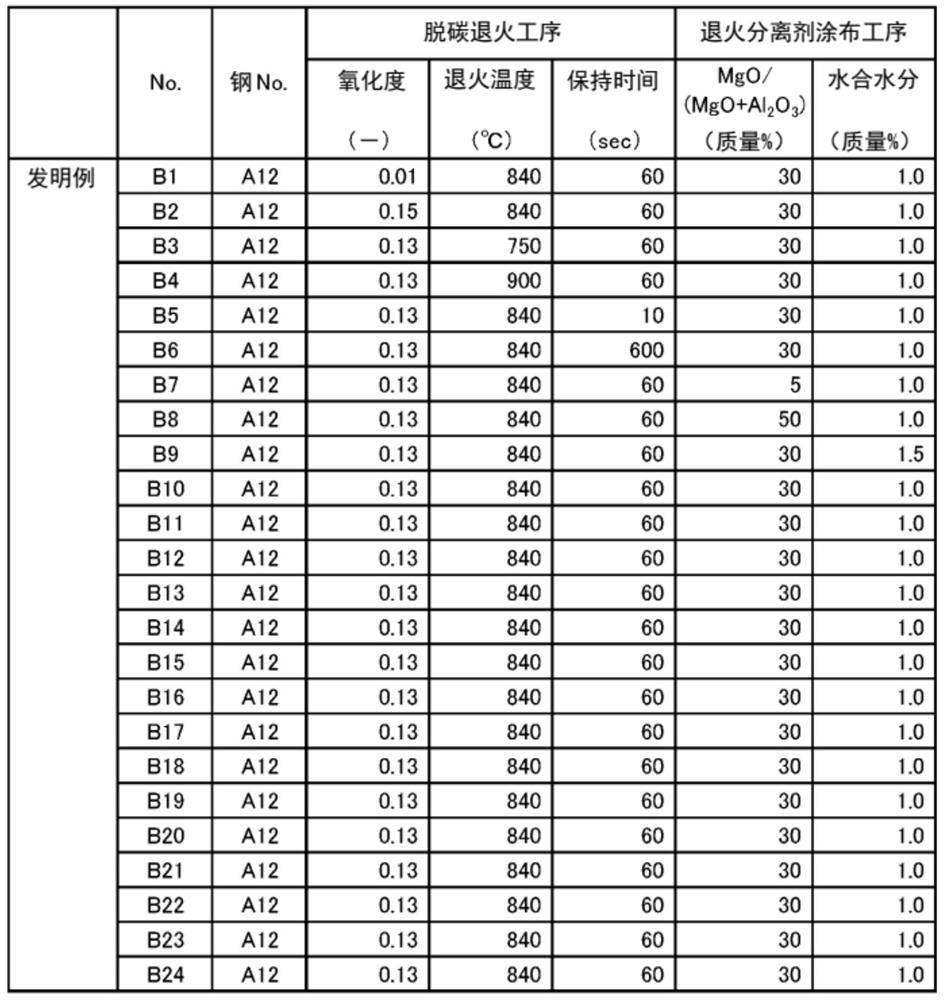

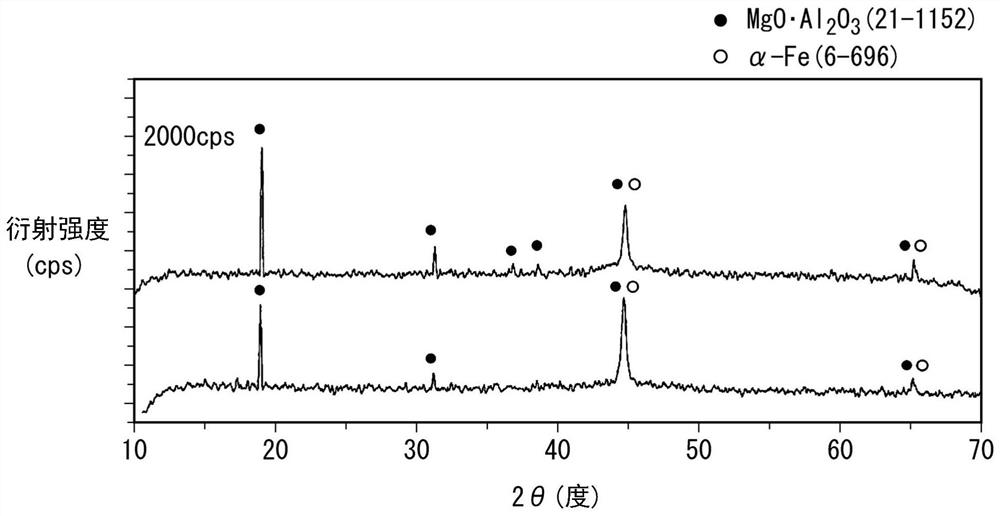

PendingCN113272458AExcellent magnetic propertiesExcellent film adhesionInorganic material magnetismFurnace typesElectrical steelMixed gas

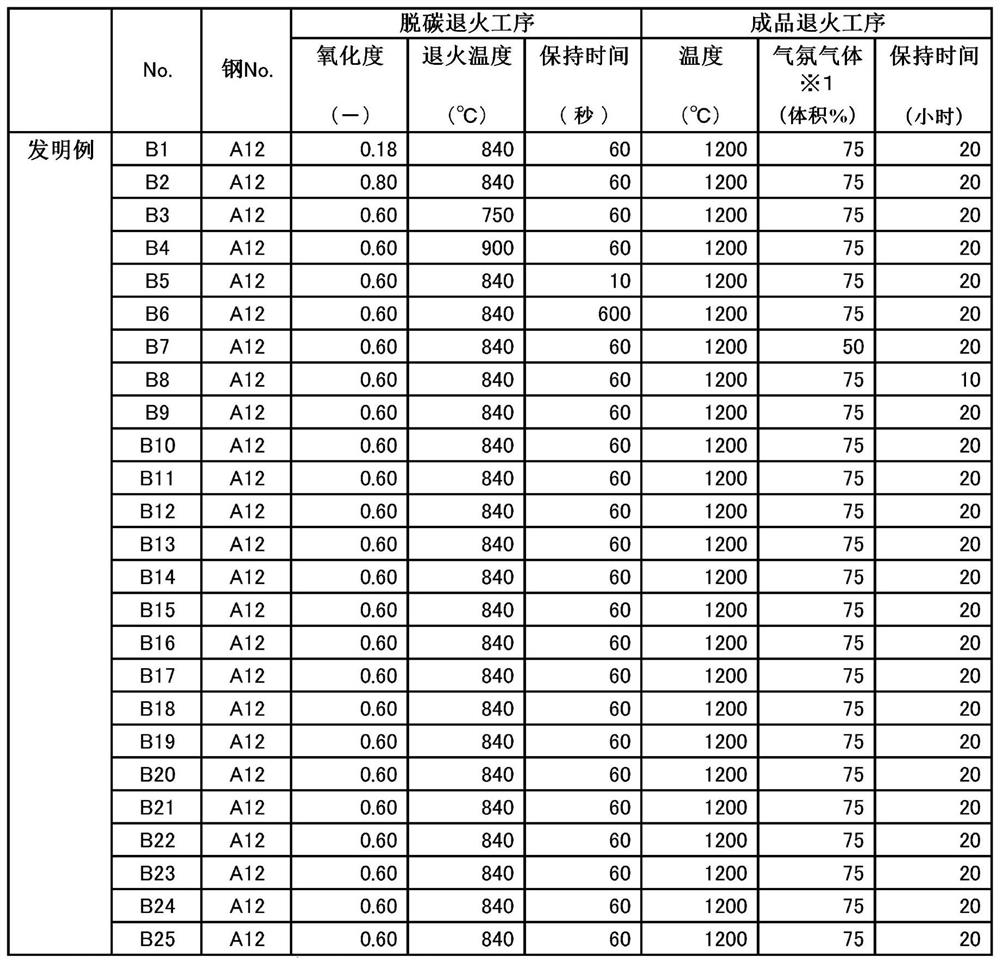

A method of manufacturing a grain-oriented electrical steel sheet involves controlling the degree of oxidation (PH2O / PH2) in a decarburization annealing step, controlling the mass ratio of MgO and Al2O3 within an annealing separator in an annealing separator application step, controlling the volume ratio of hydrogen in a mixed gas atmosphere to 50% or greater in a final annealing step, washing by using a solution to which an inhibitor has been added and then acid washing in an annealing separator removal step, controlling a mixed gas and the temperature and annealing in a smoothing step, and controlling the baking temperature and the heat treatment temperature in an insulating coating film formation step.

Owner:NIPPON STEEL CORP

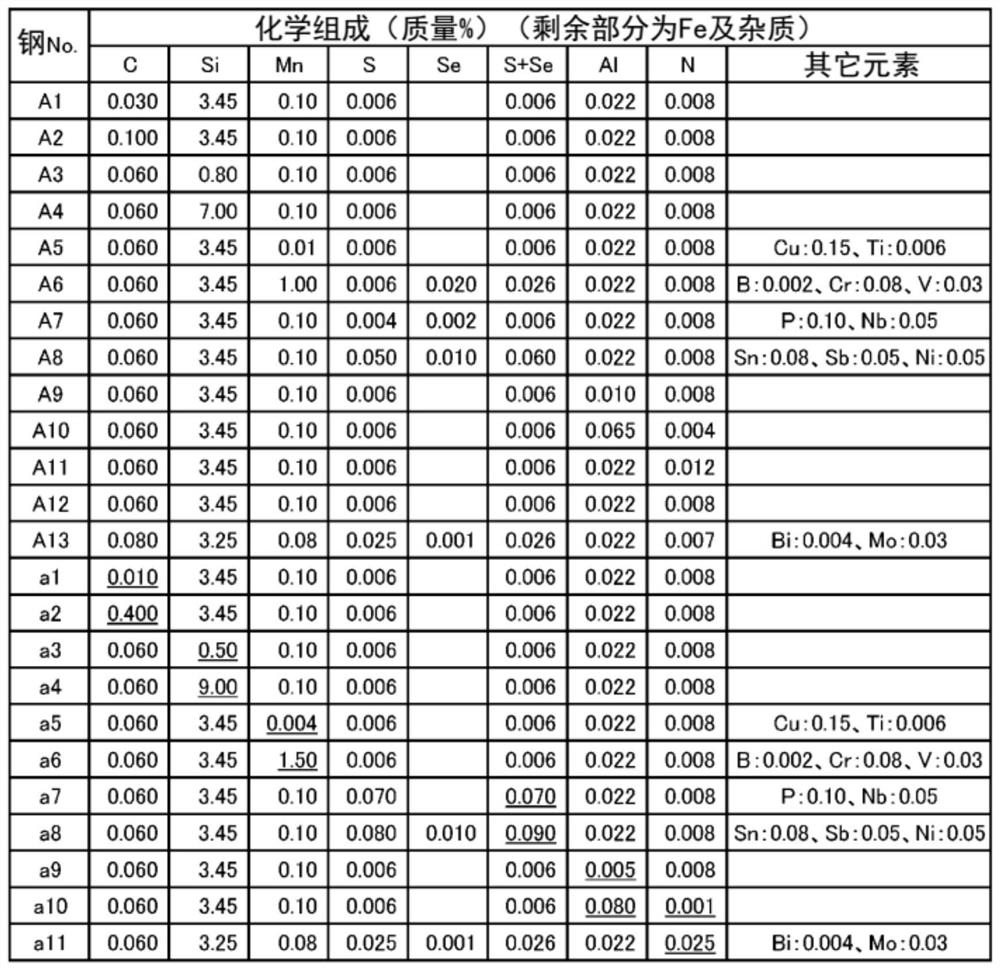

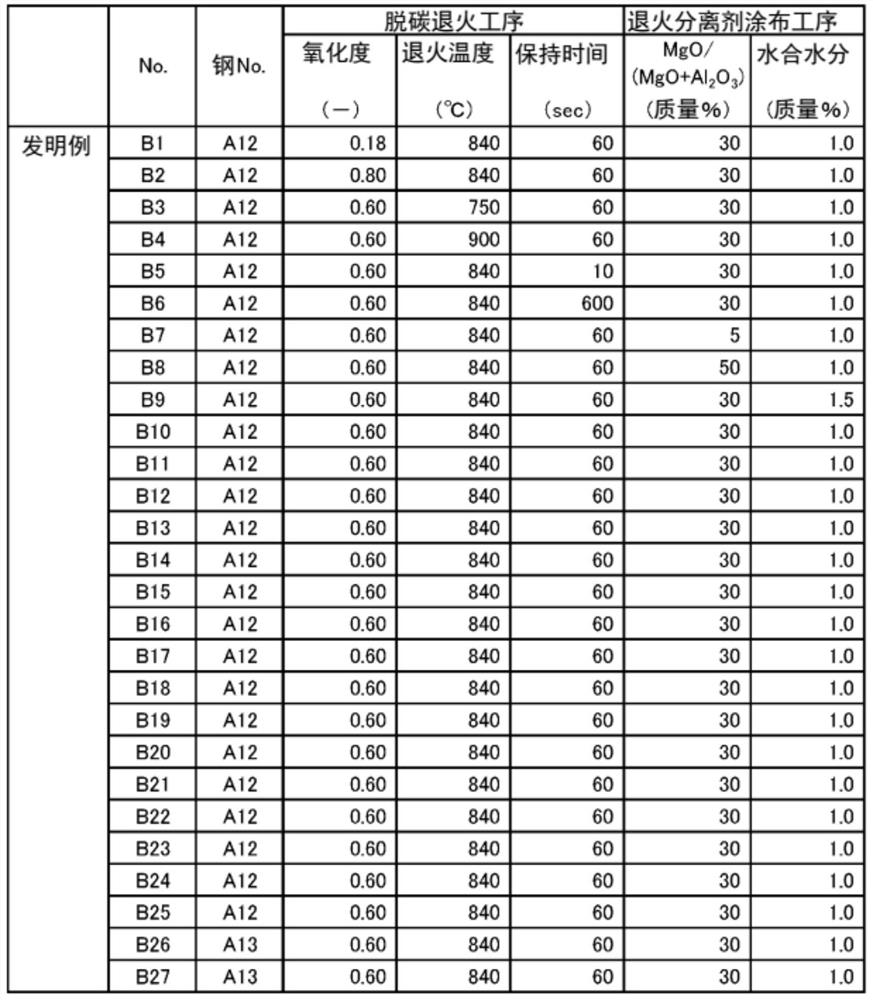

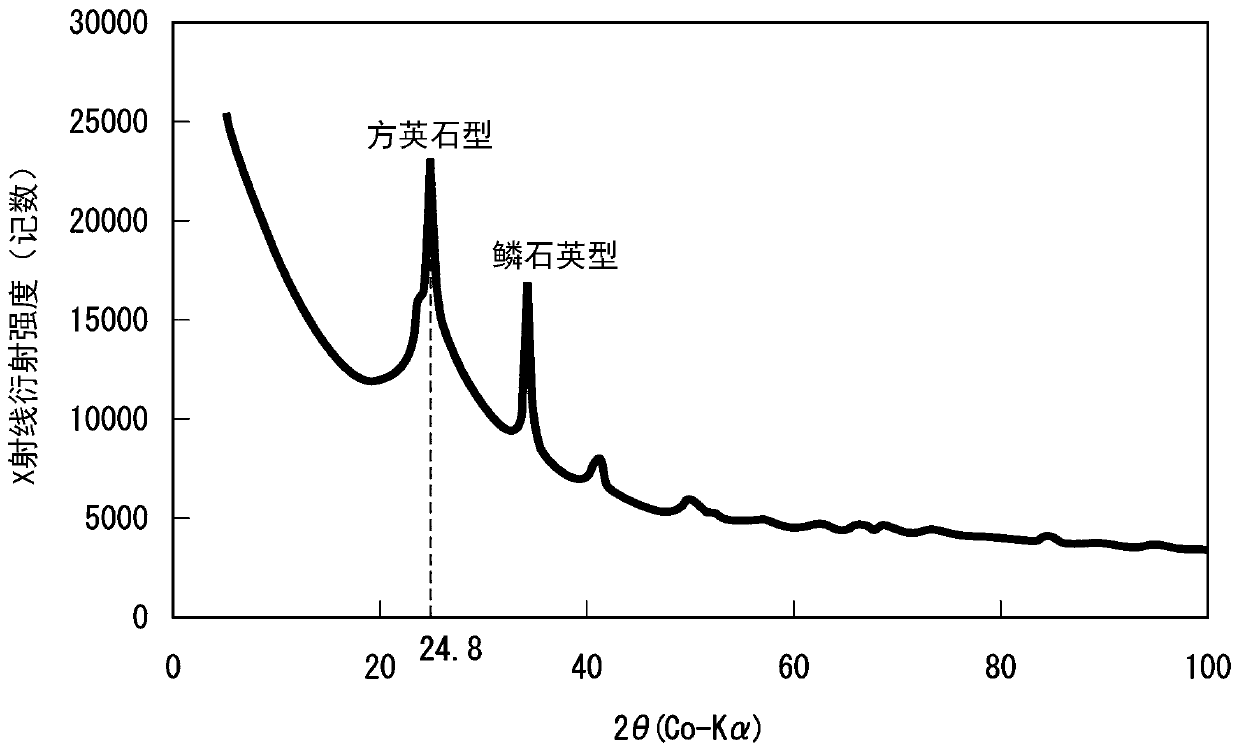

Oriented electromagnetic steel sheet

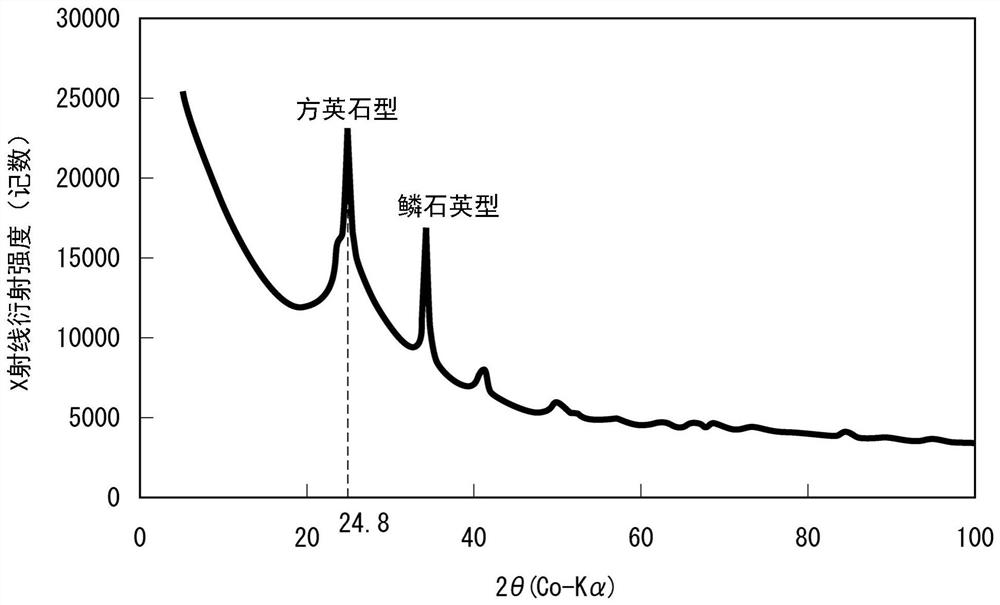

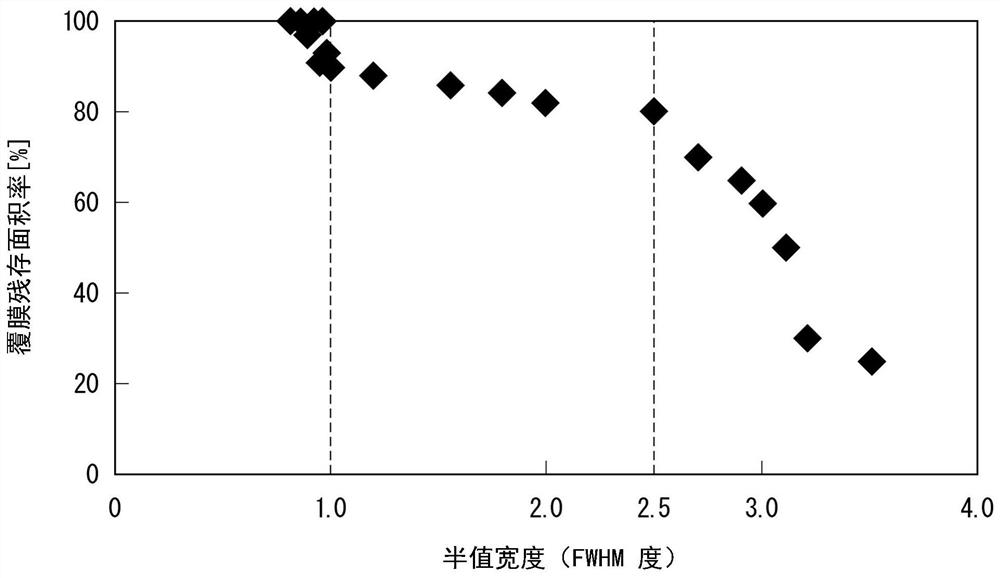

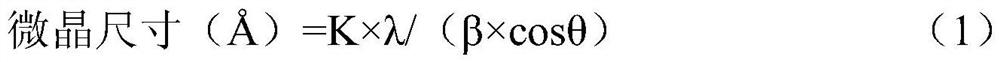

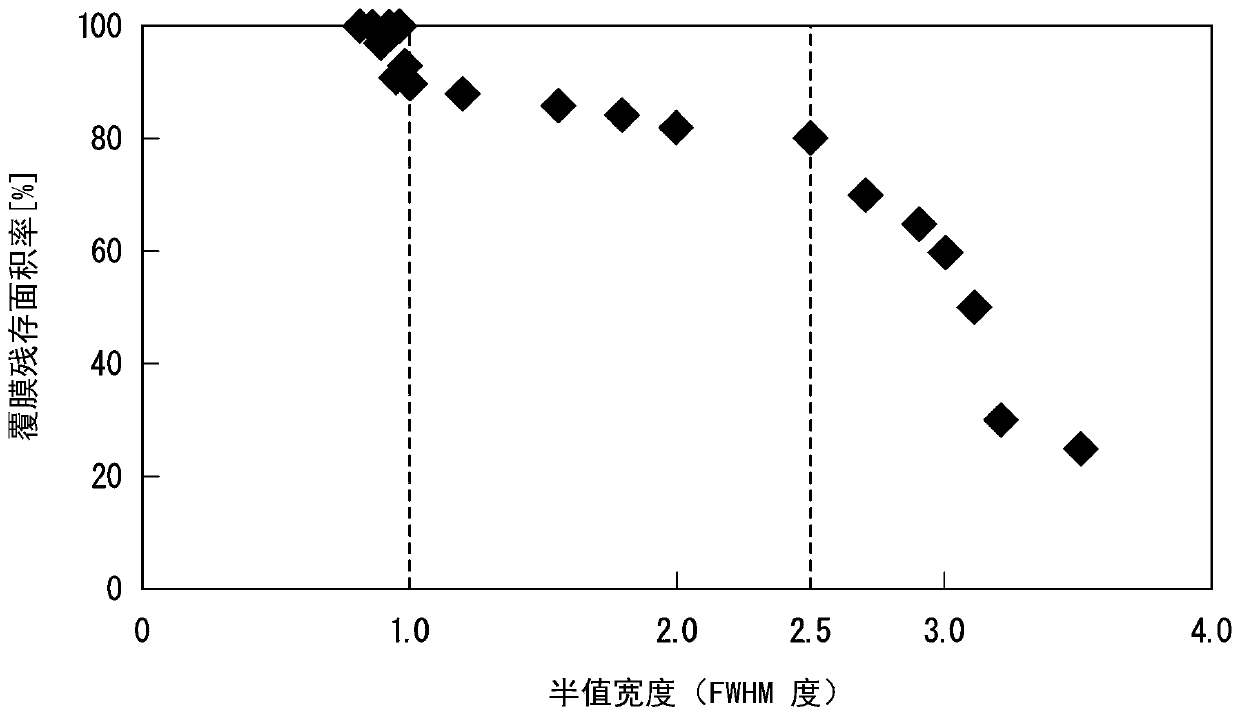

ActiveCN110832118AExcellent film adhesionInorganic material magnetismSolid state diffusion coatingChemical compositionComputational physics

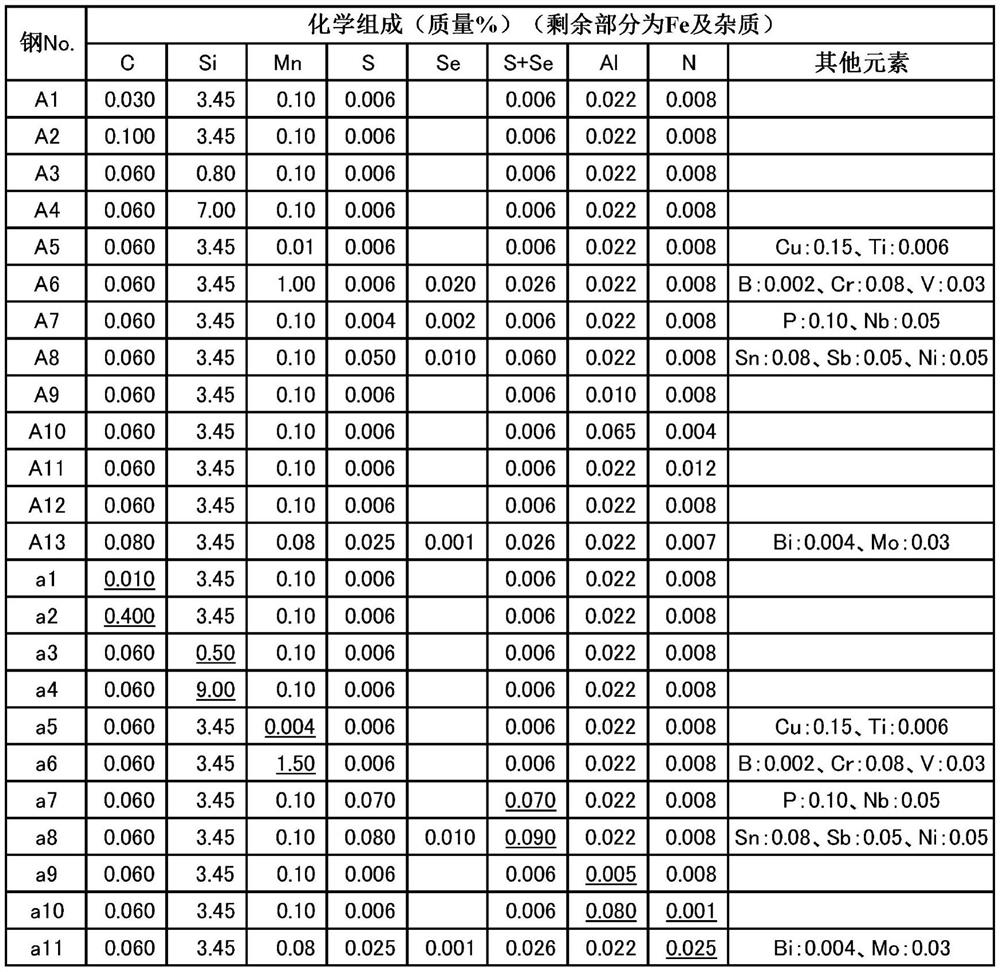

This oriented electromagnetic steel sheet is provided with a base material steel sheet, an oxide film formed on the base material steel sheet and formed from amorphous SiO2, and a tension insulating film formed on the oxide film. As chemical components, the base material steel sheet contains, by mass percent, less than or equal to 0.085% C, 0.80-7.00% Si, less than or equal to 1.00% Mn, less thanor equal to 0.065% acid soluble Al, and less than or equal to 0.050% of the Seq represented by S+0.406*Se, the remainder consisting of Fe and unavoidable impurities. Regarding the FWHMs, i.e., the half-value widths of the peaks of cristobalite-type aluminum phosphate obtained by X-ray diffraction, (i) the half-value width (FWHM-Co) of the peak appearing at 2theta = 24.8 degrees when using a Co-Kalpha excitation source is less than or equal to 2.5 degrees, or, (ii) the half-value width (FWHM-Cu) of the peak appearing at 2theta = 21.3 degrees when using a Cu-Kalpha excitation source is less thanor equal to 2.1 degrees.

Owner:NIPPON STEEL CORP

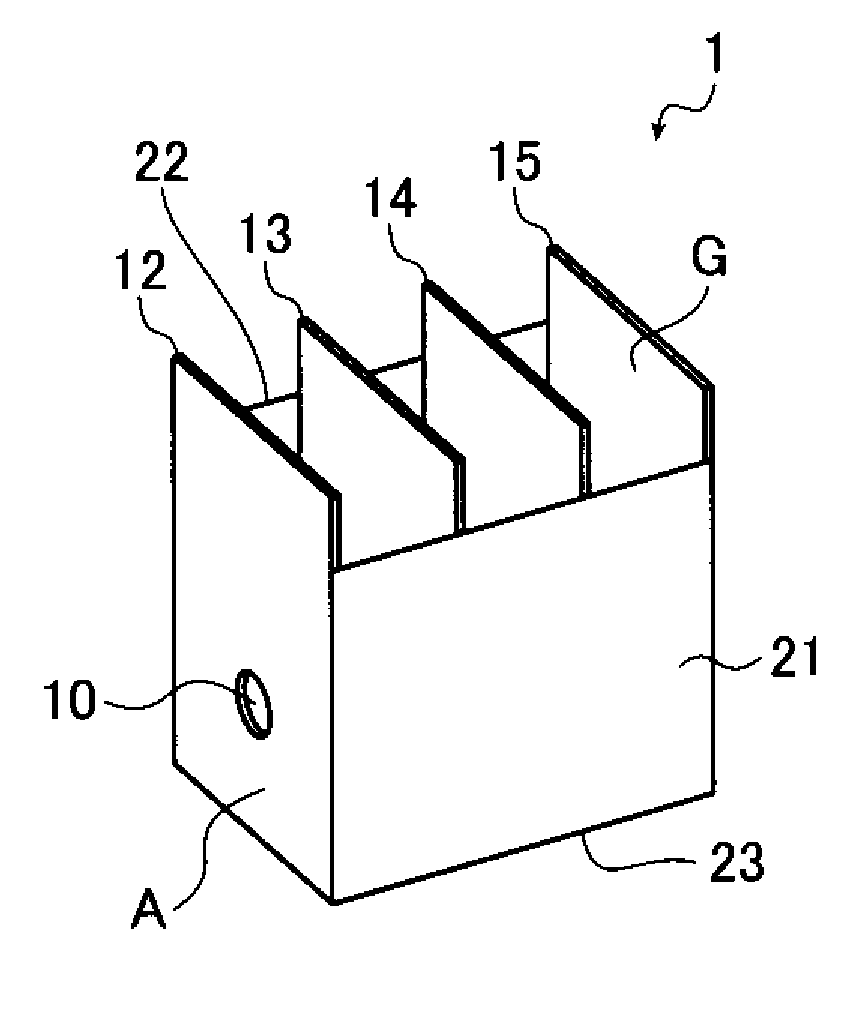

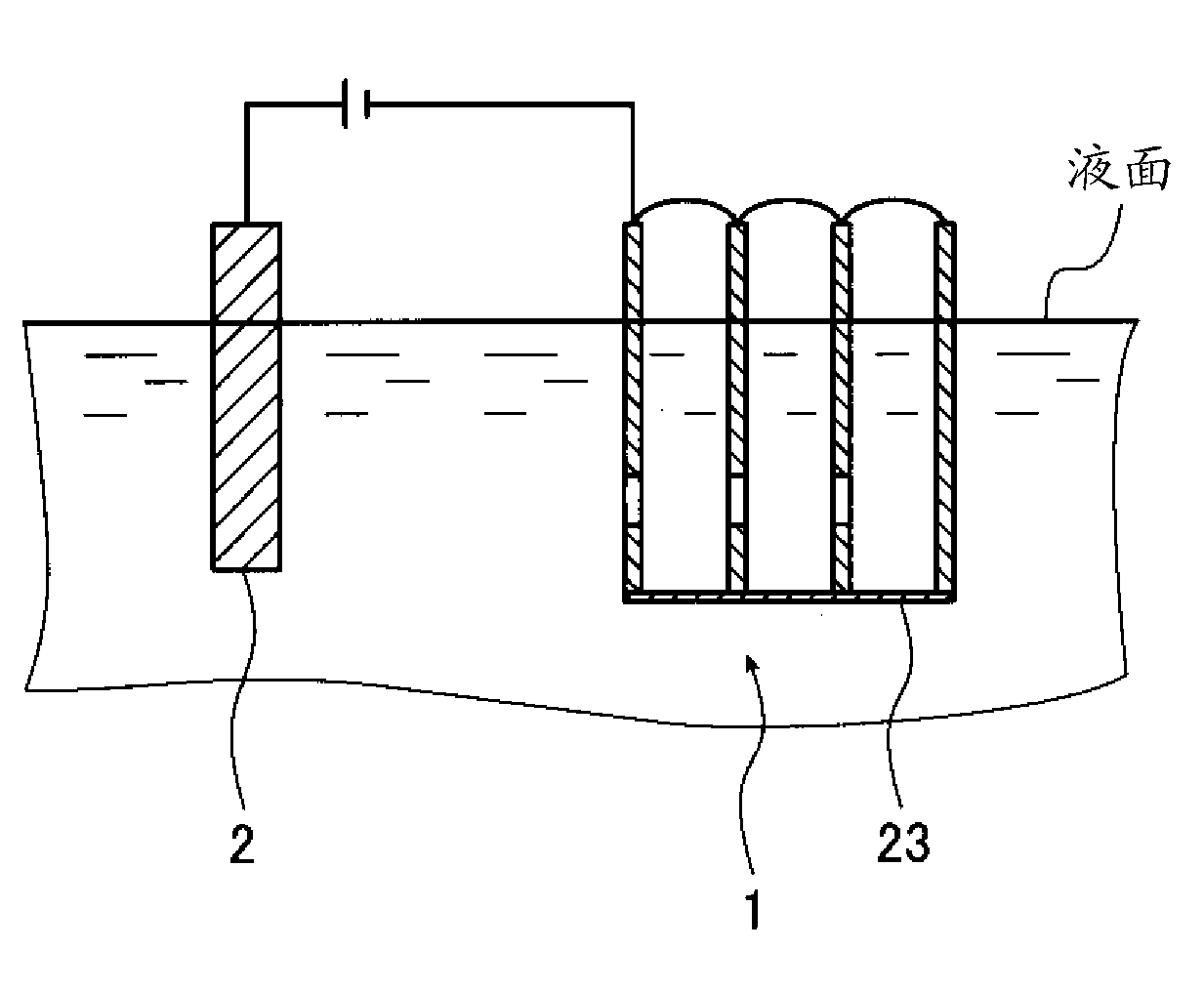

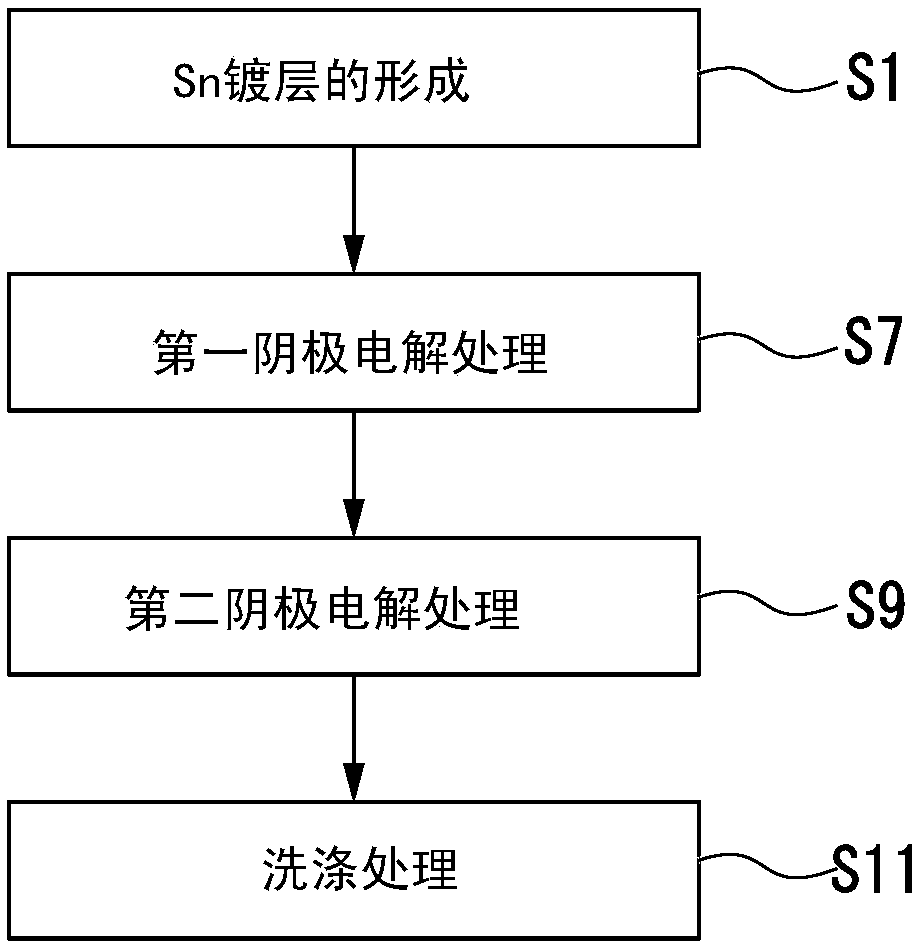

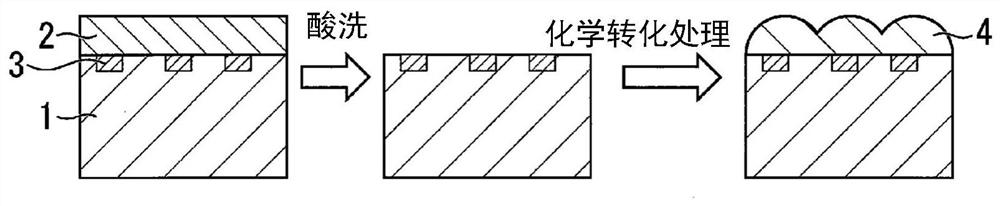

Steel Sheet For Container, And Method For Producing Steel Sheet For Container

ActiveCN107709630AExcellent film adhesionGood welding performanceHot-dipping/immersion processesElectrolytic inorganic material coatingSheet steelMeasurement point

This steel sheet for a container is provided with a steel sheet, an Sn plating layer formed on at least one surface of the steel sheet, and a chemically converted coating layer formed on the Sn plating layer, wherein the Sn plating layer contains 300-5600 mg / m2 of Sn in terms of the metallic Sn amount, the chemically converted coating layer contains 5-30 mg / m2 of a Zr compound in terms of the metallic Zr amount, and the average roughness Ra of the outermost surface of the chemically converted coating layer as determined by a scanning probe microscope is 10-100 nm. When the amount of change inthe yellowness index measured for one measurement point in the outermost surface of the chemically converted coating layer is defined as DELTAYI as represented in formula (1), the average value for the DELTAYI absolute values obtained for a plurality of measurement points included in a unit area of the outermost layer is 5.0 or less.

Owner:NIPPON STEEL CORP

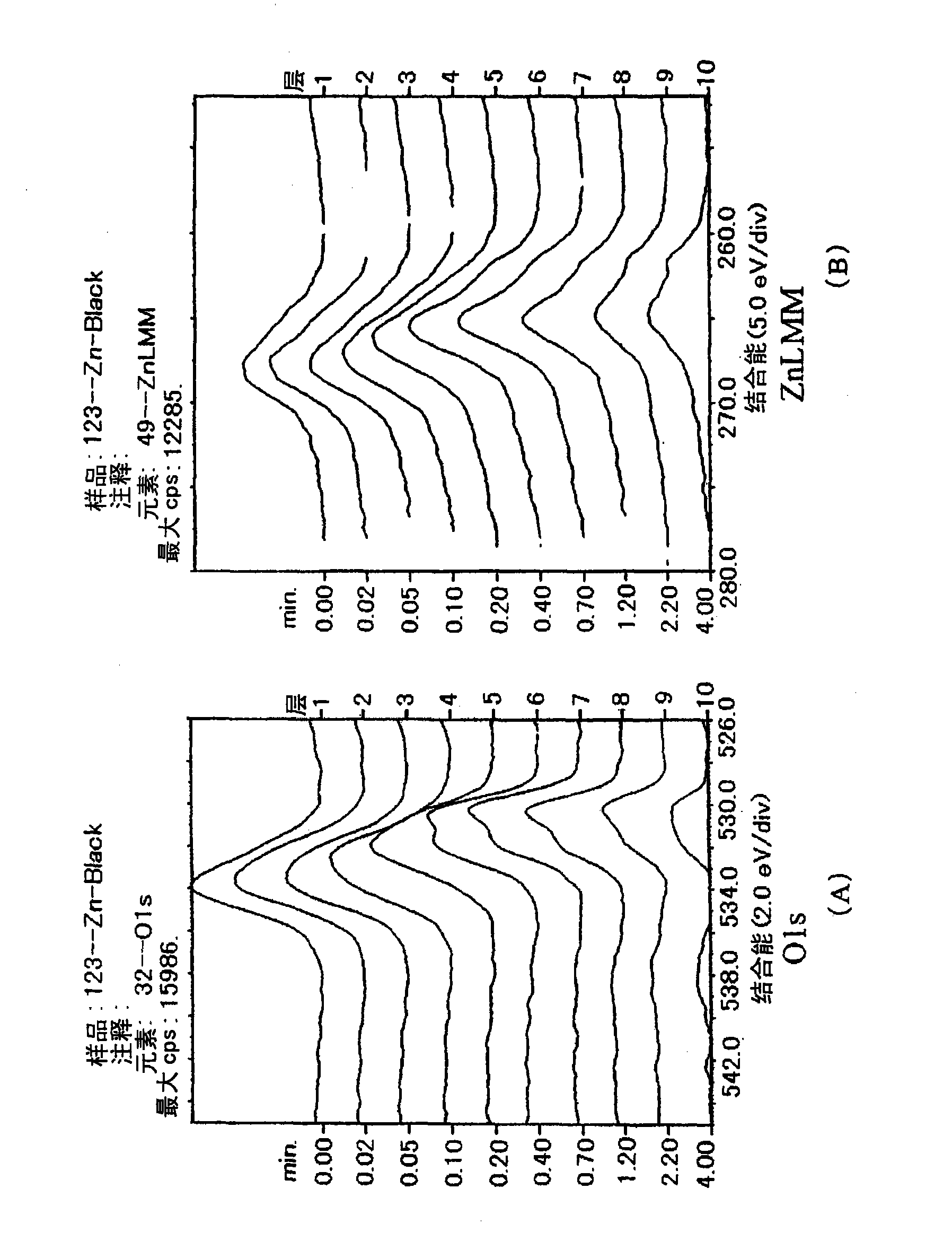

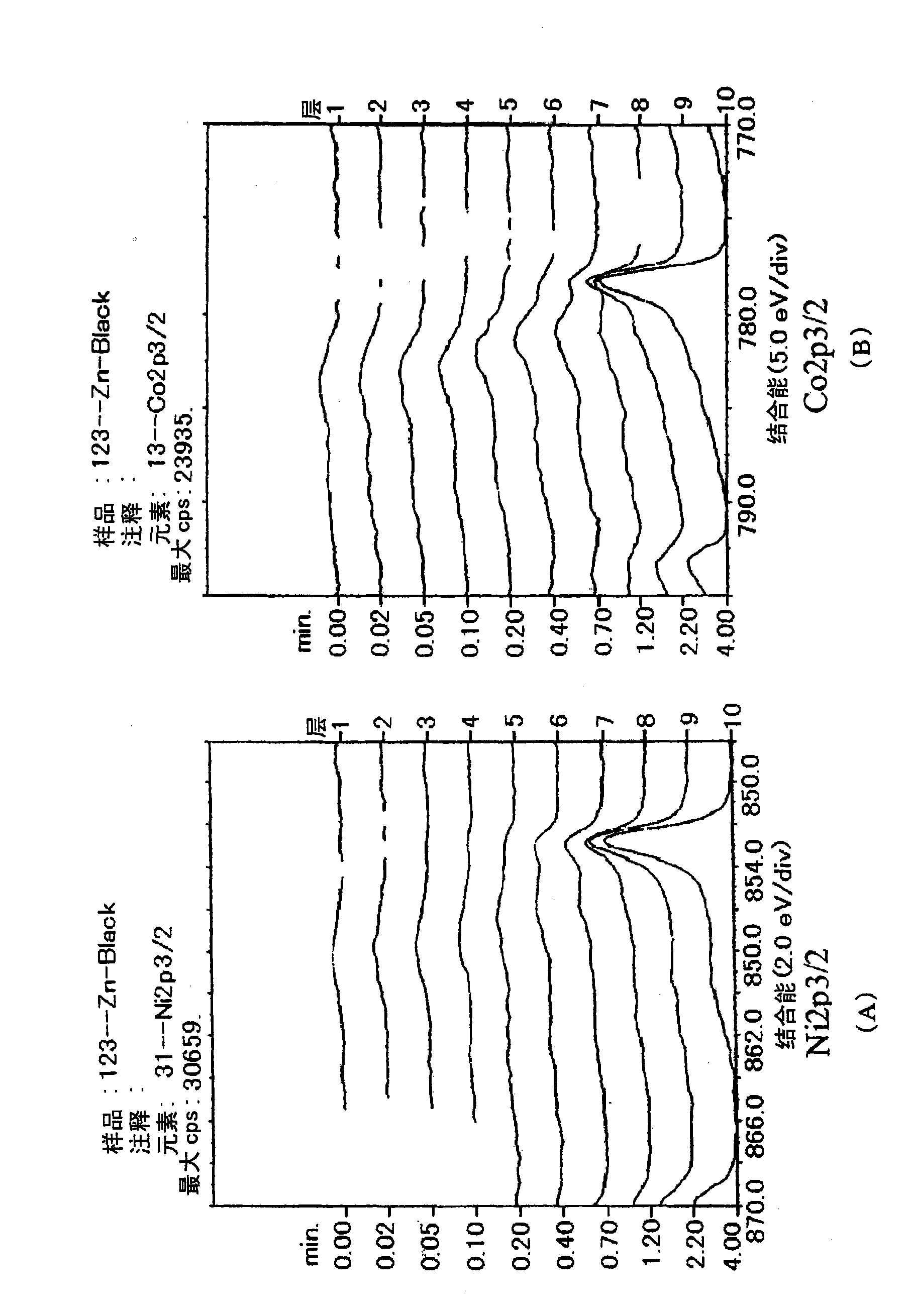

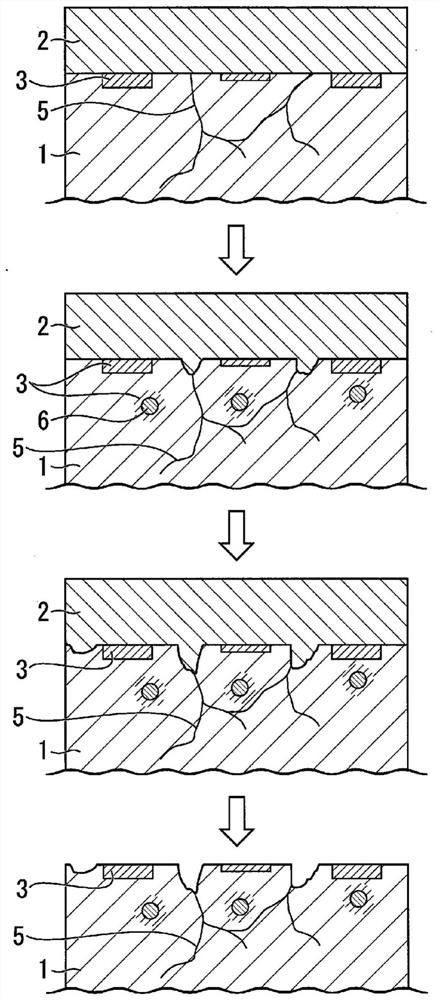

Light-absorbing member and method for producing the same

InactiveCN101842517AHigh blacknessNot easy to fall offLiquid/solution decomposition chemical coatingSuperimposed coating processCobaltWear resistance

Disclosed is a light-absorbing member wherein a black lower layer containing nickel and / or cobalt and an upper layer containing an oxide of at least one element selected from aluminum, magnesium and zinc are formed on a surface containing zinc and / or aluminum. Also disclosed is a method for producing such a light-absorbing member. In this light-absorbing member, a coating film exhibiting high light absorption and excellent wear resistance is formed on a metal material surface which is composed of zinc or an aluminum alloy.

Owner:NIHON PARKERIZING

Method for manufacturing grain-oriented electrical steel sheet

PendingCN113272453AExcellent magnetic propertiesExcellent film adhesionInorganic material magnetismFurnace typesElectrical steelDecarburization

A method of manufacturing a grain-oriented electrical steel sheet involves controlling the degree of oxidation (PH2O / PH2) in a decarburization annealing step, controlling the mass ratio of MgO and Al2O3 within an annealing separator in an annealing separator application step, controlling the degree of oxidation in the case that hydrogen is present or controlling the dew point in the case that only an inert gas is present in a final annealing step, and controlling the baking temperature and the heat treatment temperature in an insulating coating film formation step.

Owner:NIPPON STEEL CORP

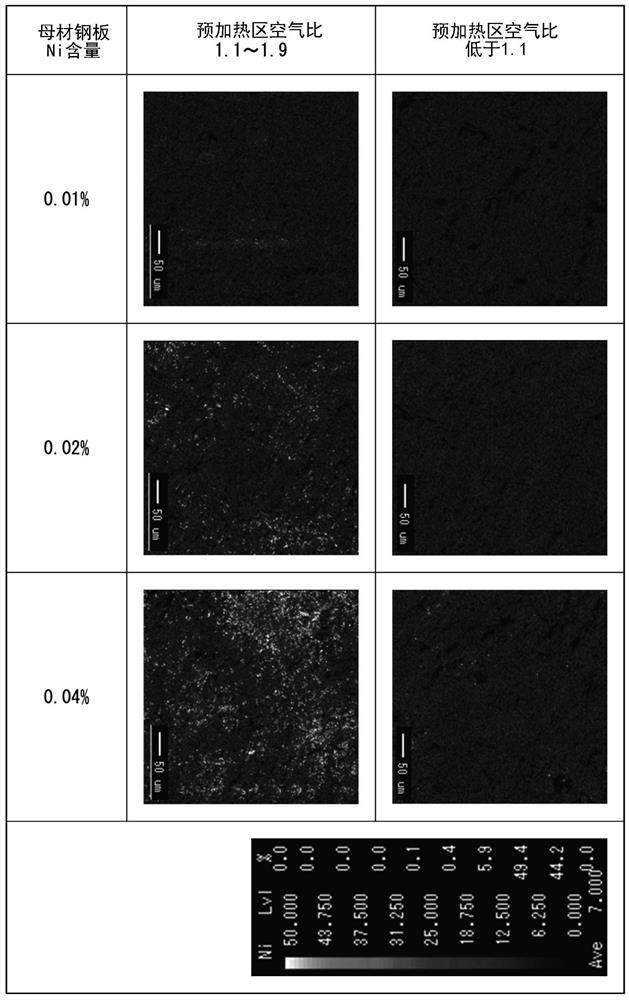

Hot-rolled steel sheet and method for manufacturing same

ActiveCN112805395AImprove corrosion resistanceHas tensile strengthFurnace typesMetal rolling arrangementsChemical compositionMetal

A hot-rolled steel sheet has a specified chemical composition, wherein, when the thickness of the steel sheet is defined as "t", a metallographic structure lying between a surface of the steel sheet and a depth t / 4 from the surface in the steel sheet contains tempered martensite and / or lower bainite in a total volume fraction of 90% or more, the tensile strength is 980 MPa or more, and the average Ni concentration in the surface is 7.0% or more.

Owner:NIPPON STEEL CORP

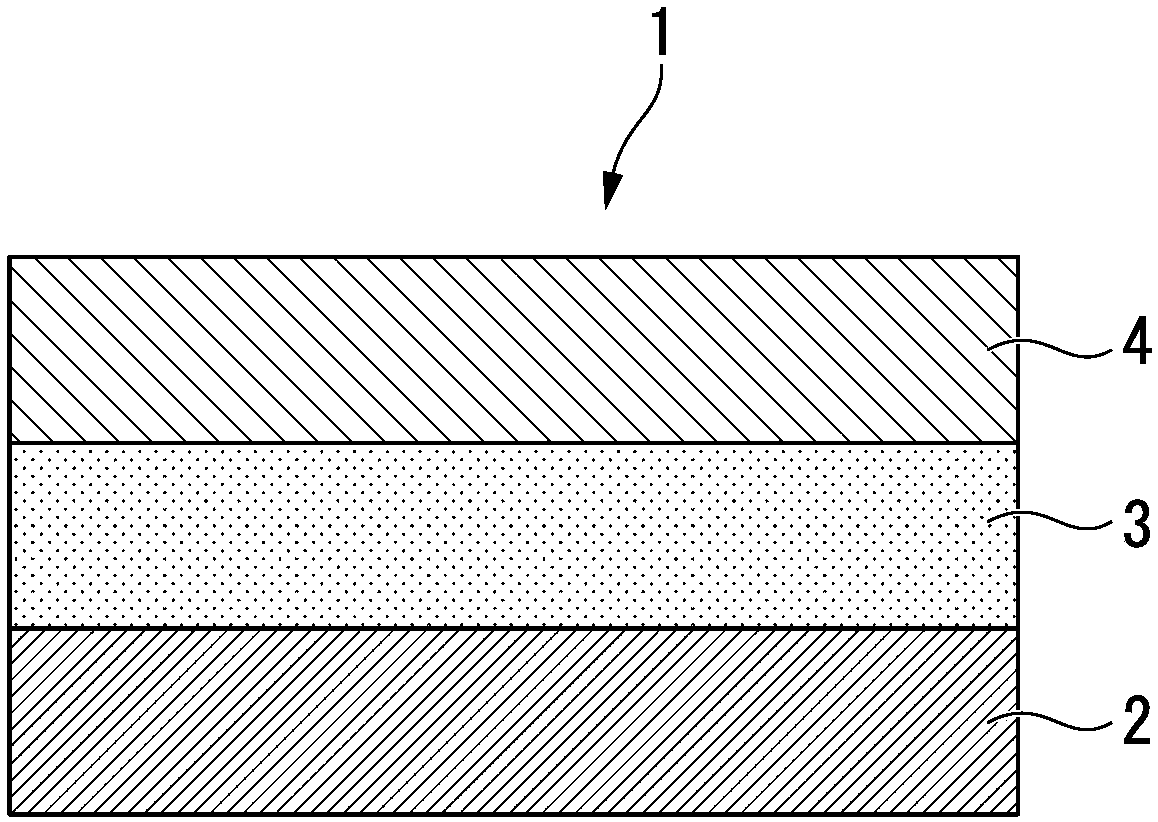

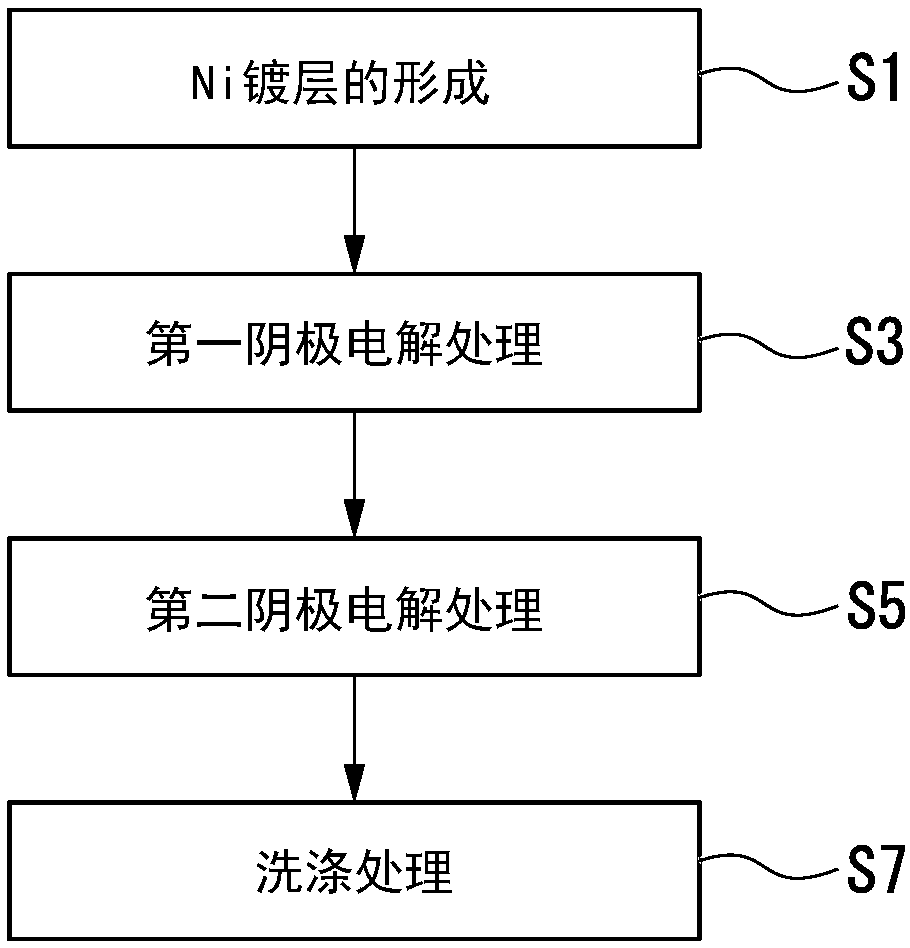

Steel Sheet For Container, And Method For Producing Steel Sheet For Container

ActiveCN107683351AExcellent film adhesionGood welding performanceFlexible coversWrappersSheet steelMeasurement point

This steel sheet for a container is provided with a steel sheet, an Ni plating layer formed on at least one surface of the steel sheet, and a chemically converted coating layer formed on the Ni plating layer, wherein the Ni plating layer contains 10-1000 mg / m2 of Ni in terms of the metallic Ni amount, and the chemically converted coating layer contains 5-30 mg / m2 of a Zr compound in terms of the metallic Zr amount. The average roughness Ra of the outermost surface of the chemically converted coating layer as determined by a scanning probe microscope is 10-100 nm, and when the amount of changein the yellowness index measured for one measurement point in the outermost surface of the chemically converted coating layer is defined as DELTAYI as represented in formula (2), the average value forthe DELTAYI absolute values obtained for a plurality of said measurement points included in a unit area of the outermost layer is 5.0 or less.

Owner:NIPPON STEEL CORP

Roll for hot-rolling apparatus and process for producing same

InactiveCN103025908BExcellent abrasion resistanceExcellent plate passabilityMolten spray coatingSolid state diffusion coatingThermal sprayingAlloy

A roll suitable for use in hot-rolling apparatuses is provided at low cost, the roll comprising a roll base which has a high hardness and is less apt to suffer deformation damages such as dents and a coating film formed on the surface of the roll base by thermal spraying, the coating film having excellent adhesion, wear resistance, and steel-sheet-conveying properties. Also provided is a process for advantageously producing the roll. The surface of a roll base comprising a steel which contains 0.9-3.2 mass% Cr and has a carbon equivalent Ceq, defined by equation (1), of 0.45-1.65 mass% is coated by thermal spraying with a coating film constituted of a self-fluxing alloy containing hard ceramic particles. Thereafter, the coated roll base is subjected to fusing treatment in a non-oxidizing atmosphere to form a diffusion layer having a thickness of 30-200 µm between the coating film formed by thermal spraying and the roll base, and is then cooled or heat-treated. Thus, the roll base is made to have a hardness of 35-60 in terms of Shore hardness HS.

Owner:TOCALO CO LTD +1

Electrical steel sheet with insulating coating and manufacturing method thereof

ActiveCN111684106BExcellent film adhesionReduce tensionVacuum evaporation coatingSputtering coatingColloidal silicaO-Phosphoric Acid

Owner:JFE STEEL CORP

Method for manufacturing grain-oriented electrical steel sheet

PendingCN113302318AExcellent magnetic propertiesExcellent film adhesionInorganic material magnetismSolid state diffusion coatingElectrical steelMixed gas

Owner:NIPPON STEEL CORP

Grain-oriented electrical steel sheet

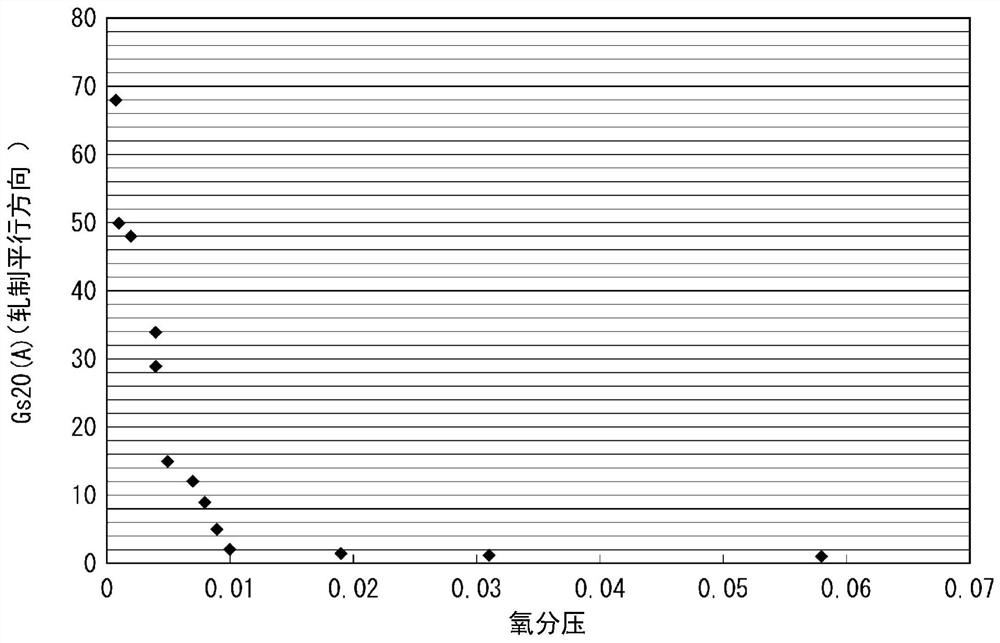

PendingCN113286911AExcellent iron lossExcellent film adhesionInorganic material magnetismFurnace typesElectrical steelChemical composition

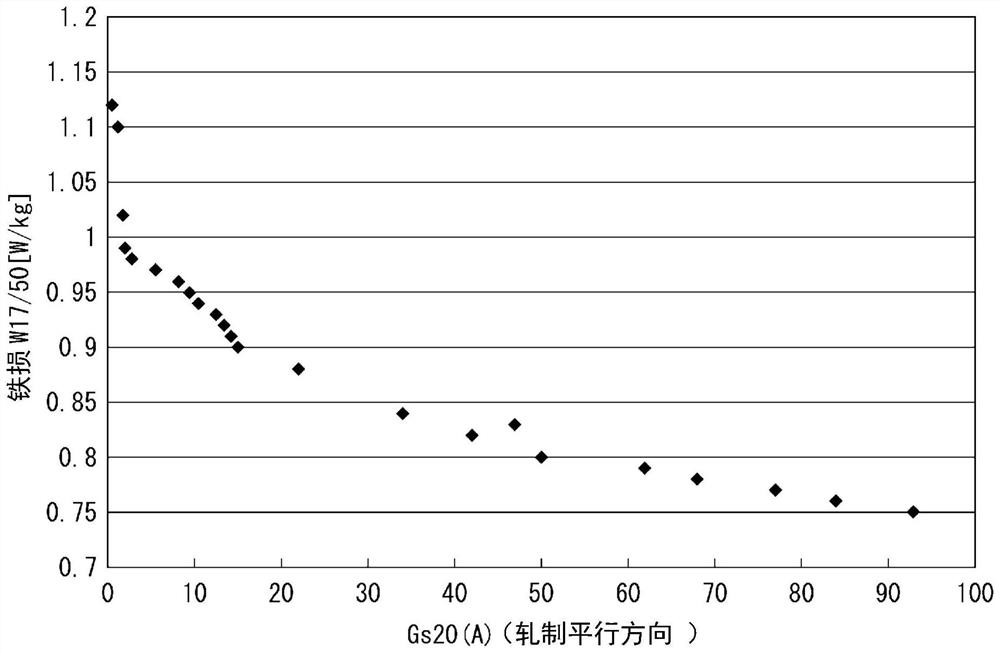

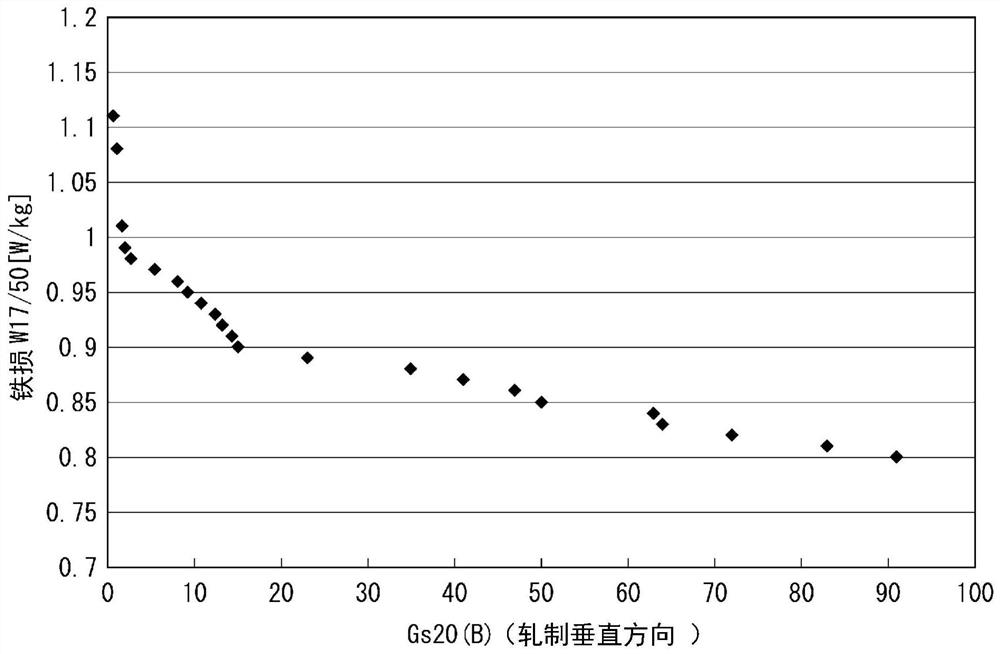

This grain-oriented electrical steel sheet is characterized by having a base steel sheet, an amorphous oxide film formed on the base steel sheet, and a tension insulating film formed on the amorphous oxide film, the base steel sheet containing as the chemical composition thereof, in terms of % by mass, no more than 0.085% C, 0.80-7.00% Si, no more than 1.50% Mn, no more than 0.065% acid-soluble Al, no more than 0.013% S, 0-0.80% Cu, 0-0.012% N, 0-0.50% P, 0-1.00% Ni, 0-0.30% Sn, 0-0.30% Sb, the remainder comprising Fe and impurities, the surface glossiness Gs20(A) in the direction parallel to the rolling direction being 2.0-70, and the surface glossiness Gs20(B) in the direction perpendicular to the rolling direction being 2.0-70.

Owner:NIPPON STEEL CORP

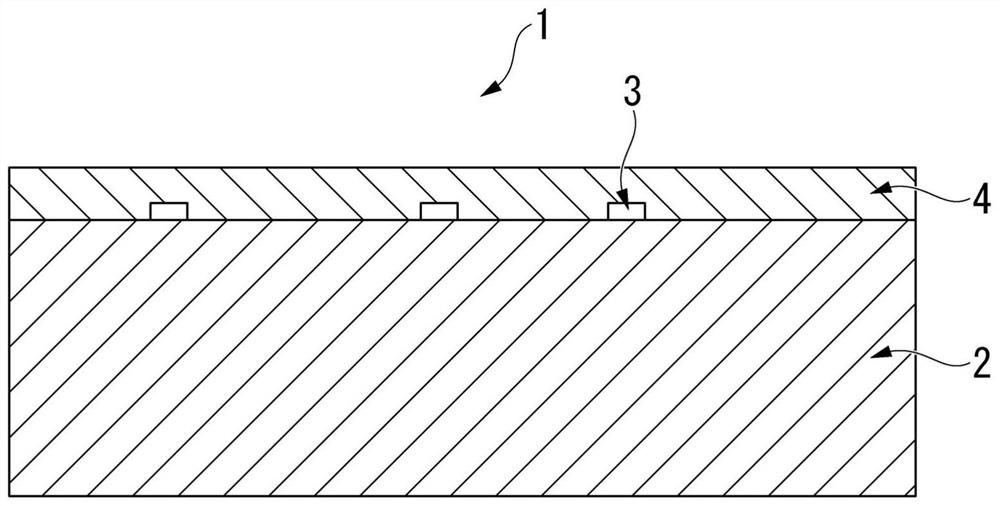

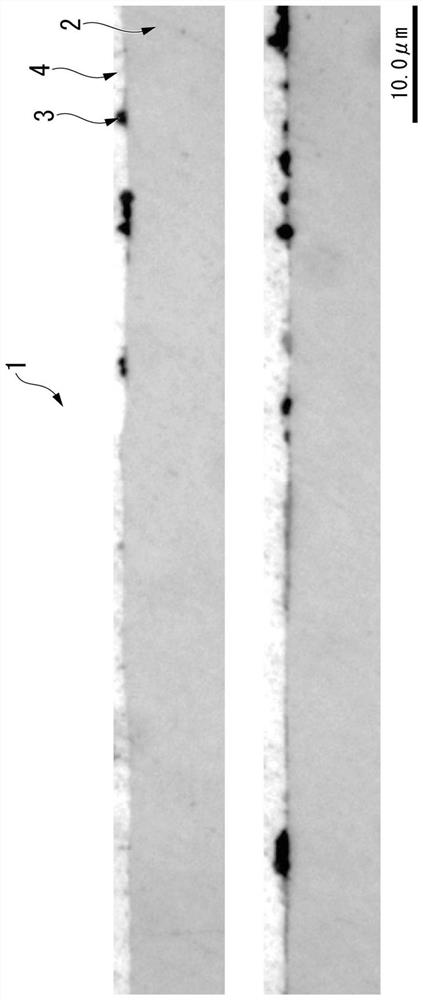

Grain-oriented electrical steel plate and method for producing same

ActiveCN113302324AExcellent adhesionExcellent magnetic propertiesInorganic material magnetismFurnace typesElectrical steelSteel plates

The grain-oriented electrical steel plate is characterized by having a steel plate, an insulating film arranged on the steel plate, and spinel present fitted into the insulating film in a part on the steel plate that is at the interface of the steel plate and the insulating film, and by the amount of spinel being 5-50 mg / m2 per unit area of the surface of the steel plate.

Owner:NIPPON STEEL CORP

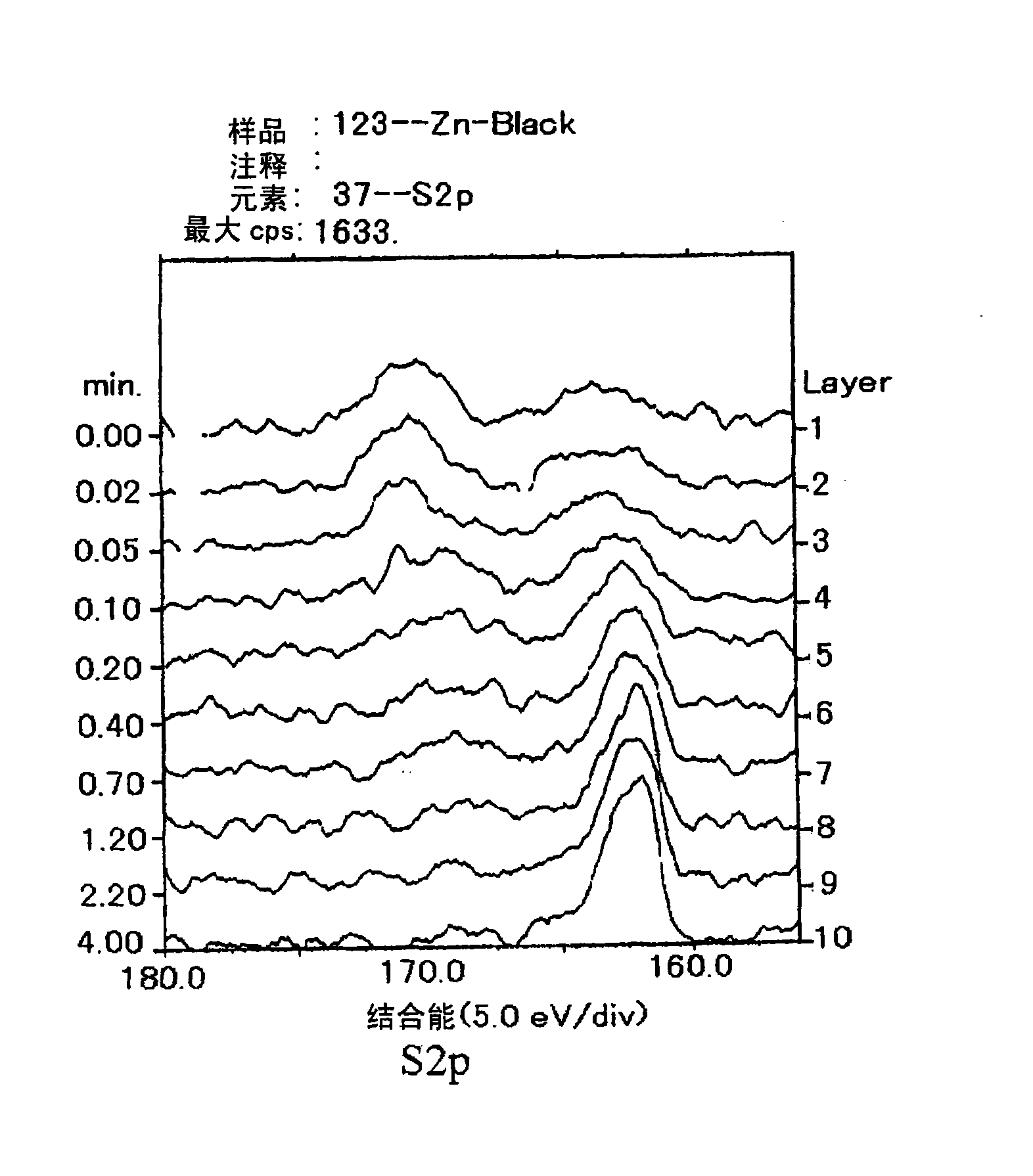

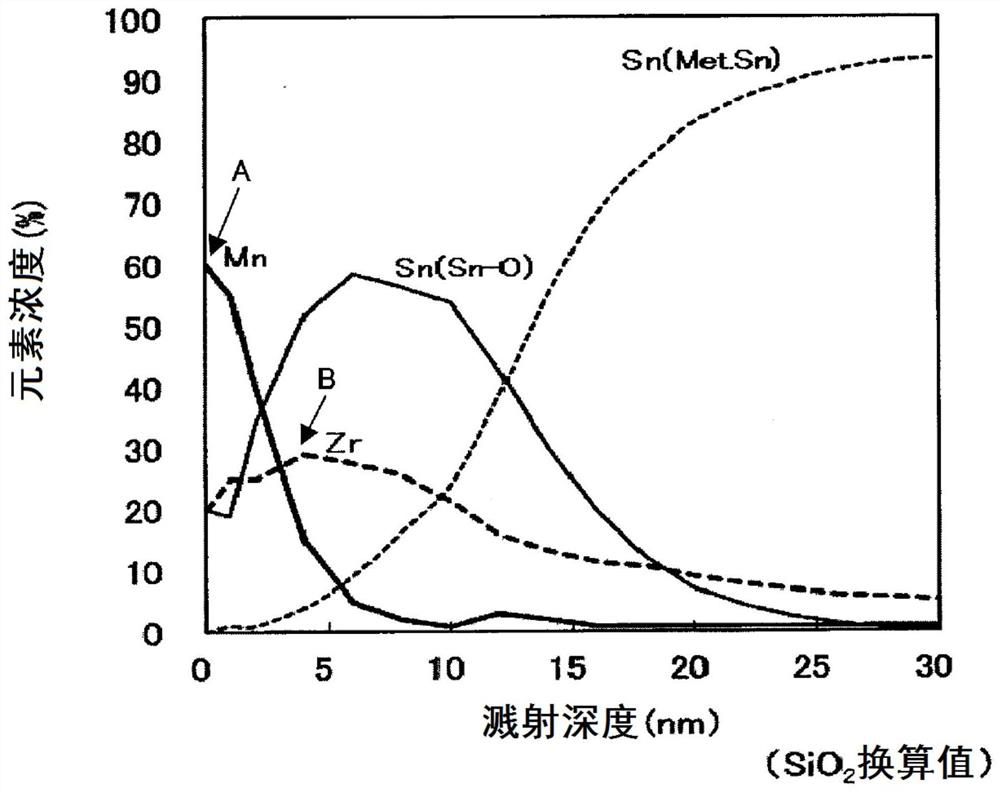

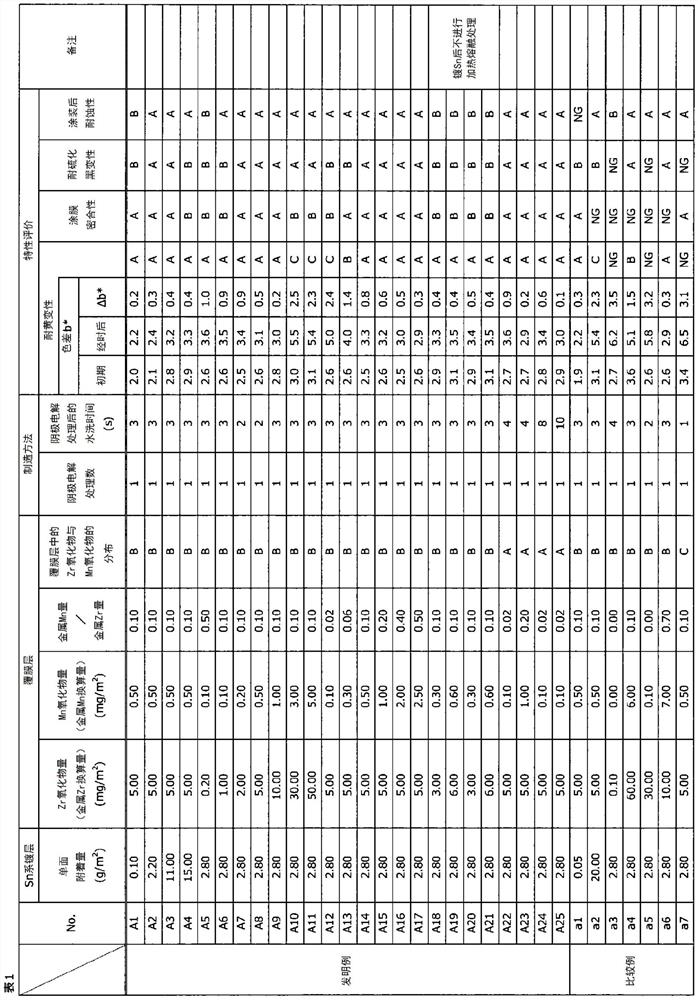

Sn-plated steel sheet

PendingCN114829675AGood yellowing resistanceExcellent film adhesionFlexible coversWrappersElemental analysisMetal

Provided is a Sn-based plated steel sheet having excellent yellowing resistance, coating film adhesion, and sulfur blackening resistance without being subjected to conventional chromate treatment. This Sn-plated steel sheet has a steel sheet, an Sn-plated layer positioned on at least one surface of the steel sheet, and a coating layer positioned on the Sn-plated layer, the Sn-plated layer containing 0.10-15.00 g / m2 of Sn per single surface in terms of metal Sn, the coating layer containing Zr oxide and Mn oxide, the content of Zr oxide being 0.20-50.00 mg / m2 per single surface in terms of metal Zr, and the content of Mn oxide being 0.20-0.50 mg / m2 per single surface in terms of metal Zr. The content of the Mn oxide in terms of metal Mn is 0.01-0.50 times by mass relative to the content of the Zr oxide in terms of metal Zr, and the depth position A at which the elemental concentration of Mn is maximum is positioned on the surface side of the coating layer compared to the depth position B at which the elemental concentration of Zr is maximum in depth-direction elemental analysis by XPS. The distance in the depth direction between the depth position A and the depth position B is 2 nm or more.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com