Surface-treated steel sheet

A technology for surface treatment of steel plates and steel plates. It is applied in the plating, coating, and metal material coating processes of superimposed layers. It can solve the problems of insufficient effect and insufficient effect, and achieve excellent barrier properties and coating film density. synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

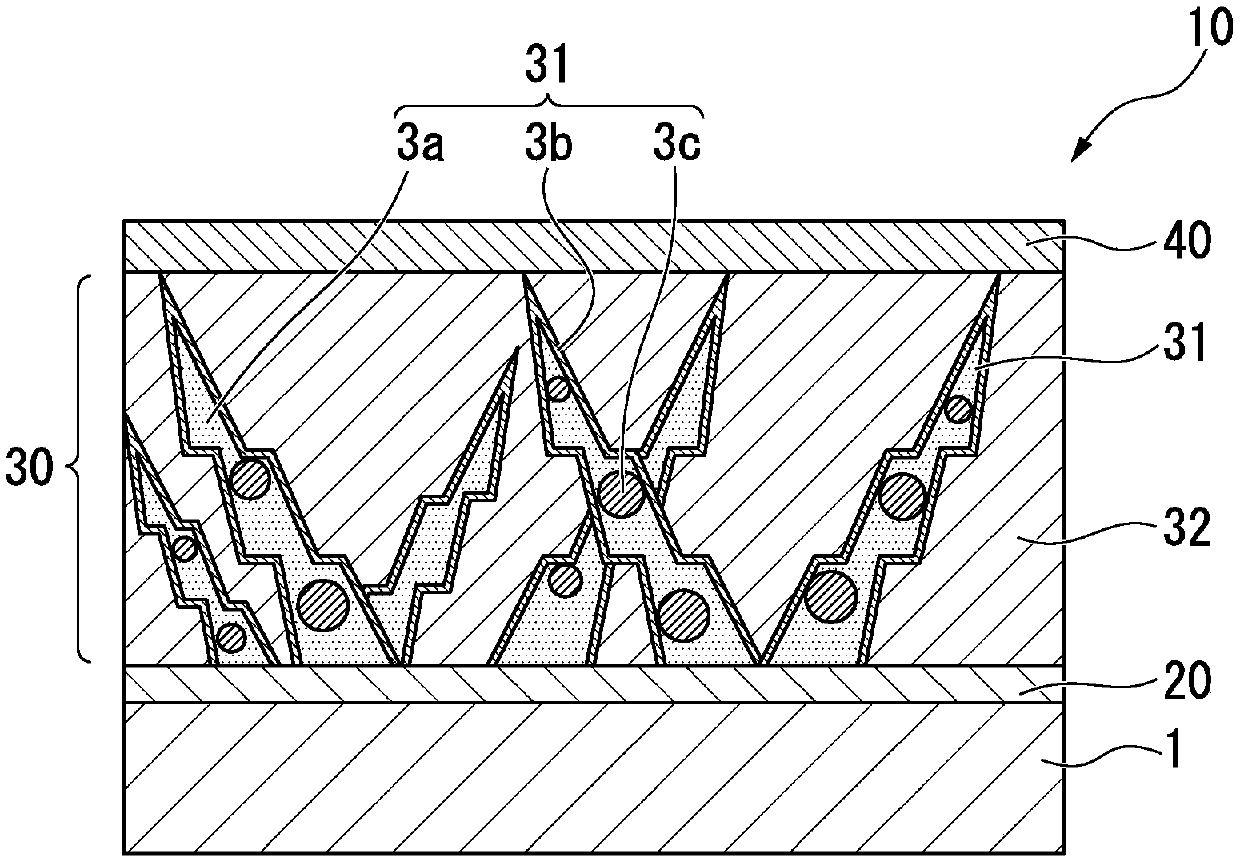

[0052] "First Embodiment, Surface-Treated Steel Sheet 10"

[0053] Hereinafter, the surface-treated steel sheet 10 of the first embodiment in which the plating layer contains vanadium will be described in detail with reference to the drawings.

[0054] figure 1 It is a cross-sectional schematic diagram for demonstrating an example of the surface-treated steel plate 10 of this embodiment. figure 1 In the surface-treated steel sheet 10 shown in , a base layer 20 , a plated layer 30 , and a surface layer 40 are formed on both sides of the steel sheet 1 in order from the steel sheet 1 side. figure 1 Only the base layer 20, the plating layer 30, and the surface layer 40 formed on one side (upper side) of the steel plate 1 are described in the figure, and the description on the other side (lower side) is omitted.

[0055] In the present embodiment, the steel sheet 1 on which the plating layer 30 is formed is not particularly limited. For example, as the steel plate 1, very low C ty...

no. 2 Embodiment approach

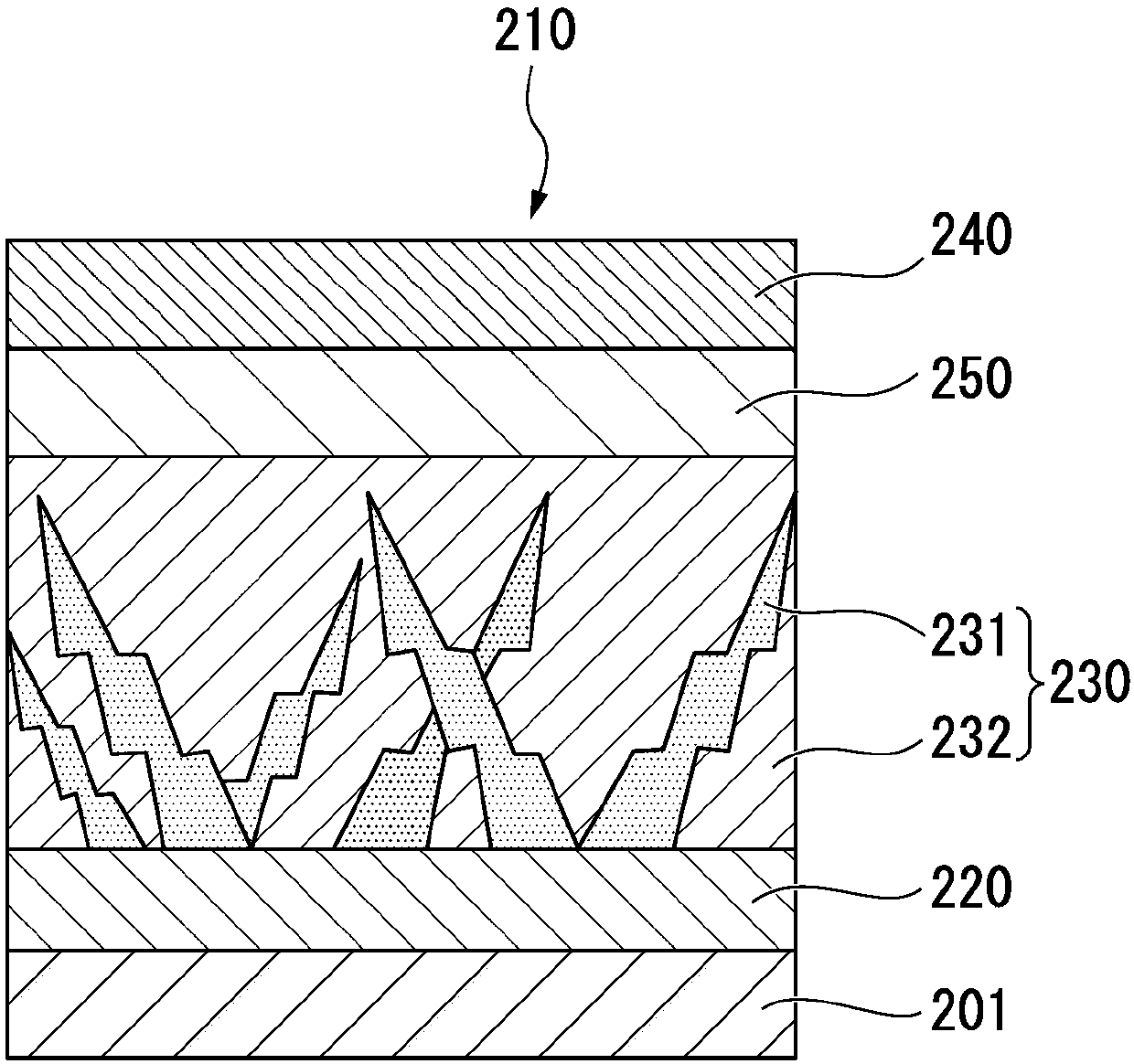

[0169] "Second embodiment, surface-treated steel plate 210"

[0170] The surface-treated steel sheet 210 of the second embodiment in which the plating layer 230 contains zirconium will be described below.

[0171] The surface-treated steel sheet 210 of the present embodiment includes: a steel sheet 201; and a plating layer 230 formed on one or both surfaces of the steel sheet. The coating 230 contains zinc and zirconium. In addition, the coating 230 contains: dendrites 231 comprising metallic zinc; and intercrystalline filling regions 232 comprising one or both of hydrated zirconium oxide or zirconium hydroxide. The surface-treated steel sheet 210 will be described in detail below.

[0172] Since the steel plate 201 is the same as the steel plate 1 of the first embodiment, description thereof will be omitted.

[0173] As noted above, the coating 230 has dendrites 231 comprising metallic zinc and an intercrystalline fill region 232 comprising one or both of hydrated zirconiu...

Embodiment 1

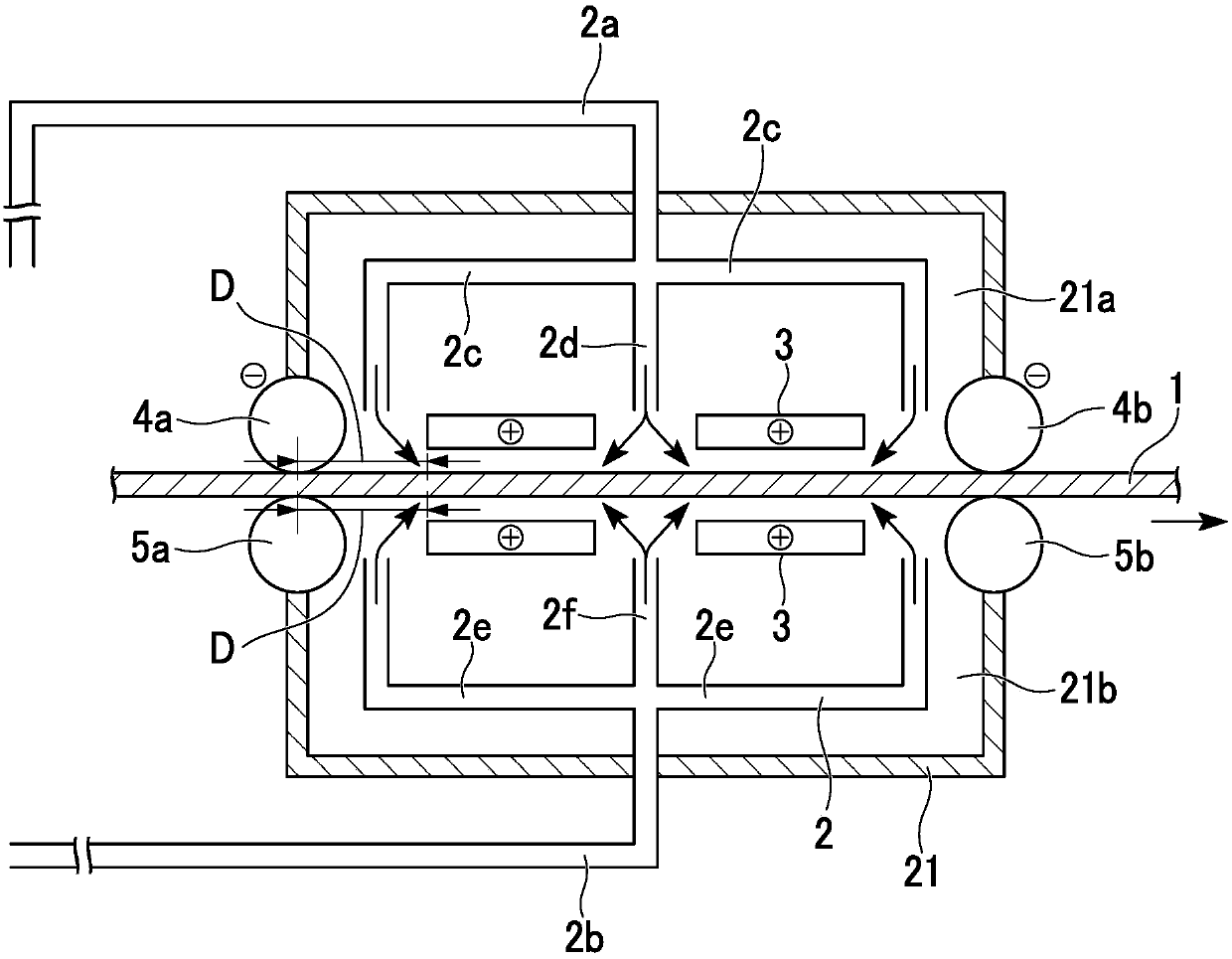

[0213] "Test results of surface-treated steel sheets containing vanadium"

[0214] use image 3 Surface-treated steel sheets having vanadium-containing plating layers on both sides of the steel sheet were prepared by the method shown below using the plating apparatus shown in , and evaluated.

[0215] A plating bath in a flowing state in which the plating bath composition, temperature, and pH shown in Table 1 were circulated at a relative average flow rate of 100 m / min was prepared.

[0216] Table 1

[0217]

[0218] As the steel plate, a steel plate having a plate thickness of 0.5 mm as SPCD for drawing a cold-rolled steel plate specified in JIS G 3141 was used.

[0219] The above-mentioned steel sheet was subjected to pretreatment (nickel plating) and used as a cathode.

[0220] During the pretreatment, firstly, the following plating bath was prepared as the plating bath for nickel plating: ion-exchanged water, concentrated sulfuric acid and NiSO 4 ·6H 2 O mixed as N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com