Grain-oriented electromagnetic steel sheet and method for producing grain-oriented electromagnetic steel sheet

A technology of an electrical steel sheet and a manufacturing method, which is applied in the field of manufacturing grain-oriented electrical steel sheets and grain-oriented electrical steel sheets, can solve the problems of reduced tensile stress and high manufacturing costs, and achieve the effects of excellent film adhesion and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0211]

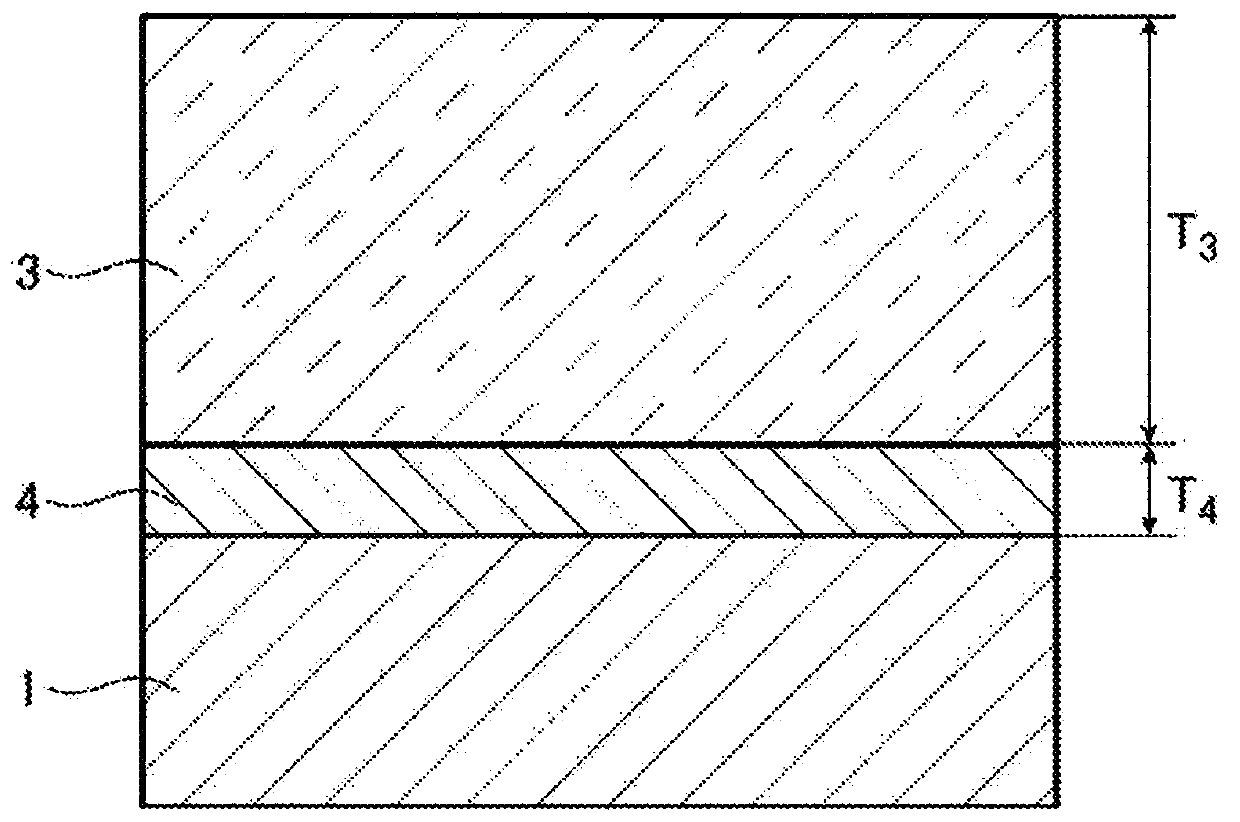

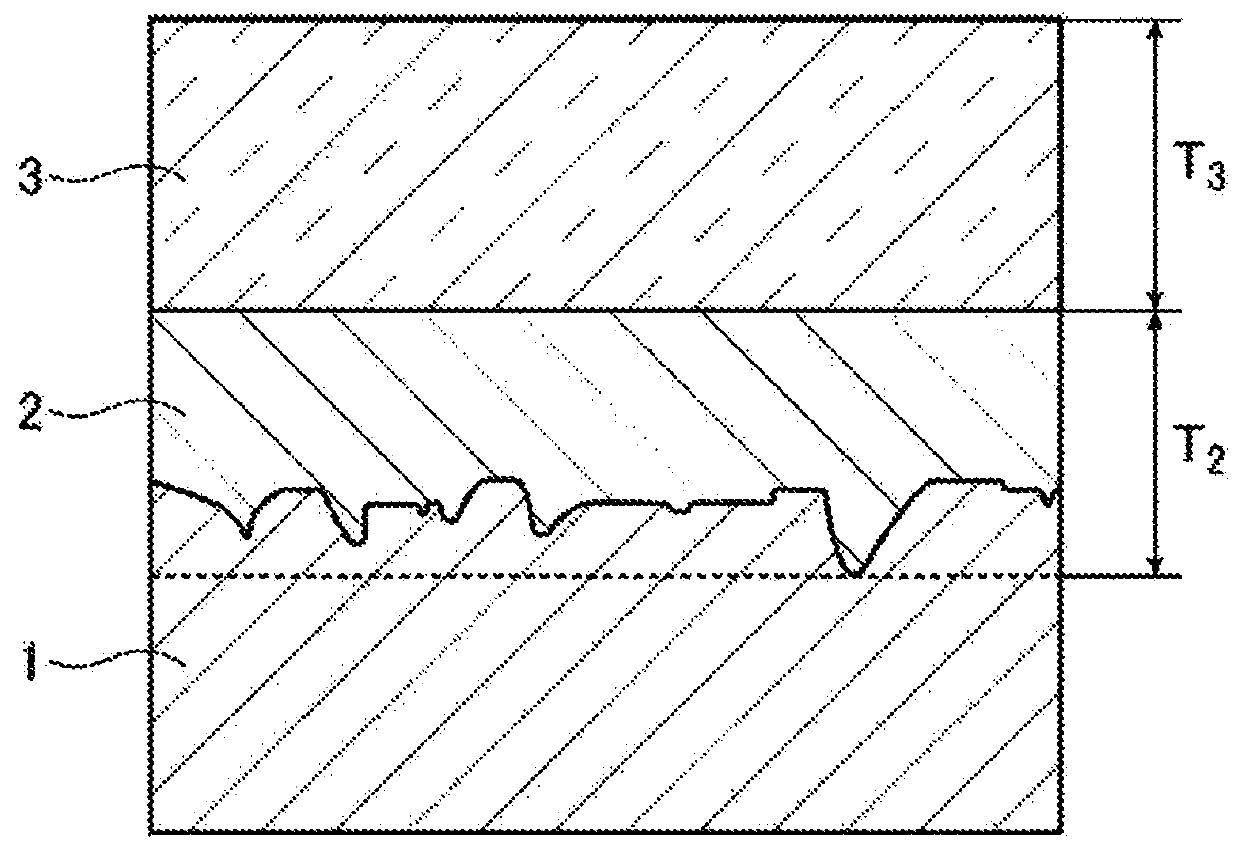

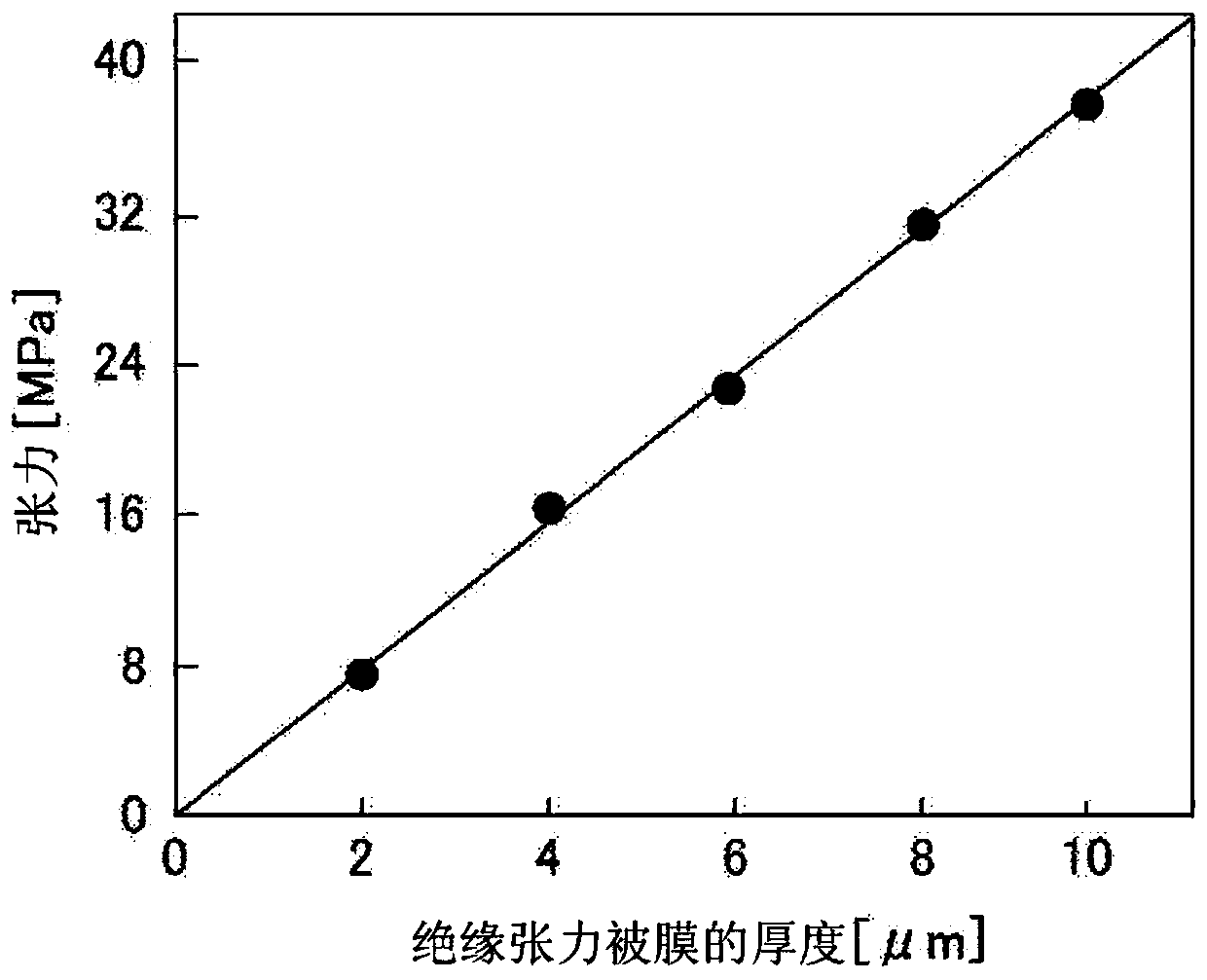

[0212] A film layer A (ceramic film) and a film layer B (insulating tension film) were sequentially formed on the steel sheet as follows to obtain a grain-oriented electrical steel sheet.

[0213] "Steel Plate"

[0214] A steel ingot is used that contains, by mass %, C: 0.05%, Si: 3.2%, Mn: 0.05%, Al: 0.03%, N: 0.005%, and Se: 0.01% as components in the steel, and the remainder consists of unavoidable impurities and Fe composition.

[0215] The steel ingot was hot-rolled, hot-rolled sheet annealing was performed, and a final cold-rolled sheet with a thickness of 0.23 mm was produced by two-pass cold rolling with intermediate annealing, and the secondary sheet having a Goss orientation was made by decarburization annealing and final annealing. The recrystallized grains are developed. Thus, a steel plate with a forsterite coating was obtained.

[0216] Thereafter, the forsterite coating on the surface of the obtained steel sheet with the forsterite coating was remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com