Grain-oriented electrical steel sheet

An electromagnetic steel plate and directional technology, applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve the problems of iron loss adverse effects, hindering the movement of magnetic domain walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157] A silicon steel slab having a composition shown in Table 1 (the remainder being Fe and impurities) was heated to 1100°C and subjected to hot rolling to prepare a hot-rolled steel sheet with a thickness of 2.6 mm, and the hot-rolled sheet was subjected to a temperature of 1100°C. After annealing, a single cold rolling was performed to prepare a cold-rolled steel sheet with a final thickness of 0.23 mm, and the cold-rolled steel sheet was subjected to decarburization annealing and nitriding annealing.

[0158] [Table 1]

[0159]

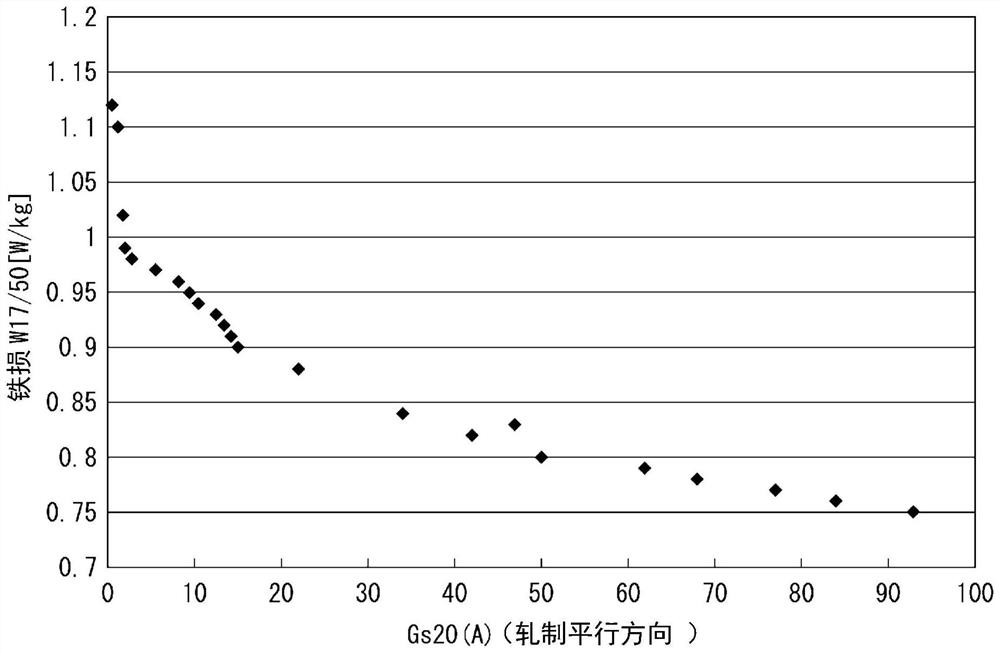

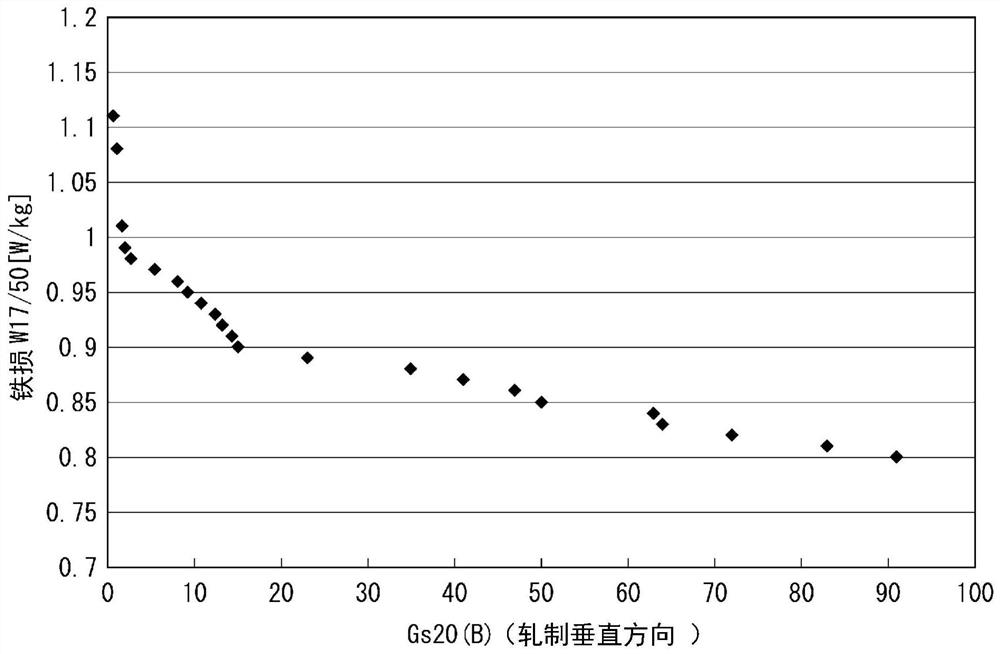

[0160] Next, the cold-rolled steel sheet subjected to decarburization annealing and nitriding annealing was coated with an aqueous slurry of an annealing separator mainly composed of alumina, and final annealing was performed at 1200° C. for 20 hours to obtain no forsterite on the surface of the steel sheet. A grain-oriented electrical steel sheet with a stone-based coating, a mirror-like luster, and the completion of secondary recrystallizat...

Embodiment 2

[0178] The silicon steel slab with the composition shown in Table 1 was heated to 1100°C and subjected to hot rolling to prepare a hot-rolled steel sheet with a thickness of 2.6 mm, and the hot-rolled sheet was annealed at 1100°C, and then cooled once. It rolled to obtain a cold-rolled steel sheet with a final thickness of 0.23 mm, and the cold-rolled steel sheet was subjected to decarburization annealing and nitriding annealing.

[0179] Next, the cold-rolled steel sheet subjected to decarburization annealing and nitriding annealing was coated with an aqueous slurry of an annealing separator mainly composed of alumina, and final annealing was performed at 1200° C. for 20 hours to obtain no forsterite on the surface of the steel sheet. A grain-oriented electrical steel sheet with a stone-based coating, a mirror-like luster, and the completion of secondary recrystallization.

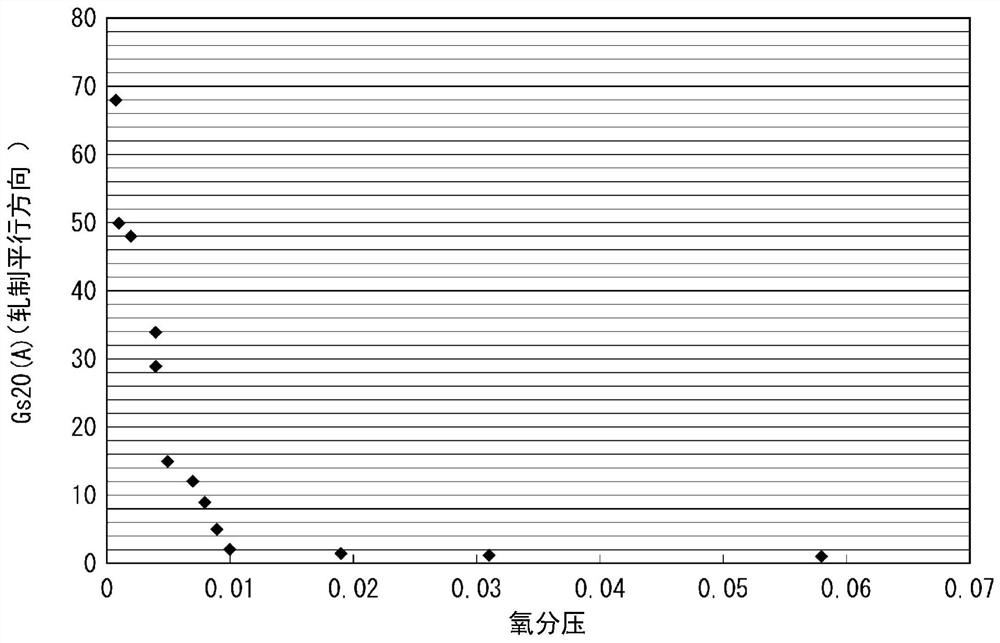

[0180] Formed from 25% nitrogen and 75% hydrogen, the partial pressure of oxygen (P H2O / P H2 ) in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com