Manufacturing method of grain oriented electrical steel sheet

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, photographic plate-making process of patterned surface, and magnetism of inorganic materials, etc., can solve problems such as generation of burrs, inhibition of etching speed, huge etching equipment, etc., achieve good iron loss, maintain The effect of iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] A steel slab containing Si: 3.0% by mass, C: 0.05% by mass, Mn: 0.03% by mass, Al: 0.02% by mass, N: 0.01% by mass, with the remainder consisting of Fe and unavoidable impurities is heated at 1400°C Afterwards, hot rolling is carried out to form a plate thickness of 2.2 mm, after implementing hot-rolled plate annealing at 1100 ° C × 60 seconds, cold rolling is carried out to make the plate thickness 1.8 mm, after implementing intermediate annealing at 1100 ° C × 60 seconds, use the first Secondary cold rolling to form a final plate thickness of 0.23 mm.

[0100] The cold-rolled steel sheets obtained as described above were subjected to magnetic domain refining treatment by various methods shown in Table 2.

[0101] Here, in the gravure offset printing, the grid provided on the plate roll is set so that the uncoated parts extending in the width direction of the plate with a width of 100 μm are arranged at a pitch of 3 mm in the rolling direction. Epoxy-based resists are...

Embodiment 2

[0113] Various resists shown in Table 3 were applied to the same cold-rolled steel sheet coils as those produced in Example 1. Here, a resist other than gravure offset printing was uniformly coated on the surface of a steel sheet by a roll coater, and the light source shown in Table 3 and a mask formed with a slit or a shielding portion with a width of 100 μm were used to apply the resist through a mirror. The projection type of the optical system of the lens carries out exposure. The projection magnification is set to equal magnification.

[0114] Then, the steel sheet coated with the chemically amplified resist was heat-treated at 80° C. for 30 seconds. Next, development is performed with a developer suitable for the resist. For gravure offset printing, a plate roll having uncoated portions with a width of 100 μm formed at a pitch of 3 mm in the rolling direction was produced, and an epoxy resin was printed on the surface of the steel sheet.

[0115] These steel sheets we...

Embodiment 3

[0120] On the same cold-rolled steel sheet coil as the coil produced in Example 1, roll-coat a positive-type resist with a novolac resin and a naphthoquinonediazide photosensitive agent as main components with a film thickness of 3 μm, and implement Heat treatment at 100°C x 30 seconds. Then, exposure was performed on one side of the steel plate under various conditions by using three exposure methods: proximity mask, projection type, and direct drawing type.

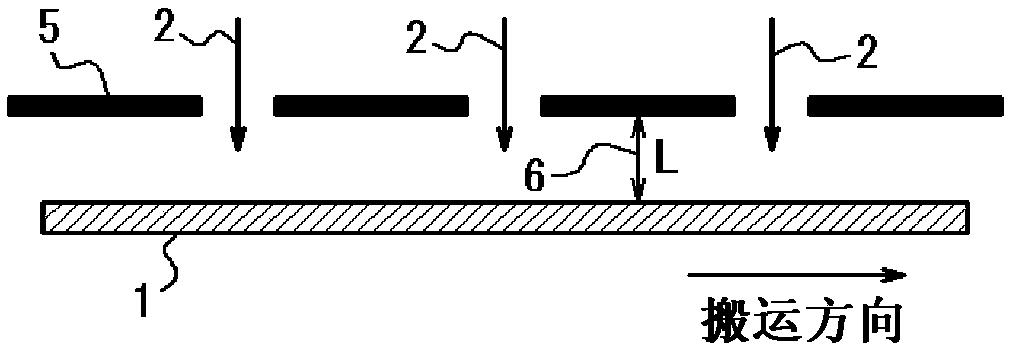

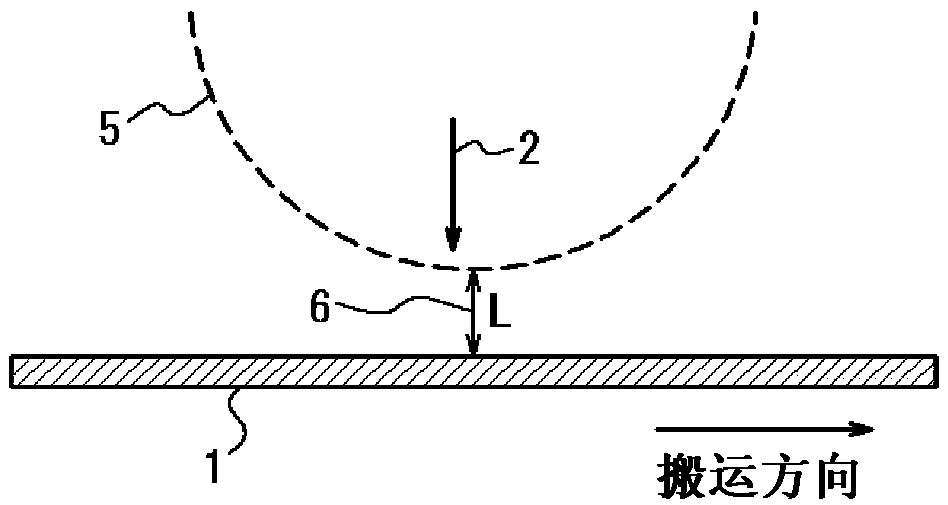

[0121] In the proximity mask, a mask with slits of 100 μm width extending in the sheet width direction was made at a pitch of 5 mm in the rolling direction, and the distance between the mask and the steel sheet was changed in the range shown in Table 4, Use illuminance of 50mW / cm 2 A 3-second exposure was performed using an ultra-high pressure mercury lamp.

[0122] In the projection type, a plurality of masks are produced in such a way that a region extending in the width direction of the steel plate with a width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com