Nonoriented electromagnetic steel sheet

An electromagnetic steel plate and non-directional technology, applied in the direction of inorganic materials, circuits, magnetic materials, etc., can solve the problems of iron loss degradation and achieve excellent iron loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

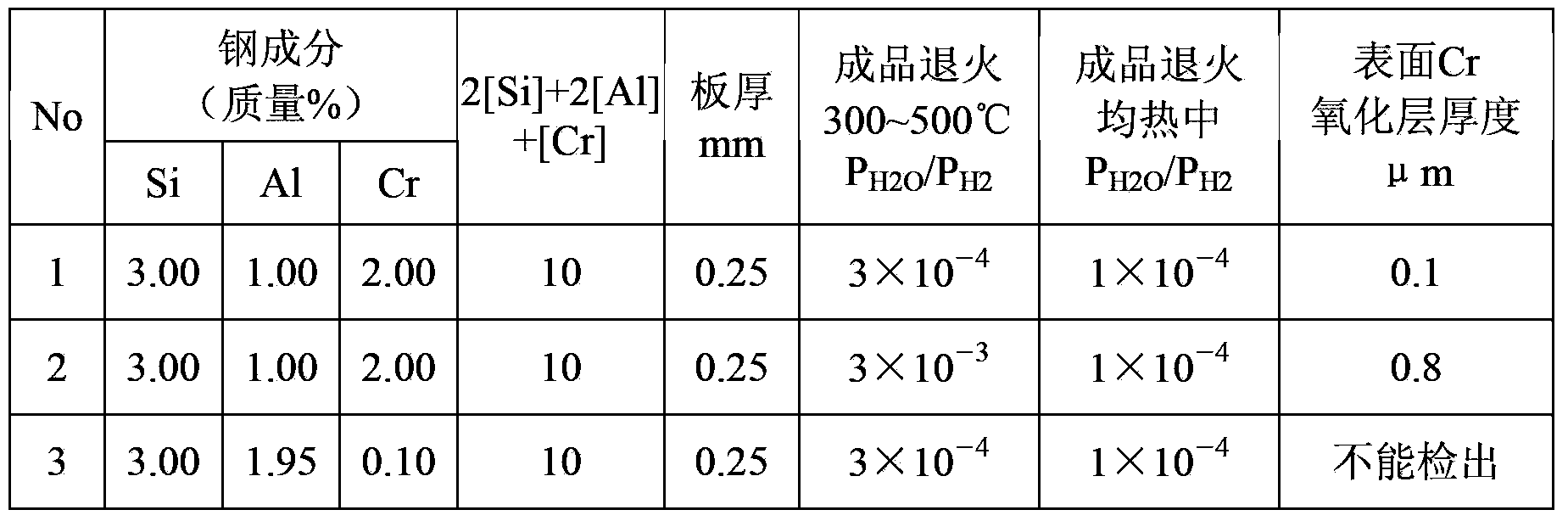

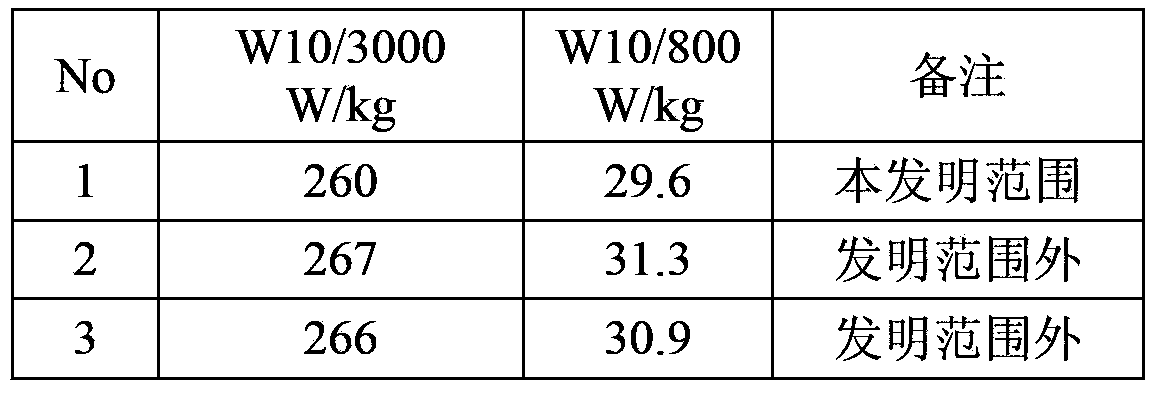

[0056] First, a hot-rolled sheet containing C: 0.002% by mass, S: 0.002% by mass, N: 0.002% by mass, and Mn: 0.3% by mass, Si, Al, and Cr having the composition shown in Table 1 below was prepared and pickled. A cold-rolled sheet having a thickness of 0.25 mm was obtained by cold rolling. Next, the oxygen potential was controlled under the conditions shown in Table 1, and finish annealing was performed at 1000° C. to obtain a non-oriented electrical steel sheet.

[0057] Table 1

[0058]

[0059] Next, samples for magnetic measurement were cut out from the obtained non-oriented electrical steel sheet, and iron loss W10 / 3000 at 3000 Hz and 1T and iron loss W10 / 800 at 800 Hz and 1T were measured. In addition, a sample for observation was cut out, and the cross section of the non-oriented electrical steel sheet was observed. As an observation method, SEM and GDS were used to measure the thickness of the Cr oxide layer. As a result, the thickness of the Cr oxide layer is sho...

Embodiment 2)

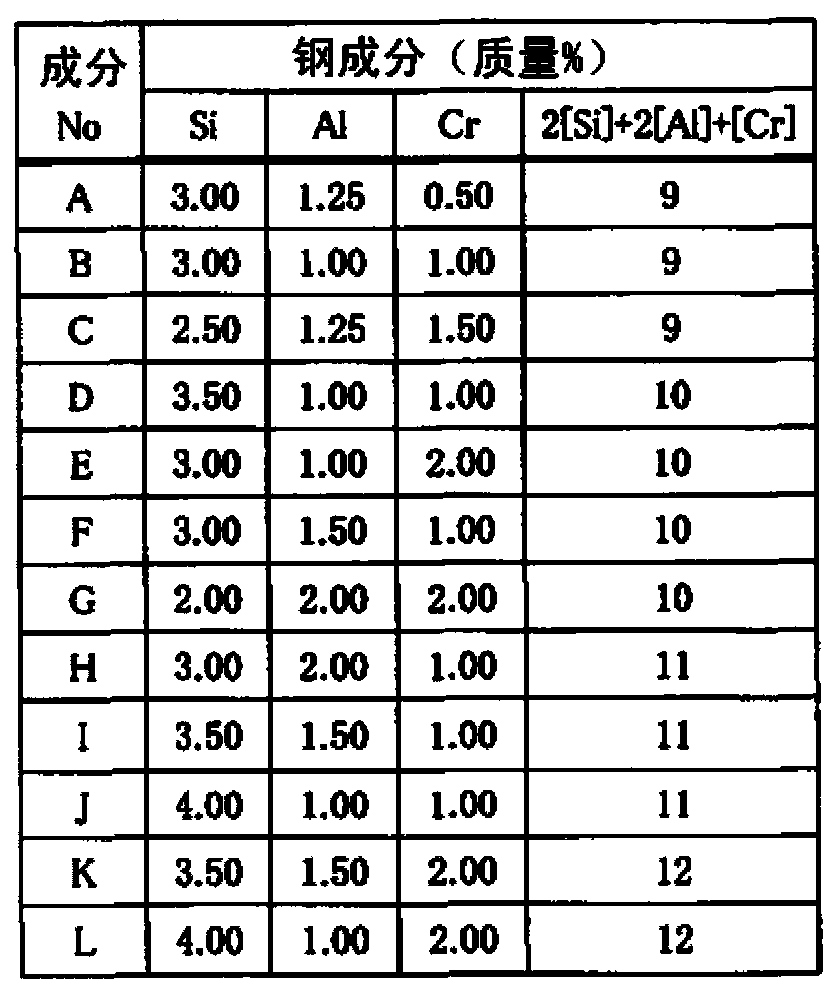

[0064] First, a hot-rolled sheet containing C: 0.002% by mass, S: 0.002% by mass, N: 0.002% by mass, and Mn: 0.3% by mass, Si, Al, and Cr as components A to L shown in Table 3 below was prepared. , pickled, and cold-rolled to obtain a cold-rolled sheet with a thickness of 0.15 mm to 0.30 mm. Next, finish annealing at 1000° C. was performed in a dry hydrogen atmosphere. The oxygen potential P at this time H2O / P H2 3×10 at 300-500°C during heating -4 , 1×10 in soaking -4 , to obtain a non-oriented electrical steel sheet.

[0065] table 3

[0066]

[0067] Next, samples for magnetic measurement were cut out from the obtained non-oriented electrical steel sheet, and iron loss W10 / 3000 at 3000 Hz and 1T, iron loss W10 / 800 at 800 Hz and 1T, and iron loss W10 / 400 at 400 Hz and 1T were measured. In addition, the thickness of the Cr oxide layer was measured in the same procedure as in Example 1. As a result, the thickness of the Cr oxide layer was in the range of 0.01 μm to 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com