Electrical steel sheet with insulating coating and manufacturing method thereof

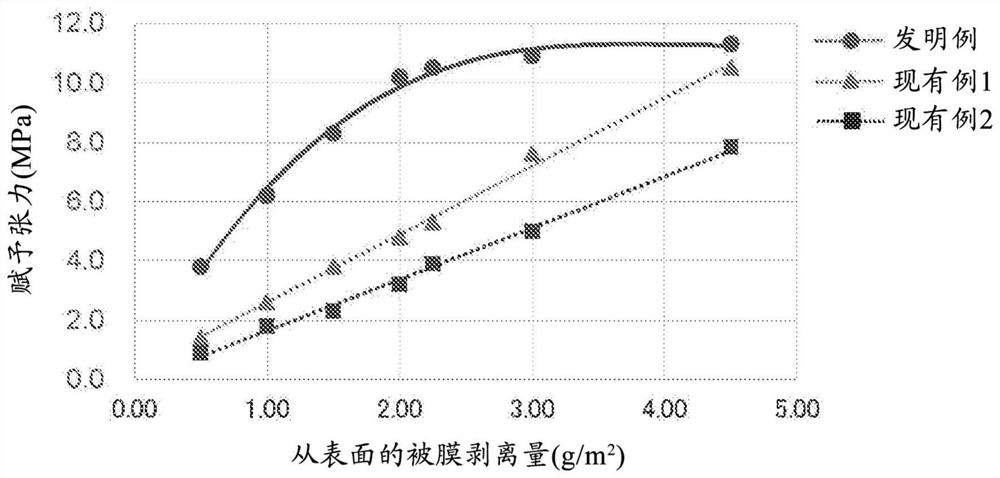

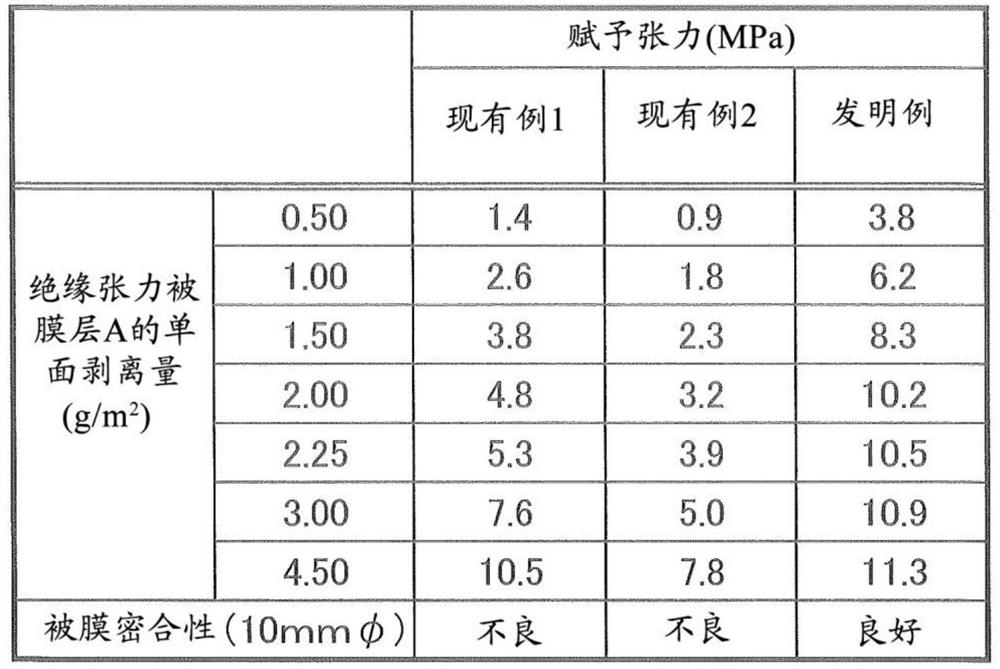

A technology of insulating film and electromagnetic steel sheet, applied in the direction of manufacturing tools, circuits, magnetic objects, etc., can solve the problems of excessive thermal expansion coefficient difference, core peeling, large shear stress, etc., to achieve large film tension and film adhesion. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

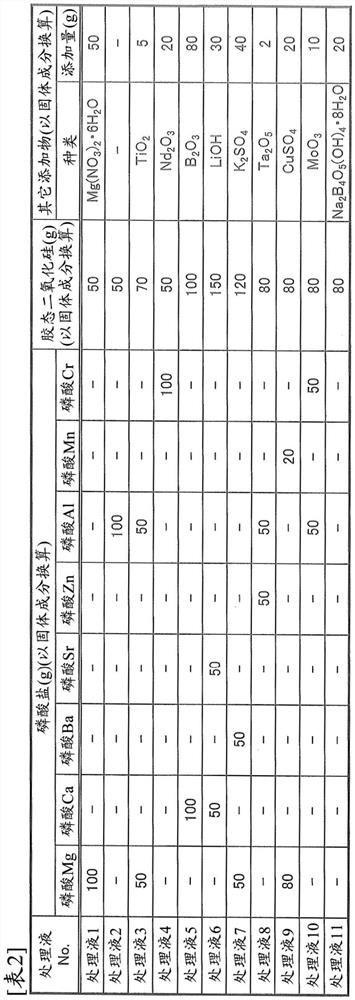

[0106] A silicon steel sheet containing Si: 3.25%, C: 0.04%, Mn: 0.08%, S: 0.002%, sol.Al: 0.015%, N: 0.006%, Cu: 0.05%, Sb: 0.01% in mass % After heating the billet at 1150°C for 20 minutes, hot rolling was performed to obtain a hot rolled sheet with a thickness of 2.4 mm, and after annealing at 1000°C for 1 minute, a final thickness of 0.27 mm was obtained by cold rolling. A sample with a size of 100 mm × 400 mm was taken from the central part of the sample, and the temperature was raised from room temperature to 820 °C at a heating rate of 80 °C / s, and the primary recrystallization annealing was performed at 820 °C for 60 seconds in a humid gas atmosphere. Next, 5 parts by mass of TiO was mixed with respect to MgO: 100 parts by mass 2 The obtained annealing separator was made into a water slurry, and then applied and dried. After raising the temperature of the steel sheet from 300°C to 800°C over 100 hours, the temperature was raised to 1200°C at 50°C / hr, and the final fin...

Embodiment 2

[0113] A silicon steel sheet containing Si: 3.25%, C: 0.04%, Mn: 0.08%, S: 0.002%, sol.Al: 0.015%, N: 0.006%, Cu: 0.05%, Sb: 0.01% in mass % After the billet was heated at 1150°C for 20 minutes, it was hot rolled to obtain a hot rolled sheet with a thickness of 2.2 mm, annealed at 1000°C for 1 minute, and then cold rolled to obtain a final thickness of 0.23 mm. The temperature was raised from room temperature to 820°C at 50°C / s, and the primary recrystallization annealing was performed at 820°C for 60 seconds in a humid gas atmosphere. Then, 150 parts by mass of Al was mixed with respect to MgO: 50 parts by mass 2 O 3 , 1 mass part of Na 2 B 4 O 7 ·10H 2 The annealing separator made of O was made into a water slurry, and then applied and dried. After raising the temperature of the steel sheet from 300°C to 800°C for 100 hours, the temperature was raised to 1200°C at 50°C / hr, and the final finish annealing was performed at 1200°C for 5 hours. 2 O 3 ·5SiO 2 ) as the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com