Grain-oriented electrical steel plate and method for producing same

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, circuits, magnetic objects, etc., can solve the problems of reduced productivity, and achieve the effects of excellent adhesion, excellent adhesion between magnetic properties and film, and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

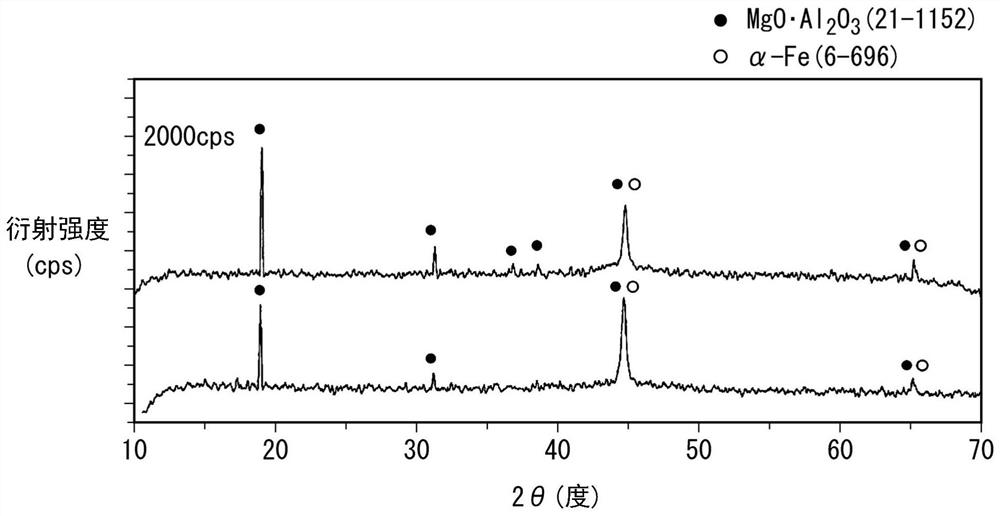

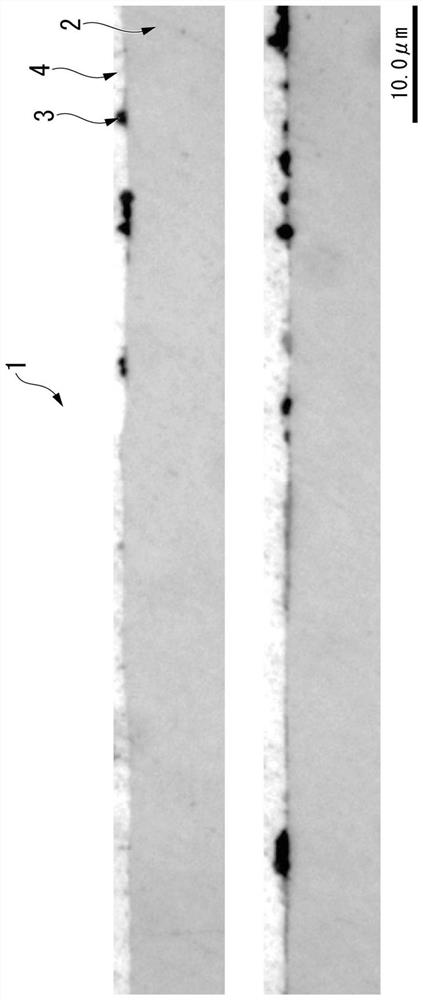

[0118] An annealing separator was coated on a primary recrystallized decarburized annealed sheet (sheet thickness: 0.23 mm) having the chemical composition shown in Table 1-1, and dried. The components of the decarburized annealed sheet were measured by ICP-AES, C and S were measured by combustion-infrared absorption method, and N was measured by inert gas melting-thermal conductivity method. As an annealing separator, use Al 2 o 3 and MgO, the weight of MgO relative to Al 2 o 3 The annealing separator adjusted to the ratio of the total weight of MgO and the BET specific surface area of MgO to the value described in Table 2. In addition, for the Al used in the annealing separator 2 o 3 , collect X-ray diffraction patterns in the range of about 2θ=10-70°. Then, the interplanar spacing is obtained for each diffraction line, and then the obtained interplanar spacing is compared with the α-phase Al in the JCPDS card. 2 o 3 interplanar spacing and κ-phase Al 2 o 3 Check...

Embodiment 2

[0147] A unidirectional electrical steel sheet was produced under the same conditions as in Example 1. However, in this example, Al 2 o 3 The proportion of the κ phase and the coating amount of the annealing separator also changed.

[0148] Samples were collected from the obtained unidirectional electrical steel sheet, and the amount of spinel formed between the steel sheet and the spinel was measured by the same method as in Example 1 to evaluate iron loss and film adhesion.

[0149] The results are shown in Table 3.

[0150]

[0151] As shown in Table 3, it can be seen that the grain-oriented electrical steel sheet obtained under these conditions has low iron loss and excellent coating adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com