Sn-plated steel sheet

A steel plate and coating technology, which is applied in the field of Sn-based plated steel plates, can solve the problems of reduced sulfur blackening resistance, reduced coating film adhesion, and yellowing appearance, and achieves excellent sulfuration blackening resistance and coating film adhesion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

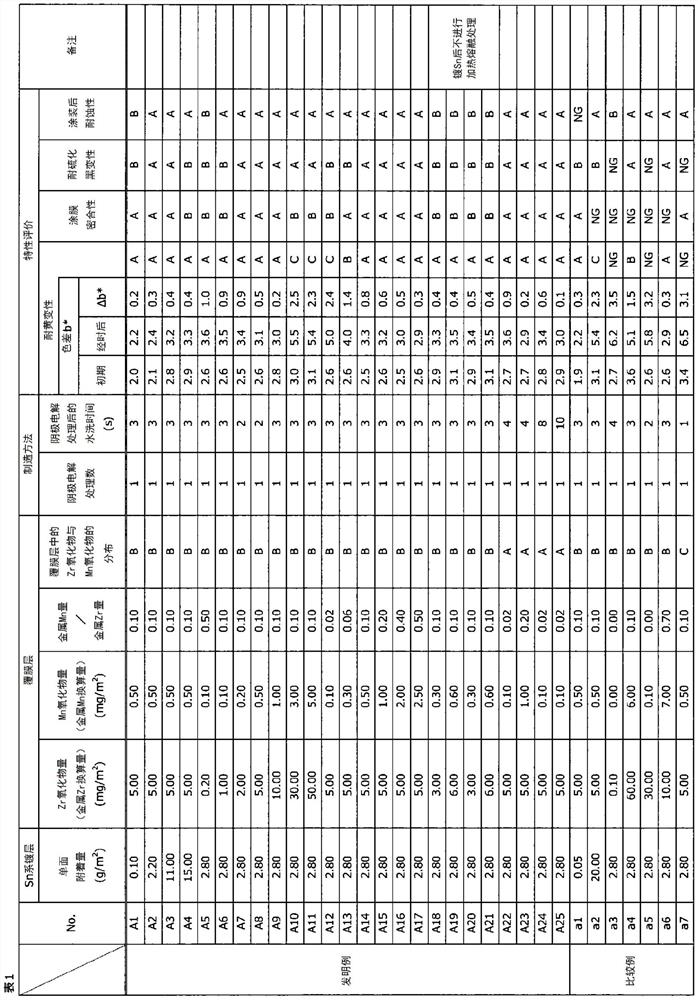

[0143] According to the method described in the above-mentioned , the adhesion amount of zirconium oxide and manganese oxide was changed, and the Sn-based plated steel sheet was produced.

[0144] Sn plating can be produced from a well-known tin-plated steel sheet bath by an electrolytic method. The amount of Sn adhesion reaches 0.05g / m 2 Above and 20g / m 2 The amount of current during electrolysis changes. In addition, both the test piece to which the heating and melting process was performed after the Sn plating and the test piece not to which the heating and fusion process was performed were produced.

[0145] When a film containing zirconium oxide and manganese oxide is formed on the Sn-plated surface, the Sn-based plated steel sheet is subjected to an aqueous solution having a zirconium ion concentration of 50 ppm or more and 5000 ppm or less and a manganese ion concentration of 3.5 ppm or more and 12500 ppm or less. Cathodic electrolysis forms various coating layers in...

Embodiment 2

[0152] Next, according to the method described in the above-mentioned , the distribution of zirconium oxide and manganese oxide in the coating layer was changed, and an Sn-based plated steel sheet was produced.

[0153] Sn plating can be achieved by electrolysis from a well-known tin-plated steel sheet bath with a Sn adhesion amount of 2.8 g / m 2 way to make.

[0154] Thereafter, the Sn-based plated steel sheet was subjected to cathodic electrolysis (first treatment) in an aqueous solution containing no manganese ions but zirconium ions, and then washed with water for the washing time shown in Table 2 below, and further, without Instead of zirconium ions, cathodic electrolysis (second treatment) was performed in an aqueous solution containing manganese ions to prepare test pieces B1 to B6. In addition, as in Example 1, cathodic electrolysis was performed in an aqueous solution containing zirconium ions and manganese ions, followed by washing with water for the washing time sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com