Method for producing silver nanowire ink, the silver nanowire ink, and transparent electroconductive coating film

A technology of silver nanowires and manufacturing methods, applied in the field of silver nanowire ink manufacturing, capable of solving the problems of bulky and complex processing devices, reduced transparency, etc., and achieving excellent optical properties, excellent film adhesion, and excellent electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

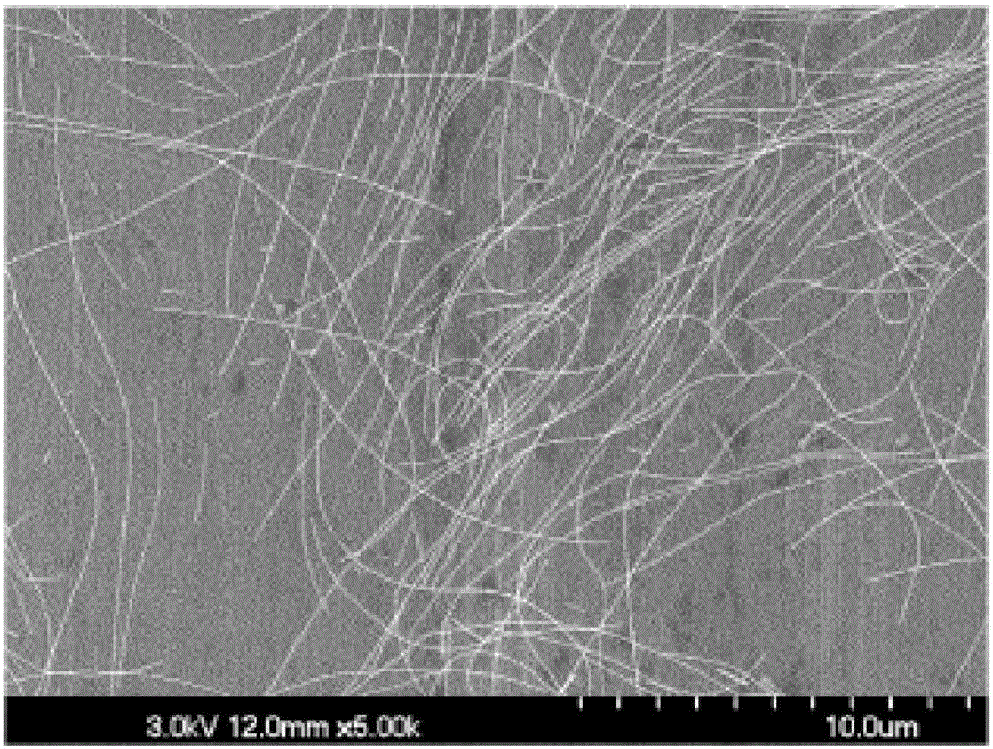

Image

Examples

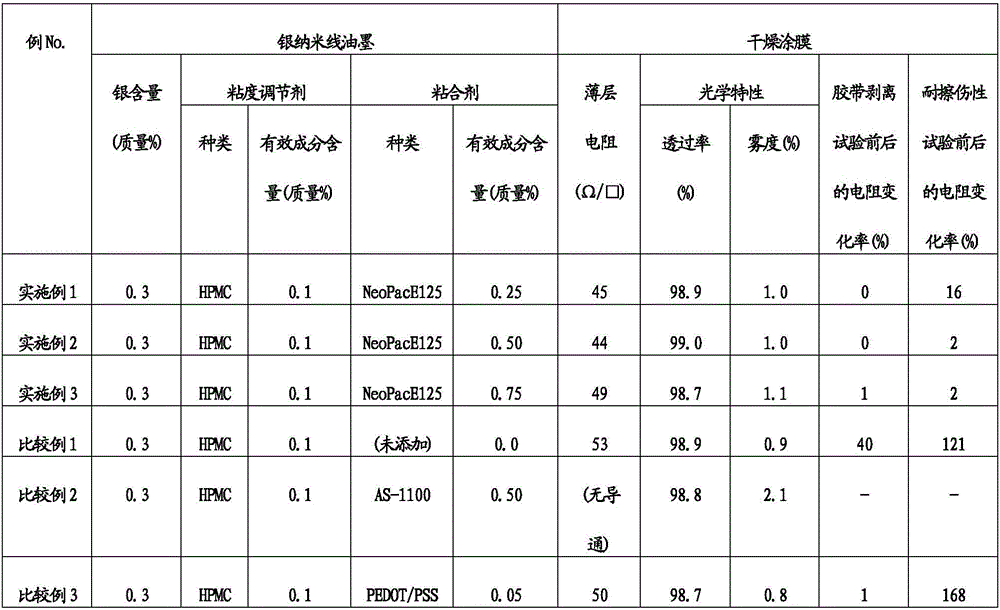

Embodiment 1

[0067] 〔Synthesis of silver nanowires〕

[0068] As alcohol solvent, prepare propylene glycol, silver nitrate, lithium chloride, potassium bromide, lithium hydroxide, aluminum nitrate nonahydrate, as organic protective agent, prepare vinylpyrrolidone and diallyldimethylammoniumnitrate (diallyldimethylammoniumnitrate) Copolymer (prepared as a copolymer based on 99% by mass of vinylpyrrolidone and 1% by mass of diallyldimethylammonium nitrate, with a weight average molecular weight of 130,000).

[0069] Copolymerization of 0.030 g of lithium chloride, 0.0042 g of potassium bromide, 0.030 g of lithium hydroxide, 0.0416 g of aluminum nitrate nonahydrate, vinylpyrrolidone, and diallyldimethylammonium nitrate were added and dissolved in 500 g of propylene glycol at room temperature Compound 5.24g, made solution A. In a separate container, 4.25 g of silver nitrate was added and dissolved in 20 g of ethylene glycol to prepare a solution B.

[0070] After the total amount of solution ...

Embodiment 2

[0102] An experiment was performed under the same conditions as in Example 1, except that the silver nanowire ink was prepared so that the amount of the water-soluble acrylic-urethane copolymer resin component used as the binder was 0.50% by mass. Compared with Example 1, the resistance change rate before and after the scratch resistance test was improved.

Embodiment 3

[0104] An experiment was performed under the same conditions as in Example 1, except that the silver nanowire ink was prepared so that the amount of the water-soluble acrylic-urethane copolymer resin component used as the binder was 0.75% by mass. Compared with Example 1, the resistance change rate before and after the scratch resistance test was improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com