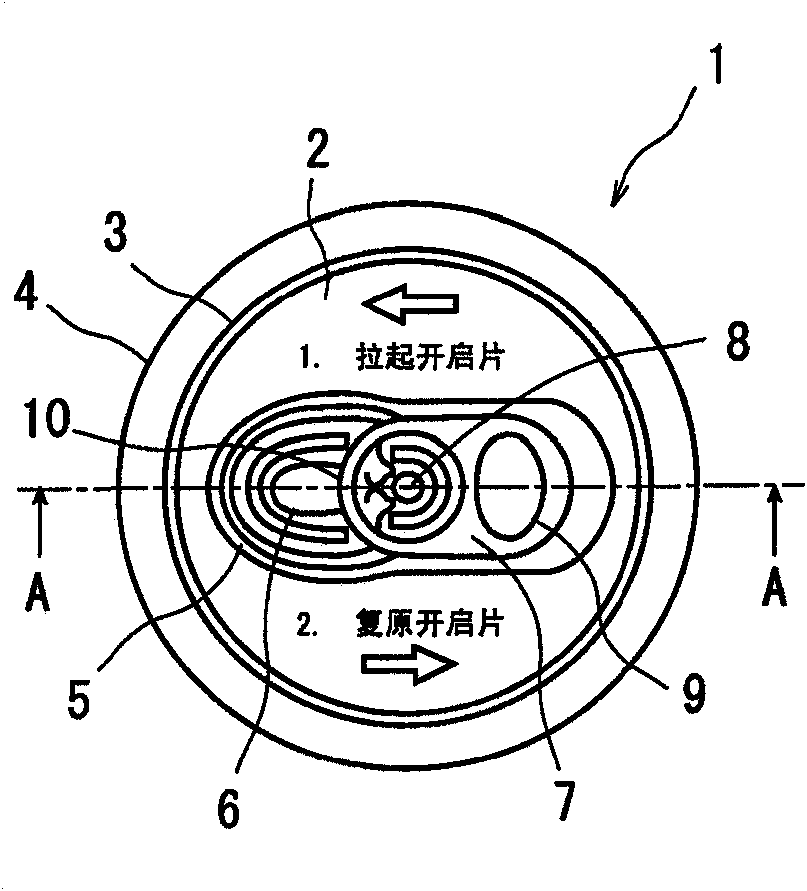

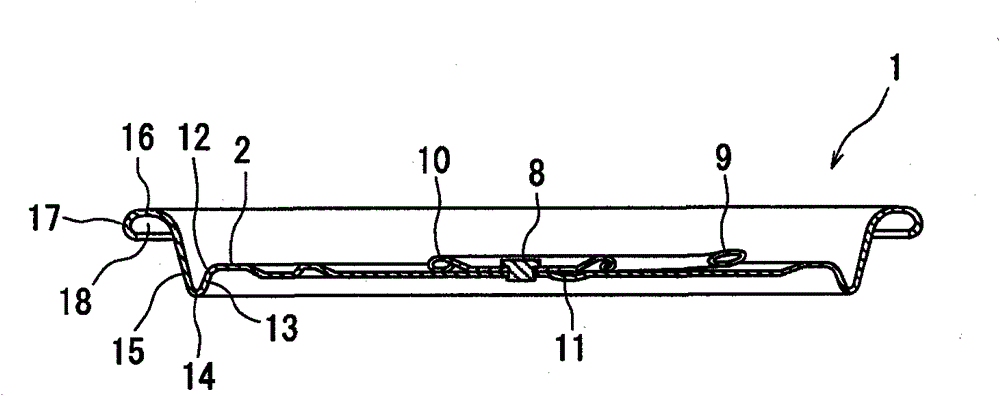

Aluminum lid provided with coating film composed of aqueous coating material

A technology for aluminum caps and coatings, applied in rigid containers, packaging, transportation and packaging, etc., can solve problems such as metal corrosion, and achieve the effects of improving corrosion resistance, inhibiting occurrence and expansion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] [Preparation of water-based paint]

[0093] The aqueous paint used in the present invention is obtained by using the carboxyl group-containing acrylic resin in an amount of 5 to 30 parts by weight, especially 15 to 25 parts by weight, per 100 parts by weight of the base resin (solid component). That is, the base resin and the carboxyl group-containing acrylic resin are uniformly dissolved or dispersed in an organic solvent, and thereafter, the carboxyl groups in the resin are at least partially neutralized with a neutralizing agent including a basic compound to disperse them in an aqueous medium, whereby Get water-based paint.

[0094] The neutralization method may be a method of gradually adding the acrylic-modified epoxy resin to the aqueous medium under stirring, or neutralizing the acrylic-modified epoxy resin with a basic compound, and then adding the aqueous medium under stirring. A method of adding to the neutralized product or adding the neutralized product to ...

Embodiment 1

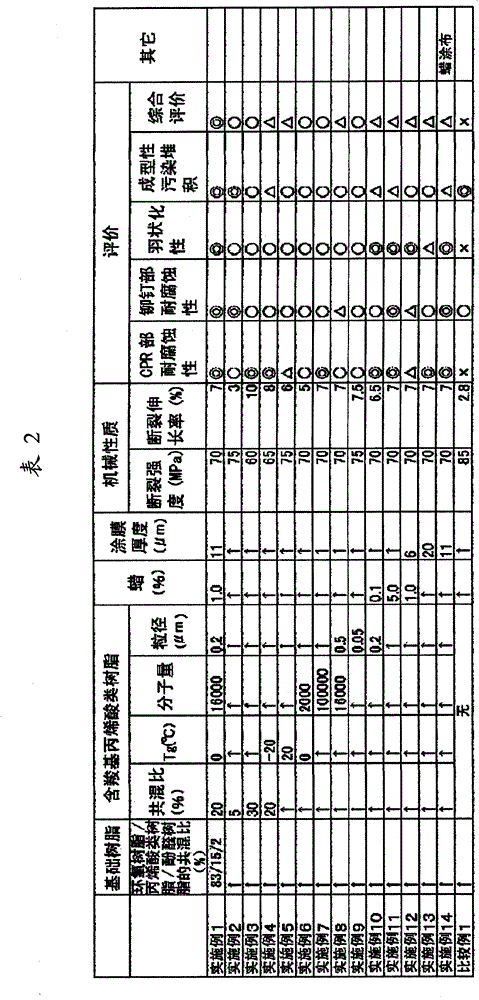

[0186] SOT caps including the aqueous paint (c-1) were prepared and evaluated in the manner described above. The composition of the water-based paint, the thickness of the coating film, the mechanical properties of the water-based paint film, and the evaluation results of the SOT cap are shown in Table 2.

[0187] The corrosion resistance of the CPR part was ◎, the corrosion resistance of the rivet part was ◎, the feathering property was ◎, the formability (contamination accumulation) was ◎, and the overall evaluation was ◎.

Embodiment 2

[0189] An aqueous paint (c-2) having a solid content of 32.5% was prepared in the same manner as the aqueous paint (c-1) except that the carboxyl group-containing acrylic resin solution (d-1) was added in an amount of 17 parts by weight. An SOT cap was fabricated in the same manner as in Example 1 except that the water-based paint (c-2) was used instead of the water-based paint (c-1).

[0190] The corrosion resistance of the CPR portion was ◯, the corrosion resistance of the rivet portion was ⊚, the feathering property was ◯, the formability (pollution accumulation) was ⊚, and the overall evaluation was ◯.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com