Aqueous coating composition

A water-based coating agent and composition technology, applied in the direction of coatings, nuts, bolts, etc., can solve the problems of poor durability and adhesion, and achieve the effects of low environmental load, effective sealing, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

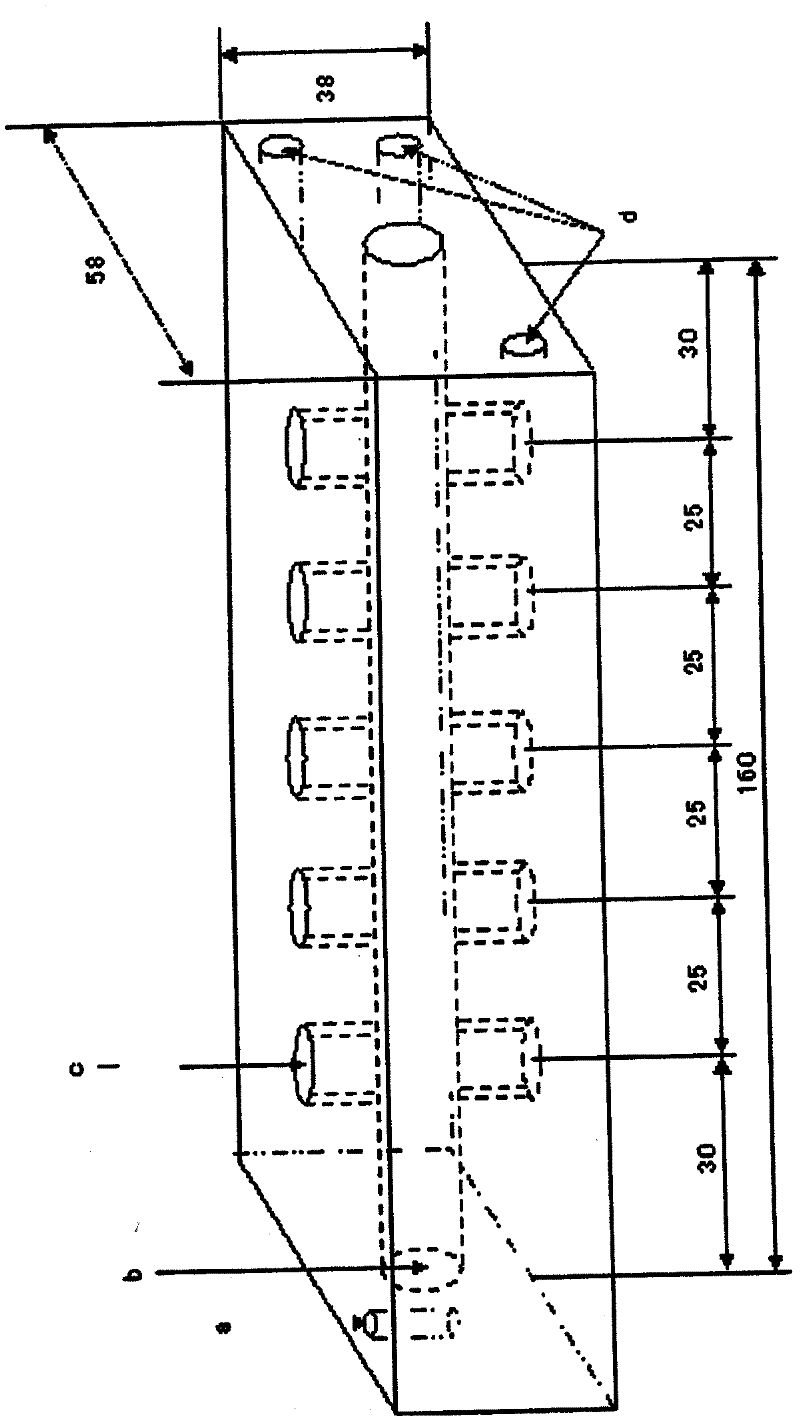

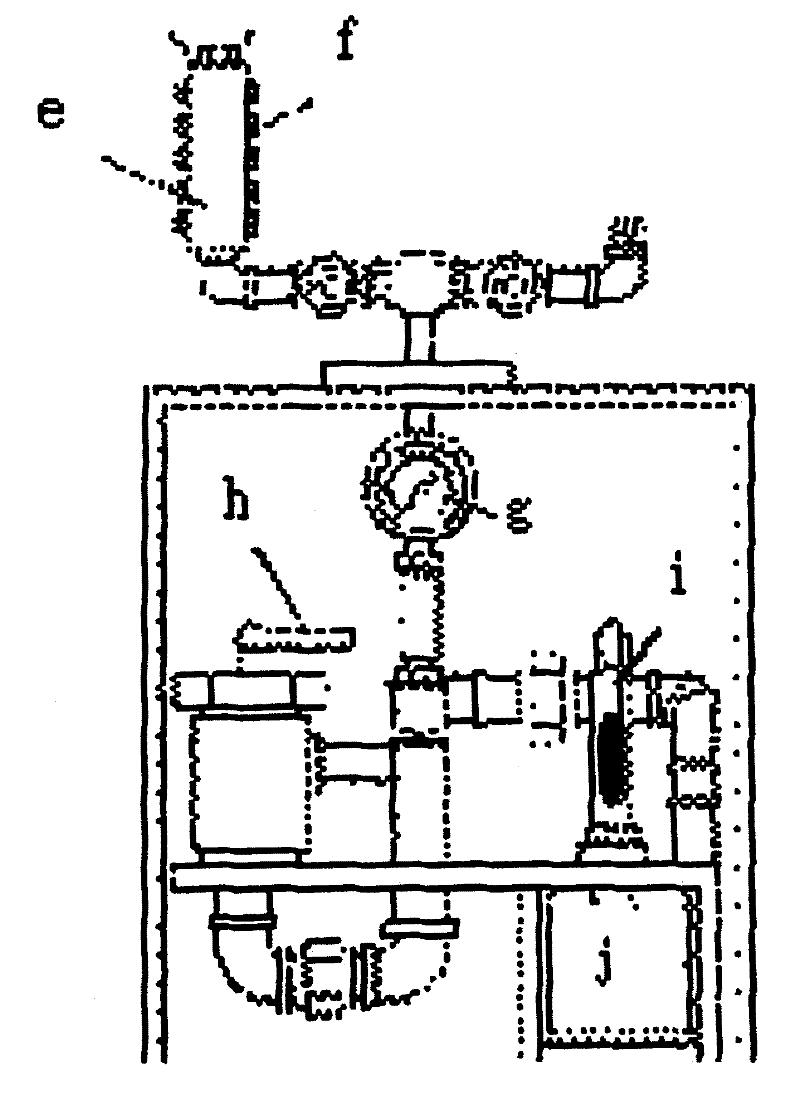

Image

Examples

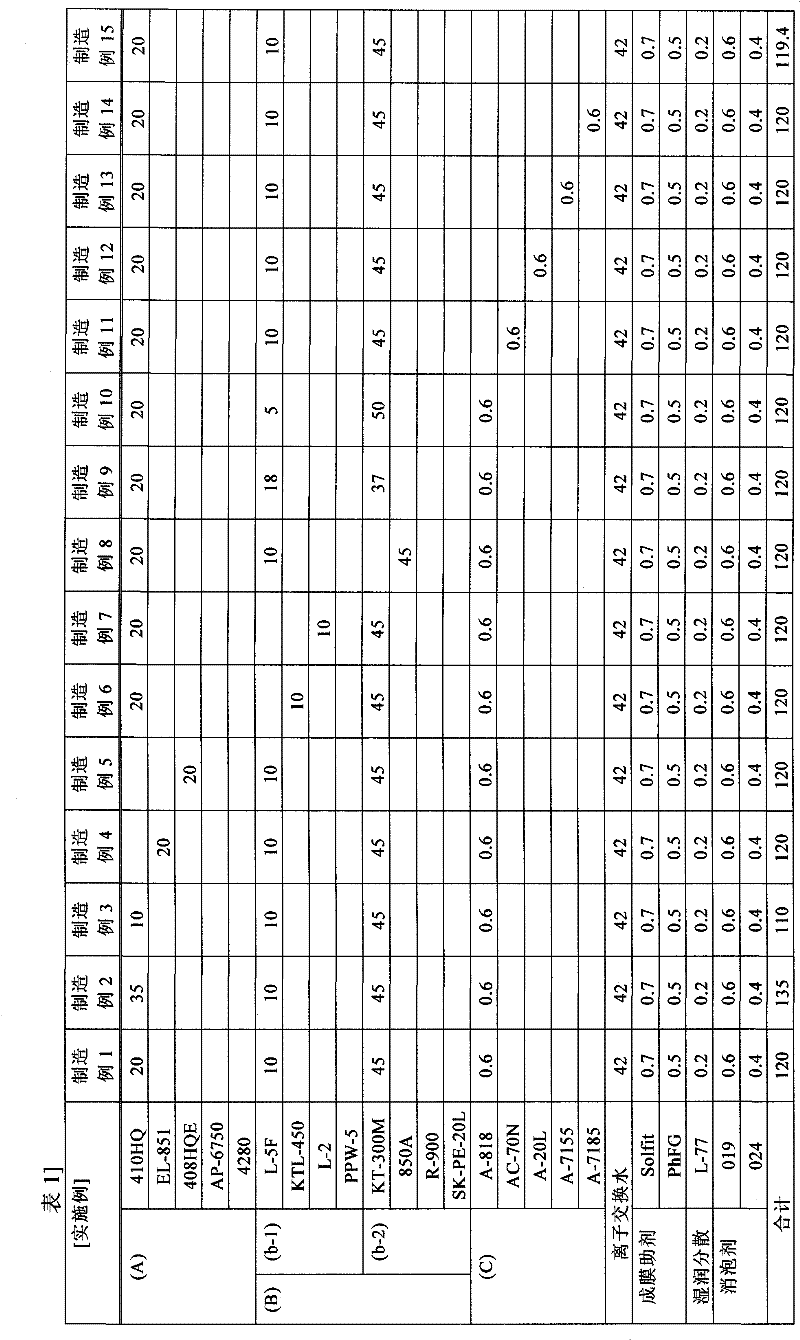

manufacture example 1~15、 comparative manufacture example 1~8

[0058] Preparation of Aqueous Coating Agent Composition

[0059] The aqueous coating composition used in the Example and the comparative example was prepared using the following components.

[0060] [ingredient (A)]

[0061] Sumikaflex 410HQ (ethylene-vinyl acetate copolymer resin emulsion, Tg-18°C, viscosity 3000mPa·s, elongation 700%, solid content 53%, manufactured by Sumika Chemtex Co., Ltd., hereinafter referred to as "410HQ")

[0062] Sumikaflex 408HQE (ethylene-vinyl acetate copolymer resin emulsion, Tg0°C, viscosity 800mPa·s, elongation 650%, solid content 50%, manufactured by Sumika Chemtex Co., Ltd., hereinafter referred to as "408HQE")

[0063] ●Polysol EVA EL-851 (ethylene-vinyl acetate copolymer resin emulsion, Tg0°C, viscosity 10000mPa·s, elongation 1200%, solid content 50%, product of Showa High Molecular Co., Ltd., hereinafter referred to as "EL-851")

[0064] Polysol AP-6750 (styrene-acrylic synthetic resin emulsion, Tg 36°C, viscosity 4000mPa·s, elongation 15...

Embodiment 1~15、 comparative example 1~8

[0095] Method for evaluating properties of aqueous coating composition

[0096] ●Liquid property evaluation method: For each composition produced in the production example and the comparative production example, the initial viscosity and the initial liquid property change were evaluated. The initial viscosity was measured as follows. After each composition was prepared, it was left to stand for 10 minutes, then stirred with a stirring bar, and measured according to the viscosity measurement method specified in JIS K 7117 (BL-type viscometer, 60 rpm / min. 25° C.). Regarding the initial change in liquid properties, each composition left to stand for ten minutes immediately after production and after production was stirred with a stirring bar, and the changes in the respective liquid properties were confirmed respectively. As an evaluation of the initial change in liquid properties, the case where almost no change in properties was observed immediately after production and ten min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com